You often see spline vs keyway in machines. These machines need to move power or keep parts spinning together. The difference between spline and keyway is in how they connect and lock parts. A spline has many ridges on a shaft. These ridges fit into grooves in another part. This gives strong and even power transfer. A keyway has one slot and a key. It holds a shaft and hub together. You can find these designs in many industries:

| Industry | Application Description |

|---|---|

| Automotive | Used in transmission systems, drive shafts, and steering systems for power transfer. |

| Aerospace | Used in landing gear and flight control systems for safety and performance. |

| Industrial Machinery | Keeps machines like packaging and manufacturing equipment working together. |

| Power Generation | Moves rotation energy well in power plants. |

| Robotics | Helps with accurate movement and positioning in robots. |

Key Takeaways

- Splines have many ridges that spread force out. This makes them great for jobs with a lot of turning force. Keyways have one slot and one key. They work well for light or medium loads. They are good for simple connections. Pick splines if you want something strong and exact. Splines last longer and need less fixing than keyways. Keyways are easier and cost less to make. This makes them good for easy jobs. In cars and planes, people like splines. Splines can handle heavy loads and keep things lined up. When you pick between splines and keyways, think about how much turning force you need. Also, think about how exact your project must be. You can make splines and keyways by milling or broaching. Each way is good for different needs. Knowing how splines and keyways are different helps you choose the right one for your machines and projects.

Table of Contents

Difference Between Spline vs Keyway

What Is a Spline

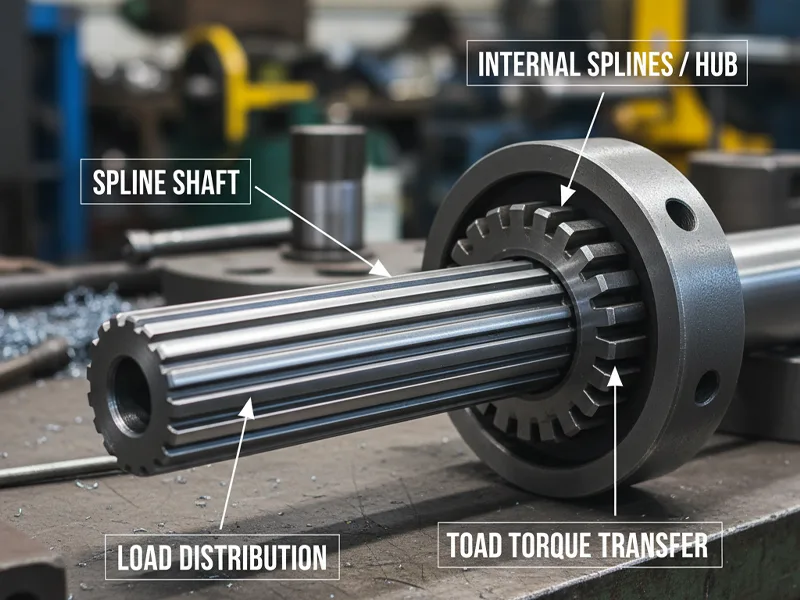

You will find splines in many machines that need to transfer power smoothly and reliably. A spline is a shaft with several ridges or teeth cut along its length. These ridges fit into matching grooves inside a hub or gear. When you use a spline, you get a connection that spreads the force across many contact points. This design helps you move higher torque without causing too much wear on any single spot.

You can see the difference between spline and keyway in how they handle stress. Splines distribute the load evenly over all the teeth. This means you can use splines for heavy-duty jobs where you need to move a lot of power. You also get less wear and longer life for your parts. Splines are common in automotive drive shafts, industrial gearboxes, and aerospace systems.

International standards help you design and measure splines correctly. Here are some examples:

| Standard | Description |

|---|---|

| BS 2059/3:1957 | Specification for straight-sided serrations. Internal and external |

| BS 5686:1986 | Specification for straight-sided splines for cylindrical shafts: metric nominal dimensions, tolerances and gauging requirements |

| BS EN ISO 6413:2018 | Technical product documentation. Representation of splines and serrations |

These standards make sure your splines fit and work as expected, no matter where you build or use them.

What Is a Keyway

A keyway is a simpler way to connect a shaft and a hub. You cut a single slot, called a keyway, into both the shaft and the hub. Then you insert a metal piece called a key. The key locks the two parts together so they turn as one. You often see keyways in pumps, fans, and small machines.

The difference between spline and keyway becomes clear when you look at how each one transmits torque. A keyway relies on just one key to carry all the force. This can create stress in the shaft and the key itself. If you push the system too hard, the key or the slot might wear out or even break. Keyways work best for light to medium loads, where you do not need to move a lot of power.

You will also find standards for keyways, but they are usually simpler than those for splines. The keyway method is easy to make and repair. You can cut a keyway with basic tools, which makes it a popular choice for many small or medium-sized machines.

Tip: When you choose between a spline and a keyway, think about the load, the need for precision, and how often you will need to take the parts apart. Splines give you more strength and smoother power transfer. Keyways are easier and cheaper for simple jobs.

When you compare the two, you see the main difference between the spline and keyway is in how they share the load and how much power they can handle. Splines are better for high-torque, high-precision work. Keyways are good for simple, low-cost connections.

You will use the difference between spline and keyway to decide which one fits your project. If you need to move a lot of power or want a long-lasting connection, splines are the better choice. If you want something quick, easy, and low-cost, a keyway might be enough.

Keyways and Splines in Machining

How Machining Creates Keyways and Splines

Machining gives you many ways to make keyways and splines. You can use milling, broaching, hobbing, wire EDM, or keyseating. Each method works best for certain jobs, so you can pick what fits your needs.

- Milling can make both keyways and splines. CNC machines help cut many shapes and sizes, even in blind holes.

- Broaching is quick and accurate for simple shapes. It is good when you need to make lots of parts.

- Hobbing is used a lot for splines. It works well if you want to make many at once.

- Wire EDM is very precise. It lets you cut hard materials or tricky shapes.

- Keyseating is another way to make keyways. It is helpful for blind bores or when you want a fast setup.

| Process | Advantages | Limitations | Use Cases |

|---|---|---|---|

| Milling | Works with many materials, flexible sizes, CNC use, and blind holes | Needs special tools, not for all shapes, slower than broaching | Prototyping, automotive, general engineering |

| Broaching | Fast for batches, accurate for simple shapes | Expensive tools, need thru-hole, not for hard materials | High-volume, simple keyways |

| Hobbing | Good for splines, great for big runs | Not for all shapes, needs special hobs | Spline shafts, gear production |

| Wire EDM | Very accurate, cuts hard alloys, blind holes | Slow, costs more per part, used last by most shops | Precision, tricky keyways, and splines |

| Keyseating | Good for blind bores, low tool cost, fast | Slower for big batches, not used as much | Short runs, hard materials |

Machining lets you make keyways and splines for almost any job. You can choose the process that gives you speed, accuracy, or works with special materials.

Material and Precision Considerations

When you pick materials for keyways and splines, you should think about strength, rust resistance, weight, and price. Some common choices are stainless steel, carbon steel, alloy steels, and aluminum alloys. Stainless steel is strong and does not rust, so it is good for boats or planes. Carbon steel is cheaper and is used in many machines. Alloy steels are stronger and last longer, so they are used for tough jobs. Aluminum alloys are light and do not rust, so you see them in planes or places where weight matters.

| Material | Properties | Applications |

|---|---|---|

| Stainless Steel | Strong, does not rust, lasts long | Marine, aerospace |

| Carbon Steel | Cheaper choice | Industrial machinery, automotive |

| Alloy Steels | Stronger, lasts longer | Heavy-duty applications |

| Aluminum Alloys | Light does not rust | Aerospace, weight-sensitive |

| Other Materials | Brass, bronze, and titanium for special needs | Specialized uses |

Modern machines, like those at AFI Industrial Co., Ltd, help you make keyways and splines with high accuracy. You can get complex shapes and smooth finishes, even for custom or special parts. Machining works with many materials, so you can always find what you need for your project.

Note: If you need custom or high-performance parts, machining keyways and splines helps you meet strict rules for accuracy and strength. You can use this process for small or large orders.

Machining lets you get keyways and splines that fit your needs, from a simple slot to a complex spline. This makes machining the best choice for many industries.

Design and Performance Comparison

Torque and Load Capacity

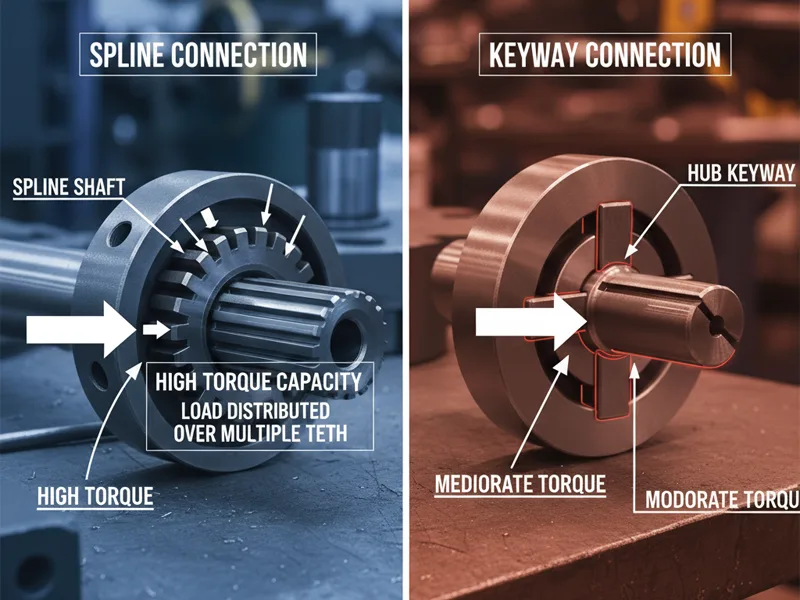

How you connect parts in a machine is important. Splines and keyways do this job in different ways. Splines are stronger because they have many teeth. These teeth share the load. You use splines when you need to move a lot of torque. The teeth fit into grooves, so the force spreads out. This means each part of the shaft feels less stress.

- Splines are much stronger than keyed joints.

- Splines can handle high-torque loads because they have many engagement points.

- Keyways work for moderate torque loads but may not handle extreme stress well.

- Keyways can weaken the shaft and lower its torque-carrying ability.

If you want a connection that does not break under heavy use, pick splines. That is why you see splines in cars, trucks, and big machines.

Alignment and Precision

Keeping parts lined up is important for smooth motion. Splines help with this because the teeth guide the hub and shaft. This makes the connection more exact. Keyways can sometimes make parts crooked. The single key may not keep the hub straight, especially after a long time.

Here is a quick comparison:

| Feature | Splines | Keyways |

|---|---|---|

| Load Handling | High-torque loads | Moderate torque loads |

| Alignment | Superior alignment | May introduce misalignment |

| Stress Distribution | Uniform load distribution | Concentrated stress at edges |

| Fatigue Life | Improved, less stress | Less favorable, more stress |

Splines help you get better results when you need high accuracy. You will notice less shaking and smoother running.

Durability and Maintenance

Splines last longer because they spread the force over many teeth. This means they wear out more slowly. You can use them longer and fix them less often. Keyways put all the force on one small spot. Over time, this can wear out the key or the slot. Sometimes, it can even break.

You do not need to check or fix splines as much. Keyways may need more checks and repairs, especially in machines that work hard or fast.

Tip: If you want a connection that lasts longer and needs less care, use splines for tough jobs. Use a keyway for simple, cheap setups where loads are light.

Splines work better for most heavy-duty and exact jobs. They help your machines run well and stop less for repairs.

Application Scenarios for Keyways and Splines

When to Use a Spline

You should pick a spline if you need high torque and exact alignment. Splines are great when you want parts to last a long time. They work well for moving lots of power without wearing out fast. You often see splines in car transmissions, big machines, and airplanes. These industries use splines because the design spreads force over many teeth. This lowers stress and makes the parts last longer. If you need a strong connection that can handle heavy loads and keep things lined up, splines are the best choice.

Here is a simple table showing how splines and keyways compare in tough jobs:

| Feature | Splines | Keyways |

|---|---|---|

| Contact Area | Multiple teeth for uniform contact | Limited area, higher stress |

| Torque Transmission | Excellent for high-precision, high-torque | Depends on size and design |

| Stress Concentration | Low, better distribution | High, can cause fatigue fractures |

| Load Performance | Superior under heavy loads | Varies, best for moderate loads |

You will find splines in gearboxes, drive shafts, and robots. These places need smooth and steady movement.

When to Use a Keyway

You should use a keyway if you want a simple and cheap way to connect a shaft and hub. Keyways are best for light or medium loads and when you want to save money. Keyed shafts are common in pumps, fans, and small machines. Many industries, like cars, planes, and factories, use keyed shafts. They are easy to make, fix, and swap out.

Keyed shafts have these good points:

- Lower cost to make, especially for small numbers.

- Simple design that works for easy jobs.

- Fast repairs and easy to change parts.

You will see keyed shafts in gear-making, machines, and even some car and airplane parts. Keyway broaching is used when you need slots that fit well and hold strongly.

Tip: Keyed shafts are a good pick if you want to save money or need a quick, easy connection.

Choosing the Right Solution

To pick between splines and keyed shafts, think about a few things:

- Torque and Load: Splines are better for high torque and heavy loads. If your machine works hard, splines are more reliable.

- Precision: Splines keep parts lined up better and have less wiggle. Use them when you need things to move just right.

- Cost: Keyed shafts cost less for simple jobs and small batches. Spline broaching costs more because it is harder to do, especially for special shapes.

- Durability: Splines last longer in tough places. Keyed shafts might wear out faster if you use them a lot.

Splines are best for jobs that need high performance and exact movement. Keyed shafts are good for machines, cars, and planes, where saving money and keeping things simple is important.

Note: If you need something special or a custom part, talk to machining experts. They can help you pick the best connection for your job. This way, you get the right mix of strength, accuracy, and price.

Pros and Cons Overview

Spline Advantages and Disadvantages

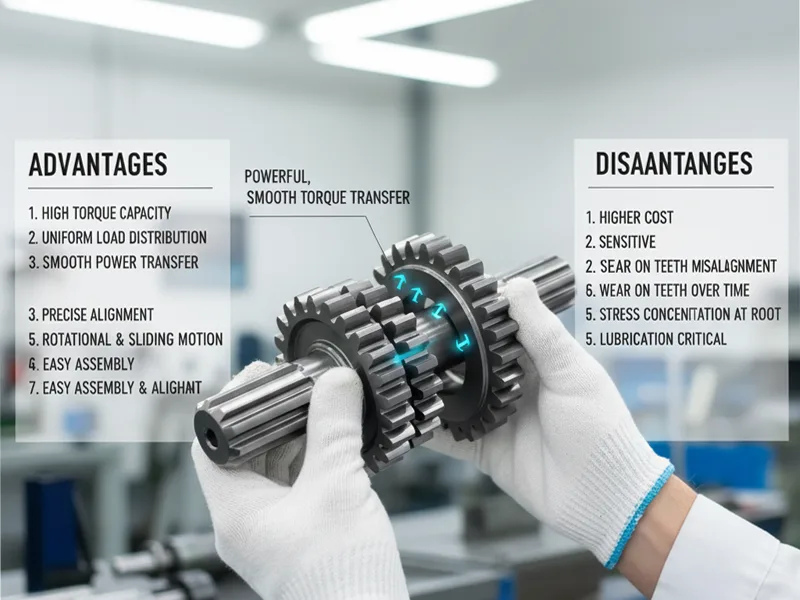

When you pick splines, your machine gets many benefits. Here are the main good things about splines:

- Splines spread force over many teeth, so power moves smoothly.

- They can handle high torque, which is good for tough jobs.

- Parts last longer because the load is not on one spot.

- Splines keep parts lined up, which helps machines work right.

- You can use splines for turning or sliding, like with helical splines.

- It is easy to put together or take apart parts with splines.

- Splines work in many fields, like cars and planes.

- They help stop slippage, so machines run better.

- Their small size saves space in your equipment.

- Parts last longer because the load is shared evenly.

Note: Splines are great if you want strong, reliable, and long-lasting parts.

But splines also have some downsides:

- Making splines costs more than making keyways, especially for special shapes.

- You need special tools and machines to make splines.

- If splines break, they can be harder to fix or swap out.

- For small or easy jobs, splines might be too much.

Keyway Advantages and Disadvantages

Keyways give you a simple and cheap way to connect parts. Here are the main good things about keyways:

| Advantage | Description |

|---|---|

| Cheap manufacturing cost | You save money when making parts. |

| Well-standardized | Keyways follow the rules used all over the world. |

| Medium to high torque | Keyways can handle a lot of force. |

| Easy mount and dismount | You can put together or fix parts quickly. |

Keyways also have some bad points you should know:

- One key takes all the force, which can cause stress and wear.

- The key or slot can wear out or break if used a lot.

- Keyways may not keep parts lined up as well as splines.

- For jobs that need high strength or accuracy, keyways may not be enough.

- Cutting a slot for the key can make the shaft weaker.

Tip: Use keyways for easy, low-cost jobs where you do not need a lot of strength or perfect fit.

If you know the good and bad sides, you can pick what works best. Splines are strong and exact for hard jobs. Keyways are quick and cheap for lighter work.

Summary Table: Spline vs. Keyway

Comparison Table

It is important to compare splined shafts and keyways before you choose. This helps you pick the best one for your machine. The table below shows how each one works in real life. You can see the main features side by side. This makes it easier to decide what fits your needs.

| Feature | Keyway | Spline |

|---|---|---|

| Torque Capacity | Moderate | Excellent |

| Relative Cost | Low | High |

| Assembly Complexity | Simple | Simple |

| High-Speed Balance | Poor | Good |

| Stress Concentration | High (at corners) | Moderate |

| Backlash | Prone to develop | Minimal (at first) |

| Alignment | May shift over time | Maintains precise alignment |

| Durability | Wears faster | Lasts longer |

| Maintenance | Needs more frequent checks | Needs less frequent checks |

| Application Range | Light to medium-duty machines | Heavy-duty, high-precision |

| Customization | Limited | Highly customizable |

| Load Distribution | Single key, high stress | Multiple teeth, shared stress |

| Typical Use | Pumps, fans, small machines | Automotive, aerospace, robotics |

Splined shafts are better when you need to move a lot of torque. They also keep parts lined up very well. Splined shafts have many teeth that share the force. This means each tooth gets less stress. Because of this, splined shafts last longer, even in hard jobs. You will see splined shafts in places where machines must work smoothly and carry heavy loads. For example, splined shafts are used in car transmissions, robots, and airplanes.

Keyways are good for simple jobs. You can use keyways if you want something fast and cheap. Keyways use one key to lock the shaft and hub. This setup is easy to make and fix. But keyways can wear out faster because all the force goes through one spot. You might need to check keyways more often, especially if your machine works hard or runs fast.

If you want less maintenance and more reliability, splined shafts are a better choice. Splined shafts also help stop problems with parts moving out of place or shaking at high speeds. When you use splined shafts, your machine runs smoother and stays balanced. That is why splined shafts are picked for high-performance machines.

Tip: Always pick what matches your machine’s needs. Splined shafts cost more but are stronger and last longer. Keyways save money at first and work well for lighter jobs.

You can use this table to help you choose between splined shafts and keyways. It lets you see the good and bad points, so you get the best choice for your project.

You now know splines and keyways connect machine parts in different ways. Splines can handle more force and keep parts lined up better. They also last longer than keyways. Keyways are easier to make and cost less money. When you pick one, think about how much force you need to move. Also, think about how straight the parts must stay and how long you want them to last. If your job is hard or needs special care, ask a machining expert for help. If you want to learn more, you can look at these standards:

| Standard | Description |

|---|---|

| ISO 4156-1:2021 | Straight cylindrical involute splines — Metric module, side fit |

| ISO 6413:2018 | Technical product documentation — Representation of splines |

| ISO 14:1982 | Straight-sided splines for cylindrical shafts — Dimensions |

FAQ

You use a spline when you need to transfer more torque and keep parts aligned. A keyway works for lighter loads and simpler connections. Splines have multiple teeth; keyways use a single slot and key.

You can replace a keyway with a spline if you need higher torque or better alignment. You must redesign both the shaft and hub to match the new spline profile.

You will find keyways easier and cheaper to make. You can cut them with basic tools. Splines need special machines and more precise work.

You should choose a keyway for simple, low-cost connections. Keyways work well in pumps, fans, and small machines where loads are not high.

Splines spread force over many teeth. This reduces wear and keeps parts aligned. You get smoother power transfer and longer part life.

You check splines less often because they wear slowly. Keyways need more frequent checks. The single key can wear out or loosen over time.

You can use both if you need extra security or want to prevent movement in two directions. This setup is rare but possible in special designs.