To cut aluminum extrusion accurately, use a carbide saw blade. You can use a table saw or a cutoff saw. Always make sure the material is held tightly before cutting. Safety is very important when cutting aluminum extrusion. If you make mistakes, you could get hurt badly. You might have an accident with the machine, get burned, or breathe in something dangerous. The table below lists some dangers you might face when cutting aluminum extrusions:

| Risk Type | Description |

|---|---|

| Machinery accidents | Workers can get caught, crushed, or hit by moving machine parts. |

| Exposure to high heat or molten metal | Touching hot aluminum can cause bad burns or even death. |

| Toxic exposure | Breathing in fumes, dust, or chemicals can hurt your lungs. |

| Falls | Wet floors or high places can make you fall and get hurt. |

| Electrical hazards | Bad wiring or open wires can shock or electrocute you. |

| Mechanical failures | Broken machines can cause very serious accidents. |

You will get smoother and better cuts if you use the right tools and follow the correct steps.

Key Takeaways

- Use a carbide saw blade for clean cuts on aluminum extrusion.

- Wear safety gear like gloves, goggles, and hearing protection to stay safe.

- Measure and mark your cuts with care, and check your measurements twice to avoid mistakes.

- Clamp the aluminum extrusion tightly so it does not move when you cut.

- Put lubricant on the blade and material to lower friction and heat, which helps make smoother cuts.

- Cut slowly and at a steady speed to keep control and stop rough edges.

- Deburr the edges after cutting to get rid of sharp spots and keep things safe.

- Use a checklist before, during, and after cutting to stay organized and safe.

Table of Contents

Cut Aluminum Extrusions: Tools and Setup

When you cut aluminum extrusion, you need the right tools. You also need protective gear. This helps you make clean cuts. It keeps you safe from getting hurt.

Essential Tools

Carbide Saw Blade

Pick the blade that fits your project. A carbide saw blade gives a sharp edge. It also makes the finish smooth. Carbide blades last longer than regular blades. You do not have to replace them often. They work well for cutting aluminum extrusion profiles. They also cut other metals. The table below shows why carbide saw blades are better than other blades:

| Benefit | Description |

|---|---|

| Longevity | Carbide saw blades stay sharp longer, so you do not need to sharpen or replace them often. |

| Superior Performance | They make cleaner and more precise cuts, so you spend less time sanding or cleaning up edges. |

| Versatility | You can use them to cut extruded aluminum, copper, and carbon steel. |

Using the right blade is important for safety. It also helps you cut accurately. Saws with blade guards and cooling systems help stop accidents. Always hold the material tight before you cut.

Table Saw, Cutoff Saw, Circular Saw

You can use different saws to cut aluminum. Table saws, cutoff saws, and circular saws are good choices. Each saw works best for certain sizes and amounts. The table below compares circular saws and band saws for cutting aluminum:

| Tool Type | Diameter Range | Volume Capacity | Finish Quality |

|---|---|---|---|

| Circular Saws | 0.5 to 6 in. | Up to 5,000 parts/shift | Very clean finish |

| Band Saws | 6 in. diameter and larger | 1,000 parts or fewer/shift | Good control, thinner kerf |

Circular saws with aluminum blades make a clean finish. Band saws are good for bigger pieces. They also give you good control. Always use a blade made for cutting aluminum.

Lubricant

Lubricant keeps the blade cool. It also lowers friction when you cut. Put lubricant on the blade and the aluminum extrusion. This stops the blade from getting too hot. It helps your blades last longer. Lubricant also makes cuts smoother. It helps stop burrs from forming.

Safety Gear

Gloves

You must wear ppe when you cut aluminum extrusions. Gloves keep your hands safe from sharp edges. They also protect you from hot surfaces. Cut-resistant gloves stop cuts and scrapes. Heat-resistant gloves protect your hands from burns.

Eye Protection

Goggles protect your eyes from flying bits. Safety glasses or goggles block small chips and dust. Always wear goggles when you use a metal cutting blade. Wear them when you work with aluminum extrusion profiles.

Hearing Protection

Cutting aluminum is loud. Hearing protection like earplugs or earmuffs helps your ears. Use hearing protection every time you use saws to cut aluminum.

Tip: Always wear ppe before you start cutting. This means gloves, goggles, and hearing protection. It lowers your chance of getting hurt. It helps keep you safe.

The table below shows how personal protective equipment helps stop injuries:

| Personal Protective Equipment | Role in Injury Prevention |

|---|---|

| Safety glasses or goggles | Protect eyes from flying debris and sharp objects during cutting operations |

| Cut-resistant gloves | Prevent cuts and abrasions when handling materials |

| Hearing protection | Safeguard against hearing loss in high-noise environments |

You should also think about wearing fire-resistant clothes. Respirators give extra protection. The right gear keeps you safe. It helps you focus on making good cuts.

Cutting Aluminum Extrusions: Preparation

Get ready before you cut aluminum extrusion. Good preparation helps you make clean cuts. It also keeps you safe.

Measure and Mark

Speed Square, Machinist Square

Use the right tools to measure and mark. A speed square or machinist square helps you draw straight lines. These tools help you keep your marks at the right angle. This is important for a good cut.

Other measuring tools can help with different jobs. The table below shows which tool is best for each job:

| Tool | Precision Level | Best For |

|---|---|---|

| Calipers | Moderate | Basic profiles |

| Micrometers | High | Small, intricate details |

| Laser Measuring Devices | Very High | Large-scale and complex profiles |

Tip: Use a pencil or a marker to make clear lines.

Measure Twice, Mark Once

You do not want to make mistakes. Always measure and mark two times before cutting. This helps you find errors and makes your cuts better. If you skip this, you might waste material or get the wrong size.

Secure the Extrusion

Clamps

Keep your aluminum extrusion from moving when you cut. Use strong clamps to hold it still. Clamps help you make straight cuts. They also keep your hands safe by holding the material tight.

Workbench

A strong workbench gives you a safe place to work. Hold the aluminum extrusion tight on the workbench before you start. This helps you cut better and stops accidents.

The table below shows how each part of your setup helps you stay safe and work well:

| Feature | Contribution to Safety and Functionality |

|---|---|

| Durable Work Surface | Gives you a strong workspace that does not scratch or break. |

| Heavy-duty Vises | Holds your work tight so it does not move when you cut. |

| Clamps | Makes your material steady, so you cut safely and accurately. |

- Hold the aluminum extrusion tight on the workbench.

- Measure and mark the length you need clearly.

- Use a square tube to help you line things up.

Always wear safety gear before you start. Safety glasses, gloves, and hearing protection keep you safe while you get ready and cut.

If you take time to measure, mark, and secure your aluminum extrusion, you will get better results. Careful setup makes cutting safer and helps you do a good job.

Cutting Aluminum Extrusions: Step-by-Step Guide

Set Up Saw and Blade

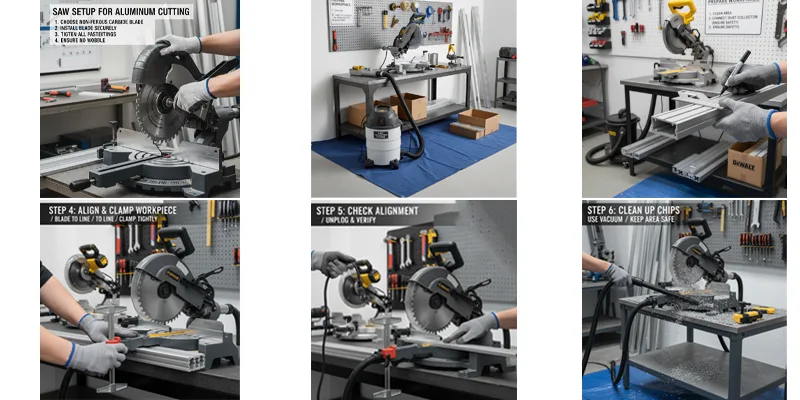

Before you cut aluminum extrusions, set up your saw and blade the right way. This helps you make clean cuts and keeps you safe. Follow these steps to get good results:

- Install the Blade

Pick a non-Ferris carbide blade for cutting aluminum extrusion. Put the blade on your saw. Make sure it is tight and does not wobble. - Prepare Your Workspace

Put your saw in a clean spot. If you have a dust collector, connect it. If not, use tarps or a box to catch aluminum chips. This keeps your area safe and neat. - Mark the Cut Line

Use a square and a sharp pencil to draw your cut line. Check your measurements again to be sure they are right. - Align and Clamp the Workpiece

Line up the blade’s longest tooth with your cut line. Clamp the extrusion tight to the workbench. This stops it from moving and helps you cut straight. - Check Alignment

Unplug the saw first. Check if the blade and extrusion line up. Make sure everything is ready for a good cut.

Tip: Clean up aluminum chips after you finish. A clean area helps stop accidents and keeps your tools working well.

Taking time to set up your saw and blade is very important. This helps you cut aluminum extrusion safely and accurately. It also helps you get professional results.

Adjust Cutting Speed

Cutting speed is important for safety and how your cut looks. You need to pick the right speed for your job. If you cut too fast, the blade can get hot and wear out. This can be dangerous. If you cut too slow, the blade stays cool and lasts longer, but the cut may look rough.

Try a medium speed first and watch the blade. If you see too much heat or rough edges, change the speed. This helps you get smooth cuts and keeps your tools safe.

Note: Always follow the manufacturer’s rules for cutting speed. This helps you cut safely and get good results.

Changing the speed the right way is a good method for cutting aluminum extrusions. It helps you cut better and keeps your area safe.

Apply Lubricant

Lubricant is very important when you cut aluminum extrusions. It lowers friction and heat. This helps you make smooth and clean cuts. The right lubricant also keeps your blade and aluminum safe.

Here is a table that shows what to look for in a good lubricant:

| Criteria | Description |

|---|---|

| Excellent cooling performance | Keeps the workpiece and cutting tool cool during cutting. |

| Excellent lubrication | Reduces friction and helps remove chips for a smooth finish. |

| Corrosion resistance | Prevents pitting and damage to the aluminum surface. |

| pH level | Should be between 8.0 and 8.5 to stop oxidation. |

| Anti-rust agent | Contains agents like phosphate and sodium silicate to protect the workpiece from rust. |

Put lubricant on the blade and aluminum extrusion before you cut. This helps stop burrs and keeps the blade sharp. You will see better cuts and a smoother finish.

Tip: Use a spray bottle or brush to put on lubricant. This easy step helps you get better cuts.

Using lubricant is a big part of cutting aluminum extrusions. It helps you cut well, protects your tools, and gives you great results.

Make the Cut

You have set up your saw and checked the speed. You put lubricant on the blade. Now you can cut the aluminum extrusion. It is important to be precise. First, check that the aluminum extrusion is clamped tightly. This stops it from moving. It helps you make a straight and clean cut.

Here are steps for a safe and accurate cut:

- Wear Your Safety Gear

Put on gloves, safety goggles, and hearing protection. These protect you from flying chips and loud sounds. - Position the Blade

Line up the saw blade with your marked line. Keep the blade straight for regular cuts. Change the miter saw angle for angled cuts. - Start the Saw

Turn on the saw. Wait until it is at full speed before you start cutting. This helps stop the blade from catching or jumping. - Feed the Blade Slowly

Move the saw blade through the aluminum extrusion slowly. Do not hurry. Slow and steady pressure stops chipping. It also keeps the blade cool. - Complete the Cut

Let the blade finish cutting before you lift it away. Wait for the blade to stop spinning before you take out the extrusion.

Tip: Always use a blade made for non-ferrous metals like aluminum. Put low-viscosity cutting oil on the blade to keep it cool and make it last longer.

Cutting aluminum extrusion carefully gives you a smooth edge and the right length. If you need an angled cut, change the blade angle and check your measurements again. Miter saws are good for angled joints and exact cuts.

You can use these steps for both straight and angled cuts. Always clamp the aluminum tight and use the correct blade. This way, you cut aluminum extrusions safely and get professional results.

Deburr Edges

After you cut, you will see sharp edges or burrs on the aluminum. Burrs can hurt you and make parts fit badly. Deburring is important to finish your project.

There are different ways to deburr aluminum:

- Manual Deburring

Use a deburring blade, sandpaper, or a file to smooth sharp edges. This is fast and good for small jobs. Cotton Fiber Mounted Points help smooth edges without changing the part’s shape. - Brush Deburring

Use a wire brush or abrasive wheel for faster work. This is good for big batches but can make new burrs if you are not careful. - Advanced Methods

For tricky shapes or lots of work, try thermal deburring or electrochemical deburring. These methods clean hard-to-reach places and keep the part’s shape.

Note: Aluminum is soft, so burrs may bend instead of breaking off. Use tools made for aluminum so you do not damage your workpiece.

The Orbitool is a special tool that removes burrs from cross-drilled holes and tough spots. It only takes away burrs and leaves the rest of the surface alone. This is important when you need very exact sizes.

Always check your cut edges after deburring. Gently run your finger along the edge to feel for sharp spots. Good deburring makes sure your aluminum extrusion is safe to touch and ready to use.

Safety Tips for Cutting Aluminum Extrusions

You need to follow safety tips when cutting aluminum extrusions. These steps help you stay safe and keep your area clean. Many accidents happen if you skip steps or hurry. You can stop most problems by being careful and using good methods.

Prevent Jumping and Bending

Jumping and bending can happen when you cut aluminum extrusion. If the material moves, your cut may not be straight. You could also get hurt. To stop these problems, do these things:

- Clamp the extrusion tight before you cut. This keeps it from moving or jumping.

- Use the right amount of force to straighten the extrusion. Too much force can bend it. Too little force can also make it bend.

- Lift big pieces from both ends. This helps stop bending.

- Be gentle with small profiles. They bend easily if you move them too fast.

- After aging, profiles are less likely to bend. Move them gently when you put them on shelves.

Tip: Use a vise or other tool to hold the extrusion still. This gives you more control and helps you cut straight.

Avoid Fast Cutting Speeds

Cutting too fast is a mistake. High speed can make the blade hot. This can cause rough edges or break the blade. You might also lose control of the material. To stay safe, do these things:

- Start at a medium speed and change if needed.

- Watch for smoke or color changes. These mean the blade is too hot.

- Use sharp blades that are in good shape. Dull blades need more force and can cause accidents.

- Work in a bright place on a steady table. This helps you see and keeps your hands steady.

Note: Always follow the maker’s rules for cutting speed. This helps you get smooth cuts and keeps your tools safe.

Handle Sharp Edges

Cut aluminum extrusions have sharp edges. These can cut you if you are not careful. Do these things to stay safe:

- Wear goggles or safety glasses to protect your eyes from flying pieces.

- Use gloves that stop cuts and scrapes.

- Wear clothes that protect your skin from sharp edges.

- Always use the right tool for the job. Check your tools to make sure they are sharp and safe.

- Teach everyone in your shop how to use tools safely. Training helps stop accidents.

- Use a vise or other tool to hold the extrusion when you smooth or move it.

Callout: Never hurry when cutting aluminum extrusions. Take your time and follow all safety steps. This keeps you safe and helps you do a good job.

If you follow these safety tips, you can stop many mistakes when cutting aluminum extrusion. Careful work, good setup, and the right gear help you stay safe and work well.

Troubleshooting Cutting Aluminum Extrusions

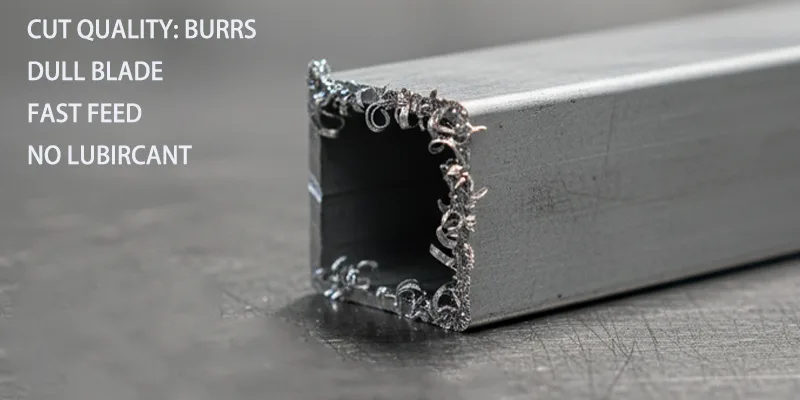

Burrs on Edges

After you cut aluminum extrusions, you might see burrs on the edges. Burrs can make your parts unsafe. They also make it hard for pieces to fit together. You can stop burrs if you know what causes them. You can also change how you cut to help.

Some things that cause burrs are:

- Tool sharpness: If your blade is dull or not straight, it makes more friction. This can cause burrs.

- Feed rate: Pushing the material too fast adds pressure. This can bend the metal and make burrs.

- Material properties: Some aluminum alloys are harder or softer. These types can get burrs more easily.

- Machine settings: If the machine goes too fast or gets too hot, burrs can form.

- Tool selection and maintenance: Sharp, good blades make less friction. They also give you better edges.

- Cutting parameters: Changing how fast or deep you cut can help stop burrs.

- Coolant and lubrication: Using enough coolant keeps the blade and metal cool.

- Quality control: Checking your work often helps you find burrs early.

Tip: Always use sharp blades and check your machine before you cut. Put on lubricant to keep the blade cool and help chips come off.

If you see burrs after cutting, use a deburring tool or sandpaper. This makes the edges smooth and safe. Your aluminum extrusion will be ready to use.

Inaccurate Cuts

Bad cuts can mess up your project and waste material. You need to know what causes these mistakes. You also need to know how to fix them. Many things can make your cuts wrong.

Things that cause bad cuts:

- Choice of cutting tools: The wrong blade or saw can make uneven cuts.

- Pressure during cutting: Too much force can bend the metal. Too little force can make the blade move off the line.

- Stability of the workpiece: If the extrusion moves, your cut will not be straight.

To make your cuts better, do these things:

- Use blades made for aluminum. These blades make cleaner, straighter cuts.

- Clamp the extrusion tight before you cut. This keeps it from moving.

- Pick the right way to cut for your project. For example, use a miter saw for angled cuts.

Note: Always check your measurements and marks two times before you cut. This helps you avoid mistakes and get the right size.

If your cuts are not right, look at your setup and how you cut. Change your tools or how you hold the material to get better results.

Blade Binding

Blade binding happens a lot when you cut aluminum extrusions. It can break your blade and ruin your work. You need to know why blades bind and how to stop it.

Main reasons for blade binding:

- Curved cuts: Too much pressure can bend the blade. This makes it cut in a curve, especially with band saws.

- Angled edges: A bent blade can make edges that are not straight up and down. This makes it hard to join parts.

- Chipping and burrs: Soft aluminum can chip and leave burrs. These need extra cleaning.

You can fix blade binding by getting better tools and changing how you cut:

| Solution | Benefit |

|---|---|

| Use dedicated circular saw blades | Makes cuts cleaner and more exact |

| Upgrade to miter or mounted band saw | Makes better cuts and stops binding |

| Apply steady, even pressure | Stops the blade from bending or curving |

Callout: Let the blade do the work. Do not push the metal too hard. Use the right blade for aluminum and keep your tools in good shape.

If your blade binds, stop and check your setup. Make sure your blade is sharp and the metal is held tight. Change your speed and pressure to stop this from happening again.

Excessive Noise

If you hear a lot of noise when cutting aluminum extrusions, something is wrong. Loud sounds mean your process or tools may have problems. Too much noise can hurt your ears. It can also make it hard to focus on your work. You need to find out why it is so loud and fix it. This keeps your workspace safe and comfortable.

When cutting is noisy, you might have these problems:

- The saw blade could be dull or broken.

- The blade might not fit the aluminum extrusion profile.

- The machine may shake or vibrate while cutting.

- You could be cutting too fast or too slow.

- The blade teeth might not have the right spacing.

Noise can also happen if your setup is not stable. If your workpiece moves or clamps are loose, the blade will get louder. Always check that your aluminum extrusion is held tight before you cut. A steady setup helps you cut cleaner and makes less noise.

A study found that using a new saw blade with different tooth spacing can make cutting quieter. Look for blades made for aluminum cutting. These blades have special tooth shapes and spacing. They help you cut smoother and with less noise.

Here is a table that shows what causes noise and how to fix it:

| Cause of Noise | Solution |

|---|---|

| Dull or damaged blade | Replace with a sharp, new blade |

| Wrong blade type | Use a blade made for aluminum cutting |

| Loose clamps or workpiece | Tighten clamps and secure extrusion |

| Incorrect feed rate | Adjust speed for smoother cutting |

| Machine vibration | Check machine setup and maintenance |

Tip: Always wear hearing protection when you cut aluminum extrusions. Earplugs or earmuffs keep your ears safe from loud sounds.

You should also check your cutting lubricant. If you do not use enough, friction goes up and noise gets worse. Put on lubricant before and while you cut to keep the blade cool and quiet.

If it is still noisy after you try these fixes, check your machine for old parts. Worn bearings, belts, or motors can make cutting louder. Keeping your machine in good shape helps stop these problems.

You can make cutting quieter by doing these things:

- Use the right blade for aluminum cutting.

- Hold your workpiece tight with strong clamps.

- Change your feed rate for steady cutting.

- Use lubricant to lower friction.

- Take care of your cutting tools.

Too much noise is not just annoying. It can mean bigger problems with your cutting process. Fixing the cause makes your workspace safer and helps you cut better.

Quick Checklist for Cutting Aluminum Extrusions

A checklist helps you stay safe and organized. Use it before, during, and after cutting aluminum extrusions. This way, you get good results every time.

Pre-Cut Checks

Check these steps before you start cutting. Experts say these checks help you avoid mistakes. They also keep your workspace safe.

| Recommendation | Description |

|---|---|

| Follow production plan specifications | Make sure your profile lengths match your project requirements. |

| Don’t feed too fast | Slow down to avoid damaging the ends of the aluminum extrusion. |

| Clamp ends securely | Hold the material tight to prevent movement during cutting. |

| Remove sharp edges and burrs | Clean up edges for a smooth, safe finish after each cut. |

Tip: Always check your setup before you cut. Getting ready saves time and stops waste.

Accuracy Tips

You want every cut to be exact. Machinists use these tips for better accuracy and safety.

- Use cutting lubricant or wax to lower friction and heat.

- Go slow and do not rush the cut.

- Leave a little extra and file down for perfect size.

- Clean your saw blade often so aluminum does not build up.

- Practice on scrap pieces before you cut your real material.

Try these best practices for even better results:

- Use a good measuring tool and mark your cut line clearly.

- Check your mark with a square to keep it straight.

- Use a miter saw or guided circular saw set to 90 degrees for straight cuts.

- After cutting, check the edge with a machinist’s square and fix with a file if needed.

Callout: Measuring carefully and cutting slowly helps you get a professional look. It also stops you from wasting material.

Post-Cut Cleanup

Clean up your workspace and tools after you finish cutting. This keeps your area safe and your tools working well.

- Use a dust collector to pick up metal pieces.

- Sweep away chips and dust after each cutting session.

- Check and clean all your tools to remove aluminum bits.

Note: Keeping your workspace clean stops accidents. It also makes your tools ready for next time.

If you follow this checklist, you will cut aluminum extrusions safely and accurately. You will also make your tools last longer and your projects look better.

You can get good cuts on aluminum extrusions if you follow the right steps. First, measure and mark your aluminum with care. Pick a blade made for aluminum. Hold the extrusion tight with clamps. Put cutting oil on the blade to keep it cool. Always wear safety glasses, gloves, and ear protection. After you cut, smooth out any sharp edges. Use a checklist for each project. Try new cutting methods as you learn more.

- Measure and mark with care.

- Pick the correct blade.

- Clamp the extrusion tight.

- Use oil or coolant.

- Wear safety gear.

- Clean up and smooth edges.

FAQ

You should use a carbide-tipped blade designed for non-ferrous metals. This blade gives you clean, accurate cuts and lasts longer than standard blades.

You can cut without lubricant, but you risk rough edges and blade wear. Lubricant keeps the blade cool and helps you get a smoother finish.

Clamp the extrusion tightly to your workbench. Use at least two clamps for longer pieces. This setup keeps your material steady and your cuts straight.

Wear safety glasses, cut-resistant gloves, and hearing protection. These items protect you from sharp edges, flying chips, and loud noise.

Deburr the edge with a file, sandpaper, or a deburring tool. Always check the edge by touch to make sure it feels smooth and safe.

You should not use a regular wood saw. The blade can dull quickly and may not cut cleanly. Always use a blade made for cutting aluminum.

Stop cutting right away. Check if the blade is sharp and the extrusion is clamped tightly. Adjust your feed rate and make sure you use enough lubricant.

Use a miter saw or adjust your saw’s angle setting. Mark your angle clearly with a square. Double-check your setup before you cut.