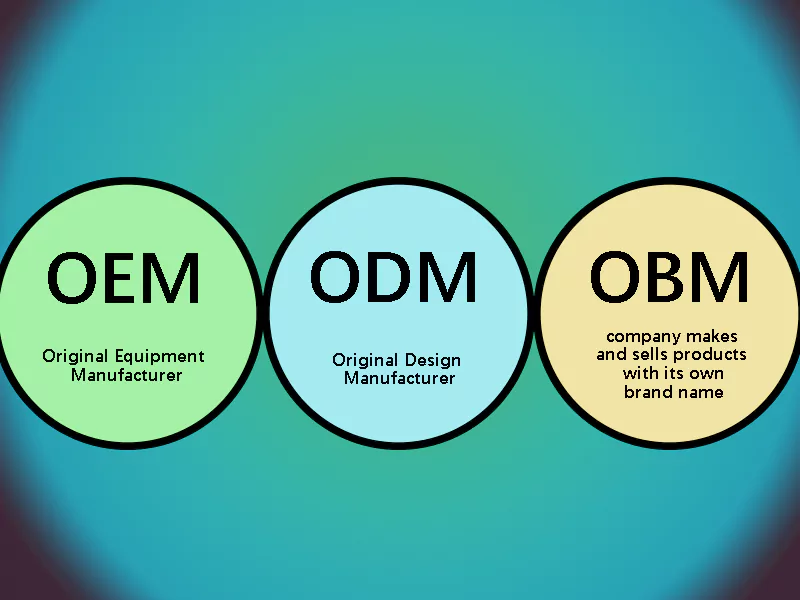

You might hear the words OEM, ODM, and OBM when you shop for parts. This happens a lot with cars and electronics. Knowing what are oem vs ODM vs OBM parts can help you choose better. OEM means Original Equipment Manufacturer. These companies make parts from a customer’s design. They sell these parts with the customer’s brand name. ODM is when a company designs and builds products for someone else. They follow what the customer wants. OBM is when a company makes and sells products with its own brand name.

Look at the table below for quick meanings:

| Term | Definition |

|---|---|

| OEM | Makes parts and equipment for other companies to use in their products. |

| ODM | Designs and makes products for another company and does all the work. |

| OBM | Makes and sells products with its own brand name. |

It is important to know these differences. OEM parts are reliable and fit well, which matters a lot for cars. When you know what are oem parts, you can pick the best product for you.

Key Takeaways

- OEM parts are made by the company that built your car. They fit well and are very good quality.

- Picking OEM parts helps keep your car’s warranty safe. It also helps your car keep its value when you sell it.

- ODM parts let you change things and sell them faster. But they might not be special or different.

- OBM parts let you choose the look and name. But you need to spend more money and work harder to manage them.

- Always make sure the parts fit and are good quality. This helps you avoid problems later.

- Think about how much money you have and what you want for your business before you pick OEM, ODM, or OBM.

- Buying OEM parts can help you save money over time. They last longer and have a warranty.

- Making good connections with suppliers helps you get good parts. It also helps you get them on time.

Table of Contents

what are oem parts

oem definition

When you ask what are oem parts, you want parts made by the original equipment manufacturer. These parts match the exact rules set by the company that built your car or device. You get factory parts that fit right and work well. Many people call these oe parts or original parts. You can trust oem parts because they come from the same place as the parts put in during assembly. Parts with an oem tag meet tough standards and pass many tests before you get them.

If you compare oem parts to aftermarket choices, you will find the advantages of oem parts:

- oem parts are the same as those first put in your car or device.

- oe parts promise a perfect fit and good performance.

- Aftermarket parts can be different in quality and price, and sometimes need changes.

Picking parts that carry an oem tag means you get replacement oem parts that keep your equipment working right. You also get a parts warranty, which helps you feel safe.

oem manufacturing

You might wonder how oem parts are made. The process starts with the original equipment manufacturer making factory parts for certain models. These oe parts must follow technical rules and pass checks. Makers use advanced machines and strict controls to make oem parts that match the original plan.

Here is a table showing how oem parts compare to other choices:

| Type of Part | Description |

|---|---|

| Original (OEM) | Parts made just for a car brand to use on the assembly line. |

| Substitutes | Same as oem parts but made in other factories or shops. |

| Other | Parts that do not fit in the above groups. |

Makers focus on making sure parts fit and cost less. They often use the same oe parts in many models to save money. Following rules, like the DVO Directive in the EU, makes sure oem parts meet market standards. When you pick oem parts, you know they passed all needed tests and checks.

oem quality

Quality makes oem parts better than other choices. You get oe parts that meet high rules for lasting long and working well. Makers use strict quality checks for every batch of oem parts. These checks include checking suppliers, regular reviews, and inspections at delivery. You get factory parts that passed tests for strength, safety, and reliability.

Here are some common quality checks for oem parts:

- Checking supplier records, like ISO certificates.

- Reviewing how parts are made and checked.

- Inspecting parts when they arrive to make sure they are good.

- Using automatic checks and data tools for accuracy.

- Sharing quality needs between buyers and suppliers.

You get oem parts that went through many tests, like checks for lasting long and fitting right. For example, an oe water pump must pass thousands of hours of testing in different situations. This means you get benefits of oem parts like long life and good performance. When you buy oem parts, you choose quality and peace of mind.

oem cost

You might notice that oem parts often cost more than other options. The higher price comes from strict quality checks and advanced manufacturing. When you buy oem parts, you pay for parts that match the original design. These parts use top materials and pass many tests. You get peace of mind because oem parts last longer and fit better.

Here are some reasons why oem parts cost more:

- Makers use special machines and skilled workers to build oe parts.

- Each oe part must pass safety and performance tests.

- You get a warranty with most oem parts, which adds value.

- The company controls the supply chain to keep quality high.

If you compare oem parts to aftermarket parts, you see a clear difference in price. Aftermarket parts may look cheaper at first, but they might not last as long. You could spend more money fixing problems later. When you choose oem parts, you invest in your car or device’s future.

Tip: Always check if the price includes a warranty or support. This can save you money over time.

oem compatibility

You want your replacement parts to fit and work right. That is why oem parts stand out. Each oe part matches the exact size, shape, and function of the original. You do not need to worry about making changes or adjustments. The company designs oem parts to work with your specific model.

Here is a table to show how oem parts compare to other types for compatibility:

| Type of Part | Fit and Function | Need for Adjustments | Warranty |

|---|---|---|---|

| OEM Parts | Perfect | None | Yes |

| Aftermarket | May Vary | Sometimes | Maybe |

| Used Parts | May Vary | Sometimes | No |

You get the best compatibility with oem parts. This means fewer problems and less time spent on repairs. When you use oe parts, you keep your equipment running like new. You also protect your investment and avoid risks that come with non-oem parts.

odm parts

odm definition

You may wonder what makes ODM parts different from oem parts. ODM stands for Original Design Manufacturer. In electronics manufacturing, ODMs create, design, and manufacture fully customized products for businesses or brands. You get products that match your needs because ODMs develop their own intellectual property. This means you can ask for changes that fit your market. ODMs offer flexibility and innovation in product design. You can outsource production to an ODM and focus on marketing and sales. Even though the ODM handles production, you keep ownership of the design and IP rights.

Here is a quick look at what ODM means:

- ODMs design and build products from scratch.

- You can request changes to match your brand.

- ODMs handle manufacturing, so you do not need your own factory.

- You keep control of your brand and product rights.

If you compare ODM to oem, you see that ODMs offer more freedom in design. You do not have to follow the strict rules set by an original equipment manufacturer. ODMs help you bring new ideas to life.

odm customization

Customization is a key benefit of ODM parts. ODM manufacturers provide basic designs that you can modify to fit your brand identity or customer needs. You work with the ODM to make sure the product matches what your market wants. The process involves close teamwork between you and the manufacturer. You can adjust branding elements, colors, and features.

Here is how ODM customization works:

- You choose a base design from the ODM.

- You ask for changes to match your brand style.

- The ODM makes adjustments and shows you samples.

- You approve the final design before production starts.

ODM manufacturers offer tailored solutions for branding and design. You get products that stand out in the market. You do not need to worry about the disadvantages of oem parts, such as limited design options. ODMs help you create products that fit your vision.

odm pros

You gain many advantages when you use ODM parts, especially if you run a small or medium-sized business. The cost of manufacturing with an ODM is lower than doing it in-house or with an oem. You do not pay for technical designs or special tooling. ODMs help you save time and money.

Here are the main benefits of ODM parts:

- Lower manufacturing costs.

- Faster time to market.

- Quick response to market trends.

- No need to design or test new products from scratch.

- You can focus on branding and marketing.

- ODMs offer expert design capabilities and design quality.

- Pre-designed solutions can be adapted quickly.

Tip: If you want to launch a product fast, consider using ODM parts. You save resources and get expert help with design and production.

odm cons

When you think about using ODM parts, you should also look at the downsides. ODM manufacturers give many good things, but there are some problems too. Knowing these problems helps you make smart choices and not get caught off guard.

A big problem is you do not have full control over the design. ODMs make the main design, and you can only change some things. If you want a special feature, you might not get it unless the ODM says yes. This can make it hard to be different from others in the market.

Quality can be a problem too. ODMs work with many companies, and sometimes they use the same design for different brands. You might get products that look like your competitors’ items. If the ODM does not check quality well, you could get parts that are not good enough. You need to watch quality and ask for updates often.

There are also risks with intellectual property. ODMs own the first design, and you only get to use it. If you want to keep your brand safe, you must read the contract closely. Sometimes, ODMs sell almost the same products to other companies. You could lose your edge if your product is not special.

Problems with the supply chain can happen if you depend on one ODM. If the maker has delays or runs out of parts, your business can have trouble. You may not have other choices if something goes wrong. You need to plan for these risks and talk often with your ODM.

Here is a table showing common cons of ODM parts:

| ODM Cons | Description |

|---|---|

| Limited Design Control | You cannot change every part of the product. |

| Quality Variability | Product quality may not be the same each time. |

| IP Risks | ODM owns the design, not you. |

| Supply Chain Dependence | You rely on one maker for all parts. |

| Market Similarity | Products may look like those from others. |

Note: Always compare ODM parts with other choices. Sometimes, oem parts’ problems are not as bad if you need fast production. But you should think about all risks before you decide.

You should think about your long-term plans. If you want full control and special products, ODM may not be right for you. You should talk with your ODM about quality, design, and delivery before you sign anything. Good planning helps you avoid trouble and keeps your business strong.

obm parts

obm definition

You might wonder what OBM means when you shop for parts. OBM stands for Original Brand Manufacturer. An OBM owns its products and controls every step. This includes design, making, and selling the products. The brand makes all choices about how things look and work. You get special products because the brand handles everything. This gives full control over quality and the brand’s image. OBMs do not just make parts for other companies. They build their own brands and decide on every detail. Many companies start as oem or ODM and then become OBM. They want more control and to sell better products.

When you pick OBM parts, you choose a brand that cares about every part of its products.

obm branding

Branding helps OBM companies stand out from others. These brands use research to make new and better products. In cosmetics, OBMs use science to follow trends and meet safety rules. You get safe products that match what people want. Companies like COSMAX use smart ideas and market knowledge to be different. OBMs use two main ways to reach more people and build trust.

| Strategy Type | Example Brands | Description |

|---|---|---|

| Horizontal Differentiation | Nike, H&M, Levi’s, Uniqlo | You can buy custom items online and regular ones in stores. |

| Vertical Differentiation | Sharp Electronics, Li-Ning | You find top-quality items in stores and cheaper ones online. |

OBMs care about both product quality and brand style. They use research to keep their products ahead of others. You get items that are safe, cool, and different from the rest.

obm pros

You get many good things when you pick OBM parts for your business. OBM companies let you control how your products look and work. You do not have to depend on oem or ODM for design. You also make more money because you sell directly. Your brand grows stronger with every sale.

| Benefit | Description |

|---|---|

| Complete control over product design | You make products that show your brand’s style. |

| Greater profit margins | You keep more money by selling yourself. |

| Build and capitalize on brand value | You grow your brand and make customers loyal. |

Tip: If you want your brand to stand out, OBM parts help you make products that show your values.

OBM companies can change fast when the market changes. You can make and sell new products quicker than oem or ODM companies. You also build trust because you control everything. OBM parts let you shape your brand and help your business grow.

obm cons

When you choose OBM parts, you take on many responsibilities. You control the design, production, and sales. This gives you freedom, but it also brings challenges. You need to know the risks before you decide to use OBM parts for your business.

Here are the main disadvantages of OBM parts:

- High Investment Costs

You must spend a lot of money to build your brand. You pay for research, product development, and marketing. You also need to set up your own production lines or work with trusted factories. These costs can be much higher than using OEM or ODM parts. - Complex Brand Management

You manage every part of your brand. You need to create a strong brand image and keep it consistent. This takes time and skill. If you make mistakes, your brand reputation can suffer. You must watch market trends and respond quickly. - Market Risks

You face direct competition from other brands. If your products do not sell well, you lose money. You need to understand your customers and offer products they want. If you fail, your business can struggle. - Resource Demands

You need skilled workers for design, marketing, and production. You must train your team and keep them motivated. You also need good suppliers and partners. Managing all these resources can be hard. - Longer Time to Market

You spend more time developing new products. You must test your ideas, fix problems, and get approvals. This can slow down your launch. If your competitors move faster, you can lose your place in the market. - Quality Control Challenges

You are responsible for product quality. You must set up strict checks and fix any issues. If you miss problems, your customers can lose trust in your brand.

Note: You need to plan carefully before you start with OBM parts. Make sure you have enough money, skilled workers, and a clear brand strategy.

Table: Common OBM Cons

| OBM Cons | Description |

|---|---|

| High Investment Costs | You pay more for research, production, and marketing. |

| Brand Management | You must build and protect your brand image. |

| Market Risks | You face direct competition and sales risks. |

| Resource Demands | You need skilled workers and strong partners. |

| Time to Market | You spend more time developing new products. |

| Quality Control | You must manage all quality checks yourself. |

You need to weigh these cons against the benefits. If you want full control and a strong brand, OBM parts can help you grow. If you want less risk and lower costs, you may want to look at OEM or ODM options. Always think about your goals and resources before you choose.

oem vs odm vs obm

manufacturing

You should know how making things works for each model. The steps are different for oem, ODM, and OBM. Each one gives you a different amount of control and work.

Here is a table that shows the main differences:

| Model | Responsibilities | Intellectual Property | Ideal For |

|---|---|---|---|

| OEM | Brand owner handles R&D; production outsourced | Retained by brand owner | Established brands entering new markets |

| ODM | Factory handles design and production | Not owned by brand owner | Startups with limited resources |

| OBM | Factory manages R&D, production, and sales | Owned by factory | Factories with strong capabilities in R&D and marketing |

If you pick oem, you keep control over research and design. You make the plans, but another company builds the parts. This is good for brands that want to sell in new places. You do not need your own factory. You get oem parts that fit what you want.

If you choose ODM, the factory does both design and building. You do not own the design, but you save time and money. This helps new companies that need fast answers and have less money.

OBM means the factory does everything. They design, build, and sell the products with their own name. This works for companies with strong teams for research and selling. They own the ideas and run all the steps.

design

Who controls the design changes with each model. You need to know who decides how your product looks and works.

Here is a table that explains the differences:

| Model | Responsibilities | Advantages | Disadvantages | Best For |

|---|---|---|---|---|

| OEM | Produces based on another company’s design | High control over design and branding | Higher development costs | Businesses with strong R&D capabilities |

| ODM | Designs and manufactures products for rebranding | Saves time and money on R&D | Lack of personalization options | Retailers or startups expanding quickly |

| OBM | Designs, manufactures, and sells under its own name | Strong control over branding | High R&D and marketing costs | Established businesses forming independent brands |

With oem, you make the design for the parts. You pick how it looks and works. You get lots of control, but it costs more to design. This is best for companies with good design teams.

ODM lets the factory design and make the product. You can put your name on it, but you cannot change everything. You save money and launch faster, but lose some control. This is good for stores or new companies that want to grow fast.

OBM means the factory does all the work. They design, make, and sell the product with their own brand. You see strong branding, but it costs more for research and ads. This is best for companies that want their own brand from the start.

branding

Branding is how people see your products. You should think about trust, value, and where you fit in the market.

- Branding helps people trust your products. If you use oem parts, buyers know they get good quality. This trust helps you sell more and keep customers.

- Branding makes your product seem worth more. Small things, like a special logo, can make your product look better. You can charge more and make more money.

- Branding helps you stand out. With strong branding, your products look different from others. You show why your parts are special.

Tip: Spend time on branding, even for oem parts. A strong brand lets you charge more and get more buyers.

Branding also changes how you compete. With oem, you focus on quality and fit. With ODM, you use fast solutions and flexible branding. OBM lets you build a special brand and control every part. You should pick the model that fits your goals and what you have.

cost

When you choose between OEM, ODM, and OBM parts, cost plays a big role in your decision. Each model has its own price structure. You need to know what you pay for and how it affects your budget.

OEM Parts Cost

- You pay more for OEM parts. Manufacturers use strict quality checks and advanced machines.

- OEM parts come with warranties and support. These add value but increase the price.

- You invest in reliability and perfect fit. You avoid extra repair costs later.

ODM Parts Cost

- ODM parts usually cost less than OEM. The factory handles design and production.

- You save money because you do not pay for research and development.

- ODMs offer pre-designed solutions. You get faster production and lower upfront costs.

- You may face hidden costs if you need special changes or extra quality checks.

OBM Parts Cost

- OBM parts require the highest investment. You pay for research, branding, marketing, and production.

- You control every step, but you need skilled workers and strong partners.

- You spend more time and money before you launch your product.

- You keep more profit per sale, but you risk losing money if your products do not sell well.

Tip: Always check the total cost, not just the price tag. Include design, testing, branding, and support when you compare options.

Here is a table to help you see the cost differences:

| Model | Upfront Cost | Ongoing Cost | Risk Level | Profit Margin |

|---|---|---|---|---|

| OEM | High | Medium | Low | Medium |

| ODM | Medium | Low | Medium | Low |

| OBM | Very High | High | High | High |

You need to match your choice to your business goals. If you want fast results and lower costs, ODM works well. If you want full control and higher profits, OBM fits your needs but brings more risk. OEM gives you peace of mind and strong support, but you pay more upfront.

Choosing the right model helps you manage your budget and grow your business. Always plan for hidden costs and think about long-term value.

choosing parts

factors

You face many choices when you select parts for your business. You must look at your goals and how each option fits your needs. The right decision helps you save money and build a strong brand. Use the table below to compare important factors:

| Factor | Description |

|---|---|

| Business Model and Goals | Match your manufacturing choice with your company’s strategy. Focus on brand strength and research. |

| Market Research and Competitors | Study the market and know what buyers want. Check if the market is crowded before you choose oem or ODM. |

| Budget and Volume | Look at your budget and how many parts you need. Pick the option that fits your financial plan. |

| Product Complexity and Expertise | Think about how complex your product is. Choose oem if you need special designs and have skilled workers. |

You should ask yourself these questions:

- Do you want full control over design and branding?

- Is your budget tight, or can you invest more for quality?

- Does your team have the skills to manage complex products?

- Are you entering a market with many competitors?

If you answer these questions, you can find the best path for your business.

applications

You see oem, ODM, and OBM parts in many industries. Each type fits different needs and markets. The table below shows where you find these parts most often:

| Type | Sector | Application Examples |

|---|---|---|

| OEM | Automotive | Parts like engines, transmissions, or electronics for vehicles |

| ODM | Consumer Electronics | Products branded and sold by companies like Xiaomi |

| OBM | Fashion | Clothing and accessories designed and produced for brands |

You notice oem parts in cars and trucks. These parts help vehicles run safely and smoothly. ODM parts show up in electronics, such as phones and tablets. OBM parts appear in fashion, where brands want control over style and quality.

- OEMs produce essential parts for vehicle assembly and electronic devices.

- ODMs provide design and manufacturing services for quick market entry.

- OBMs oversee production and branding, ensuring quality and brand loyalty.

You must match your choice to your industry and business needs.

tips

You can make better choices if you follow a few simple tips. Many buyers make mistakes when they rush or ignore key details. Use these steps to avoid common problems:

- Check the fit and compatibility. Make sure oem parts match your equipment exactly.

- Compare costs. Look at the total price, including support and warranty.

- Ask about quality checks. Choose suppliers who test their products well.

- Review contracts. Read all terms before you agree to buy ODM or OBM parts.

- Plan for growth. Pick a model that lets you expand your business later.

- Watch for hidden fees. Ask about extra charges for shipping or changes.

- Build strong relationships with suppliers. Good communication helps you solve problems fast.

Tip: Always test a small batch before you order in large numbers. This step helps you spot issues early and protect your investment.

You can avoid mistakes if you stay informed and ask questions. You should never choose parts based only on price. Quality, support, and compatibility matter just as much.

summary

oem parts recap

You want parts you can trust when you need replacements. oem parts make you feel safe because they follow strict rules from car makers. These parts fit just right and work with your machine. Many experts say to use oem so you keep your warranty and your car’s value. You also feel calm knowing each part passed hard tests.

Here is a table that shows the main facts about oem parts:

| Key Point | Description |

|---|---|

| Rigorously Tested | Made with strong materials and checked to meet car maker rules. |

| Made to Fit | Built for certain models, so they fit and work well. |

| Can be Warranteed | Often come with a warranty, so you do not pay for defects. |

| Maintaining Vehicle Warranty | Using oem parts keeps your warranty safe. |

| Quality Assurance Testing | Made and tested for safety and good performance. |

| Consistent Operation | Work well with other parts, keeping things running right. |

| Maintaining Resale Value | Help keep your car’s value high when you sell it. |

| Peace of Mind | Give you confidence in quality and fit. |

You see oem parts work well and last a long time. You skip problems that can happen with other types of parts.

odm parts recap

You might want to sell products fast or spend less on design. ODM helps you get to market quickly, but you lose some control. You use designs that already exist, so you cannot change everything. This makes it hard to make your brand special. Other companies might sell almost the same thing.

- ODM lets you sell faster but you cannot change much.

- It can be tough to stand out from others.

- Not being able to change things can hurt your brand.

Tip: Pick ODM if you want speed and less work, but pick oem if you want full control and a strong brand.

You should think about if you want to move fast or build a strong brand.

obm parts recap

You want to control your products and your brand. OBM lets you handle design, making, and selling. You need to match your marketing, research, and making plans to build a strong brand. Telling your story and talking to buyers helps you connect with them. Your team must work together and be ready to change.

- Companies must match marketing, research, and making to build a brand.

- Telling stories and talking to buyers makes your brand stronger.

- Working together and being flexible helps your business grow.

You have more work with OBM, but you can shape your brand and react to changes. You need enough people and a good plan to make OBM work for you.

You have lots of choices when you pick parts. The table below shows how oem, ODM, and OBM are different:

| Model | Advantages | Disadvantages |

|---|---|---|

| OEM | Lower costs to make, focus on what you do best, chance to work with many brands | Depend on the brand owner, not much control over the product, hard to stand out |

| ODM | Cheaper to make, can change things, more control over making parts | Depend on the client, not much control over the final product, others might copy your idea |

| OBM | Full control over the product, strong brand, can make more money | More risk for your brand, costs more at the start, not as easy to change things |

Pick oem if you want parts that fit well and last long. ODM is good if you need something fast and cheap. OBM is best if you want to control everything and build a strong brand. Before you choose, think about these things:

- Who controls the design

- What happens with ideas and inventions

- How much you can change the product

- How much money you need to spend

- How fast you can get the product ready

- What risks you might face

- How different your product can be

Always look at oem, ODM, and OBM for how good they are, how much they cost, and if they fit your needs. If you are not sure, ask someone who knows or read more about it.

FAQ

OEM stands for Original Equipment Manufacturer. You get parts made to match your car’s original specifications. These parts fit perfectly and maintain your vehicle’s performance and safety.

You can use ODM parts if they meet your needs. ODM parts offer customization, but they may not always match the exact fit or quality of OEM parts. Always check compatibility before buying.

OEM parts cost more because manufacturers use strict quality controls and advanced materials. You pay for reliability, warranty, and a perfect fit. Aftermarket parts may save money but can vary in quality.

You can check the packaging for the manufacturer’s logo and part number. OEM parts often come with documentation and a warranty. Ask your supplier for proof if you are unsure.

OBM parts give you full control over design, branding, and quality. You build your brand and set your standards. This helps you stand out in the market and create loyal customers.

ODM parts can be safe if you choose a trusted manufacturer. Always ask for safety certifications and test reports. Reliable ODM suppliers follow industry standards for electronics.

You keep your warranty when you use OEM parts. Manufacturers recommend OEM replacements to protect your warranty and your vehicle’s value. Using non-OEM parts may risk your coverage.

You should consider your budget, quality needs, and branding goals. OEM works best for reliability. ODM helps with fast market entry. OBM suits you if you want full control and a strong brand.