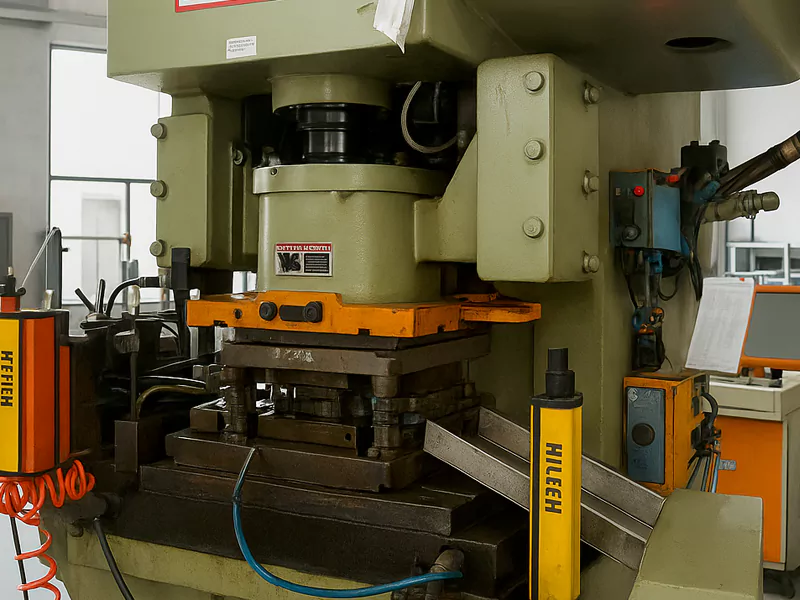

You want metal parts that are very accurate and reliable. The fine blanking process is a great way to solve new manufacturing problems. Fine blanking can make parts as exact as machining. It often keeps the space between parts very small, less than one percent of the material’s thickness on each side. This helps you get parts with no cracks or tears. The size of the parts is always correct. New data shows more people use the fine blanking process now. In 2023, 68% of car makers used it. In Europe, 52% of tooling companies used it:

| Year | Adoption Rate (%) | Sector Focus |

|---|---|---|

| 2023 | 68 | Automotive |

| 2023 | 52 | European Tooling Firms |

Manufacturers pick the fine blanking process because it makes parts look smooth and the size is always right. This helps meet the need for very exact parts. AFI Industrial Co., Ltd is a leader with new ideas. You can trust every part they make.

Key Takeaways

- Fine blanking produces metal parts with great precision. It can reach tolerances as close as ±0.001 inches.

- The process gives parts smooth edges with no burrs. This means less extra work is needed to finish them.

- Fine blanking uses almost all of the metal sheet. This cuts down on waste and helps the environment.

- It can make complex shapes in just one step. This saves time and keeps the parts accurate.

- Picking fine blanking can reduce the cost of making parts. It removes the need for extra work and workers.

- The process gives the same quality for many parts in big batches. This makes it a good choice for many industries.

- Fine blanking is getting more popular. Many car and tool companies use it now.

- AFI Industrial Co., Ltd gives advanced fine blanking services. They make high-quality parts to fit what customers want.

Table of Contents

Dimensional Accuracy with Fine Blanking

Tight Tolerances

You want all your parts to fit just right. Fine blanking helps you control the size of each part. This process lets you make parts with very tight tolerances. The size of every part stays almost the same, even if you make thousands. For example, you can get a tolerance as small as ±0.001 inches. This is much better than regular stamping. You can see how fine blanking does in the table below:

| Tolerance Range | Description |

|---|---|

| ±0.001 inches | Achievable tolerance in fine blanking |

Fine blanking uses special tools and a strong press. The metal sheet is held very tightly during cutting. This keeps the metal from moving or bending. Your parts will match your design every time. If you need gears, brackets, or connectors, fine blanking can help. AFI Industrial Co., Ltd uses advanced machines and skilled workers. They make sure your parts meet strict size rules. You do not have to worry about parts being too big or too small.

Consistent Part Quality

You want every part to work the same way. Fine blanking helps you reach this goal. The process makes parts with smooth, straight edges and almost no burrs. This is important for high-precision metal parts. You do not need to spend extra time or money fixing the edges. Here is what you get with fine blanking:

- Fine blanking makes parts with smooth, straight edges and very few burrs. This is important for high-precision jobs.

- Regular stamping may not give you the same edge quality, especially if you need smooth edges.

- The tool set in fine blanking has a recoil punch and a hold-down device. These tools help make the cut surfaces better, so you do not need more finishing.

You can see the difference when you compare fine blanking to regular stamping. Fine blanking gives you better edges and more reliable parts. The process uses a hold-down device and a recoil punch. These tools keep the metal flat and steady. Your parts will look and work better. When you pick AFI Industrial Co., Ltd, you get their fine blanking experience. They check every part for quality. You get parts that are precise and always the same.

Tip: If you want to waste less and skip extra steps, pick fine blanking for your next project. You will notice better quality and performance.

Edge Quality in the Fineblanking Process

Burr-Free Edges

Fineblanking gives you parts with smooth edges. These edges do not have burrs. Burrs are sharp pieces left after cutting metal. They can hurt people or cause problems. Fine blanking makes edges almost as smooth as a mirror. It does this in one step. You do not need to do extra work to fix the edges. Other ways of cutting metal often leave burrs. Those burrs must be removed later.

Fineblanking uses a strong press and special tools. These tools hold the metal sheet very tightly. The process shapes the metal with a lot of force. This keeps the edges straight and clean. The parts look nice and feel smooth. If you care about how your parts look and feel, fine blanking is a good choice.

AFI Industrial Co., Ltd uses new fineblanking machines. Their workers are skilled and careful. They check every part for good edge quality. You can trust your parts will look right every time. This matters for cars, electronics, and medical devices. Even a small burr can cause big trouble.

Note: Fine blanking gives you a better surface finish than other ways of shaping metal. You get tight tolerances, tricky shapes, and smooth edges all at once.

Enhanced Safety and Performance

Smooth edges are not just for looks. They also make your parts safer and better. Burrs can cut people who touch the parts. Sharp edges can hurt workers or users. Taking off burrs is important for safety. Fineblanking helps you avoid these dangers. Your parts are safe to touch and use.

Here are some reasons why smooth edges help safety and performance:

- Burrs can cut people and cause injuries.

- Sharp edges can make parts fit badly during assembly.

- Burrs can stop parts from working well or lasting long.

- Taking off burrs keeps workers and users safe.

Fine blanking gives you parts that fit together well. Smooth edges help stop problems when putting parts together. Your products will work as they should. There will be fewer problems from rough edges. AFI Industrial Co., Ltd checks every part for smooth edges. You know your parts are safe and work well.

If you want safer and better products, pick fineblanking. You save time, lower risks, and give your customers better results.

Repeatability and Reliability in Fine Blanking

Uniform Production

You want every part in your order to look and work the same. Fineblanking helps you reach this goal. The fine blanking process uses special tools and machines to keep each part uniform. When you use fineblanking, you get parts that match your design, even if you make thousands at a time.

Fineblanking stands out because it controls every step. The die clearance, or the space between the cutting tools, is set just right for each material. For example, you use 6-8% clearance for mild steel and 10-12% for stainless steel. This careful setup keeps the edges smooth and the size exact. If you do not set the clearance correctly, you might see burrs or bent edges. These problems can ruin a big batch of parts.

You can see how fine-tuning helps you avoid these issues:

- The process uses tight die clearance to keep parts the same size.

- Each part comes out with the same edge quality and thickness.

- You do not have to worry about some parts being rough or out of shape.

- The process works well for large orders, so you get the same results every time.

When you choose AFI Industrial Co., Ltd, you get more than just machines. Their team checks every step to make sure your parts are uniform. You can trust that your parts will fit and work as planned.

Tip: Uniform production means less waste and fewer problems during assembly. Fine blanking gives you this advantage.

Process Control

You need reliable parts for your business. Fineblanking gives you that reliability. The process uses careful monitoring and control to keep every part within your standards. Skilled workers watch the machines and make small changes when needed. This keeps the process stable and the results steady.

AFI Industrial Co., Ltd uses a strong quality control system. They check the parts at each stage. If they see a problem, they fix it right away. This means you get parts that meet your needs, every time.

Here is how process control helps you:

- Workers check the die clearance and machine settings before each run.

- They monitor the process for changes, like burr height or edge shape.

- If something changes, they adjust the setup to keep the parts right.

- Quality checks happen during and after production, so you get only the best parts.

Fine blanking and fine blanking both focus on repeatability. You get the same high quality, no matter how many parts you order. This is important for industries like automotive, electronics, and medical devices, where precision matters.

Note: Reliable process control means fewer surprises and more confidence in your products. Fineblanking helps you deliver on your promises.

Complex Geometries with Fine Blanking Process

Intricate Features

You may want to make parts with hard shapes. Regular stamping cannot do this easily. Fineblanking lets you make these shapes in one step. You can get sharp corners and small holes at the same time. The process uses special tools and strong pressure to shape metal. You do not need to cut or finish the part again. The part comes out smooth and without tears.

Look at this table to see how fineblanking and regular stamping are different:

| Feature | Fine Blanking | Conventional Stamping |

|---|---|---|

| Cutting Gap | Reduced to approx. 0.5% of sheet thickness | Larger cutting gaps |

| Cutting Edge | Right-angled cutting edges up to 100% thickness | Varies, often not right-angled |

| Surface Quality | Tear-free cut surfaces usable as functional surfaces | May require finishing |

| Additional Processing Steps | Can combine with countersinking, stamping, etc. | Limited to stamping only |

Fineblanking lets you add holes, grooves, and steps in one go. You do not have to move the part to another machine. This saves time and keeps the part correct. You get smooth edges and high precision every time.

Design Flexibility

Fineblanking gives you more choices when you design parts. You can make shapes that are too hard or expensive in other ways. This process allows for complex shapes and tight sizes. You can do blanking, trimming, and finishing all at once. You do not need extra cutting or grinding.

Here is a table that shows how fineblanking cuts down on extra work:

| Feature | Fine Blanking | Traditional Stamping |

|---|---|---|

| Surface Finish | Exceptional | Rougher edges |

| Tolerances | Tight | Looser tolerances |

| Secondary Operations Needed | Often eliminated | Frequently required |

| Complexity of Shapes | High complexity achievable | Limited complexity |

You can see the good things about fineblanking:

- You get high precision when stamping metal sheets

- The edges are smooth, and the size is exact

- You can blank, trim, and finish in three steps

- You do not need much extra work

Fineblanking helps you make parts for cars, electronics, and medical devices. You can trust it to make the shapes you need. AFI Industrial Co., Ltd uses fineblanking to help customers get special parts. Their team can handle hard designs and keep every part the same.

Tip: If you want to skip extra steps and get tricky parts fast, pick fineblanking. You will save time and get better parts.

Some problems come up when making complex shapes with fineblanking. You need smart die design, good material, and strong dies for big jobs. You also need to keep tight sizes and make sure the dies last. AFI Industrial Co., Ltd fixes these problems with skilled workers and new machines. You get good parts, even for the hardest jobs.

Fineblanking lets you try new designs. You can make parts that fit your needs without extra work. This process gives you the freedom and accuracy you want.

Cost and Efficiency Advantages of Fine Blanking

Reduced Waste

You want to use your materials well and not waste them. Fineblanking helps you do this in one strong step. It cuts metal parts fast and uses almost all the metal sheet. There is very little leftover metal. You get the shape you want right away. This saves money and helps the environment.

Fineblanking uses each metal sheet almost fully. You get more parts from the same sheet and waste less.

Here is a simple table to show the difference:

| Feature | Fineblanking | Traditional Stamping |

|---|---|---|

| Material Usage | Very efficient | More waste |

| Waste Produced | Minimal | Higher |

| Steps Needed | One main step | Several steps |

Fine blanking also helps the planet. Less waste means less trash and less recycling. You can tell customers your parts are made in a way that helps the earth.

Lower Production Costs

You want to spend less money and keep your business strong. Fineblanking helps you save in many ways. The process makes parts ready to use. You do not need extra steps like grinding or polishing. This saves time and work. You also use less energy because you skip finishing steps.

Fine blanking saves money for these reasons:

- You do not pay for extra machines or workers.

- The process gives smooth edges, so you do not fix rough spots.

- You can make many parts at once, which is good for big orders.

Here is a table that shows why fine blanking is smart for your budget:

| Evidence Type | Description |

|---|---|

| Cost-Effective | Cuts out extra machining, so costs go down |

| Material Efficiency | Uses material well with exact cuts |

| High Volume Production | Good for making lots of parts that are all the same |

Fineblanking helps you stay ahead in 2025. Companies want to be fast, green, and save money. Fine blanking lets you offer better prices and quick delivery. AFI Industrial Co., Ltd uses fineblanking to help you win in a tough market. Their process gives you good parts with less waste and lower costs.

Tip: If you want to save money and help the earth, pick fineblanking for your next job. You will see better prices and better parts.

Fine blanking has many good points for making metal parts. You get parts with smooth edges and tight sizes. There is less waste, so you save more material. The process is great for making hard shapes. It also helps you spend less money. Here are the main benefits:

| Benefit | Description |

|---|---|

| High Efficiency | Makes fast, accurate parts for things like cars. |

| Precision | Gives smooth edges, so you need less extra work. |

| Cost-Effectiveness | Parts last longer and cost less to keep working. |

| Complex Part Production | Makes hard shapes and uses strong materials. |

- Fine blanking works for cars, electronics, and medical tools.

- More people use fine blanking every year.

- AFI Industrial Co., Ltd has new machines and skilled workers to help you.

Want better parts? Contact AFI Industrial Co., Ltd to talk to our team and learn how fine blanking can help your business.

FAQ

Fine blanking is a metal forming process. You use it to make parts with smooth edges and tight tolerances. This process uses strong presses and special tools to cut metal sheets very precisely.

Fine blanking holds the metal sheet tightly during cutting. You get smoother edges and more accurate parts. Regular stamping may leave burrs or rough edges. Fine blanking often removes the need for extra finishing.

Yes! You can make parts with holes, grooves, and sharp corners in one step. Fine blanking lets you create complex designs that regular stamping cannot achieve easily.

Absolutely. Fine blanking works best for high-volume production. You save money by reducing waste and skipping extra finishing steps. You get more parts from each metal sheet.

You find fine blanked parts in cars, electronics, and medical devices. Many industries choose fine blanking for its precision and reliability.

Usually, you do not. Fine blanking gives you smooth, burr-free edges. You often skip grinding or polishing, which saves time and money.

AFI Industrial Co., Ltd uses advanced machines and skilled workers. They check each part during and after production. You get parts that meet strict standards every time.

Yes, you can. Fine blanking is great for small, detailed parts. You get high accuracy and smooth edges, even on tiny components.