When you ask, “Is steel easy to manufacture?” most people refer to mild steel. Experts and the AFI Industrial Co., Ltd team agree that mild steel is easy to work with and has low carbon content. This type constitutes about 80 to 90% of steel produced globally. Manufacturers choose mild steel because it is cost-effective and consistently high in quality. It can be utilized for a wide range of applications. If you are looking for steel that performs well, mild steel is the best choice.

Key Takeaways

- Mild steel is the easiest steel to make because it has low carbon. This makes it cheap and useful for many things.

- Choosing mild steel can help save time and money. It needs fewer steps to make and uses normal tools for shaping and welding. Energy use is important.

- Mild steel melts at a lower temperature, so it costs less to make and keeps quality steady.

- Machining is very important in making steel. New CNC machines help make steel parts faster and more exact.

- Knowing what is in the alloy is important. The right mix of elements can make steel stronger and easier to work with. This helps make production easier.

- How much does change cost, and how well does it work? Making more at once lowers the price for each part and keeps the quality the same.

- AFI Industrial Co., Ltd gives expert help and uses new technology. They make sure steel parts are high-quality and fit your project.

- Think about the environment and what the steel needs to do before you choose. Mild steel is good for most jobs. Stainless and tool steels are better for special uses.

Table of Contents

Is Steel Easy to Manufacture?

If you wonder if steel is easy to make, you need to think about a few things. People in the industry say it is easy if you can shape and finish it without much trouble. You want steel that works well, does not cost a lot, and is good quality. AFI Industrial Co., Ltd has a lot of experience making metal parts. Their knowledge helps you see why some steel is easier to use than others.

What Makes Steel Easy to Manufacture

Processing Steps

The steps to make steel are not always the same. Some steel types need fewer steps, so they are easier to make. Mild steel does not need as much heat or as many extra elements. This makes the process less hard. If you use steel with simple steps, you save money and time. The biggest problems in making steel are:

- Getting the raw materials

- Moving and shipping the steel

- Making the steel in the factory

- Keeping track of the steel in storage

- Selling and sending steel around the world

You can solve many of these problems by picking steel that is easy to work with. The kind of elements you add to steel matters a lot. Copper and nickel are easier to use because they do not react with oxygen as much as chromium or manganese. This means you get better steel with less work. Picking the right elements also changes how the steel grows or shrinks when you make it, which is important for making metal parts that fit well.

Energy and Cost Factors

If you ask if steel is easy to make, you should think about energy and cost. Steel that needs less energy to melt and shape is easier and cheaper to make. Mild steel is good because it melts at a lower temperature and does not need costly extra elements. This keeps your costs low and helps you make steel faster. You also get steel that is the same quality every time, which is important for things that need to work well. If you pick steel that is easy to make, you can use it in many jobs without worrying about high prices or hard steps.

Role of Machining in Steel Manufacturing

Machining is a big part of making metal parts. You use machining to cut and shape steel the way you want. New machines help you make steel parts that fit just right and look smooth. This is important for how well the parts work. You want your steel parts to fit together and last a long time. Good machining stops tools from wearing out too fast, which saves money and keeps quality high.

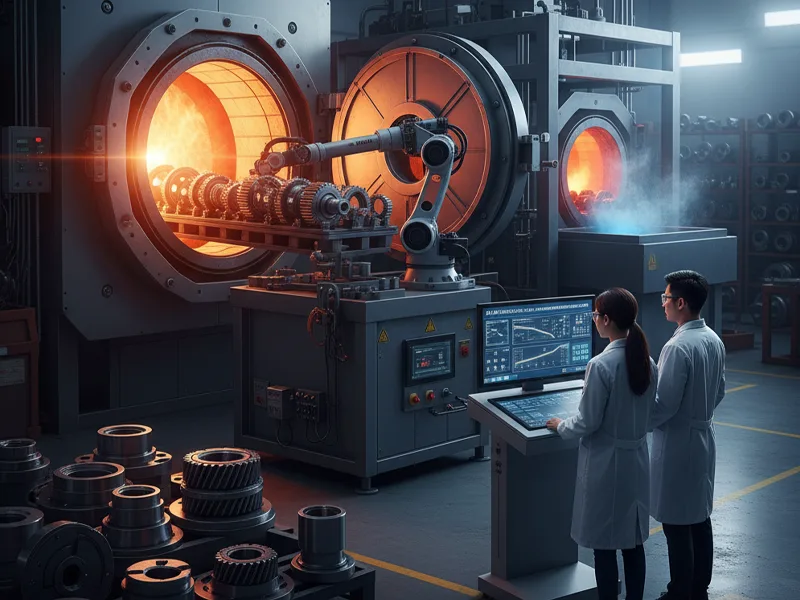

You also use things like grinding and polishing to make steel parts smooth. CNC machining lets you make hard shapes with great accuracy. Cryogenic treatment makes steel parts harder and stronger. Automated welding makes sure the joints are strong, which is needed for many uses.

AFI Industrial Co., Ltd’s Machining Capabilities

If you work with AFI Industrial Co., Ltd, you get some of the best machines in the business. They use multi-axis CNC machines, automatic checking systems, and robots to put things together. These tools help you make steel parts that are very exact and fast. The table below shows how AFI’s tools match up with others:

| Equipment/Technology | Benefit |

|---|---|

| Multi-axis CNC machining centers | Makes parts more exact and faster |

| Automated inspection systems | Lowers the mistakes in making parts |

| Robotic assembly and material handling | Speeds up making and moving parts |

| Advanced CAD/CAM software integration | Makes designing and making parts easier |

| Quality control labs with CMM | Checks that parts are of high quality |

You can get steel parts made to within ±0.01mm and as smooth as Ra0.4μm. This means your steel parts will be made very carefully. You get parts that work well and do not cost too much. AFI’s skill makes sure your steel parts are ready for tough jobs, like cars or airplanes. You can count on AFI to give you the quality and speed you need for any steel job.

Steel Types Overview

Mild Steel

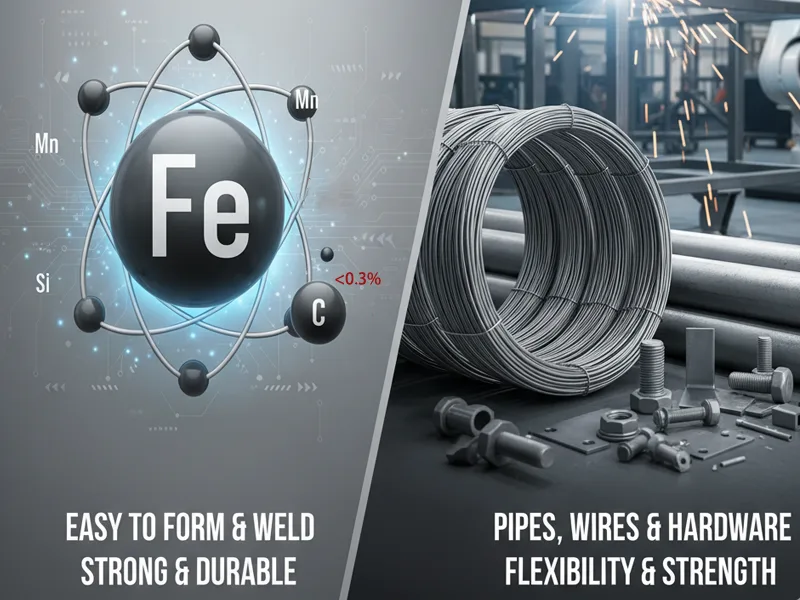

Mild steel is the most used steel grade. It has less than 0.3% carbon. This makes it easy to shape and weld. You can cut and bend mild steel without much trouble. Many companies use it for pipes, wires, and hardware. Mild steel is strong and lasts a long time for its price. It is good for jobs that need both flexibility and strength. When you pick mild steel, it is simple to work with and finish.

AFI Industrial Co., Ltd knows a lot about machining mild steel. Their team uses CNC machines to make exact parts from this steel. You get smooth and even results every time. Mild steel is also easy to paint or coat. This helps stop rust and makes it last longer.

Tip: If you want to save time and money, pick mild steel. It works for both small and big jobs.

Carbon Steel

Carbon steel has many grades with different carbon amounts. There are low, medium, and high carbon steel types. Low-carbon steel is like mild steel but a bit stronger. Medium and high carbon steel is even stronger and lasts longer. But they are harder to machine. You may need special tools or more steps to work with them.

Carbon steel is used for railroad parts, machines, and building things. Use it when you need more strength than mild steel gives. AFI Industrial Co., Ltd can machine all carbon steel grades. Their team helps you pick the right steel for your job. This way, you get the best mix of strength and lasting power.

Alloy Steel

Alloy steel has extra metals like chromium, nickel, or manganese. These make the steel stronger and tougher. Some alloy steel can resist heat, wear, and rust. This is good for planes, cars, and big machines. Alloy steel is harder to machine than mild or carbon steel. You need special machines and skilled workers for the best results. AFI Industrial Co., Ltd uses CNC machines for tough alloy steel. Their team makes sure your parts are strong and last a long time. You can trust them to give you good quality, no matter what steel you pick.

Here is a quick look at these steel grades:

| Type of Steel | Key Characteristics | Common Applications |

|---|---|---|

| Mild Steel | Low carbon, easy to machine, good weldability | Pipe, wire, hardware |

| Carbon Steel | Varies by carbon content, higher strength options | Railroad, mechanical parts |

| Alloy Steel | Contains extra metals, high strength and durability | Aerospace, automotive, industry |

Each steel grade has its own good points. Mild steel is the easiest to make. Alloy steel is the strongest and lasts the longest for hard jobs. AFI Industrial Co., Ltd can help you pick and machine any steel grade you need.

Stainless Steel

Stainless steel stands out for its resistance to rust and corrosion. You often see it in kitchens, hospitals, and chemical plants. This steel contains chromium, which forms a protective layer on the surface. That layer keeps the steel from rusting, even in wet or harsh environments. You can use stainless steel for sinks, medical tools, and food processing equipment.

Manufacturing stainless steel takes more steps than manufacturing mild steel. You need to add chromium and sometimes nickel or molybdenum. These elements make the steel harder to cut and shape. You may notice that stainless steel wears down cutting tools faster. You need sharp tools and slower speeds to get a smooth finish. AFI Industrial Co., Ltd has experience with stainless steel machining. Their team uses advanced CNC machines and special cutting fluids. This helps you get precise parts with clean edges and shiny surfaces.

Note: Stainless steel is a good choice when you need parts that last a long time and look clean. It works well for products that must stay strong and resist stains.

You can also polish or coat stainless steel for extra shine. AFI’s team can help you pick the right grade and finish for your project. They know how to handle the challenges of cutting and shaping this tough material.

Tool Steel

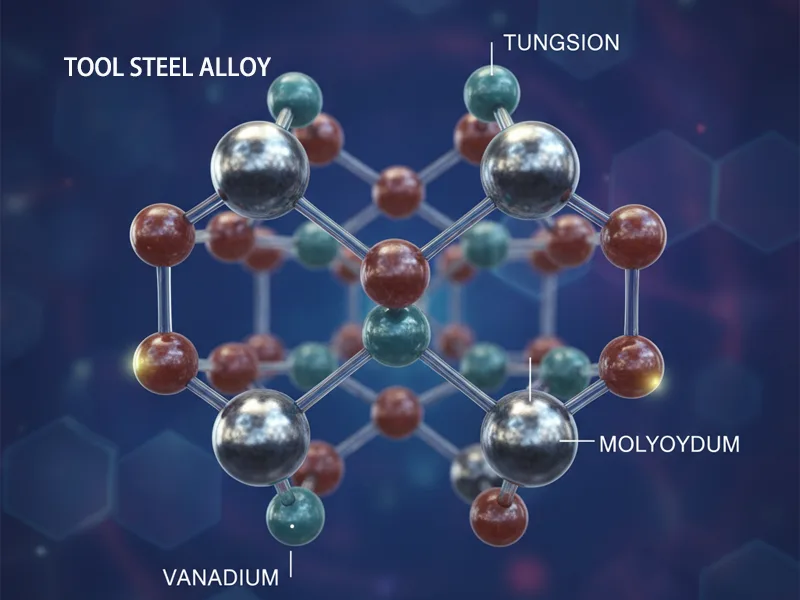

Tool steel is a special type made for making tools, dies, and molds. You use it when you need steel that stays hard and sharp, even under heavy use. Tool steel contains extra elements like tungsten, vanadium, or molybdenum. These elements give it high hardness and the ability to keep a sharp edge.

You will find tool steel in cutting tools, drill bits, and machine parts. It can handle high heat and pressure without losing its shape. Making tool steel is more complex than making mild or carbon steel. You need careful heat treatment to get the right hardness. Machining tool steel takes skill and strong machines. AFI Industrial Co., Ltd uses high-precision CNC equipment to shape tool steel. Their engineers know how to choose the best cutting speeds and tools for each job.

Tip: If you need parts that cut, shape, or press other materials, tool steel is the best option. It gives you long-lasting performance and high strength.

AFI’s experience with tool steel means you get reliable parts for demanding jobs. Their quality control ensures every piece meets strict standards.

Manufacturing Process Comparison

Mild Steel Manufacturing Process

Machining and Forming

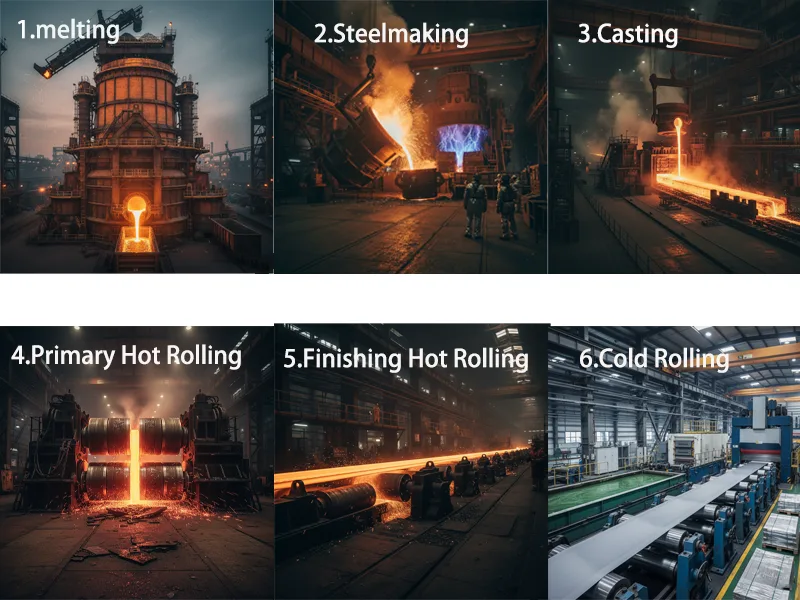

Making mild steel is not hard. First, iron ore is mixed with coke and limestone. This mix goes into a blast furnace. The furnace makes molten iron. Next, the molten iron is turned into steel. This happens in a Basic Oxygen Furnace or an Electric Arc Furnace. Other metals are added to get the right properties. Then, the steel is shaped by casting. You can use ingot casting or continuous casting.

After casting, the steel is made thinner and shaped. This is done by hot rolling. The steel is heated again and rolled in mills. This gives the steel its main shape. Cold rolling, surface finishing, and cutting come next. These steps make the steel smooth and ready to use. Mild steel is easy to bend, cut, and weld. Standard tools work well because of the low carbon content. Tools last longer, and the process is fast. You get smooth parts that work well.

AFI Industrial Co., Ltd uses advanced CNC machines for mild steel. Their team can make complex shapes with tight sizes. The parts are strong and last a long time. Mild steel is used for pipes, wires, and hardware. It is good for jobs that need both strength and flexibility.

Tip: Mild steel is easy to shape and finish. It saves time and money.

Cost and Efficiency

Mild steel is cheap and efficient to make. It melts at a lower temperature, so less energy is needed. You do not need costly extra metals. This keeps costs down. You can make a lot of mild steel quickly. The process is the same each time, so quality stays high.

Mild steel is a good choice for big and small jobs. It is strong and lasts a long time. Many industries use it because it works well and is not expensive. AFI Industrial Co., Ltd helps you work faster with their machines. Their checks make sure every part is good.

| Step | Description | Benefit |

|---|---|---|

| Ironmaking | Get iron ore, mix with coke and limestone | Start for making steel |

| Steel Making | Change molten iron, add metals | Get the right properties |

| Steel Casting | Shape steel by casting | Many shapes possible |

| Hot Rolling | Make the shape and thickness better | Same size every time |

| Finishing Touches | Cold rolling, finishing, cutting | Smooth, ready-to-use steel |

Mild steel gives you strength and saves money. The process is simple and works for many uses.

Carbon Steel Manufacturing Process

Carbon steel is made almost like mild steel. You start with ironmaking and steelmaking. The main change is how much carbon is added. Low-carbon steel is close to mild steel. Medium and high carbon steel needs more careful control. You must watch the carbon to get the right strength.

After casting, you use hot and cold rolling to shape the steel. Higher carbon steel may need extra heat treatment. This makes it harder and stronger. Machining carbon steel is harder than mild steel. You need sharper tools and slower speeds. More carbon means tools wear out faster. The parts are strong, but you must be careful when machining.

AFI Industrial Co., Ltd knows how to work with all carbon steel grades. Their team helps you pick the best way to make your parts. You get strong and tough parts. Carbon steel is used for trains, machines, and buildings. It is good for jobs that need more strength.

Alloy Steel Manufacturing Process

Making alloy steel is more complicated. You start with ironmaking and steelmaking. During steel making, you add metals like chromium, nickel, or manganese. These make the steel stronger and tougher.

After that, you cast and roll the steel. Sometimes, special machines are needed. Alloy steel often needs advanced heat treatment. This gives it the right properties. Machining alloy steel is harder than mild or carbon steel. You need strong tools and skilled workers. The extra metals make the steel tough. The process takes more time and effort.

AFI Industrial Co., Ltd uses top CNC machines for alloy steel. Their engineers pick the best tools and speeds. You get strong parts that work well in hard jobs. Alloy steel is used in planes, cars, and big machines. It is best for jobs that need the most strength and toughness.

Stainless Steel Manufacturing Process

Working with stainless steel is not easy. This steel does not rust and looks shiny. But making it is harder than making other steels. You have to be careful at every step to get good results.

To make stainless steel, you melt iron ore with chromium. Sometimes you add nickel or molybdenum. These give the steel its special features. After melting, you pour the steel into shapes. Then you use hot rolling and cold rolling. This makes the steel the right thickness and smooths the surface. You must control each step so the steel stays strong and has no problems.

Stainless steel is harder to cut than mild or carbon steel. It gets hot fast and does not move heat away well. This makes heat build up when you cut it. Too much heat can hurt your tools and the steel. You need sharp, strong tools and the right speed. If you use the wrong settings, you can mess up the surface. You might also make the steel lose its rust protection.

Here are some big problems you might have with stainless steel:

- Too much heat when cutting because the heat does not move away

- Hard to get a smooth surface, which can hurt rust protection and welding

- You need to know a lot to pick the right tools and speeds

- The steel gets hard fast, so it is even tougher to cut

- Tools cost more because they wear out quickly and need replacing

SS Cutting by AFI Industrial Co., Ltd

AFI Industrial Co., Ltd helps you with these problems using new cutting machines. Their team uses plasma arc systems that work at high temperatures. They also use water jets with very high pressure. These tools cut stainless steel fast and very accurately. You get your parts quicker and spend less money.

| Cutting Technology | Efficiency Improvement | Cost Reduction |

|---|---|---|

| High-temperature plasma arc | 30% faster cutting | 20% lower cost per piece |

| 6000Bar ultra-high pressure water jet | Cuts with ±0.1mm accuracy and stays cold | N/A |

| Intelligent numerical control systems | Makes sure size and surface are always right | N/A |

You get stainless steel parts that are the right size and smooth. Smart control systems make every cut just right. You save time and money and still get great parts. AFI’s skill with stainless steel means your parts will work well in tough places, like kitchens or chemical plants.

Tool Steel Manufacturing Process

Tool steel is special because you use it to make tools and molds. Making tool steel needs extra care. You start by adding tungsten, vanadium, or molybdenum. These make tool steel hard and able to stay sharp.

You shape tool steel with advanced methods. Some ways are Direct Energy Deposition (DED) and Powder Bed Fusion (PBF). Each way has its own problems.

| Manufacturing Method | Associated Difficulties |

|---|---|

| Direct Energy Deposition (DED) | Bigger melted areas, built-in tempering |

| Powder Bed Fusion (PBF) | Fast cooling, tiny structures, holes, leftover stress |

You must watch the heating and cooling very closely. If you do not, cracks or weak spots can form. Tool steel also needs special heat treatment to get hard enough. Cutting tool steel takes skill and strong machines. You need the right speed and cutting fluids so your tools do not break.

AFI Industrial Co., Ltd uses very exact CNC machines to shape tool steel. Their engineers pick the best way for your job. You get strong, long-lasting parts that meet tough rules. Tool steel is best when you need parts that must stay sharp and strong for a long time.

Factors Affecting Manufacturing Ease

Alloy Content

When you pick steel for a project, alloy content matters a lot. Different elements change how steel acts when you make it. For example, manganese helps remove oxygen and makes steel harder. It also makes steel stronger and helps it last longer. Manganese is used in things like shafts, axles, and gears. But if you add too much manganese and not enough nickel, the steel can get less tough. The table below shows how different alloy elements change steel and how easy it is to make:

| Alloy Element | Mechanism | Property Enhancements | Applications | Cause and Effect |

|---|---|---|---|---|

| Manganese (Mn) | Acts as a deoxidizer, increases hardenability, and contributes to solid solution strengthening | Improved hardenability, better wear resistance, enhanced strength | High levels can reduce toughness if not balanced with other elements, like nickel | High levels can reduce toughness if not balanced with other elements like nickel |

You need to choose the right mix of alloys for your job. AFI Industrial Co., Ltd helps you pick steel with the best alloy content. This makes machining easier and gives you good results.

Heat Treatment

Heat treatment changes how steel acts and looks. You heat and cool steel in special ways to make it harder or stronger. This helps you get steel that is tough and lasts longer. Heat treatment also helps stop steel from bending or breaking when you use it.

- Makes the product last longer.

- Makes steel tougher and stronger.

- Makes welding easier.

- Makes steel more flexible.

- Helps steel resist wearing out.

- Makes the part last longer overall.

You see these good things at every step of making steel. When you treat steel the right way, it is easier to cut, weld, and finish. AFI Industrial Co., Ltd uses new heat treatment methods to make sure your steel parts are strong and safe.

- Heat treatment makes steel harder and stronger.

- It changes things like how much force steel can take before breaking.

- Good heat treatment helps get rid of stress inside steel, so it is easier to cut or weld.

Machinability

Machinability means how easy it is to cut and shape steel. You check machinability by looking at how long tools last, how smooth the steel is, how much power you use, and the machinability rating. If steel is easy to machine, your tools last longer, and the surface is smoother. You also use less power, which saves you money and time.

| Measurement Parameter | Description |

|---|---|

| Cutting Tool Life | Measures how long a cutting tool can be used on a material before needing replacement or resharpening. |

| Surface Finish | Indicates the quality of the surface produced, reflecting changes in machinability. |

| Power Consumption | Relates to the force required to cut materials; harder materials consume more power. |

| Machinability Rating | A practical method to rank materials based on their machinability, though less scientific. |

AFI Industrial Co., Ltd uses very exact CNC machines to help machinability. Their team picks the best speeds and tools for each steel type. You get parts that look good and last a long time. Good machinability means you do not have to change tools as much, and you finish faster.

Tip: Always think about machinability when you plan your steel job. It helps you save time and keeps your quality high.

Production Scale

Production scale plays a big role in how easy it is for you to manufacture steel. When you make steel in large quantities, you can use bigger machines and more advanced technology. This helps you lower costs and finish jobs faster. If you only need a small amount of steel, you might use simpler tools and smaller machines. This can make each piece cost more and take longer to produce.

You should think about your project size before you choose a steel type or a manufacturing method. Large-scale production lets you buy raw materials in bulk. This often means you pay less for each unit. You can also set up automated lines that keep quality high and reduce mistakes. AFI Industrial Co., Ltd has experience with both small and large production runs. Their team knows how to adjust the process to fit your needs.

Here are some ways production scale affects steel manufacturing:

- Cost Efficiency: Making more steel at once spreads out the cost of machines, labor, and energy. You save money on each part.

- Consistency: Large batches help you keep the quality the same for every piece. Automated checks catch problems early.

- Lead Time: Bigger production runs usually mean you get your steel parts faster. Machines run longer without stopping.

- Customization: Small batches let you make special shapes or sizes. You can test new designs without a big investment.

Tip: If you want to save money and time, plan your production scale early. Talk to your supplier about the best batch size for your project.

AFI Industrial Co., Ltd uses over 100 machines to handle different production scales. Their CNC systems can switch between small custom orders and large bulk runs. This flexibility means you always get the right amount of steel parts, made to your exact needs.

The table below shows how production scale can change your manufacturing process:

| Production Scale | Typical Equipment Used | Cost per Unit | Customization | Lead Time |

|---|---|---|---|---|

| Small Batch | Manual/CNC machines | Higher | High | Longer |

| Large Batch | Automated lines, robots | Lower | Lower | Shorter |

You should match your production scale to your project goals. If you need many steel parts, large-scale production is best. If you want special features or only a few pieces, small-scale works better. AFI’s team can help you decide which path fits your needs. They make sure you get high-quality steel parts, no matter the order size.

Comparison Table

Steel Type vs. Manufacturing Process

You can use a steel comparison chart to see how each steel type matches up with different manufacturing steps. This chart helps you pick the right steel for your job. You will notice that mild steel stands out for its simple manufacturing process. Carbon steel, alloy steel, stainless steel, and tool steel each have their own strengths and challenges. The steel comparison chart below shows how each steel type performs in key areas:

| Steel Type | Manufacturing Process Ease | Machinability | Corrosion Resistance | Strength | Typical Uses |

|---|---|---|---|---|---|

| Mild Steel | Very Easy | High | Low | Medium | Pipes, wires, hardware |

| Carbon Steel | Easy to Moderate | Moderate | Low | High | Machinery, construction |

| Alloy Steel | Moderate | Moderate | Medium | Very High | Automotive, aerospace |

| Stainless Steel | Difficult | Low | Very High | High | Medical, food, chemical |

| Tool Steel | Difficult | Low | Medium | Very High | Tools, dies, molds |

You can use this steel comparison chart to quickly compare the main features of each steel type. The chart also helps you see which steel will work best for your project.

Cost and Practicality

When you look at cost and practicality, the steel comparison chart gives you a clear view. Mild steel is the most cost-effective choice. You can use it for many jobs without spending much. Carbon steel costs a bit more but gives you extra strength. Alloy steel and stainless steel cost more because they need special elements and extra steps. Tool steel is the most expensive, but you need it for jobs that require high hardness and durability.

Here are some points to help you use the steel comparison chart for your next project:

- Mild steel saves you money and works for most general uses.

- Carbon steel gives you more strength for a small increase in price.

- Alloy steel and stainless steel are best for tough jobs or harsh environments.

- Tool steel is the top choice when you need parts that stay sharp and strong.

You can trust AFI Industrial Co., Ltd to handle any steel type you choose. Their team uses advanced machines and strict quality checks. You get steel parts that fit your needs, whether you want a simple part or a complex tool. The steel comparison chart makes it easy to match your needs with the right steel.

You can always ask AFI’s experts for advice. They help you read the steel comparison chart and pick the best steel for your job. Their experience covers every steel type and manufacturing process. You get reliable results every time.

Choosing the Right Steel

When to Use Mild Steel

Pick mild steel if you want something easy to shape and weld. Mild steel works for pipes, wires, and hardware. It is popular because it costs less and is simple to machine. You can use mild steel for small or big projects. It fits many jobs where you need both flexibility and strength.

Think about a few things before you choose a steel grade. You should look at the environment, what the part needs to do, and how easy it is to make. The table below shows what matters most:

| Factor | Description |

|---|---|

| Environment | Will the part get wet, be outside, or face heat? |

| Mechanical needs | Does it need to be strong, bend easily, or last long? |

| Manufacturing fit | Should it be easy to machine, weld, or form into shapes? |

Check if your project needs to resist rust. Mild steel might need a coating if used outside. When you compare mild steel to other types, it often gives you good value and lasts a long time. Mild steel is a smart pick for many jobs.

When to Use Stainless or Tool Steel

Use stainless steel or tool steel for special needs. Stainless steel is best if you want parts that do not rust. You see stainless steel in kitchens, hospitals, and chemical plants. Tool steel is good when you need parts that stay sharp and strong, like cutting tools or molds.

The table below shows when to pick stainless or tool steel:

| Scenario | Reason for Preference |

|---|---|

| Corrosion resistance | Needed for marine, food, and medical jobs |

| High strength and durability | Needed for tough jobs |

| Hygiene and cleanliness | Needed in medical and food places |

| Heat resistance | Needed in hot environments |

Pick stainless steel for jobs that need to stay clean and last. Tool steel is best for jobs that need to be strong and tough. Both types work well in hard places. Choose your steel based on what your job needs.

AFI Industrial Co., Ltd’s Solutions

AFI Industrial Co., Ltd helps you pick and make steel parts. You get fast and exact solutions for simple or complex parts. Their team can use any drawing or file, so you can make custom steel parts.

AFI uses CNC milling and laser cutting for high-precision parts. They use robots and automatic systems to make production safer and better. You get strong quality checks for every part. The table below shows how AFI helps with steel:

| Service Type | Description |

|---|---|

| Precision Machining | Custom machining for many industries. |

| Quality Control Systems | Careful checks at every step. |

| Cost-effective Production | Ways to save money and keep quality high. |

| Technical Support | Over 30 kinds of help and more than 10 surface treatments. |

| Equipment Variety | CNC lathes, CNC mills, and stamping machines for different jobs. |

You can trust AFI to give you steel parts that work well and last. Their team has experience with many jobs, so you always get the right steel for your project.

Mild steel is the easiest steel to make. It is simple to process and works for many uses. The quality stays the same each time. When you pick steel, think about how easy it is to machine and how much it costs. These things change how fast you can work and how long your tools last. They also affect how good your finished parts are. The table below explains why these points are important:

| Aspect | Description |

|---|---|

| Machinability | Let’s you get good results without spending too much |

| Cost Efficiency | Lets you get good results without spending too much |

AFI Industrial Co., Ltd makes exact steel parts for any job. You can count on their team to give you good parts for your next project.

FAQ

You find mild steel easy to manufacture because it has low carbon content. You can shape, cut, and weld it with standard tools. You save time and money on production.

No, you cannot. Stainless steel resists cutting and wears down tools faster. You need special equipment and slower speeds for best results.

Alloy content changes how steel behaves. More alloys can make steel stronger or more resistant to rust. You may need advanced machines and extra steps to process high-alloy steels.

Large production runs lower your cost per part. You use automated machines for big orders. Small batches let you customize parts but may cost more per piece.

Machinability tells you how easy it is to cut and shape steel. High machinability means longer tool life, smoother finishes, and lower costs. You finish jobs faster with fewer tool changes.

You should choose tool steel when you need parts that stay sharp and hard. Tool steel works best for cutting tools, molds, and dies that face heavy use.

AFI Industrial Co., Ltd offers advanced CNC machining, strict quality checks, and expert support. You get custom steel parts made to your exact needs, whether for small or large projects.

Yes, you can. AFI Industrial Co., Ltd provides options like painting, coating, and polishing. You choose the finish that fits your project and environment.