What is aluminum extrusion? Aluminum extrusion is a process that changes raw aluminum by pushing it through a special die, resulting in long pieces with precise shapes. Many factories use this method because it provides lightweight and strong parts tailored to their needs.

- More people in North America are interested in what is extrusion, especially aluminum extrusion, with usage reaching 5.5 billion pounds in 2018.

- Car companies are increasingly adopting what is extrusion for both electric and regular vehicles, using more extruded aluminum components.

- Lightweight extruded products created through what is extrusion perform well in tough conditions, making them popular in transportation and other industries.

Key Takeaways

- Aluminum extrusion changes raw aluminum into special parts. It pushes aluminum through a die. This makes products that are light and strong.

- The process works fast. It helps make complex shapes quickly. This saves time and cuts down on waste.

- Picking the right aluminum alloy is very important. Different alloys have special features. Some are strong. Some resist rust. Some are easy to shape.

- Extrusion is used in many industries. These include construction, automotive, electronics, and consumer goods. It is popular because it can do many things.

- Cooling and finishing steps are very important. They help keep the product strong and good quality.

- Aluminum extrusion is good for the environment. It lets us recycle. It makes lighter products. Lighter products use less energy.

- Extrusion technology is getting better. Smart sensors and automation help improve quality and speed.

- Using aluminum extrusion can save money on big projects. This makes it a smart choice for manufacturers.

Table of Contents

What Is Aluminum Extrusion

Definition

You might hear “what is extrusion” in factories. Extrusion means pushing aluminum through a shaped hole called a die. This makes long pieces with special shapes. These shapes are used in window frames, car parts, and electronics. There are rules that help people make good extrusions. The table below lists some important rules for making and testing extrusions:

| Standard Code | Description |

|---|---|

| ASTM B221-08 | Tells how to design, make, check, and use aluminum profiles. |

| EN 755-9 | Explains materials, how to make, check, label, and test quality. |

| GB/T5237.1-2008 | Lists what is needed and how to test aluminum profiles for buildings. |

| GB/T6892-2008 | Gives rules and tests for industrial aluminum extrusions. |

| GB/T3190-2008 | Describes how to test the strength of aluminum and its alloys. |

These rules help make sure every extrusion is safe and works well.

Purpose

Extrusion shapes aluminum into forms you need. The main reason for what is extrusion is to make strong, light, and custom parts. This process lets you design things with tricky shapes. Other ways would be harder. Extrusion is used in building, cars, and electronics. You pick extrusion when you want parts that last and are easy to put together.

Tip: If you need parts with exact sizes and smooth surfaces, extrusion is a good choice.

Materials Used

You pick aluminum alloys based on what you need. The most common alloys for extrusion are:

- 6063 Aluminum Alloy: You use this for window frames, heat sinks, and wires. It looks nice and is easy to shape.

- 6463 Aluminum Alloy: You use this for buildings. It is strong and looks good, especially after heating.

- 6005 Aluminum Alloy: You find this in ladders and car parts.

- 2XXX and 7XXX Series: You use these when you need strong but light parts, like in planes or big machines.

- 5XXX Series: You use these when you need parts that do not rust easily.

- 6XXX Series: You use these for many projects because they have balanced features.

Extrusion works best with alloys that are strong, do not rust, and are easy to shape. You choose the right alloy for your job to get the best results.

Extrusion Process

The extrusion process changes raw aluminum into new shapes. It uses several important steps. You need to know each step to get good results.

Preparation

You must get the materials and tools ready before starting. Preparation is very important in the extrusion process. You want everything set up so things go well.

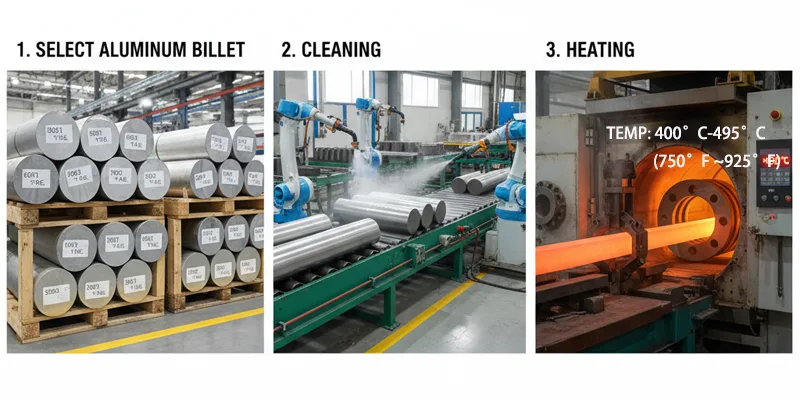

Billet Selection

First, you pick the right aluminum billet. The billet is a solid aluminum cylinder. You choose the alloy for strength, rust resistance, and finish. For example, 6063 is good for window frames. 6005 works well for car parts. The right billet gives your extrusion the features you want.

Cleaning

Next, you clean the billet to remove dirt or oil. Clean billets stop problems and help the process go smoothly. You also clean the die and tools. This step helps you avoid mistakes in your finished product.

Tip: Clean billets and dies help you make better extrusions with fewer issues.

Heating

Heating comes after cleaning in the extrusion process. You heat the billet to make it soft enough to push. This step is very important for the process.

Temperature Range

You heat the billet to a certain temperature. Most processes use 400°C to 495°C (750°F to 925°F). The table below shows some common temperature ranges:

| Source | Temperature Range (°C) | Temperature Range (°F) |

|---|---|---|

| Almag | 400-480 | 750-900 |

| Bonnell | 427-495 | 800-925 |

| Sinoextrud | 390-420 (Flat dies) | N/A |

| Sinoextrud | 410-440 (Porthole dies) | N/A |

You must watch the temperature closely. If it is too cold, the billet will not move. If it is too hot, the billet or die can get damaged.

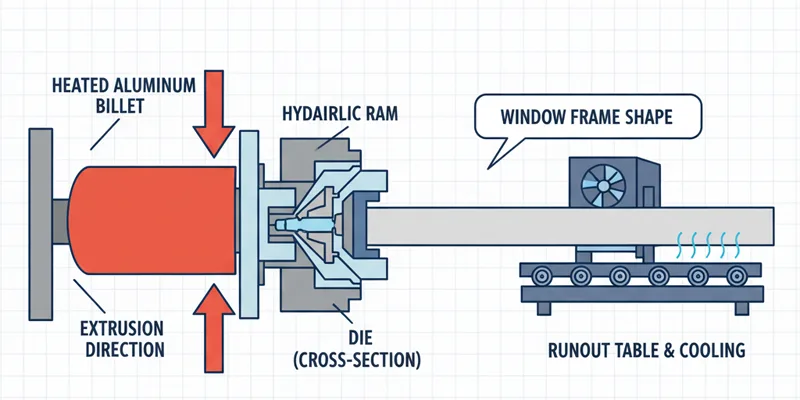

Through the Die

The main part of the process is pushing the hot billet through the die. The die shapes the aluminum into the form you want. This step is a key part of the process.

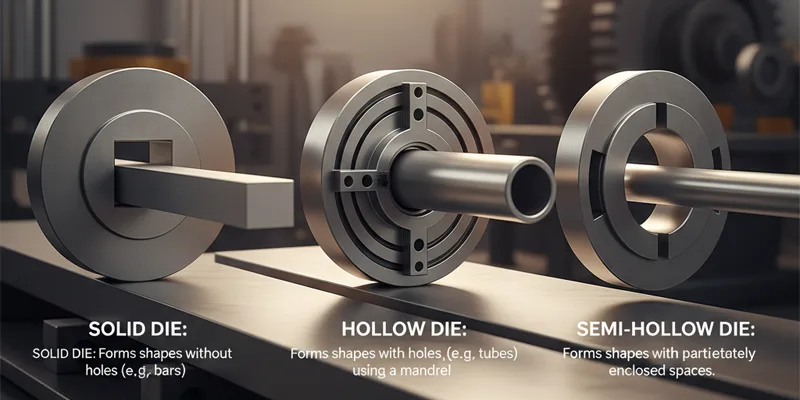

Die Types

You pick the die based on the shape you need. There are three main die types:

- Solid dies make shapes with no holes, like rods.

- Hollow dies make shapes with holes, like tubes, using a mandrel.

- Semi-hollow dies make shapes with partly closed spaces and need careful design.

The die shape decides the final look of your extrusion. Special dies let you make custom shapes for special uses.

| Die Type | Description |

|---|---|

| Solid Die | Makes shapes with no holes, like bars and channels. |

| Hollow Die | Makes shapes with holes, like tubes, using a mandrel and cap. |

| Semi-Hollow Die | Makes shapes with partly closed holes and needs careful planning. |

Pressure

You use pressure to push the billet through the die. Pressure control is very important in this process. Too much pressure can bend the aluminum or make it come out too fast. This can cause problems and make cooling hard. You want just enough pressure to shape the aluminum well every time.

Note: The right pressure helps you keep your extrusions strong and even.

The extrusion process needs careful control at every step. You plan the shape, get the billet ready, heat it, push it through the die, and control the pressure. These steps work together to make strong, light, and custom aluminum products.

Cooling

After you push aluminum through the die, you must cool it quickly to keep its shape and strength. Cooling is a key part of the extrusion process. You choose the right method based on the alloy and the final use of the product. If you cool aluminum too slowly, it can bend or lose strength. If you cool it too fast, it might crack or warp.

Methods

You have several ways to cool aluminum after extrusion. Each method helps you control the final quality. The most common cooling methods include:

| Cooling Method | Description |

|---|---|

| Water Quench Bath | You pass the extruded aluminum into a water bath for even cooling. This method works well for most profiles. |

| Spray Quench | You use high-pressure water sprays for complex shapes. This helps you avoid water getting trapped inside. |

| Air Cooling | You let the aluminum cool in the open air. This method suits alloys like 6063, where you do not need fast cooling. It can also be a step before water quenching. |

| Combination Quench | You start with forced-air cooling and then use water spray or immersion. This helps you reduce warping and keep the shape steady. |

- You use air cooling for 6063 aluminum profiles after quenching.

- Air cooling can give you results similar to water cooling if you keep the cooling rate high.

- You often choose air cooling when you want to bend the profiles later and do not need the T6 state.

Tip: You must pick the right cooling method to keep your extrusion strong and straight. Fast cooling helps you lock in the metal’s properties.

Finishing

Once you finish cooling, you move to the last steps of the extrusion process. Finishing makes your aluminum look better and last longer. You use different techniques to improve the surface and get the right size.

Surface Treatment

You use surface treatments to protect aluminum and make it look good. These treatments help you fight rust, add color, and create a smooth finish. The most popular surface treatments in the extrusion process include:

- Anodizing: You add a protective layer that stops corrosion and lets you pick bright colors.

- Powder Coating: You spray powder and bake it on. This gives you many color choices and is safe for the environment.

- Mechanical Finishes: You buff, polish, or grind the surface to make it smooth and shiny.

- Pretreatment: You clean and prepare the surface so coatings stick better.

- Bright Dipping: You dip the aluminum to get a mirror-like finish. You can anodize it after for extra protection.

- Liquid Paint: You paint the surface for a smooth, even look with many color options.

- Sublimation: You transfer patterns onto the aluminum for a decorative finish.

Note: You must choose the right surface treatment to match your product’s needs. Good finishing helps your extrusion stand out and last longer.

Cutting

After you treat the surface, you cut the extrusion to the size you need. You use saws or special machines to make clean cuts. You measure each piece to make sure it fits your design. Cutting is the last step in the extrusion process before you ship or use the product.

- You cut long extrusions into shorter pieces for windows, doors, or car parts.

- You check each cut to keep the edges smooth and the size correct.

- You can use automated machines for fast and accurate cutting.

Tip: Careful cutting helps you avoid waste and keeps your extrusion process efficient.

You control each step in the extrusion process to get strong, light, and custom aluminum products. Cooling, finishing, and cutting help you deliver high-quality extrusions for many uses.

Why Extrusion Is Unique

Custom Profiles

Extrusion lets you make special shapes that other methods cannot. You can design many different sizes and forms for your project. You pick what features you want, like grooves or holes. You can also add special coatings. Extrusion is flexible, so you can change designs fast. You can use the same profile again for new projects.

Here is a table that shows how extrusion is different from other ways:

| Feature | Aluminum Extrusion | Other Metal Forming Methods |

|---|---|---|

| Customization | High – allows complex shapes and designs | Limited – typically simpler shapes |

| Energy Efficiency | Lower melting point, less energy required | Higher melting points, more energy |

| Strength | Can be enhanced with additives | Varies, steel may be stronger |

| Weight | Lightweight, ideal for various applications | Heavier, may not suit all designs |

| Corrosion Resistance | High – enhances longevity | Varies, often less resistant |

Extrusion gives you more choices for shape and size. This helps you meet special needs in building, cars, and electronics.

Efficiency

Extrusion is faster and wastes less than casting or rolling. You can make many parts quickly. This saves you money and time. The process works well for big orders. You can make tricky shapes that are hard to do with other methods.

Here are some ways extrusion is efficient:

- You can make shapes that casting or rolling cannot do.

- You can design parts with special features just for you.

- You get the same quality all through each profile, which is good for exact jobs.

- You save money on big orders because you waste less and work faster.

Extrusion helps you work better and spend less when you make things.

Material Properties

Extrusion makes strong and dependable aluminum parts. The process lines up the metal’s grain, so it is stronger than casting. You also get a smoother surface, so your parts look nice and work well.

You do not get problems like porosity, which can make cast parts weak. Extrusion gives you steady results, so you can trust each piece.

When you compare extruded aluminum to rolled aluminum, extrusion keeps good strength. You can pick the alloy and settings to make your part as strong as you need.

Your parts last longer and fight rust, so extrusion is a smart pick for tough jobs.

Extrusion Benefits

Flexibility

Extrusion gives you a lot of flexibility for your projects. You can make custom shapes and sizes that fit what you need. You can design profiles with grooves, holes, or channels. You do not have to use only standard parts. You can change your designs quickly and easily.

Here is a table that shows how extrusion helps you make flexible products:

| Aspect | Description |

|---|---|

| Complex Geometries | Custom dies let you make shapes that standard options cannot. |

| Material Optimization | Precise dies help you waste less and work faster. |

| Quality Improvement | CAD tools lower mistakes by about 20%, so you finish faster. |

| Reduced Assembly Steps | Adding features during production means less assembly and stronger products. |

| Cost Efficiency | Studies show you can cut labor costs by 20% with fewer parts. |

| Simplified Assembly | Fewer parts fit better and put less stress on joints. |

| Real-time Changes | Aluminum extrusions let you change designs fast with little extra work. |

| Versatile Manufacturing | One die can make many shapes, so you do not need new tools. |

| Comparison with Other Methods | Aluminum extrusion gives you more design choices than die casting or plastic molding. |

You can change your product design while making it. You do not have to stop the machines or buy new tools. This flexibility helps you keep up with what customers want.

Tip: If you want to make assembly easier and pay less for labor, extrusion is a good choice.

Strength

Extrusion makes aluminum parts that are strong and reliable. The process lines up the metal grains, so the parts are stronger in one direction. These parts can hold heavy loads and do not bend easily. You do not get the same problems as casting, like random grain patterns or empty spaces inside.

- The force in extrusion makes aluminum stronger than casting does.

- Extruded aluminum has fewer empty spots inside, so it is stronger.

- Tests show extruded parts can hold more weight before bending or breaking than cast parts.

- In tests, extruded parts lasted over 500,000 cycles, but cast parts broke at about 300,000 cycles because of empty spaces.

- Extruded aluminum has grains that go in one direction, which makes it even stronger.

You can count on extruded aluminum for jobs that need tough and long-lasting parts. Every piece gives you the same good quality and performance.

Note: If you need parts that last and work well under pressure, extrusion is a smart pick.

Cost

You save money when you use extrusion for big jobs. The process is faster than other ways, so you spend less time making things. You also use less energy, which lowers your bills. Extrusion is a cheap way to make things and helps you stay ahead.

Here is a table that shows how extrusion saves you money:

| Benefit | Description |

|---|---|

| Reduced manufacturing time | Extrusion is faster than other ways, so you pay less. |

| Energy efficiency | Extrusion machines use less energy than other machines. |

| Cost effectiveness | Extrusion costs less than casting or welding. |

| Lightweight and durable products | Aluminum lets you make strong and light products. |

You can make light and strong products without spending more. You also waste less and pay less for workers. Extrusion helps you make good products for less money.

Tip: If you want to save money and work better, extrusion is a great choice.

Sustainability

When you pick aluminum extrusion, you help the planet. This process is good for the environment in many ways. Aluminum is special because you can recycle it again and again. It does not lose its strength or quality. Every time you use recycled aluminum, you save resources and cut down on waste.

During production, aluminum extrusion makes scrap pieces. You can collect this scrap and recycle it into new materials. Most aluminum products today have a lot of recycled content. By using extrusion, you help keep useful materials out of landfills.

You also help the environment by making lighter products. Aluminum has a high strength-to-weight ratio. This means you need less material to get the same job done. Lighter products use less energy to move. This saves fuel and lowers pollution. Choosing extrusion for cars, buildings, or other goods is smart for the earth.

Let’s look at some numbers that show how aluminum extrusion helps the environment:

| Metric | Value |

|---|---|

| Crude Oil Saved per Pound of Aluminum | 3.1 gallons |

| CO2 Saved per Pound of Aluminum | 20 pounds |

| Annual Savings from Aluminum in Vehicles | 100 million gallons of crude, 700 million pounds of CO2 |

| Energy Required for Recycling Aluminum | 8% of primary production energy |

| CO2 Equivalents Saved per Ton of Recycled Aluminum | 9 tons |

Recycling aluminum uses only a small amount of energy. It takes just 8% of the energy needed to make new aluminum. For every ton of recycled aluminum, you save 9 tons of CO2. Using aluminum extrusion in vehicles saves 100 million gallons of oil each year. It also keeps 700 million pounds of CO2 out of the air.

Tip: You can make your products greener by picking extrusion and recycled aluminum. This choice helps you reach your eco-friendly goals and shows you care about the earth.

Here are some ways extrusion helps the environment:

- You recycle scrap to make new materials.

- You use products with lots of recycled aluminum.

- You design lighter products that use less energy and make less pollution.

Aluminum extrusion is a great way to help the planet. You save resources, lower pollution, and make strong products. When you choose extrusion, you help the earth and your business.

Extrusion Applications

Construction

You see extrusion used a lot in building today. Builders use commonly extruded materials for window frames and door rails. They also use them for curtain walls and roofing systems. These parts stay straight and do not rust. This makes them great for buildings that last a long time. Aluminum profiles can be shaped to fit any design. You can make simple beams or fancy trims.

- The building and construction segment will be 34.9% of the extruded aluminum profiles market by 2025.

- You find extruded aluminum in long, straight pieces for walls and roofs.

- Many architects like extrusion because it is flexible and looks clean.

Extrusion lets you build with light but strong parts. You can put these parts in fast and trust them in bad weather. When you pick commonly extruded materials, you get good results for homes, offices, and schools.

Tip: If you want strong and easy-to-use building parts, extrusion is a smart choice.

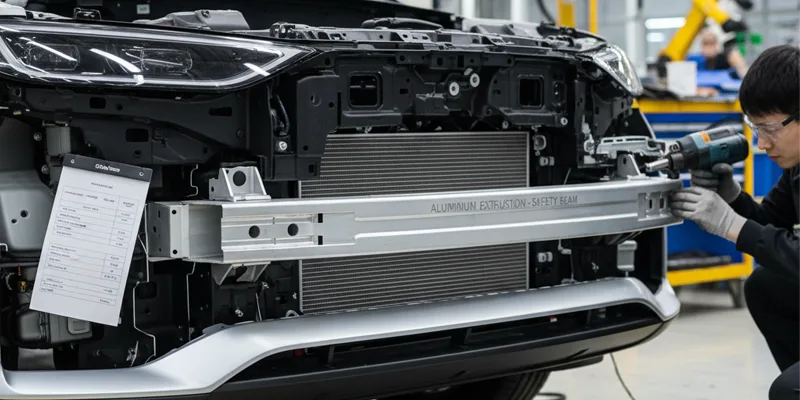

Automotive

You need extrusion to make better cars. Car makers use commonly extruded materials for chassis and subframes. They also use them for crash management systems. These parts make cars lighter and safer. Aluminum is light, so cars use less fuel and electric cars go farther.

- Lightweight parts help cars use less fuel and electric cars go farther.

- High strength-to-weight ratio keeps cars safe but lighter than steel.

- Corrosion resistance helps extruded parts last longer in tough places.

- Sustainability is good because aluminum can be recycled again and again.

Aluminum extrusion shapes many car parts without losing strength. You see these parts in bumpers, roof rails, and engine mounts. When you use extrusion, cars work better and stay safe on the road.

Note: Extrusion gives you strong, light, and recyclable parts for cars and trucks.

Electronics

You find extrusion in lots of electronics you use every day. Makers choose commonly extruded materials for their good thermal and electrical properties. You see these materials in heat sinks, enclosures, and LED lighting strips. These uses help devices stay cool and last longer.

| Application Type | Description |

|---|---|

| Heat Sinks | Used for good heat dissipation because of thermal conductivity. |

| Enclosures | Light, non-magnetic, and non-sparking, good for holding parts. |

| LED Lighting Strips | Used in lighting for their look and how they work. |

You get electronics that stay cool and safe because extrusion makes exact shapes for each part. You can trust these products to work well in computers, phones, and lights.

Tip: When you want reliable and efficient electronic parts, extrusion gives you the performance you need.

Consumer Goods

You see extrusion in lots of things you use every day. This process helps make products light and strong. It also makes them easy to use. Manufacturers use extrusion to shape aluminum into long, straight parts. These parts fit well in things at home, work, or outside.

You find extrusion in many products such as:

- Home appliance trim and refrigerator condensers

- Ladders and fitness equipment

- Lawn and garden tools like weed trimmers and extendable saws

- Flashlights and camping chairs

- Sporting goods, including baseball bats, golf clubs, and lacrosse sticks

- Bicycles and pleasure boats

- Cookware and beverage cans

- Office furniture, partition systems, and seating for the hospitality industry

- Furniture pieces for indoor and outdoor use

Extrusion makes products last longer and keeps them from rusting. Your camping chair is light but holds your weight. Your bike frame is strong and does not bend. Sporting goods like bats and clubs use extruded aluminum for better performance.

Manufacturers pick extrusion to make custom shapes for each product. You see this in furniture with cool designs and cookware that heats evenly. More companies use extrusion to make products lighter and stronger.

Tip: If you buy things made with extruded aluminum, you get style, strength, and reliability.

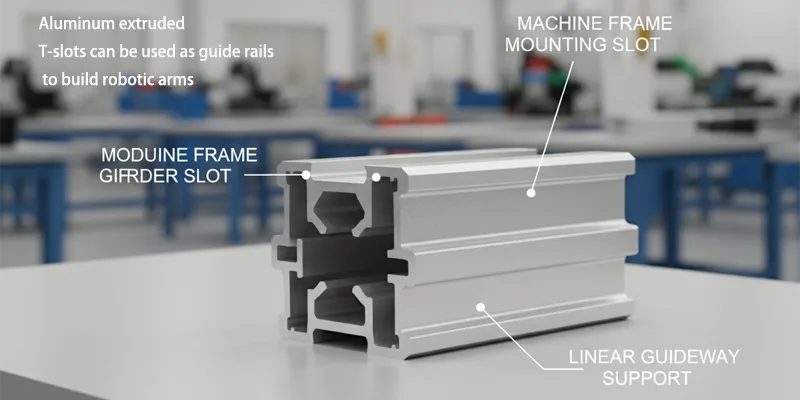

Machinery

You find extrusion in many modern machines. This process helps make parts strong, light, and tough. Makers use extrusion for frames, supports, and other machine parts.

Extrusion gives machinery many benefits:

- Aluminum’s strength-to-weight ratio helps machines work better.

- You get complex shapes and tight fits for important jobs.

- Custom extrusions last longer than plastic or steel parts.

- Aluminum does not rust and works in hot or cold places.

- Aluminum is lighter than steel, so shipping costs less.

- The process lets you make detailed designs for each machine.

- Rust resistance makes extruded parts good for outdoor and tough jobs.

You see extrusion in machines for factories, farms, and building sites. Frames, robotic arms, and conveyor systems use extruded aluminum. These parts stay straight and do not wear out fast. Custom profiles mean machines fit your needs.

Extrusion helps you get machines that work well in hard places. You save money because equipment lasts longer and needs less fixing. More industries use extrusion for better machines.

Note: If you pick machines with extruded aluminum, you get strength, accuracy, and value that lasts.

Extrusion Factors

Alloy Choice

When you pick an alloy for extrusion, you change how the product works. Each alloy has its own special features. You need to match the alloy to your project. Here are some things to think about:

- Strength is different for each alloy. Strong alloys are good for heavy jobs.

- Some alloys do not rust. The 5000 series is best for boats and water places.

- Some alloys bend easily or are easy to cut. This helps you make tricky shapes.

- Some alloys move heat well. These are good for cooling parts.

- The look of the product depends on the alloy. You can pick alloys that look nice for homes or stores.

- Price matters. Special alloys cost more, so you need to think about your budget.

Picking the right alloy helps you get better results. Your products last longer, look nicer, and work for your needs.

Die Design

Die design decides the shape and quality of your extrusion. You need a die that matches your part. Hard shapes need careful planning and sometimes extra supports. Here are things to remember:

- The shape and details of your part decide how the die works. Fancy shapes need good planning.

- Metal must move evenly. If it does not, you get thin or bent parts. You need to plan how metal flows.

- Keeping the die cool is important. Good cooling stops bending or breaking.

- Easy-to-fix dies save you time. Dies that come apart quickly help you fix problems fast.

- Price and what you can make matter. You need dies that fit your money and your factory.

Tip: Check your dies often for damage. Regular checks help you find problems early. This keeps your dies working longer and your parts looking good.

Before you start, heat the die to the right temperature. This helps the metal move smoothly and stops sudden changes.

Process Settings

You control how good your extrusion is by changing the settings. Temperature and speed are very important. You must heat the billet just right. If you get it wrong, you can get bad parts. The right heat makes the metal soft but still strong.

Speed matters too. If you go too fast, you might get cracks or uneven parts. If you go too slow, you waste time and energy. You need to find the best speed for each alloy and shape.

Watching and changing these settings helps you get strong and smooth extrusions every time. Careful control gives you the best results.

Extrusion Trends

Technology

Extrusion technology is changing very quickly today. Factories now use smart sensors to check quality all the time. These sensors and computers help make each step better. CNC machining lets workers control machines closely and change settings fast. This saves money and makes fewer mistakes. IoT and data tools help watch the process and find problems early. Robots and machines do more work, so things go faster and safer. High-pressure extrusion makes strong and tricky shapes for planes and other big jobs. AI and computer vision can spot mistakes early, so products turn out better.

- Smart sensors and real-time checks make products better.

- CNC machines and IoT systems help save money and cut waste.

- Robots and automation make work safer and faster.

- AI and computer vision stop mistakes before they get big.

Tip: New technology helps you get strong, high-quality extrusion profiles for hard jobs.

Sustainability

You help make extrusion better for the planet. Many companies now use less energy to make products. More factories use recycled aluminum in their profiles. The Environmental Product Declaration (EPD) lets you show how green your work is. Factories use recycled aluminum and save energy to help the earth. Good waste plans and safe finishing steps keep pollution low. The industry works hard to use greener ways and lower harm to nature.

- Using less energy saves important resources.

- Recycled aluminum means less waste and helps the earth.

- EPD reports show you care about being green.

- Safe finishing steps protect the environment.

Note: Picking extrusion with recycled aluminum helps you reach your green goals and shows you care about the future.

New Uses

You find new ways to use extrusion every year. Designers now put many jobs into one profile, so building is easier and costs less. Automation helps make custom aluminum parts faster and more even. CAT X-ray scanning checks profiles quickly and helps keep quality high. Fast cooling systems help products stay strong and even. AI helps fix machines before they break and makes better die designs.

- Closed-loop recycling lets you use materials again and again.

- New alloys make light and strong parts for tough jobs.

- Mixing materials lets extrusion work in more places.

- Automation and smart tools help make things faster.

- Additive manufacturing helps with testing and small orders.

- Digital twins help plan and improve making products.

- AI and machine learning study data to make work better.

You see extrusion profiles in solar panels, which makes them easier to put up and work better. Electric cars use more aluminum profiles because they are light and strong. The clean energy industry uses extrusion for parts that must be light and last a long time.

Tip: You can try new industries and ideas by picking extrusion for creative projects.

Aluminum extrusion changes raw aluminum into strong, special shapes. You do this by following a few main steps. First, you get everything ready. Then, you heat the aluminum. Next, you push it through a die to make the shape. After that, you cool it down. Last, you finish the surface. This process gives you many good things. You get parts that are flexible, strong, and good for the planet. You find extrusion used in buildings, cars, electronics, and machines.

- You can pick extrusion if you want parts that are light and work well.

- You make your products better and help nature at the same time.

Think about using aluminum extrusion for your next project. You might find new ways to make things as technology gets better.

FAQ

You can make many shapes with aluminum extrusion. These include solid bars, tubes, and channels. You can also make custom profiles for special jobs. The die design lets you pick almost any cross-section you want.

Extruded aluminum parts are strong for their weight. You can pick alloys and settings to get the strength you need. Many industries use these parts for tough jobs.

Yes, you can recycle aluminum extrusion scrap. Most factories collect and reuse leftover pieces. Recycling aluminum saves energy and helps keep things green.

You should pick the alloy that fits your project. Think about strength, rust resistance, and how easy it is to shape. Common choices are 6063, 6005, and 6061 alloys.

The extrusion process is fast. You can make many feet of profile in just minutes. Getting ready and finishing may take longer, but extrusion itself is quick.

Aluminum extrusion is best for big jobs. You pay for the die at the start. For small projects, each piece may cost more. You save money when you make lots of parts.

You see aluminum extrusion in construction, cars, electronics, and machinery. It is also used in consumer goods. These industries like its strength, light weight, and custom shapes.