When you think about metal injection molding for your project, you notice its good points and bad points. Look at the table below to see the most common pros and cons:

| Advantages of Metal Injection Molding | Disadvantages of Metal Injection Molding |

|---|---|

| Makes lots of complex parts quickly | Needs a lot of money to start |

| Creates detailed features without extra steps | Too expensive for small batches |

| Lets you design many different shapes | Only works for small or medium parts |

| Has strong mechanical properties like other metals | Needs skilled workers for the process |

| Gives smooth surfaces so you may not need extra work | N/A |

This is why car and electronics companies pick metal injection molding instead of powder metallurgy or other ways. MIM is growing fast because it makes exact, tricky shapes with less waste. Looking at both the good and bad sides helps you choose the best way to make your products.

Key Takeaways

- Metal injection molding (MIM) makes complex parts fast and easy.

- MIM saves money for big jobs but costs more for small ones.

- This method uses many materials, like stainless steel and titanium.

- MIM parts are strong, so they work well in tough jobs.

- The process makes little waste, so it is good for the environment.

- Precision is a big plus, so parts match exact designs.

- Starting costs for tools and setup are high, which can stop small projects.

- MIM works best for small or medium parts, but not for big or thick ones.

Table of Contents

Metal Injection Molding Overview

What Is MIM

Metal injection molding helps make small metal parts. These parts can have tricky shapes and need to be very exact. This way of making things mixes how plastic injection molding works with the power of metal. You get strong parts that meet tough rules. Metal injection molding is special because it lets you design parts that are hard to make with old metal methods.

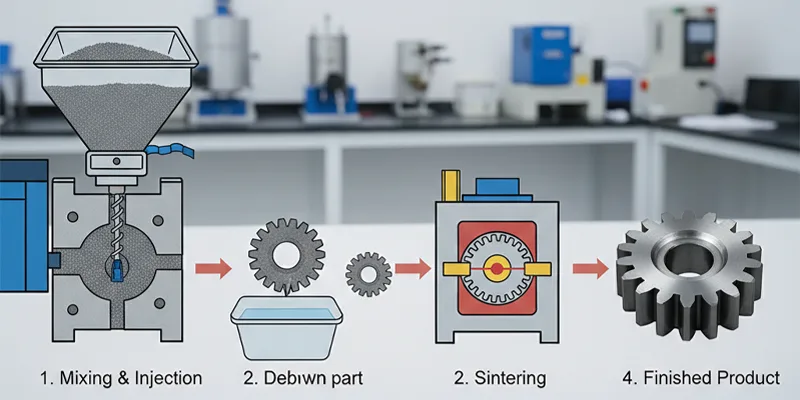

MIM Process

You use several steps to make parts with metal injection molding. Each step helps shape and make your part stronger.

Feedstock

First, you mix tiny metal powders with a plastic binder. This mix is called feedstock. It is easy to move and shape.

Molding

Next, you put the feedstock into a mold. The mold gives the part its shape. After it cools, you have a “green” part. This part looks right but is not strong yet.

Debinding

Then, you take out the binder from the green part. Now you have a “brown” part. It is weak but ready for the next step.

Sintering

You heat the brown part in a furnace. The metal pieces stick together. This makes a solid part with great strength.

Tip: Metal injection molding uses these steps to make parts with hard shapes and close measurements. This makes it different from other ways like powder metallurgy or die casting.

Metal Injection Molding Applications

Metal injection molding is used in many fields. Companies pick this way because it makes strong and detailed parts. The table below shows where metal injection molding is used most:

| Industry | Notable Applications |

|---|---|

| Defense Industry | Weapon parts, including 5.56mm, 7.62mm, and .50 MG parts |

| Consumer Electronics | Components like keyboard keys, mouse shells, and frames |

| Medical Devices | Surgical instruments, diagnostic kits, prosthetic parts |

| Automotive | Dashboard components, light housings, and bumpers |

| Household Items | Kitchen appliances, containers, and plastic cutlery |

| Packaging | Beverage containers, food storage solutions |

| Agricultural Products | Tool handles, irrigation fittings, and seed trays |

| Musical Instruments | Keys for wind instruments, drum parts, and music stands |

| Furniture | Chair bases, ergonomic components, and decorative elements |

AFI Industrial Co., Ltd is one company that makes good metal injection molding parts for these fields. If you need strong parts, you can find suppliers who know what your project needs.

Advantages of Metal Injection Molding

Complex Geometries

Metal injection molding lets you make parts with hard shapes. You can design shapes that old machines cannot make. You do not need to worry about tools reaching small spaces. You also do not need extra steps for tiny details. This process shapes metal like plastic injection molding does. You get parts with shapes almost as complex as plastic ones. You can put many features into one part. This saves time and makes the part better.

- Metal injection molding helps you make tricky parts without much extra cost.

- Old ways have trouble with hard shapes, but MIM keeps making parts fast.

- You get very accurate and good quality parts every time.

If you need lots of special parts, AFI Industrial Co., Ltd can help. They know how to make strong and exact parts for you.

High Efficiency

Metal injection molding is very fast and efficient. You can make many parts quickly and they all look the same. The process takes less time and needs fewer workers. This saves you money and materials. If you need thousands or millions of parts, MIM keeps costs low and quality high.

- MIM makes hard and exact parts fast, saving time and money.

- You get better speed and more parts than with old machines.

- This way is great for making lots of good parts for cars and electronics.

- When you make more parts, each one costs less, so MIM saves money.

You get the same good parts in every batch. This makes MIM great for jobs that need fast and steady results.

Material Versatility

You can pick from many materials with metal injection molding. This means you can choose the best one for your job. You might need strong, tough, or special metals. MIM can use stainless steel, titanium, cobalt-chromium, and hot alloys. You can also use copper, nickel, and other metals.

- MIM gives you many choices, so you can make parts just right.

- You can pick metals that are strong, last long, and work well.

- This helps you get good parts and save money on many jobs.

AFI Industrial Co., Ltd uses new materials to make strong and exact parts. You can trust them to help you pick the right metal for your needs.

Mechanical Properties

Metal injection molding makes parts that are strong and reliable. The process gives parts great mechanical properties. After sintering, the parts get tough and last long. You can use these parts where strength is important, like in cars and planes.

Metal injection molding lets you make small and tricky parts that stay strong under pressure. You do not need molten metal for this, which is different from die casting and investment casting. You can trust each part to be high quality. The process mixes plastic molding’s flexibility with metal’s strength. The parts last longer and work better.

AFI Industrial Co., Ltd uses advanced methods to make sure your parts meet strict rules. You can count on these parts for hard jobs in many fields.

Note: Metal injection molding helps you get strong metal parts that are almost the right shape and size. These parts have great strength and last a long time.

Cost-Effectiveness

Metal injection molding saves you money when you make lots of parts. The price for each part goes down as you make more. This way works best for small and detailed parts. Die casting may cost less for big and simple parts, but metal injection molding is better for parts that need to be exact and complex. CNC machining often costs more because it takes longer and wastes more material.

- Metal injection molding is great for making lots of detailed parts.

- You spend less on workers and materials than with old ways.

- The process needs fewer extra steps, so you save time and money.

AFI Industrial Co., Ltd helps you spend less by using smart molding methods. You get good quality and more value for your money.

Low Waste

Metal injection molding helps the environment. This process uses almost all the metal you put in. You waste less metal than with older ways. Near-net-shape forming means you do not need much extra cutting, so you throw away less. Companies save money on materials and make less trash.

| Aspect | Sustainable Practices | Traditional Methods |

|---|---|---|

| Waste Generation | Recycling and smart molding cut down on waste. | Older ways make more waste and use less efficient steps. |

- Metal injection molding uses up to 97% of the material.

- You save money and help the planet by wasting less.

AFI Industrial Co., Ltd uses smart recycling and molding. You get strong parts and help the earth at the same time.

Precision

Metal injection molding helps you make very exact parts. This process lets you create metal pieces with tight tolerances. Every part matches your design each time. Precision is important in cars and medical tools. Small mistakes can cause big problems in these fields.

- High precision means your parts are always accurate.

- Mistakes can make products not work well.

- You need precision for important jobs.

Many things help you get this accuracy:

- Tooling design shapes your part just right.

- Picking the right material gives good fit and strength.

- Process control keeps each step correct.

- Quality checks find errors before shipping.

AFI Industrial Co., Ltd uses strong controls and smart tools. They help you get the precision you want. You can trust them for parts that meet strict rules.

Surface Finish

You want parts that look nice and work well. Metal injection molding gives a smooth surface finish. It is often better than other ways. You can get a surface roughness of Ra 1μm. This is smoother than Ra 1.6 to 3.2 μm from die casting. Smooth parts may not need extra polishing or machining.

Sometimes, you might see small rough spots or shrinkage after sintering. Die casting can give a great as-cast surface. But metal injection molding still makes high-quality finishes for most jobs. Your parts look good and work well.

AFI Industrial Co., Ltd works hard to give top surface quality. You can count on them for parts that look and work great.

Disadvantages of Metal Injection Molding

High Initial Cost

Metal injection molding costs a lot at the start. This is a big problem for many projects. You need expensive molds and special machines. You must pay for design and setup before making parts. These costs are hard for small businesses or small orders.

- Tooling costs change based on:

- Mold design. Hard shapes need better tools.

- Maintenance. Tools must stay in good shape.

- Customization. Special designs cost more.

Other things also make costs go up:

- Material and worker costs.

- Design difficulty and energy use.

- Batch size and special cost tools.

If you make many parts, each part costs less later. For small batches, the high cost is a big problem. AFI Industrial Co., Ltd can help you figure out these costs and see if this way works for you.

Note: High starting cost makes metal injection molding bad for prototypes or small jobs.

Size Limitations

Another problem is the size of parts you can make. Metal injection molding works best for small and medium parts. Big or thick parts can have problems with quality.

| Aspect | Details |

|---|---|

| Wall Thickness | Best is 1 mm to 6 mm |

| Maximum Dimension | Usually 25 mm to 35 mm, biggest is 250 mm |

| Mass | 0.1 g to 200 g, best is about 10 g |

| Thinnest Wall Thickness | 0.3 mm |

| Avoid Thick Sections | Over 12.5 mm can cause problems |

You must design parts that fit these limits. If not, you may get defects like warping or missing spots. If your part is too big, you need another way to make it. This problem means you cannot make large products with this process.

Material Restrictions

Picking materials is another problem. Not all metals work with metal injection molding. Some cannot handle the heat or pressure. Others may break or form defects.

| Material Type | Reason for Unsuitability |

|---|---|

| Low Melting Point Materials | Do not melt enough under high heat and pressure |

| Porous Materials | Air pockets cause problems during molding |

| Multiphase Combinations | Different densities make parts separate |

| Flexible Rubbers | Stretchiness makes them hard to remove from molds |

- Low melting point materials do not melt well.

- Porous materials trap air and cause problems.

- Multiphase combinations separate because of different densities.

- Flexible rubbers stretch and stick, so they are hard to take out.

You must check if your material works with this process. If not, you need another way to make your part. This problem limits what materials and designs you can use.

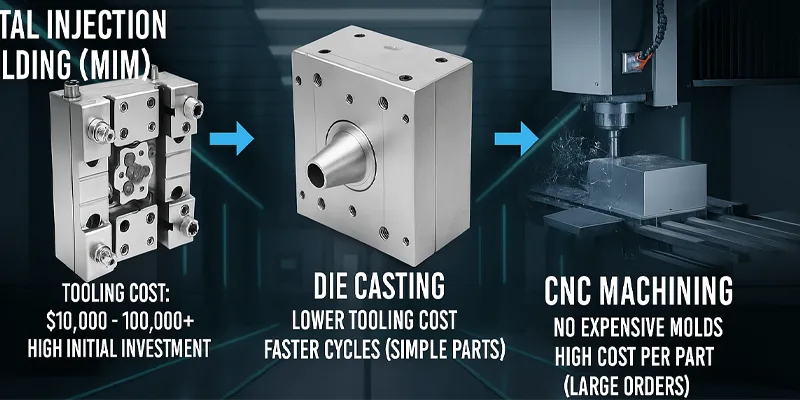

Tooling Expense

You face high tooling expenses when you choose metal injection molding. The molds and tools for MIM cost much more than those for other methods. You need to invest a lot before you start making parts. Here is how MIM tooling costs compare to other methods:

- Tooling for metal injection molding can range from $10,000 to over $100,000. This is usually higher than the cost for die casting molds.

- Die casting offers lower tooling costs and faster cycles, which can help you save money if your parts are simple.

- CNC machining does not need expensive molds, but the cost per part stays high, especially for large orders.

- MIM becomes more cost-effective when you make many complex parts. The high tooling cost spreads out over a large number of pieces.

If you plan to make only a few parts, the high tooling expense may not make sense. AFI Industrial Co., Ltd can help you decide if your project fits MIM or if another method works better.

Lead Time

You need to plan for longer lead times with metal injection molding. The time from design to finished part depends on how complex your part is and how busy the shop is. Here are some things to keep in mind:

- Simple molds can be ready in 2 to 4 weeks. If your part is easy, you get results faster.

- Complex molds may take 6 to 8 weeks to finish. More features mean more time.

- If you already have a part design, mold design can start right away and usually takes 6 to 8 weeks.

- If you need help with the design, you may spend 2 to 5 weeks just on planning.

- For production runs up to 10,000 units, simple molds can be ready in about 2 to 3 weeks.

- Large orders or complex parts can push lead times to a month or more.

You should talk to your supplier, like AFI Industrial Co., Ltd, early in your project. This helps you set a clear timeline and avoid delays.

Shrinkage Control

Shrinkage control is a big challenge in metal injection molding. The metal part shrinks as it cools and sinters. You must plan for this shrinkage to get the right size and shape. Many factors affect how much your part will shrink:

| Factor | Impact on Shrinkage |

|---|---|

| Material Selection | Different alloys shrink at different rates. |

| Cooling Rate | Fast cooling makes parts shrink more. |

| Part Geometry | Complex shapes and thin walls increase shrinkage. |

If you do not control shrinkage, you can face several problems:

- Your parts may not match the size you need.

- Warping or distortion can make parts unusable.

- Weak spots can lower the strength of your parts.

You need skilled engineers and good process control to manage shrinkage. AFI Industrial Co., Ltd uses advanced tools to help you get accurate and strong parts. Always check with your supplier about how they handle shrinkage before you start your project.

Small Batch Cost

You may find that metal injection molding does not work well for small production runs. The cost of making molds is high. If you only need a few dozen or a few hundred parts, the price per part can be much higher than with other methods. You pay thousands of dollars just for the mold, even before you make your first part.

- For small batches, the cost of injection molding is much higher than other options.

- Silicone casting or 3D printing often costs less and takes less time for low-volume jobs.

- You only see savings with metal injection molding when you make large numbers of parts.

If your project needs a small batch, you should look at other ways to make your parts. AFI Industrial Co., Ltd can help you compare your options and choose the best method for your needs.

Post-Processing

After you finish molding, you still need to do more work on your parts. Metal injection molding always needs debinding and sintering. These steps use special equipment and take extra time, especially for complex shapes. You may also need to add finishing steps like machining or heat treatment to get the exact size or surface you want.

- Debinding adds cost because it needs special machines and careful control.

- Sintering uses high heat and a controlled space, which increases your costs, but it works better for big batches.

- You may need extra finishing, such as machining or polishing, to meet tight tolerances or get a smooth surface.

These extra steps can slow down your project and raise your total cost. You should plan for post-processing when you choose metal injection molding.

Environmental Factors

Metal injection molding helps you use almost all your material, which means you waste less metal. The process can use up to 97% of the input material, making it more efficient than many old methods. You also need fewer steps, which can lower your energy use and reduce your carbon footprint. Many factories use advanced filters to cut down on harmful emissions.

- You waste less metal because of high material efficiency.

- Fewer steps mean you use less energy and create less pollution.

- Modern plants use filters to keep the air cleaner.

However, if you only make a small number of parts, the total energy use and environmental impact can be higher. This happens because you still need to make the mold and use solvents, even for a small batch.

When you plan your project, think about both the good and bad effects on the environment. AFI Industrial Co., Ltd can help you find ways to make your process greener and more efficient.

MIM vs Other Methods

Powder Metallurgy

You might ask how metal injection molding is different from powder metallurgy. Both use metal powders, but they are good for different jobs. Metal injection molding makes parts that are stronger and last longer. These parts can also bend more before breaking. Powder metallurgy parts are less dense, about 80% to 90%. This is good if you need parts with tiny holes, like self-lubricating bearings.

Here is a quick comparison:

| Process | Mechanical Properties | Cost | Application Suitability |

|---|---|---|---|

| MIM | High strength, excellent surface finish | Higher initial costs | Best for small, complex parts in medical, aerospace, and electronics |

| PM | Controlled porosity, lower density | Cost-effective for high-volume parts | Common in automotive and industrial uses |

- MIM gives you stronger parts, but it costs more at first.

- PM is better for simple shapes and big orders when you want to save money.

If you need tiny, detailed parts for tough jobs, MIM is the best pick. If you only need basic shapes and lots of them, PM is cheaper.

CNC Machining

CNC machining cuts away metal to make your part. You can use almost any metal with this method. It is very accurate, but it wastes more metal. Each part takes longer to make. The setup does not cost much, but each part still costs a lot, even if you make many.

- CNC machining does not get much cheaper per part as you make more.

- If you need over 20,000 parts, MIM can save you 60-70% per part compared to CNC machining.

MIM is better for making lots of small, tricky parts. You save time and money when you order more. For just a few parts or samples, CNC machining might be better.

Die Casting

Die casting pushes melted metal into a mold using high pressure. You get smooth parts and good accuracy. But MIM makes even smoother parts and tighter fits for small pieces.

| Process | Surface Finish | Dimensional Accuracy |

|---|---|---|

| MIM | Very good, smooth as molded finish | Excellent |

| Die Casting | Good surface finish | Good dimensional accuracy |

- MIM tolerance: 1~2%

- Die casting tolerance: 2~3%

Pick MIM if you need very exact, tiny parts with a smooth finish. Die casting is good for bigger parts or if you want faster work and cheaper tools.

Additive Manufacturing

Additive manufacturing builds metal parts one layer at a time. It uses 3D printing to make shapes that old tools cannot reach. You can design parts with curves, hollow spots, and thin walls. This method lets you change designs fast. You do not need new molds for every change.

Let’s look at how metal injection molding and additive manufacturing compare for tricky metal parts:

| Feature | Metal Injection Molding (MIM) | Additive Manufacturing (AM) |

|---|---|---|

| Complex Geometries | Makes thin walls and hard shapes | Builds almost any shape, even with undercuts |

| Cost-Effectiveness | Saves money for big batches | Best for prototypes and small batches |

| Consistent Quality | Automated machines give high-quality parts | Quality can change between batches |

| Material Selection | Uses many metals like stainless steel and titanium | Limited by printable alloys |

| Density & Strength | High density and strong parts | Lower density, may need extra treatments |

Metal injection molding gives you many benefits. You can make thousands of parts that are all the same. Machines do most of the work, so you see fewer mistakes. You can pick from many metals. MIM parts are strong and work well in tough jobs.

Additive manufacturing lets you change your part’s shape easily. You do not pay extra for new designs. You waste less material because you only build what you need. You can make test parts quickly and try new ideas.

Tip: If you want to test a new design or make a few parts, additive manufacturing saves time and money. You can print a part, check if it fits, and change the design before making lots of them.

Additive manufacturing has some problems. You often need extra steps like machining or heat treatment to finish the part. Printing can cause stress inside the part, so you may need to fix it. You cannot use as many metals as with MIM. Printed parts may not be as strong or dense.

MIM also has challenges. You pay a lot at the start for molds and machines. You wait longer for setup. If you change the design, you need new molds, which costs more and takes time.

- MIM is best for big orders and strong parts.

- Additive manufacturing is good for test parts and custom designs.

- Both ways help you make hard shapes, but each fits different needs.

AFI Industrial Co., Ltd knows both MIM and advanced manufacturing. You can ask their engineers for help. They will help you pick the best method, material, and design for your project.

Choosing Metal Injection Molding

Material Choice

You have to pick the right metal for your project. The metal you choose changes how your parts work. It also affects how long your tools last. In metal injection molding, you use metals like low alloy steels, magnetic alloys, stainless steel, titanium alloys, tool steel, and tungsten alloys. Each metal gives your parts special features. Stainless steel does not rust. Tool steel is very strong.

Think about what your part needs to do. Some metals can take high heat or strong hits better than others. Your tools must handle high pressure and heat too. Tool steels like H13, S7, and A2, and hard stainless steel alloys, are good choices. They do not wear out fast and last longer. If you want strong tools and good parts, talk to experts like AFI Industrial Co., Ltd.

Tip: Picking the right metal helps your parts work well and your tools last longer. This saves you time and money.

- Common MIM metals:

- Low alloy steels

- Magnetic alloys

- Stainless steel

- Titanium alloy

- Tool steel

- Tungsten alloy

Part Size

You need to think about how big your part is. Metal injection molding works best for small and medium parts. If your part weighs less than 200 grams, you get the best results. Bigger parts over 200 grams are not as easy to make. You cannot fit many big parts in one mold.

| Part Size (grams) | Production Efficiency Impact |

|---|---|

| Under 200 | Best for making lots of parts |

| Larger than 200 | Not as good because molds hold fewer parts |

If your part is big, it may cost more and take longer to make. Try to keep your part size in the best range for good results.

Production Volume

You should match how many parts you need to the best way to make them. Metal injection molding is great when you need lots of parts. The first setup costs a lot, but each part gets cheaper when you make more. If you only need a few parts, each one costs more. Other ways, like metal additive manufacturing, may be better for small batches.

- MIM saves money when you make many parts.

- Making only a few parts costs more for each one.

- Additive manufacturing is good for small batches and test parts.

If you want thousands or millions of parts, metal injection molding is the best deal. For smaller jobs, ask AFI Industrial Co., Ltd about other ways that might work better for you.

Cost Factors

You need to look at all the costs before you choose metal injection molding. The price for your project depends on several things. You pay for tooling, materials, labor, and post-processing. Each part of the process adds to your total cost.

- Tooling: You spend the most money on molds. Complex shapes and tight tolerances make molds more expensive.

- Materials: The type of metal you pick changes the price. Stainless steel and titanium cost more than basic alloys.

- Production Volume: Making more parts lowers the cost per piece. Small batches cost more because you spread tooling costs over fewer parts.

- Post-Processing: You may need extra steps like machining or polishing. These steps add to your budget.

Tip: You can save money by designing parts that fit standard mold sizes and by choosing metals that are easy to process.

AFI Industrial Co., Ltd helps you plan your budget. Their engineers can show you ways to lower costs and improve efficiency. You get a clear price breakdown before you start production.

| Cost Factor | Impact on Budget |

|---|---|

| Tooling | High upfront investment |

| Material | Varies by metal type |

| Labor | Skilled workers needed |

| Post-Processing | Adds extra cost |

| Volume | More parts, lower cost |

Tolerance Needs

You must decide how precise your parts need to be. Tolerance means how close your part matches the design. Tight tolerances make your parts fit better and work well in tough jobs. Metal injection molding gives you good accuracy, but very tight tolerances may need extra steps.

- Standard MIM tolerances are ±0.3% of the part’s size.

- If you need tighter tolerances, you may need machining after molding.

- Loose tolerances cost less and speed up production.

Note: Always tell your supplier about your tolerance needs. This helps avoid mistakes and delays.

AFI Industrial Co., Ltd checks every part for accuracy. Their team uses advanced tools to measure and control tolerances. You get parts that meet your standards every time.

Lead Time

You want to know how long it takes to get your parts. Lead time means the total time from design to finished product. Metal injection molding takes longer than some other methods because you need to make molds and set up machines.

- Simple parts take about 4 to 6 weeks.

- Complex designs may need 8 to 12 weeks.

- Changes in design or material can add more time.

You should plan your project early. Talk to your supplier about your timeline. AFI Industrial Co., Ltd gives you a clear schedule and updates you at every step. You stay informed and avoid surprises.

Tip: Start your design and mold planning as soon as possible. Early action helps you meet your deadlines and keeps your project on track.

Supplier Selection

Picking the right metal injection molding supplier is very important. You want a partner who knows what you need and gives you good parts every time. Not all suppliers are the same. You should look at your choices before you pick one.

First, check how much experience the supplier has. If they have worked with metal injection molding for many years, they can handle hard jobs and fix problems fast. A skilled supplier helps you meet tough rules and lowers your risk.

You also need a supplier who works with you on design and engineering. Working together helps you make better parts, spend less money, and avoid mistakes. If your supplier helps you with your plans, you get parts that fit your needs and cost less.

Modern machines and new ways of making things are important too. Suppliers with the best equipment can make tiny parts and fill big orders quickly and correctly. Automated machines and careful checks make sure every part is good.

Precision matters a lot. You want a supplier who can make parts that fit very well and look nice. This makes sure your parts work right and look good.

Here is a table to help you compare what to look for in a supplier:

| Key Consideration | Description |

|---|---|

| Proven Expertise | Many years of experience and strong knowledge of MIM. This lowers risk and helps your parts meet your needs. |

| Engineering and Design Collaboration | Working closely with customers to improve designs and make parts better. |

| State-of-the-Art Manufacturing | New machines for small, tricky parts. Automation and checks for big orders. |

| Ability to Deliver Precision | Can finish parts and do extra steps for tight fits and good quality. |

You should ask about how the supplier checks quality. Good suppliers test and check every part carefully. Look for companies with certificates like ISO 9001 or other special standards. These show they care about making good parts every time.

- Ask about how they check quality to make sure parts are always good.

- Look for strong testing and careful checks.

- Check if they have certificates like ISO 9001 or other special ones.

AFI Industrial Co., Ltd is a supplier with lots of skill, new machines, and works well with customers. If you pick a supplier like this, your project will do well.

When you choose metal injection molding, you gain high precision, complex shapes, and efficient production. You also face high initial costs and size limits. To decide if this method fits your project, weigh your part’s complexity, production volume, and budget. For the best results, talk with experts like AFI Industrial Co., Ltd. They can help you match your needs to the right solution.

FAQ

You can use metals like stainless steel, titanium, tool steel, and nickel alloys. Each metal makes your part strong in different ways. AFI Industrial Co., Ltd can help you choose the best metal for your needs.

Parts can be as light as 0.1 grams. This process works best for small or medium pieces. You still get exact shapes, even for tiny parts.

Metal injection molding costs a lot for prototypes. The tooling price is high, so it is better for making many parts. For just a few samples, try 3D printing or CNC machining.

It usually takes 4 to 8 weeks to get your parts. If your design is tricky, it might take longer. Talk to your supplier early to plan your schedule.

Yes, you must do debinding and sintering after molding. Sometimes, you also need machining or polishing for smoothness or tight fits.

Most leftover metal powder can be recycled. This helps you waste less and save money. Many suppliers use smart ways to recycle.

Metal injection molding is used in cars, electronics, medical devices, and defense. Companies pick it for strong, detailed, and reliable parts.

Look for a supplier with lots of experience and good machines. They should check quality carefully. AFI Industrial Co., Ltd gives expert help and makes high-quality parts for many jobs.