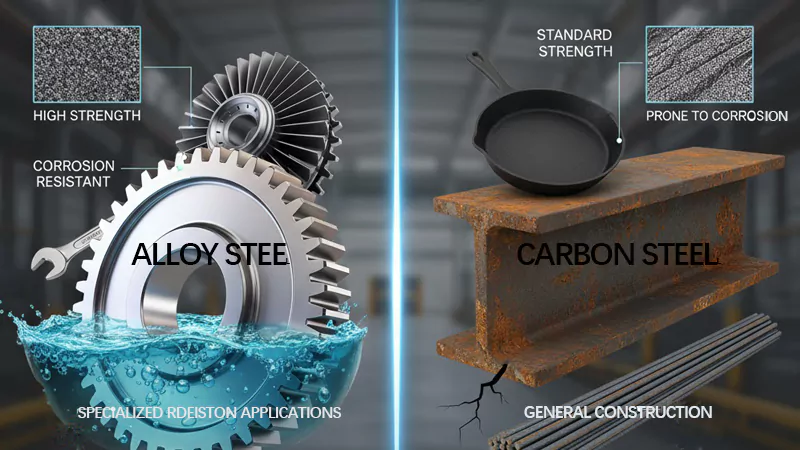

Choosing the right steel is important for your project. Understanding the differences between alloy steel vs carbon steel is crucial, as they significantly impact how you build things. These differences also affect how you machine or manufacture products. Knowing what makes each type of steel unique is essential, as your choice influences the strength of your project, its longevity, and overall costs.

- Carbon steel is widely used in most steel products around the globe.

- Alloy steel is gaining popularity for specialized applications.

| Type of Steel | Key Characteristics | Common Applications | Cost Consideration |

|---|---|---|---|

| Alloy Steel | Very strong, hard, and resistant to rust | Used in planes, oil work, and medical tools | Costs more because it is harder to produce and incorporates special materials |

| Carbon Steel | More affordable and easier to work with | Used in construction, automobiles, and factories | Costs less, making it a good option for budget-conscious projects |

Key Takeaways

- Alloy steel has extra elements like chromium and nickel. This makes it stronger and helps it resist rust better than carbon steel.

- Carbon steel costs less and is easier to use. It is a good pick for projects that need to save money.

- Pick alloy steel if you need something very strong and tough. It works well in rough places.

- Carbon steel is great for building things and car parts. It is cheap and easy to shape.

- Think about what your project needs before you choose steel. You should look at strength, rust resistance, and how easy it is to shape.

- Alloy steel is best for the outside because it does not rust easily. Carbon steel might need a special coating to stop rust.

- Knowing what is in each steel helps you choose the right one. This helps you make smart choices for your project.

- Always plan when buying steel. Prices and how much is available can change because of the market and material costs.

Table of Contents

Alloy Steel vs Carbon Steel: Key Differences

Main Properties Compared

When you compare alloy steel and carbon steel, you see some big differences. The biggest difference is what each steel is made of. Carbon steel has mostly iron and carbon. Alloy steel has iron, carbon, and other elements like manganese, silicon, nickel, chromium, molybdenum, or vanadium. These extra things change how the steel works and what you can do with it.

Alloy steel has more elements than just iron and carbon. These extra elements make it stronger, harder, and better at fighting rust. They also help the steel work better in different ways.

You can look at this table to see the main differences:

| Steel Type | Composition | Main Properties |

|---|---|---|

| Carbon Steel | Mostly iron and carbon | Strong, easy to use, and costs less |

| Alloy Steel | Iron, carbon, and other elements | Stronger, harder, and does not rust easily |

Here are some things to remember:

- Alloy steel has extra elements that make it tough.

- Carbon steel is simple and easy to cut or shape.

- The extra elements in alloy steel help it last longer and stop rust.

Performance Overview

Alloy steel and carbon steel act differently when you use them. Alloy steel is usually stronger and harder. It can take more force before it bends or breaks. This is because of the extra elements like nickel, chromium, and molybdenum.

- Alloy steel is stronger than carbon steel.

- Alloy steel bends less than carbon steel.

- Extra elements like sulfur, manganese, nickel, chromium, and molybdenum make alloy steel better.

Carbon steel is good if you want something cheap and easy to shape. It works well for pipes, pressure tanks, cutting tools, and weapons. You see it used in chemical, oil, and gas jobs. Alloy steel is better for jobs that need more strength or need to stop rust. You find it in mining, planes, cars, and trains.

Here is a table that shows where you use each steel:

| Steel Type | Common Uses | Industries Involved |

|---|---|---|

| Alloy Steel | Used to make things for mining, planes, cars, and trains. | Mining, Planes, Cars, Trains |

| Carbon Steel | Used for pipes, tanks, tools, and weapons. | Chemical, Oil, Gas |

The steel you pick changes how much your project costs and how well it works. Alloy steel costs more because it uses special materials and is harder to make. Carbon steel costs less and is easier to get.

Think about what your project needs before you choose. If you need steel that is strong, hard, and does not rust, pick alloy steel. If you want steel that is simple, cheap, and easy to work with, pick carbon steel.

Alloy steel is named for having one or more special elements in set amounts. This makes it different from carbon steel, which is mostly iron and carbon.

In short, alloy steel and carbon steel are different because of what they are made of, how they work, and where you use them. Knowing this helps you pick the best steel for your project.

What Is Carbon Steel?

Definition and Types

You will find carbon steel in many everyday products and structures. This steel is made mainly from iron and carbon. The amount of carbon in the steel changes how it behaves and what you can use it for. People often choose carbon steel because it is strong, easy to shape, and affordable.

There are several types of carbon steel. These types depend on how much carbon is in the steel. Each type has its own uses and strengths. Here is a table to help you see the main types of carbon steel and how much carbon they contain:

| Type of Carbon Steel | Carbon Content Range | Typical Applications |

|---|---|---|

| Low Carbon | 0.04% to 0.30% | Cookware, screws, and concrete reinforcement |

| Medium Carbon | 0.31% to 0.60% | Machine parts, automotive components |

| High Carbon | 0.60% to 1.4% | Springs, edged tools, high-strength wires |

| Ultra-High Carbon | 1.25% to 2.0% | Special knives, axles, punches |

You can also look at the types of carbon steel as a list:

- Low carbon steel: Also called mild steel, it is easy to shape and is used for things like cookware and building bars.

- Medium carbon steel: This type balances strength and flexibility. You see it in machine parts and car parts.

- High carbon steel: This steel is very strong and is used for tools and wires that need to handle a lot of force.

- Ultra-high carbon steel: This is the hardest type. People use it for special knives, axes, and punches.

When you pick a type of carbon steel, you should think about what you need the steel to do. Each type of carbon steel works best for certain jobs.

Core Characteristics

Carbon steel stands out because of its simple makeup and useful properties. You will notice that the main features of carbon steel depend on how much carbon it has. Low carbon steel is soft and easy to weld. Medium carbon steel gives you a good mix of strength and flexibility. High carbon steel is tough to shape, but it is very strong. Ultra-high carbon steel is the hardest and strongest, but it can break more easily if you bend it too much.

Here is a table that shows the main characteristics of each type of carbon steel:

| Type of Carbon Steel | Characteristics |

|---|---|

| Low carbon steel | Highly ductile, easy weldability |

| Medium carbon steel | Good balance of strength and ductility |

| High carbon steel | Very strong, resistant, harder to shape |

| Ultra-high carbon steel | Sturdiest, highest carbon content |

You can change how carbon steel acts by using different heat treatments. For example:

- Annealing makes the steel softer and easier to bend.

- Quenching cools the steel quickly, making it harder and stronger.

- Tempering heats the steel again to make it less brittle and tougher.

The grain structure inside carbon steel also matters. Fine-grained carbon steel is stronger and tougher than coarse-grained steel. This means it can handle more stress before breaking. However, more grain boundaries can make the steel less resistant to rust.

You will see carbon steel used in many industries because it is reliable and easy to work with. The types of carbon steel give you choices for different needs, from building bridges to making sharp tools. When you understand the core characteristics of carbon steel, you can pick the right type for your project and get the best results.

Ready to get started on your next project?

Please contact our team, and our senior engineers will provide you with the best solutions for your project!

Get Your Instant QuoteWhat Is Alloy Steel?

Definition and Types

You might ask what makes alloy steel special. Alloy steel is made from iron, carbon, and other elements. These extra elements can be things like chromium, nickel, or molybdenum. They change how the steel acts. This makes the steel stronger and tougher. It also helps the steel fight rust.

Alloy steel comes in different types. The type depends on how much of extra elements it has. Here is a table to show the main types:

| Type of Alloy Steel | Description |

|---|---|

| Low-Alloy Steel | Has less than 4% to 8% extra elements. It is used in many ways. |

| High-Alloy Steel | Has 10% or more extra elements. It costs more and has special features. |

There are two main types of alloy steel:

- Low-alloy steels

- High-alloy steels

Some steels are grouped by which elements they have. For example, some have more chromium to stop rust. Others have more nickel to make them tougher. High-alloy steels are harder to make and cost more. But they give special benefits.

Each type of alloy steel has its own job. Knowing what each type does helps you pick the right one.

Core Characteristics

Alloy steel is known for its great qualities. This steel can take a lot of force before breaking. It is tough and does not crack easily. Many people use alloy steel because it does not wear out as fast. It also fights rust better than regular steel.

Here are some important features of alloy steel:

- High tensile strength

- Great toughness

- Good at stopping wear and rust

- Strong mechanical properties

- Can handle tough environments

Alloy steel is used where strong materials are needed. You see it in planes, cars, and chemical plants. It works well in hard places. That is why people use it for big jobs.

The special elements in alloy steel help it do many things. Chromium, nickel, and molybdenum let you change the steel for different needs. You can get steel that works in high heat. You can get steel that does not rust. You can get steel that stays strong under heavy weight. This makes alloy steel popular in many fields.

Tip: If you need steel for tough jobs, think about alloy steel. Its mix of elements gives it the power for hard work.

Alloy steel is not just one kind of steel. It is a group with many strengths and uses. When you know what it can do, you can choose the best steel for your project.

Key Differences in Performance

Strength and Hardness

When you look at alloy steel and carbon steel, you see they are not the same. Alloy steel is strong because it has special elements like nickel and chromium. These elements help it stay strong when you push or pull on it. Carbon steel gets its strength from how much of carbon it has. If it has a lot of carbon, it can be strong but not very bendy.

Here is a table that shows how strong and hard these steels are:

| Property | Alloy Steel | Carbon Steel |

|---|---|---|

| Strength | Enhanced by elements like nickel and chromium; high tensile and yield strength | Varies with carbon content; high-carbon steel is strong but less flexible |

| Toughness | Improved by manganese and silicon; absorbs energy well | Lower toughness than alloy steel |

| Wear Resistance | Increased by vanadium and tungsten; good for high-wear jobs | Lower wear resistance |

| Ductility | Some types are very flexible | Ductility drops as carbon content rises |

| Hardenability | Molybdenum helps keep hardness even in thick parts | Less hardenability than alloy steel |

You can also look at how hard each steel is. For example, 1018 mild carbon steel has a Rockwell hardness of B71. 8620 alloy steel has a Brinell hardness of 201. This means alloy steel is often much harder than carbon steel.

If you want steel that is both strong and hard, alloy steel is usually better. Carbon steel is good for jobs that do not need as much strength.

Durability and Corrosion Resistance

Durability means how long something lasts before it breaks. Corrosion resistance is how well steel fights rust. Alloy steel is better at both because of its special elements.

- Alloy steel is stronger, harder, and fights rust better than carbon steel.

- Alloy steel lasts longer because of the extra elements.

- Carbon steel is cheaper and still strong, but it does not last as long in tough places.

- Carbon steel can rust quickly if it gets wet or is in a harsh place. It may need paint or other coatings to last longer.

Alloy steel stands out because elements like chromium form a thin layer on the outside. This layer helps stop rust. Nickel, manganese, and molybdenum also help alloy steel fight rust. Carbon steel does not have these extra elements, so it needs paint or coatings to keep it from rusting.

Tip: If your project will get wet or face chemicals, pick alloy steel for better protection.

Machinability and Processing

Machinability means how easy it is to cut or shape steel. Processing is all the ways you can change steel to fit your needs. Both alloy steel and carbon steel can be cut and shaped, but they act differently.

Machining Carbon Steel

Carbon steel is easier to cut, especially if it has low carbon. Low-carbon steel makes soft chips that can slow you down. Adding a little sulfur or lead can help make it easier to cut. High-carbon steel makes harder chips, but it can break more easily.

- Cold work can make carbon steel harder and easier to cut.

- Heating it up, like annealing, makes it softer and easier to shape.

- You should change your cutting speed to avoid bending the steel and to get smooth cuts.

- Using the right size of carbon steel can save time and help your tools last longer.

Note: Always use the right clamps to hold carbon steel steady when you cut it. This helps you avoid mistakes and get better results.

Machining Alloy Steel

Cutting alloy steel takes more care. The extra elements make it stronger and harder to cut. You need to watch the temperature. If alloy steel gets too hot, it can bend or stick to your tools. High-speed steel tools work, but carbide-tipped tools are better.

- Always watch the temperature so the steel does not bend or stick.

- Use carbide-tipped tools for the best results, especially with tough alloy steel.

- The shape of the steel, like plates or bars, changes how you need to hold and cut it.

- Change your cutting speed based on the type of alloy steel you use.

Tip: When you cut 4140 alloy steel, keep it cool and use strong clamps. This helps you get clean cuts and keeps your tools safe.

Special machines, like those at AFI Industrial Co., Ltd, can cut both carbon steel and alloy steel. These machines can make parts that fit just right, even with tough steel. You can get custom shapes, smooth surfaces, and good results for your project.

Summary Table: Machinability and Processing Tips

| Steel Type | Machinability | Processing Tips |

|---|---|---|

| Carbon Steel | Easier, especially low-carbon types | Use thermal treatment, adjust speeds, use proper clamps |

| Alloy Steel | Harder to machine, needs care | Monitor temperature, use carbide tools, strong clamps |

Remember: The right way to cut and the right tools help your steel parts turn out better.

Versatility and Applications

Carbon Steel Applications

Carbon steel is used in many places. It is strong and not expensive. It is also easy to use. Many industries use carbon steel for different things. Let’s see where carbon steel is used the most.

Construction

You can find carbon steel in buildings. Builders use low carbon steel for frames and pipes. Mild carbon steel is used for things like sheets and plates. These materials help make buildings safe and strong. Carbon steel gives good strength for a fair price.

| Industry | Application Description |

|---|---|

| Construction | Low carbon steel is used for steel frames and piping; mild carbon steel is used in fixtures as sheets or plates. |

Construction uses a lot of carbon steel. It is popular because it works well and does not cost too much.

Automotive and Tools

Carbon steel is also used in cars and tools. Car makers use it for frames and other parts. You can find it in exhaust systems and fasteners. Tool makers use high carbon steel for cutting tools. It stays sharp and does not wear out fast. This makes it good for hammers, saws, and knives.

| Industry | Application Description |

|---|---|

| Automotive | Carbon steel is utilized for chassis, frames, structural parts, and components like exhaust frameworks and fasteners. |

| Tool Manufacturing | High carbon steel is favored for cutting tools due to its abrasion resistance and ability to maintain sharp edges. |

The car industry uses a lot of carbon steel. The tool industry uses high-carbon steel, but not as much as cars and buildings.

Alloy Steel Applications

Alloy steel can do even more jobs. The extra elements make it stronger and better at stopping rust. Alloy steel is used when regular steel is not enough.

Aerospace and Energy

Alloy steel is very important in planes. It is used in landing gear, airframes, and engine gears. Types like 4330, 4340, 9310, and M50 are common. These steels can handle high stress and heat. Jet engines and turbine blades use alloy steel because it stays strong and lasts long.

| Sector | Alloy Steel Used | Application Description |

|---|---|---|

| Aerospace | 4330 | Manufacturing of aircraft landing gear components. |

| Aerospace | 4340 | Used for aircraft landing gear, airframe parts, and more. |

| Aerospace | 9310 | Manufacturing of gear systems in aircraft engines. |

| Aerospace | M50 | Used in jet engine bearings and turbine blades. |

| Aerospace | M50 | Ideal for rotor shafts and gears in high-speed applications. |

| Energy | 4330 | Used in heavy machinery for high tensile strength parts. |

| Energy | 4330 | Favored in oil and gas for drilling and exploration equipment. |

The energy industry needs steel that is strong and fights rust. Stainless steel and high-alloy steels are used here. Planes and spacecraft need special steels too. Planes use more alloy steel than energy jobs because they need a lot and pay more.

Plane makers buy lots of alloy steel and pay high prices. This can make wait times longer and prices go up, especially in Europe and the US. This also makes nickel cost more, so alloy steel gets more expensive next year.

Specialized Industrial Uses

Alloy steel is used in many factories. It is used for mining machines, trains, and big equipment. Alloy steel is picked for parts that must last long and work in hard places. It is the best choice when you need steel that will not break or rust.

If your job needs steel that faces a lot of stress, heat, or rust, alloy steel is the best pick. Its special mix of elements helps it work well in tough jobs.

Cost and Availability

Price Factors

When you look at the cost of steel, you see many things that can change the price. The price of steel depends on what goes into making it and how much people want to buy it. You will notice that both alloy steel and carbon steel prices can go up or down quickly. Here are some of the main things that affect the price:

- Demand for lightweight and strong materials in cars and buildings keeps rising.

- More factories and new buildings in growing countries increase the need for steel.

- The price of raw materials, like iron ore, scrap metal, and coking coal, can change a lot.

- New rules to protect the environment can make it more expensive to make steel.

- Economic growth and how busy factories are will change how much steel costs.

- New technology, such as the Hybrit Process, can also affect the price.

- If China’s economy slows down, steel prices around the world can drop.

You can see how raw material costs affect steel prices in this table:

| Raw Material | Impact on Steel Pricing |

|---|---|

| Iron Ore | Changes in cost make it more expensive or cheaper to produce steel. |

| Scrap Metal | Price swings can change how much it costs to make steel and how much profit is left. |

| Coking Coal | When the price goes up, steel makers must charge more to keep making money. |

When you buy steel, you pay more if the materials cost more. If factories need to pay extra for cleaner production, that also adds to the price. When many people want steel at the same time, prices go up. If fewer people want it, prices can fall.

Market Access

Getting steel for your project is not always easy. You may face some challenges when you try to buy alloy steel or carbon steel, especially if you need a lot or want it fast. Here are some things that can make it hard to get the steel you need:

- The price of iron ore, coal, and scrap steel can change quickly, making it hard to plan your budget.

- Many countries want steel makers to lower pollution, so factories must change how they work.

- Sometimes, there are not enough raw materials, so steel becomes hard to find.

- When lots of people want steel, you may have to wait longer to get your order.

- The cost of steel has gone up a lot since before the pandemic, making it harder for some companies to buy what they need.

You may also see that supply chain problems can cause shortages. If a factory cannot get enough materials, it cannot make enough steel. This means you might have to wait longer or pay more. When demand is high, lead times get longer, and your project may slow down.

Tip: Plan ahead when you need steel for your project. Check with your supplier about lead times and prices. If you need a special type of steel, order early to avoid delays.

You can see that both price and availability depend on many things. Knowing these factors helps you make better choices for your project.

Choosing the Right Steel

When you choose steel for your project, you want to make the best decision. Picking the right type helps your project last longer and work better. You need to look at what your project needs and how you will use the steel.

Decision Factors

You should think about several things before you decide between alloy steel and carbon steel. Each type has its own strengths and best uses. The table below shows you the main factors to consider:

| Decision Factor | Alloy Steel | Carbon Steel |

|---|---|---|

| Corrosion Resistance | Superior due to elements like chromium and nickel | Needs coatings for resistance, which adds cost |

| Strength & Durability | Higher fatigue resistance and tensile strength | Lower strength, good for less demanding jobs |

| Hardness & Impact | May have lower surface hardness | Often greater surface hardness, good for impact |

| Performance Reliability | Worth higher cost in high-risk uses | Cost-effective, but less reliable in extremes |

| Cost Efficiency | More expensive because of alloying elements | Cheaper for high-volume jobs |

| Application Type | Best for high-stress jobs (aerospace, automotive) | Good for low-stress jobs (precision machining) |

You also need to think about how you will machine or process the steel. The next table helps you see how performance and machining needs affect your choice:

| Criteria | Alloy Steel | Carbon Steel |

|---|---|---|

| Performance Requirements | Great for high-strength applications | Cost-effective for structural parts |

| Machining Efficiency | May need special tools for hardness | Easier to machine, saves time and cost |

Tip: Always match the steel to your project’s needs. If you need high strength and rust resistance, choose alloy steel. If you want easy machining and lower cost, carbon steel is a good pick.

You can use this checklist to help you decide:

- Does your project need to handle high stress or harsh environments?

- Will the steel face water, chemicals, or weather?

- Do you need to machine or weld the steel easily?

- Is cost a big concern for your project?

- What is the expected life of your product?

- Are there special rules or standards for your industry?

Common Mistakes to Avoid

Many people make mistakes when picking steel. You can avoid problems by learning from these common errors:

- Do not forget to check if the steel matches what it will touch or hold. Some materials can cause corrosion or damage.

- Do not skip a full study of how the steel will handle rust. Poor planning can lead to extra costs or early failure.

- Do not pick alloy steel just because it is strong. Sometimes, you do not need that much strength, and you pay more for no reason.

- Do not ignore how easy it is to machine or weld the steel. Harder steels may slow down your work or require special tools.

- Do not forget to think about the total cost over the life of your project, not just the price of the steel.

The Space Shuttle Challenger disaster happened because the team did not consider the environment when choosing materials. The O-ring did not flex in the cold, which led to a fatal accident. Always think about where and how your steel will be used.

Here are some questions you should ask before you choose carbon steel:

- Does it need to be machined?

- Does it need to be welded?

- What strength do you need?

- Does it need to bend or form easily?

- Should it be heat-treatable?

- Does it need to resist rust?

- What will you use it for?

Remember: Take your time to study your needs. The right steel choice saves money, time, and trouble.

You can look at this table to see how alloy steel and carbon steel are different:

| Feature | Alloy Steel | Carbon Steel |

|---|---|---|

| Strength & Durability | Better strength | Strong but not as tough |

| Corrosion Resistance | Fights rust well | Needs a coating to stop rust |

| Heat Resistance | Handles heat better | Okay with heat |

| Cost | Costs more | Costs less |

| Applications | Used in planes, energy | Used in buildings, cars |

When you pick steel, think about these things: Make sure the steel fits your project’s needs for strength, price, and where it will be used. Think about how easy it is to cut or shape. If you need special shapes or very exact parts, ask someone who knows a lot about steel.

Choose the best steel for your job so your project works well.

FAQ

Alloy steel contains extra elements like chromium or nickel. These elements make it stronger and more resistant to rust. Carbon steel has mostly iron and carbon. It is easier to shape and costs less.

Yes, you can weld both. Carbon steel is easier to weld. Alloy steel may need special care or filler materials because of its added elements.

Alloy steel works better outdoors. It resists rust and weather damage. Carbon steel needs paint or coatings to last outside.

Alloy steel is usually stronger because of its extra elements. High-carbon steel can also be very strong, but it is less flexible and more likely to break.

Think about what your project needs. Ask yourself about strength, cost, rust resistance, and how easy it is to shape or weld. Use a checklist to compare your options.

Yes. Alloy steel is harder and wears down tools faster. Use carbide-tipped or high-speed steel tools. Keep the steel cool while you work.

Alloy steel uses special elements and takes more steps to make. These factors raise the price. Carbon steel is simpler and cheaper to produce.