Galvanized aluminum is aluminum coated with a layer of zinc, achieved by dipping the aluminum into hot zinc. This process forms a durable protective barrier that helps prevent rust and corrosion. Galvanized aluminum is lightweight, strong, and has an attractive shiny appearance, making it popular for use in construction, vehicles, and outdoor equipment. When considering how to choose galvanized aluminum, think about your specific project requirements. Make sure the material’s properties match your needs and the environment where it will be used.

Key Takeaways

- Pick galvanized aluminum that fits your project’s needs, like strength, weather, and looks.

- Look at the zinc coating type and how thick it is. Thicker coatings give better protection in hard or outdoor places.

- Do not mix galvanized aluminum with metals like copper or brass. This can cause rust from galvanic corrosion.

- Use the correct fasteners and get surfaces ready before painting. This helps the metal last longer and stops paint from peeling.

- Check for certifications such as ASTM or ISO. These show the metal is safe and good quality.

- Read the warranty details and make sure you understand them. Follow care and installation steps to keep your warranty.

- Use supplier checklists to check coating, thickness, fit, and paperwork before you buy, and make a comprehensive comparison.

- Think about the environment and pick materials and coatings that work in wet, salty, or tough weather.

Table of Contents

1. American Galvanizers Association

Application

Use

If you pick galvanized aluminum from the American Galvanizers Association, it works in many fields. You can use it for bridges, building frames, guardrails, and utility poles. It is also good for outdoor equipment. Many people like galvanized steel for these jobs because it is strong and light. You will find it in transportation, farming, and energy work too. The shiny look makes it nice for places where looks are important.

Environment

Think about where you will use galvanized aluminum. This material does well in rain, snow, and sun. It does not rust or get damaged by water. That makes it great for outside use. If your project faces tough weather or chemicals, galvanized steel fights rust well. You can use it near the ocean, in factories, or in wet places.

Specifications

Coating

The coating is very important for galvanized aluminum. The American Galvanizers Association uses hot-dip galvanizing. This covers the steel with a thick zinc layer. The zinc keeps out rust and stops scratches. When you look at galvanized steel and aluminum, the zinc makes it last longer. Always check what kind of coating you get. Some coatings work better in certain places.

Thickness

You should check how thick the galvanized layer is. Thicker coatings last longer and protect better. The American Galvanizers Association has rules for how thick the coating must be. Ask for the thickness when you order. This helps you get what your project needs. Thicker coatings are best for tough or outdoor jobs.

Comparison

Reputation

The American Galvanizers Association is well-known in the business. Many builders and engineers trust their products for big jobs. You can find stories that show how strong their galvanized steel is. This good name means you get materials you can count on.

Certification

Always look for certifications when you buy galvanized aluminum. The American Galvanizers Association gives products that meet top rules. Certified products help you feel sure about safety and quality. You can ask for papers to show the product meets your needs.

Tip: Make a list of what you need before you buy. Write down use, place, coating, thickness, and certifications. This step-by-step plan helps you compare and pick the best galvanized product for your job.

Mistakes

Compatibility

You have to make sure galvanized aluminum works with other materials. Some metals do not mix well together. If you put galvanized aluminum next to copper or stainless steel, it can rust quickly. This is because of something called galvanic corrosion. Always check with your supplier if galvanized aluminum will touch other metals. Using the wrong mix can make your project not last as long.

Think about what paint or coating you want to use. Some paints do not stick well to galvanized aluminum. If you do not prepare the surface right, the paint can peel off. Follow the American Galvanizers Association’s rules for painting or powder coating. This helps your project look nice and last longer.

Warranty

Read the warranty before you buy anything. Some warranties only cover certain problems. If you use or install the product wrong, you might lose your warranty. Always follow the American Galvanizers Association’s instructions. Keep your receipts and any papers that come with your order. If you have a problem later, you will need these to ask for help.

Tip: Ask your supplier how long the warranty lasts and what it covers. A good warranty helps you feel safe and protects your money.

Checklist

Before you buy galvanized aluminum from the American Galvanizers Association, use this checklist to help you pick the right one:

- Inspect for bare spots: Check for any places without coating. Bare spots mean the surface was not done right.

- Check coating thickness: Make sure the zinc layer is thick enough for where you will use it. Thicker coatings protect better in tough places.

- Confirm ASTM standards: Ask if the product meets ASTM rules for good quality.

- Review surface preparation: Look for problems like welding marks or sand stuck on the surface.

- Verify handling and sizing: Make sure the parts were handled and sized right before coating to stop problems.

- Know the coating weight: Learn about the coating weight and choose the best one for your job.

- Check strength ratings: Look at how much weight it can hold if your project needs to be strong.

- Ask about grades: Pick the right grade, like G60 or G90, for your use.

- Consider the environment: Use thicker coatings if you are near the ocean or in places with lots of rust.

- Keep documentation: Save all your records, certifications, and warranty papers.

Using this checklist helps you avoid mistakes and makes sure your galvanized aluminum is right for your project.

2. European Aluminium

Application

Use

If you pick aluminum from European Aluminium, it works for many jobs. You can use it for building walls, windows, roofs, and outside covers. Architects and engineers like aluminum for bridges and energy projects. Aluminum is light, so it is easy to move and put in place. It is also used in boats and cars because less weight helps them work better. If you want something strong and bendable, aluminum is a good choice.

It is important to choose the right alloy grade. The 3000 series is good for building because it bends and welds easily. The 5000 series is called marine grade and is stronger and fights rust better. Match the alloy to what your project needs. Pure aluminum stops rust better, but adding magnesium or manganese makes it stronger. Always check the alloy grade before you buy.

Environment

Aluminum works well in tough places. It makes a layer that protects it from rust and bad weather. You can use it near the ocean, in cities with dirty air, or where there are strong chemicals. Galvanized steel needs a zinc layer, but aluminum protects itself. This makes it great for wet, salty, or factory areas.

European Aluminium cares about the environment. Companies use new ways to make less waste and save energy. Some methods turn leftover ore into useful things and cut down on pollution. Recycling is common, and factories try to be cleaner. When you choose European Aluminium, you help the planet.

Specifications

Coating

You should look at coatings when picking aluminum for outside use. Coatings like PVDF help panels stand up to sun, rain, and dirt. These coatings keep the panels looking nice and stop rust. In places near the sea or in factories, coatings give extra protection. Always ask your seller about the coating and what it does.

Thickness

How thick the panel is changes how strong it is. For light jobs, 3mm panels are enough. If you need more strength, 4mm panels are good for outside walls. For tall buildings or windy places, 6mm panels are best. Pick the thickness that fits your project. Thicker panels do not dent easily and last longer.

| Specification Aspect | Details and Importance |

|---|---|

| Aluminum Alloy Series | 3000 for most jobs, 5000 for boats or near the sea; check the grade for strength and rust protection. |

| Panel Thickness | 3mm for light use, 4mm for walls, 6mm for tall buildings or insulation. |

| Protective Coatings | PVDF protects from sun and weather; ask which coating is best for your area. |

| Durability | Panels do not rust, fade, or get ruined by water; good for many places. |

| Fire Safety Standards | Pick fire-safe cores for tall buildings; check local rules. |

Comparison

Reputation

European Aluminium is known for good quality and caring about the earth. Builders trust their products for big jobs. The industry recycles and tries to make less pollution. You get materials that follow strict European rules. Companies use new technology to make things better and cleaner.

Certification

Always look for certifications when you buy aluminum. European Aluminium often gives papers that show their products are safe and high quality. Look for labels that prove they follow local and world rules. Certified products help you feel sure and meet project needs.

Tip: Think about aluminum and galvanized steel before you choose. Aluminum fights rust by itself and lasts longer in hard places. Galvanized steel needs a zinc layer, but it can wear away. When you compare them, think about where your project is, how much care it needs, and how much it will cost over time.

Mistakes

Compatibility

You need to check if aluminum works with other materials. Some metals can react with aluminum and cause rust. This can make the structure weaker or stained. If you put aluminum next to copper or steel, problems can happen. You should use the right fasteners and connectors. Ask your supplier how to join aluminum with other materials.

It is also easy to forget how aluminum bends and keeps its shape. Even good European aluminum needs skilled workers to make it right. Two companies can use the same aluminum but get different results. Bad work can make aluminum bend wrong or lose its shape. This can mess up your project.

Tip: Pick manufacturers who know how to bend and build aluminum the right way.

Here are mistakes you should try to avoid with aluminum:

- Not checking the minimum bend radius can cause cracks.

- Picking the wrong alloy makes bending hard without treatment.

- Using walls that are not the same thickness causes weak spots.

- Tight tolerances in bent areas can make costs go up.

- Not planning cuts and bends before starting can cause problems.

- Thinking one tool works for all shapes is a mistake.

- Forgetting about springback means aluminum may change shape after bending.

- Not talking clearly about bending direction and measurements can cause errors.

Warranty

Always read the warranty before you buy aluminum. Some warranties only cover certain problems. If you use or install it wrong, you may lose the warranty. Follow the supplier’s instructions for care and installation. Keep your receipts and warranty papers safe.

Note: Ask your supplier how long the warranty lasts and what it covers. A good warranty helps you feel safe and protects your money.

Checklist

Before you buy European aluminum, use this checklist to help you pick the right product and support green building:

- Make sure the aluminum meets ISO 59000 standards for recycling and saving resources.

- Look for ASI certification to show the aluminum was sourced responsibly.

- Check how much recycled material is in the aluminum and if you can trace it.

- Make sure the supply chain is clear and supports responsible buying.

- Work with suppliers and groups that support recycling and reuse.

- Check the alloy grade and thickness for your project.

- Look at the surface finish and coating for your area.

- Make sure the manufacturer is known for good quality and follows best rules.

- Ask about the warranty and keep all your papers.

- Plan to recycle or reuse the aluminum when you are done with it.

This checklist helps you avoid mistakes and makes sure your aluminum project is strong, lasts long, and is good for the planet.

3. Coremark Metals

Application

Use

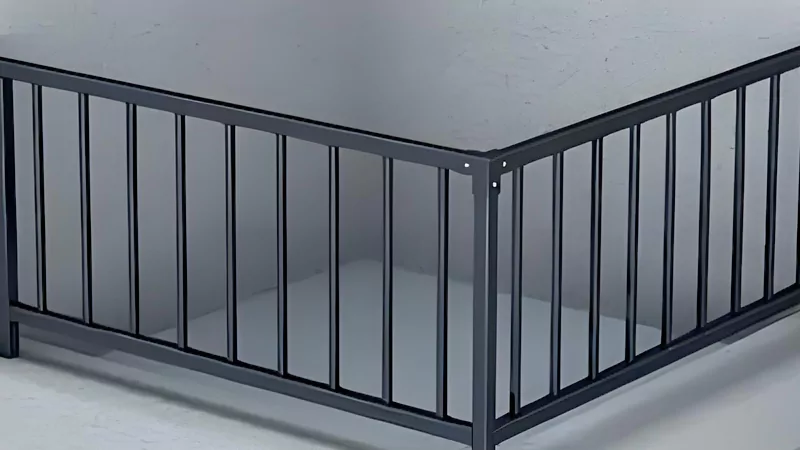

If you pick aluminum or galvanized steel from Coremark Metals, you have many choices. Galvanized steel is good for building frames, fences, brackets, and outdoor furniture. Aluminum works well for signs, panels, and light structures. You can get parts for cars, machines, or custom projects. Coremark Metals sells full pieces and also cuts them to size. This gives you options for small home jobs or big business projects.

Environment

Think about where you will use your galvanized or aluminum materials. Galvanized steel does well in rain, snow, and sun. It is great for outside use. Aluminum does not rust and works in wet or salty places. If your project faces tough weather or chemicals, both metals fight rust. You can use them near the ocean, in factories, or in damp areas.

Specifications

Coating

Coremark Metals gives galvanized steel a zinc coating. This layer protects the metal from rust and scratches. You should ask what kind of galvanizing is used, like hot-dip or electro-galvanized. Each type changes how the metal looks and works. Aluminum may have extra coatings for more protection or a better look. Always check the coating to make sure it fits your needs.

Thickness

How thick the metal is matters for strength. Coremark Metals has many thicknesses for galvanized steel and aluminum. Thicker galvanized steel lasts longer and is harder to damage. Aluminum panels come in different sizes, so you can pick what you need. If you want strong support, choose thicker metal. For light projects, thinner metal is fine.

| Material | Typical Thickness Range | Best Use Cases |

|---|---|---|

| Galvanized Steel | 16-10 gauge | Frames, outdoor structures |

| Aluminum | .032″ – .125″ | Signs, panels, lightweight builds |

Tip: Always check the thickness before you buy. Thicker metal is stronger and holds more weight.

Comparison

Reputation

Coremark Metals is known for good quality and service. You can read reviews and stories from other projects. Many people trust Coremark Metals for good products and helpful advice. When you pick a supplier, look for one with experience in galvanized and aluminum products.

Certification

Always ask for certifications when you buy galvanized steel or aluminum. Coremark Metals sells metal that meets top rules. Certifications show the metal is safe and good quality. Ask for papers to prove it meets ASTM or ISO standards. This helps protect your money and makes sure your project is done right.

Note: It is important to check your supplier. Look at their reputation, certifications, and past work before you buy. This helps you avoid problems and get the best galvanized or aluminum products for your project.

Mistakes

Compatibility

You need to make sure your galvanized aluminum or steel works with other materials. Some metals do not go well together. If you put galvanized steel next to copper or stainless steel, rust or stains can show up. This happens because of something called galvanic corrosion. You can stop this by using plastic or rubber between the metals. Always ask your supplier if you are not sure about mixing metals.

If you want to paint or coat your metal, you must get the surface ready first. Some paints do not stick to galvanized surfaces. If you skip cleaning or priming, the paint can peel off. Coremark Metals can tell you which coatings work best. You should always follow their steps for getting the surface ready.

Tip: Use the right fasteners and connectors. Pick ones made for galvanized or aluminum. This helps stop rust and keeps your project strong.

Warranty

Always read the warranty before you buy anything. Warranties tell you what is covered if something breaks. Some only cover problems from the factory. Others do not cover damage from bad installation or mixing metals. If you do not follow care rules, you might lose your warranty.

Keep all your receipts and warranty papers safe. If you have a problem later, you will need these papers. Ask Coremark Metals how long the warranty lasts and what it covers. Good suppliers will explain the details and answer your questions.

Note: Always follow the supplier’s care and installation rules. This helps you keep your warranty and protects your money.

Checklist

Before you buy galvanized aluminum or steel from Coremark Metals, use this checklist to help you pick the right product:

- Check compatibility: Make sure your metal will not touch other metals that cause rust.

- Ask about coatings: Find out which coatings or paints are best for your job.

- Review thickness: Pick the right thickness for your project’s strength.

- Confirm certifications: Ask for ASTM or ISO papers to check quality.

- Inspect for defects: Look for scratches, dents, or bare spots before you accept delivery.

- Understand warranty: Read the warranty and ask questions if you do not understand.

- Save documents: Keep all receipts, certificates, and warranty papers together.

- Plan for fabrication: Tell Coremark Metals if you need special cuts or shapes.

- Ask about delivery: Make sure you know when and how your order will come.

- Get expert advice: If you are not sure, ask Coremark Metals for help.

Using this checklist helps you avoid mistakes and makes sure your project starts with the best materials.

4. Metal Supermarkets

Application

Use

Metal Supermarkets sells many kinds of metal. You can buy galvanized aluminum, galvanized steel, and more. They have lots of shapes and sizes. Both hobbyists and workers shop here. You might need a small piece for fixing something at home. Or you may want a big order for building. You can buy just what you need. There is no minimum order. This helps you save money and not waste metal.

Galvanized aluminum is good for outdoor furniture, fences, roofs, and signs. Galvanized steel works for supports, brackets, and frames. Metal Supermarkets can cut and prepare your metal for you. Their workers can help you pick the right metal for your job.

Environment

Galvanized metals from Metal Supermarkets work well outside. You can use galvanized aluminum in rain, snow, or bright sun. The zinc coating keeps the metal from rusting. Galvanized steel is great for outdoor buildings and garden tools. If your project faces bad weather or chemicals, galvanized metals last a long time. You can trust these metals near the ocean, in factories, or anywhere wet.

Specifications

Coating

The zinc coating on galvanized aluminum is very important. Metal Supermarkets uses zinc to stop rust. This layer blocks water and air from touching the metal. You should ask what kind of galvanizing is used. Hot-dip and electro-galvanized are two types. Each type changes how the metal looks and works. Thicker zinc gives better protection in hard places.

Thickness

Pick the right thickness for your project. Thicker metal lasts longer and holds more weight. Metal Supermarkets has many thickness choices. Thin sheets are good for signs or covers. Thick pieces are best for strong jobs. Always check thickness before you buy to stay safe.

Here is a table to show the main things to look for when picking galvanized aluminum:

| Specification | Importance and Description |

|---|---|

| Formability | Lets you bend or shape metal without cracks. Good for custom parts. |

| Weldability | Lets you join pieces without losing strength or looks. |

| Machining | Makes it easy to cut, drill, or shape the metal. |

| Corrosion Resistance | Stops rust and damage from weather or chemicals. |

| Heat Treating | Lets you make the metal stronger if needed. |

| Strength | Makes sure the metal can hold up in your project. |

| Typical Applications | Helps you pick the right grade for jobs like roofing or outdoor fixtures. |

Tip: Match the specifications to your project. If you do not know what to pick, ask Metal Supermarkets staff for help.

Comparison

Reputation

Metal Supermarkets is known for good quality and service. There are over 125 stores in North America. You can also order online. Customers like the fast and friendly help. You get support for small or big orders. Many people trust Metal Supermarkets for all kinds of projects. Their big selection and smart staff make them a top choice for metals.

Certification

You can ask for certifications when you buy from Metal Supermarkets. These papers show the metal meets safety and quality rules. Certifications help you feel sure about your purchase. Always ask for these papers if your project needs proof of quality.

Mistakes

Compatibility

When you buy galvanized aluminum from Metal Supermarkets, you must think about how it works with other metals. Mixing metals the wrong way can cause rust or stains. Here are some things to remember:

- Do not mix galvanized aluminum with copper or brass. These metals can make corrosion happen fast, especially if it is wet.

- Pick the right fasteners. Use fasteners made for galvanized aluminum. Stainless steel or coated fasteners are best. Regular steel fasteners can rust and hurt your project.

- Put barriers between metals. If you need to join different metals, use plastic washers or rubber gaskets. These stop the metals from touching and help stop corrosion.

- Watch out for chemicals. Some cleaners or chemicals can hurt galvanized coatings. Always ask Metal Supermarkets staff if you do not know which products are safe.

Tip: Always ask your supplier if you want to use galvanized aluminum with other metals. This step helps you avoid repairs that cost a lot later.

Warranty

You need to know about your warranty before you buy. A warranty helps you if something goes wrong, but only if you follow the rules. Here is what you should do:

- Read the warranty. Check what is covered and what is not. Some warranties only cover factory problems.

- Follow the instructions. If you install it wrong, you might lose your warranty.

- Keep your papers. Save your receipts and warranty papers. You will need them if you have a problem.

- Ask questions. If you do not understand the warranty, ask Metal Supermarkets staff for help.

| Warranty Step | Why It Matters |

|---|---|

| Read the warranty | Know your rights and limits |

| Follow instructions | Protects your coverage |

| Keep paperwork | Needed for claims |

| Ask questions | Clears up confusion before you buy |

Note: A good warranty helps you feel safe. Always check the details before you buy.

Checklist

Before you buy galvanized aluminum from Metal Supermarkets, use this checklist to help you get the right product:

- Check if the metal will touch other metals in your project.

- Pick the right fasteners and connectors for galvanized aluminum.

- Ask about the type and thickness of the zinc coating.

- Make sure the metal is strong enough and the right size.

- Look for certifications or quality marks.

- Check the metal for bare spots, dents, or scratches.

- Read and understand the warranty rules.

- Keep all receipts and warranty papers in a safe place.

- Ask about delivery times and how to track your order.

- Get advice from Metal Supermarkets staff if you have questions.

Using this checklist helps you avoid mistakes and makes sure your galvanized aluminum project lasts a long time.

5. Metals Depot

Application

Use

When you shop at Metals Depot, you can pick from many metals. They have galvanized aluminum and other metals for lots of jobs. You can use them for building, fixing things, or making custom projects. Metals Depot helps contractors, builders, and people who like to do it themselves. You might need galvanized sheets for a roof, wall, or outdoor chair. Aluminum is good for light frames, panels, or decorations. If you want to build a fence, fix a trailer, or make a sign, Metals Depot has the right size. You can buy long pieces or ask for special cuts to fit your job.

Environment

Think about where you will use your galvanized or aluminum products. Galvanized metals do not rust easily and can handle bad weather. They are a smart pick for outside jobs. You can use them in rain, snow, or strong sun. Aluminum also does not rust and works near the ocean or in wet places. If your project faces tough weather or chemicals, both galvanized and aluminum from Metals Depot protect well for a long time.

Specifications

Coating

Metals Depot gives galvanized products a zinc coating. This layer keeps out rust and stops scratches. It blocks water and air from touching the metal. You should ask what kind of galvanizing is used, like hot-dip or electro-galvanized. Each type protects and looks a bit different. For aluminum, you can pick different finishes, like plain or painted. The right coating helps your project last longer and look nice.

Thickness

You need to pick the right thickness for your job. Metals Depot has many thickness choices for galvanized and aluminum. Thicker metal is stronger and lasts longer in hard places. For a roof, you might want a thick sheet. For a sign, a thin sheet is fine. Always check the thickness before you buy to make sure it fits your needs.

Comparison

Reputation

Metals Depot is known for having lots of metal and good service. You can order any amount, big or small, with no minimum. Many people like the fast shipping, like next day or second day air. Metals Depot can cut metal to the size you want. Some people say orders are not always perfect, but most like the quick shipping and big selection.

Certification

Always ask for certifications when you buy from Metals Depot. Certified products meet safety and quality rules. This helps you trust what you buy. Metals Depot can give you papers to show their galvanized and aluminum meet industry standards. This is important when you want to know how to choose galvanized aluminum for your job.

Tip: When you compare suppliers, look for fast shipping, easy ordering, and strong certifications. These things help you decide how to choose galvanized aluminum for your next project.

- Metals Depot offers:

- Fast shipping if you need your order quickly.

- No minimum order, so you can buy a little or a lot.

- Custom cutting to get the size you want.

- Many kinds of galvanized and aluminum products.

Mistakes

Compatibility

You need to check if your galvanized aluminum will work with other materials in your project. Some metals do not mix well. If you put galvanized aluminum next to copper or brass, you may see rust or stains. This happens because of galvanic corrosion. You can stop this by using plastic washers or rubber pads between the metals. Always ask your supplier if you are not sure about mixing metals.

You should also think about the fasteners you use. Pick fasteners made for galvanized aluminum. Stainless steel or coated fasteners work best. Regular steel fasteners can rust and damage your project. If you want to paint or coat your metal, make sure the surface is clean. Some paints do not stick to galvanized surfaces. Clean and prime the metal before painting. Metals Depot can help you choose the right products for your needs.

Tip: Always check with Metals Depot if you plan to join galvanized aluminum with other metals. This step helps you avoid costly repairs later.

Warranty

You must read the warranty before you buy. A warranty protects you if something goes wrong. Some warranties only cover factory problems. Others do not cover damage from bad installation or mixing metals. If you do not follow care instructions, you may lose your warranty.

Keep all your receipts and warranty papers in a safe place. If you have a problem, you will need these papers. Ask Metals Depot how long the warranty lasts and what it covers. Good suppliers will explain the details and answer your questions.

| Warranty Step | Why It Matters |

|---|---|

| Read the warranty | Know your rights and limits |

| Follow instructions | Protect your coverage |

| Keep paperwork | Needed for claims |

| Ask questions | Clears up confusion |

Note: A strong warranty gives you peace of mind. Always check the details before you buy.

Checklist

Before you buy from Metals Depot, use this checklist to make sure you pick the right galvanized aluminum:

- Check if the metal will touch other metals in your project.

- Pick the right fasteners and connectors for galvanized aluminum.

- Ask about the type and thickness of the zinc coating.

- Make sure the metal is strong enough and the right size.

- Look for certifications or quality marks.

- Check the metal for bare spots, dents, or scratches.

- Read and understand the warranty rules.

- Keep all receipts and warranty papers in a safe place.

- Ask about delivery times and how to track your order.

- Get advice from Metals Depot staff if you have questions.

Using this checklist helps you avoid mistakes and makes sure your project lasts a long time. If you want to know how to choose galvanized aluminum?, follow these steps for the best results. You will feel confident about your purchase and your project will be strong.

If you still wonder how to choose galvanized aluminum?, talk to Metals Depot experts. They can guide you through each step and help you find the right product for your needs.

When you pick galvanized aluminum, first think about what your project needs. You should:

- Make sure the metal is strong enough for your job. Check if it is light and if it can stop rust in your area.

- Use the checklist to see if the metal works with other parts. Look at how thick it is, what coating it has, and what fasteners you need.

- Cover any cut edges so they do not rust. Do not put it next to metals that can make it rust faster.

- Choose the right features for your job. Use rust-proof aluminum in wet places. Pick thicker coatings if your project is in a tough spot.

If you follow these steps, your project will last longer and work better.

FAQ

What is galvanized aluminum?

Galvanized aluminum is aluminum with a zinc layer on top. The zinc keeps the metal from rusting or getting damaged. You can use it outside, in buildings, or for cars. The zinc helps the aluminum last longer in hard places.

How do you choose the right thickness for galvanized aluminum?

Pick the thickness that fits your project. Thick sheets are best for heavy or outdoor jobs. Thin sheets work for signs or light covers. Always check what the maker suggests before you buy.

Can you paint galvanized aluminum?

You can paint galvanized aluminum. Clean and prime the surface first. Some paints stick better than others. Ask your supplier which paint and steps are best.

What environments suit galvanized aluminum?

Galvanized aluminum is good for wet, salty, or sunny places. You can use it by the sea, in factories, or outside. The zinc layer keeps it safe from rust and weather.

How do you avoid galvanic corrosion?

Keep galvanized aluminum away from copper or brass. Use plastic washers or rubber pads between metals. Pick fasteners made for galvanized aluminum. This stops rust and stains.

What certifications should you look for?

Ask for ASTM or ISO certifications. These papers show the metal is safe and good quality. Certified products help you trust what you buy and follow rules.

How do you maintain galvanized aluminum?

Clean the surface with mild soap and water. Do not use harsh chemicals. Check for scratches or bare spots. Fix any damage with zinc-rich paint. Regular checks help your project last longer.

Does galvanized aluminum come with a warranty?

Most sellers give a warranty. Read the warranty before you buy. Keep your receipts and warranty papers safe. Follow care rules to keep your coverage.