Precision is important when you learn how to machine aluminum parts. This is true for aerospace, cars, and electronics. You will face some problems. These include picking the right material, keeping sizes correct, making smooth surfaces, stopping heat changes, and using good machines. AFI Industrial Co., Ltd provides trusted machining help for aluminum parts. The table below lists common problems you might see:

| Challenge | Description |

|---|---|

| Material Selection | Different materials change the tool wear and surface look. |

| Dimensional Control | Cutting too much or not enough hurts accuracy. |

| Surface Quality | Burrs and rough spots can occur during the machining of aluminum. |

| Thermal Deformation | Heat can bend aluminum and lower the precision. |

| Machine Performance | Shaky machines make aluminum parts less good. |

A step-by-step plan helps you learn how to achieve precision when machining aluminum parts. You get better results when you use tested methods and new technology.

Key Takeaways

- Precision matters a lot when machining aluminum. Small mistakes can cause big problems in fields like aerospace and electronics.

- Picking the right aluminum alloy is important. It changes how easy it is to machine and how smooth the surface looks. Many people use 6061 because it is easy to work with. 7075 is chosen when more strength is needed.

- Choosing the correct tools and settings is key. Use sharp, coated tools for better results. Set the right speed and feed for each job.

- Check quality often with tools like calipers and CMMs. This helps make sure parts meet standards and lowers the chance of errors.

- Follow each step in the machining process from start to finish. This means setting up carefully, simulating toolpaths, and using good surface finishing methods.

Table of Contents

Key Factors in Machining Aluminum

Why Precision Matters

Precision is very important when you machine aluminum. Some industries, like aerospace and electronics, need very tight tolerances. Even a tiny mistake, like 0.01 mm off, can cause big problems. The table below shows how tolerances matter:

| Tolerance | Application Impact |

|---|---|

| 0.01 mm | Very important in aerospace and electronics. Small mistakes can cause big issues. |

Precision makes sure every part fits and works right. If you are not precise, parts may not fit. They can wear out faster or even be unsafe. In cars and planes, small errors can cause failures. Aluminum is easy to machine, so you can make parts quickly and save money. Being precise is not just about skill. It also means you care about quality, safety, and how things work.

Tip: Being precise with aluminum helps you follow rules and keeps your products safe.

Factors Affecting the Precision of Machining Aluminum Parts

Many things affect how well you can machine aluminum. The type of aluminum alloy matters a lot. For example, 7075 alloy is very strong, but it wears out tools fast. 6061 alloy is stable after heat treatment and is good for precise work. The table below shows some important properties:

| Aluminum Alloy | Key Properties | Machining Impact |

|---|---|---|

| 7075 | Very strong, good mechanical properties | Wears out tools fast; needs special tools for accuracy |

| 5052 | Resists rust, easy to shape | Harder to machine; not as accurate |

| 6061 | Easy to machine, can be heat treated | Stays stable after heat treatment, great for precision |

| 4032 | Has a lot of silicon | Very rough on tools, needs new tools often |

Heat and stress can change the size of aluminum parts while machining. Heat treatment helps keep parts stable and precise, especially for 6061 alloy. You also need to think about your machine tools. The right tool shape, speed, and chip removal help you stay accurate. Skilled workers are important too. They fix problems, set up machines, and check quality. Companies like AFI Industrial Co., Ltd check quality often and inspect parts to make sure they are good. Their experience with custom parts and solving problems helps you get great parts every time.

Aluminum Grade Selection

Choosing the Right Alloy

When you begin a project with aluminum, you must pick the right alloy. Each aluminum grade has special features that change how your parts look and work. Some grades are strong. Others fight rust or are easier to machine. If you pick the wrong grade, you may get rough surfaces or weak parts.

Here is a table to help you compare common aluminum alloys:

| Aluminum Alloy Series | Key Characteristics | Applications |

|---|---|---|

| 1xxx | 99% pure, very ductile, excellent corrosion resistance | Electrical, heat sinks |

| 2xxx | High strength, copper-based, good machinability | Aerospace, aircraft |

| 3xxx | Good formability, moderate strength | General purpose |

| 4xxx | Silicon-based, low melting point | Welding, architecture |

| 5xxx | High tensile strength, corrosion resistant | Marine, transportation |

| 6xxx | Versatile, good formability, corrosion resistance | Structural, custom extrusions |

6061 and 7075 are popular choices for many jobs. 6061 is easy to machine and gives a nice finish. 7075 is very strong and works well for tough jobs like aerospace.

Tip: AFI Industrial Co., Ltd can help you pick the best aluminum grade. They make sure your parts work well and do not cost too much.

Impact on Machinability

The grade you choose changes how easy it is to machine aluminum. It also affects how smooth the surface will be. Some grades, like 6061, make smooth parts with little work. Others, like 7075, are harder to machine but are stronger.

| Aluminum Grade | Machinability Characteristics | Surface Finish Quality |

|---|---|---|

| 6061 | Easy to machine | High quality |

| 7075 | Fair machinability | Dull gray finish |

| 2024 | Uniform chips, can chip easily | High finish |

| 5083 | Hard to machine, very strong | Rough surface |

Do not make mistakes by picking a grade that does not fit your needs. Always check your design and size rules before you start. AFI Industrial Co., Ltd uses its skills to help you choose the right material. This way, your project turns out great.

How to Machine Aluminum Parts: Tools and Parameters

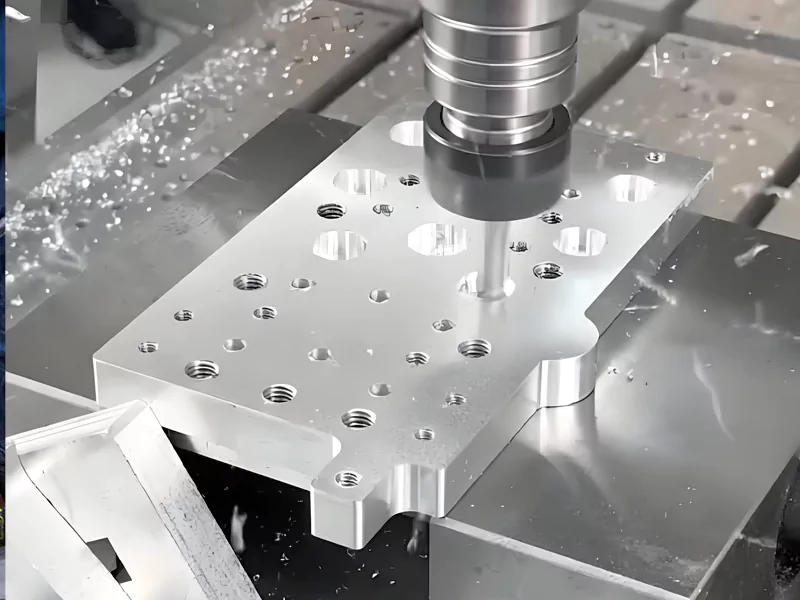

If you want to machine aluminum parts with high accuracy, you need the right tools and settings. The tools you pick and how you use them matter a lot. Tool shape, speed, and oil all change your results. AFI Industrial Co., Ltd uses modern CNC machines and strong tools to help you get great parts.

Tool Selection and Geometry

Picking the right tool is the first thing you should do. Good cutting tools for aluminum help you work faster and make smooth parts. Look for tools with shiny, smooth edges or special coatings. These features stop aluminum from sticking to the tool. This makes the tool last longer and keeps your cuts neat.

When you pick tools for milling or turning aluminum, remember these tips:

- Shiny edges or special coatings stop material from sticking and help tools last.

- Chip breakers break up long chips and keep your work area clean.

Think about what the tool is made of. Some tool materials last longer than others. Tools with cobalt or a special grain can last longer when cutting aluminum. If you use the wrong tool, it may wear out fast or even break.

AFI Industrial Co., Ltd uses CNC machines that can move in five ways at once. This lets you make hard shapes in one go. You get better accuracy and fewer mistakes. Diamond-coated tools are also a good choice. They cut better and last longer, which is important for making precise aluminum parts. Some machines use AI to change settings while working. This helps you get better results and saves time.

Tip: Always check your tool shape before you start. Sharp, shiny tools with chip breakers help you get the best results when milling or turning aluminum.

Feeds, Speeds, and Lubrication

After you pick your tools, you need to set the right speeds and feeds. These settings tell the tool how fast to move and how much to cut. To machine aluminum parts well, you must use the right numbers for your aluminum type.

Here is a table with good speeds and feeds for aluminum:

| Application Type | Cutting Speed (m/min) | Feed Rate (mm/min) | Feed per Tooth (mm/tooth) |

|---|---|---|---|

| High-precision milling | 800 | 0.1 | N/A |

| Hard aluminum machining | 400 – 500 | 100 – 300 | 0.1 – 0.3 |

If you use the right speeds and feeds, your parts look better and your tools last longer. If you go too slow or too fast, you can get rough parts or break your tool.

Lubrication is also very important. Oils and coolants keep your tools cool and stop them from rubbing too much. They also wash away chips and stop rust. Here is a table with types of fluids you might use:

| Type of Fluid | Role in Machining | Best Use Case |

|---|---|---|

| Cutting Oils | Provide lubricity, extend tool life, and improve surface finishes | Precision tasks requiring high lubricity |

| Coolants | Offer cooling properties, prevent thermal damage | High-speed operations need heat dissipation |

- Coolants take away heat from the cutting area.

- They lower the friction between the tool and the part.

- Coolants also wash away chips and stop rust.

AFI Industrial Co., Ltd uses good oils and coolants in all CNC work. This helps you get smooth parts and tools that last. When you use the right speeds, feeds, and fluids, you get the best results in aluminum machining.

Note: Always check your coolant and oil levels. Clean fluids help your tools last and keep your aluminum parts looking good.

If you follow these steps for picking tools, setting speeds, and using fluids, you will learn how to machine aluminum parts with high accuracy. AFI Industrial Co., Ltd’s modern cnc machines and skilled team can help you do well in any aluminum project.

Machining Aluminum: Step-by-Step Process

Getting precision starts with a clear plan. You must follow each step to get the best results when machining aluminum. This aluminum machining guide shows you how to go from design to a finished part.

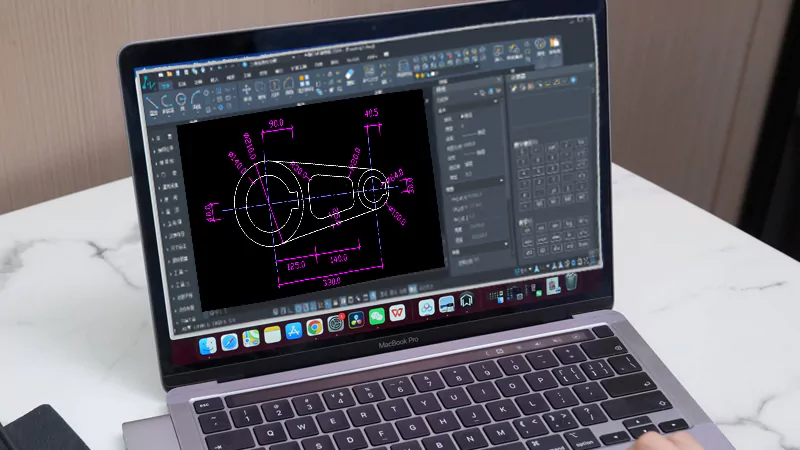

CAD Preparation and Setup

Every project starts with a strong digital plan. The CAD model shows every detail of your aluminum part. You need to prepare your files and set up carefully to avoid mistakes.

Here are the steps for a good setup:

- Create the CAD Model: Use CAD software to design your part. Check that all sizes match what you need.

- Generate Toolpaths in CAM Software: Program the CNC machine to cut in the right places.

- Convert CAD Data to G-code: Change your design into commands for the machine.

- Material Selection and Preparation: Pick the right aluminum grade. Make sure the material is flat and stable.

- Machine Setup and Tool Selection: Set up the CNC machine. Choose tools that fit your part’s features.

Tip: Always run a toolpath simulation before cutting. This helps you find mistakes early and saves time and material.

When you get your CAD files ready, check the cavity depths and diameters. Make sure the walls are thick enough to stop vibration. Remove any extra shapes that overlap. This stops extra cutting. Set the zero point on your machine carefully. This keeps your part lined up and accurate.

Roughing and Finishing Strategies

You need the right way for each step of aluminum machining. Roughing takes away most of the material fast. Finishing gives your part its final shape and smooth look.

Best ways for roughing and finishing:

- Use strong carbide inserts for roughing. These tools can handle big cuts and last longer.

- Switch to polished ceramic or finishing tools for the last passes. These tools make the surface smoother.

- Set cutting speeds and feed rates for aluminum. Fast speeds work, but you must change them for each grade.

- Use water-based cutting fluids to control heat. This keeps the part from bending.

- Use high-pressure cooling during roughing. This keeps the part cool and protects your tools.

- Lower the step-over in finishing passes. This stops lines and makes the surface better.

- Pick climb milling instead of conventional milling. Climb milling gives cleaner cuts and better accuracy.

| Strategy | Description |

|---|---|

| Separate Tools for Roughing/Finishing | Using different tools for roughing and finishing makes the surface better and lowers mistakes. |

| Optimize Cutting Parameters | Changing speeds, feed rates, and cut depth for the material helps avoid mistakes. |

| Effective Cooling Methods | Using cooling keeps heat down, stops bending, and keeps sizes right. |

Note: Always check your cutting paths. Good paths stop hot spots and help remove material evenly.

AFI Industrial Co., Ltd uses advanced CNC machines and skilled workers for these steps. You get the same good results and high-quality parts every time.

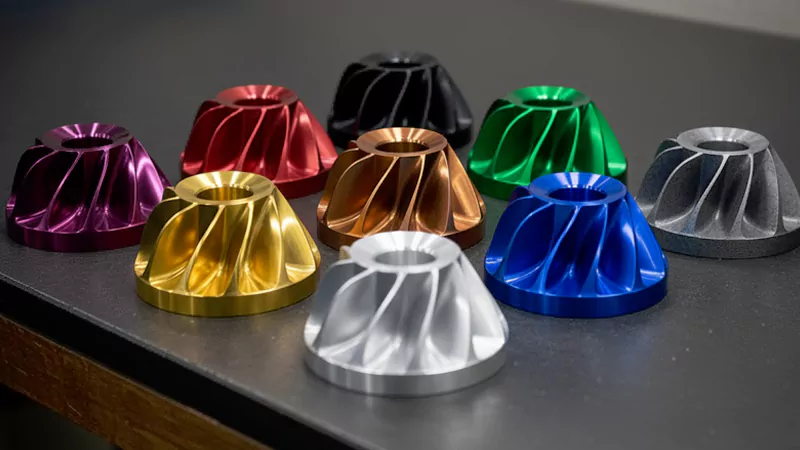

Surface Finishing and Electroplating

After machining, you need to finish the surface. This step makes your aluminum part look and work better. The best finishing method depends on what you need.

Common surface finishing techniques:

| Technique | Process | Advantages | Suitability |

|---|---|---|---|

| Polishing | Uses abrasives to smooth out flaws and make a shiny finish. | Great mirror finishes, works on many materials. | Jewelry, car trim, decorations. |

| Electroplating | Adds a thin metal layer using electricity. | Strong, shiny, and stops rust. | Car trim, bathroom fixtures. |

| Buffing | Uses wheels and compounds to polish the surface. | Works for many materials, good for small areas. | Jewelry, cookware, machine parts. |

| Chemical Polishing | Puts the part in a chemical bath to smooth it. | Very shiny finish, good control. | Small parts, optical pieces. |

| Diamond Turning | Uses a diamond tool for very smooth surfaces. | Super shiny finish with high accuracy. | Optical parts, precision work. |

Chemical polishing and electroplating are both important in this aluminum machining guide. Chemical polishing uses a special bath to remove tiny flaws. This makes the surface very shiny and smooth. Electroplating puts a thin metal layer on the part. This helps stop rust, makes it conduct electricity better, and helps it last longer. These things matter in aerospace, defense, and electronics.

Tip: Hard anodizing makes the surface harder. This helps your aluminum parts last longer in tough places.

Metal finishing also helps paint and glue stick better. If you want to paint or bond your parts, this step makes it easier and more reliable. Alodine finishes help stop rust and make the part conduct electricity better, so your parts last longer.

AFI Industrial Co., Ltd offers many finishing services. You can pick polishing, chemical treatments, or advanced electroplating. Their team uses new technology to give you shiny finishes and better performance for every aluminum part.

This aluminum machining guide gives you a clear way to go from design to finished product. If you follow each step, your parts will meet the highest standards for quality and strength.

Aluminum Machining Quality Control

Quality control is very important when making aluminum parts. You must check each part to see if it meets your standards. Careful checking and improving your process help you avoid mistakes. This keeps your customers happy.

Inspection Methods

There are different ways to check aluminum parts for accuracy. Each way looks at different things and helps you find problems early.

| Inspection System | What Is Measured | Technology/Process | Used For |

|---|---|---|---|

| Coordinate Measuring Machines (CMM) | Geometry of 2 and 3 axis components | Optical and scanning probes | Complex components, tight tolerances |

| Laser Scanners | Surface roughness, 2D/3D profiles | Model compared to CAD | Contactless, small surface variations |

You can use calipers, micrometers, and laser measuring devices. Calipers are good for simple shapes. Micrometers are best for small details. Laser measuring devices work for big or tricky parts.

| Tool | Precision Level | Best For |

|---|---|---|

| Calipers | Moderate | Basic profiles |

| Micrometers | High | Small, intricate details |

| Laser Measuring Devices | Very High | Large-scale, complex profiles |

First, look at the part to find scratches or dents. Then, measure sizes with calipers or micrometers. For the best results, use a CMM to check 3D shapes. CMMs help you keep parts accurate every time. Aerospace, medical, and car companies use these checks to stay safe.

Tip: Check your parts often to find problems early and save time.

Process Optimization

To make your aluminum machining better, you need to improve each step. Change feed rates and spindle speeds to fit the material and design. Use special modeling and tool paths to lower mistakes and keep things steady.

- Change feed rates and spindle speeds for each aluminum grade.

- Use better milling cutters to work faster.

- Use advanced modeling to stop errors before they happen.

- Pick tool paths that match your part’s shape.

You should also fix common problems. Teach your team, keep machines in good shape, and check materials before you start. Use statistical process control to watch quality and catch problems early.

AFI Industrial Co., Ltd follows strict ISO 9001 and SGS rules. These show they care about customers, leadership, and always getting better. The company uses control plans and data to make sure aluminum parts are always good.

Note: A strong quality system helps you spend less, work faster, and earn trust from your customers.

You can get very accurate aluminum parts if you use good methods. First, pick the best aluminum alloy for your job. Next, set up your tools and machine settings the right way. Keep the heat under control so your parts do not bend. Use special measuring tools like CMMs and laser scanners to check your work. Always inspect your parts and use strong quality checks.

CNC machining makes parts very exact and fast. It helps you make hard aluminum shapes without worry.

If you work with AFI Industrial Co., Ltd, you get many helpful services:

| Service Type | Description |

|---|---|

| CNC Turning | Turns parts with high accuracy |

| CNC Milling | Mills tough shapes with great precision |

| Cutting | Cuts aluminum and other metals very well |

| Welding | Welds aluminum pieces together |

| Prototype Development | Helps you make custom test parts |

| On-Demand Part Generation | Makes simple or hard parts when you need them |

To keep your work going well, use this easy checklist:

- Pick the right material and stock.

- Set up your fixtures and spindle straight.

- Choose the best tools, feeds, and speeds.

- Plan your cuts with more than one pass.

- Remove sharp edges and make surfaces smooth.

- Check and control quality at every step.

If you follow these steps, your aluminum parts will always be precise and strong.

FAQ

6061 is a good choice for most precision parts. It is easy to machine and gives a nice finish. If you need something stronger, use 7075. Always pick the grade that fits your project’s needs.

Use cooling and set the right cutting speeds. Hold the workpiece tight so it does not move. Take off small amounts of material at a time. This keeps the part steady and helps it stay the right shape.

Surface finishing takes away tiny flaws and makes parts look better. It also helps stop rust. Your parts will work better and last longer.

Use calipers, micrometers, and CMMs to measure your parts. Look at the surface to find any problems. Check your parts often to make sure they are all good.