Alloy 5052 is a type of aluminum known for its impressive alloy 5052 properties. You see it in many items around you. It is strong and lightweight, and it does not rust easily. These alloy 5052 properties make it useful for manufacturing a wide range of products today. Many industries utilize it because it performs well for various applications. The table below shows where you find this material most:

| Industry | Description |

|---|---|

| Automotive | Used in car parts and frames. |

| Building | Used in building supplies and design. |

| Consumer Electronics | Found in gadgets and their parts. |

| Others | Used for many other things. |

Alloy 5052 can assist with both challenging and straightforward tasks. You can rely on its properties for numerous needs.

Key Takeaways

- Alloy 5052 is strong and light. It does not rust easily. This makes it good for many products.

- Many industries use Alloy 5052. These include cars, buildings, and electronics. It works well in many ways.

- Magnesium and chromium are the main parts of Alloy 5052. These make it stronger and help stop rust.

- Alloy 5052 is simple to shape and weld. You can make hard parts with it. It does not crack when shaped.

- It does not rust much, so it is great for boats and docks.

- Alloy 5052 costs less than other alloys. It lasts a long time and does not cost a lot.

- Cleaning and checking Alloy 5052 often helps it look nice. This also helps it last longer.

- Picking the right thickness of Alloy 5052 is important. It helps balance strength and how easy it is to use.

Table of Contents

Alloy 5052 Overview

Composition

Alloy 5052 has aluminum mixed with other elements. Magnesium is the main element added. This makes the material strong and helps stop rust. Chromium is also in alloy 5052, but there is less of it. The table below shows how much magnesium and chromium are in alloy 5052:

| Element | Percentage by Weight |

|---|---|

| Magnesium | 2.2% – 2.8% |

| Chromium | 0.15% – 0.35% maximum |

Magnesium makes alloy 5052 tough and long-lasting. Chromium gives extra help against rust. This mix lets alloy 5052 work well in hard places. The high magnesium amount makes alloy 5052 special compared to other aluminum alloys. This mix gives alloy 5052 its special properties.

When you look at alloy 5052 and other aluminum alloys, you see how the mix changes its strength. The table below shows some main differences:

| Property | 5052 Aluminum | 6061 Aluminum |

|---|---|---|

| Tensile Strength | 210-260 MPa | 290-310 MPa |

| Yield Strength | ~130 MPa | ~240 MPa |

| Hardness (Brinell) | ~61 HB | ~95 HB |

| Fatigue Strength | Moderate | Higher |

Alloy 5052 is not as strong as 6061 aluminum. But the high magnesium helps it fight rust better and makes it easier to shape.

Tip: Pick alloy 5052 if you want metal that does not rust and bends easily.

Key Features

Alloy 5052 has many features that make it useful. The best one is its strong resistance to rust. This makes it great for things near water or in boats. You can use it for boat hulls, docks, and places with saltwater.

Alloy 5052 is simple to work with. You can bend or shape it without problems. This means you can use it for lots of products. You do not need special tools to get good results.

Here are some main features of alloy 5052:

- Excellent weldability, good for welded joints.

- High fatigue strength, so it lasts under stress.

- Not heat-treatable, so it is not as strong as 6061 and 7075.

You can weld alloy 5052 and not worry about cracks. It stays strong when used again and again. You cannot make it stronger with heat, but it is still a good choice for many jobs.

Because it is easy to shape, alloy 5052 works well for things that need bending. This makes it popular in cars, boats, and buildings. It is easy to make and take care of.

Note: If you need metal that resists rust, is easy to make, and is strong, alloy 5052 is a good choice for your projects.

Alloy 5052 Properties

Corrosion Resistance

You need a material that can handle tough places. One of the most important alloy 5052 properties is how well it fights corrosion. This means you can use it where water, salt, or chemicals might hurt other metals.

- Alloy 5052 has little copper, so it does not corrode in saltwater.

- Magnesium in the alloy makes it even better at stopping corrosion, more than alloys like 6063.

- When air or water touches alloy 5052, it forms a thin aluminum oxide layer. This layer keeps the metal safe from more harm.

If you work with boats or docks, you will see that alloy 5052 properties protect your projects from rust. It does not rust fast like steel. You can trust it for marine jobs, like hulls and frames, because it stays strong and looks nice for years.

Tip: Pick alloy 5052 for things that face saltwater or bad weather. Its corrosion resistance helps you save time and money on fixing things.

Strength and Formability

Another big part of alloy 5052 properties is its mix of strength and formability. You get a metal that is strong for many uses, but also easy to bend and shape.

Here is a table that shows the tensile strength of alloy 5052 in different tempers:

| Alloy-Temper | Tensile Strength (ksi) |

|---|---|

| 5052-O | 28 |

| 5052-H34 | 38 |

| 5052-H38 | 42 |

You can see that alloy 5052 is strong, especially in H34 and H38 tempers. This makes it good for parts that need to be strong but also shaped.

Let’s look at how alloy 5052 bends compared to other aluminum alloys:

| Property | 3003 | 5052 | 6061 |

|---|---|---|---|

| Elongation (%) | 4 – 40 | 7 – 25 | 8 – 30 |

| Workability | Easier to form | Good formability | Less formable |

| Strength | Weakest | Intermediate | Highest |

You will find that alloy 5052 properties give you a good mix of strength and flexibility. You can bend, roll, or stamp it and it will not crack. This makes it great for panels, covers, and parts that need special shapes.

Note: If you need a metal that bends easily but stays strong, alloy 5052 is a smart pick.

Weldability

Weldability is another great thing about alloy 5052 properties. You can join pieces of this alloy with different welding methods, and the joints stay strong.

Here is a table showing common welding methods for alloy 5052 and their weld strengths:

| Welding Method | Description | Typical Weld Strength |

|---|---|---|

| TIG welding | Best for thin plates (≤6mm), uses argon gas. | Close to base material strength |

| MIG welding | Good for thicker plates (≥6mm), uses mixed gas. | Varies with thickness |

| Laser welding | Fast and precise, low distortion. | High strength |

| ER5356 | Versatile filler, strong welds, resists corrosion. | Close to base material strength |

| ER5183 | For high-stress parts, very strong welds. | Up to 250MPa |

You can weld alloy 5052 without worrying about cracks or weak spots. The welds are often as strong as the original metal. This makes it a top pick for building boats, tanks, and frames where strong joints are needed.

Tip: Use alloy 5052 when you need to weld parts together. Its weldability helps you make strong, long-lasting products.

Alloy 5052 properties—corrosion resistance, strength and formability, and weldability—make it a top choice for many industries. You get a material that works hard and lasts a long time, even in tough places.

Surface Finish

When you pick alloy 5052, you get a metal that looks nice and smooth. The way the surface looks is important. It changes how your product looks and how strong it is. You can choose different ways to treat the surface to make it better.

You might use polishing, anodizing, or painting to change the surface. Each way gives a different result. Polishing makes the metal shiny and smooth. Anodizing puts a layer on top that helps stop scratches and rust. Painting adds color and more protection.

Ultrasonic shot peening can make alloy 5052 resist rust much better. It changes the surface to help stop corrosion. This process can lower the corrosion rate by 72.90%. But if you do it too long, it might hurt the resistance.

Think about where you will use the metal. If you need it outside or near water, a good finish helps it last longer. A smooth surface keeps dirt and water off. This makes cleaning easy and helps stop rust.

Here are some facts about alloy 5052 and its surface finish:

- Alloy 5052 does not have copper, so it resists saltwater rust.

- People use it in boats and chemical places because it stays strong and looks good.

- In some soils, small pits can form, depending on what is in the soil.

- Lots of magnesium helps it fight chemicals, even strong nitric acid.

You can use alloy 5052 for boats, tanks, and outdoor panels. The right finish keeps your things safe and looking new. If you want metal that fights rust and stays nice, alloy 5052 is a good pick.

5052 Aluminum Sheet Metal

Sheet Metal Work

You see 5052 aluminum sheet metal in many places. This material works well for heat exchangers, flooring panels, and general fabrication. You can use it for covers, enclosures, and panels in buildings or vehicles. Many industries choose 5052 aluminum sheet metal because it bends easily and resists rust.

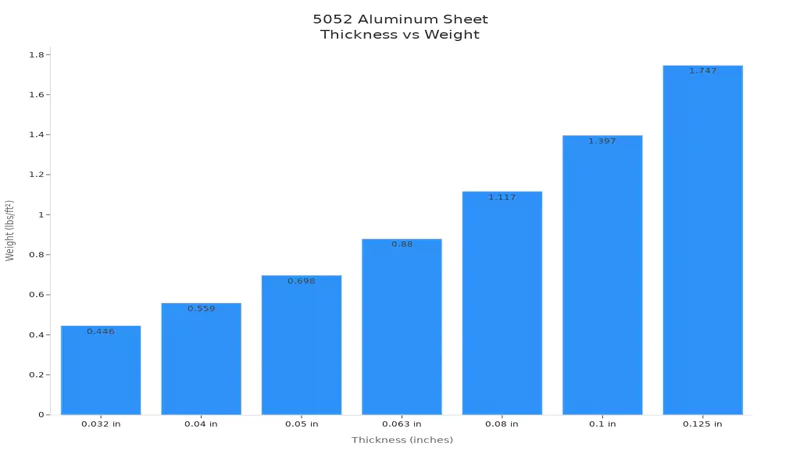

Most suppliers offer 5052 aluminum sheet metal in standard sizes. You often find sheets that measure 48 inches wide and 120 inches long. The thickness can vary, so you can pick what fits your project best. Here is a table that shows common thicknesses and weights:

| Thickness (inches) | Width (inches) | Length (inches) | Weight (lbs/ft) |

|---|---|---|---|

| 0.032 | 48.00 | 120.00 | 0.446 |

| 0.04 | 48.00 | 120.00 | 0.559 |

| 0.05 | 48.00 | 120.00 | 0.698 |

| 0.063 | 48.00 | 120.00 | 0.880 |

| 0.08 | 48.00 | 120.00 | 1.117 |

| 0.1 | 48.00 | 120.00 | 1.397 |

| 0.125 | 48.00 | 120.00 | 1.747 |

You can also look at this chart to see how the weight changes with thickness:

Tip: Choose the right thickness of 5052 aluminum sheet metal for your project. Thicker sheets give more strength, while thinner sheets are easier to shape.

Fabrication Methods

You can shape 5052 aluminum sheet metal in many ways. Factories start by making aluminum ingots with the right mix of elements. Workers roll these ingots into thin sheets. They check the thickness and strength during each step. Sometimes, they use cold working or annealing to make the sheets stronger or more flexible.

You can cut, bend, and weld 5052 aluminum sheet metal with common tools. You do not need special machines for most jobs. This makes it easy for you to use in workshops or on job sites. You can stamp or punch holes for panels and covers. You can also weld pieces together for tanks or frames.

Note: 5052 aluminum sheet metal does not crack easily when you bend or weld it. You get strong parts that last a long time.

Maintenance

You want your 5052 aluminum sheet metal to last. Good maintenance helps you keep it in top shape. Here are some simple steps you can follow:

- Schedule regular inspections to check for wear, dents, scratches, or corrosion.

- Clean regularly to prevent dirt and debris buildup that can trap moisture.

- Use rust inhibitors like corrosion-resistant primers or oil coatings to protect against corrosion and rust.

- Handle sheet metal properly with padded clamps or non-abrasive lifting straps to avoid damage.

- Store sheets in a dry, ventilated area away from moisture and direct sunlight.

If you follow these steps, you help your 5052 aluminum sheet metal stay strong and look good. You spend less time fixing problems and more time using your finished products.

Remember: Clean and inspect your 5052 aluminum sheet metal often. Proper care keeps it working for years.

Industrial Applications

Marine Uses

You often see alloy 5052 in marine applications. This alloy works well for boats, docks, and other structures near water. You can trust it because it stands up to saltwater and harsh weather. Many boat builders pick alloy 5052 for these reasons:

- It resists corrosion, even in salty or wet places.

- You can weld it without losing strength or corrosion resistance.

- You can shape it into complex forms for hulls and decks.

You find alloy 5052 in boat hulls, gangways, and dock panels. The metal keeps its strength and looks good for years. You do not need to worry about rust or damage from water. This makes your marine projects last longer and need less repair.

Tip: If you work on boats or docks, choose alloy 5052 for parts that face water every day.

Automotive Uses

You also see alloy 5052 in many vehicles. Car makers use it for body panels, floorboards, and other structural parts. You get a strong and light material that helps cars perform better. Here are some reasons why you might choose alloy 5052 for automotive work:

- High strength-to-weight ratio helps make lighter vehicles.

- Excellent corrosion resistance keeps parts safe from road salt and moisture.

- Good weldability lets you join parts easily.

Alloy 5052 is a top choice for fuel lines. It gives you both safety and durability. The table below shows why it works so well for this job:

| Feature | Benefit |

|---|---|

| Strength | Stronger than 5251 and 3003 aluminum alloys, suitable for fuel lines. |

| Corrosion Resistance | Resists corrosion well, ideal for marine and challenging environments. |

| Stress Corrosion Cracking | Better resistance to SSC than many other aluminum alloys, ensuring reliability. |

You can use alloy 5052 for parts that face vibration and changing loads. It has high fatigue strength, so it does not fail under stress. The natural oxide layer protects fuel lines from harmful substances. This keeps your vehicle safe and running well.

Note: Alloy 5052 helps you build cars and trucks that last longer and need fewer repairs.

Architectural Uses

You find alloy 5052 in many building and construction projects. Builders use it for facades, roofs, and decorative elements. You can also see it in architectural panels, siding, trim, and curtain walls. Here is why you might pick alloy 5052 for these jobs:

- It resists corrosion, so it works well outdoors.

- It has moderate strength for panels and covers.

- You can form it into many shapes for design needs.

- The smooth finish looks attractive on buildings.

You can use alloy 5052 for both practical and decorative parts. It keeps its appearance over time, even in tough weather. This makes it a smart choice for modern buildings and creative designs.

Tip: If you want a metal that looks good and lasts, alloy 5052 fits many architectural needs.

Chemical Handling

Sometimes you need metal that can handle chemicals. Alloy 5052 works well for many chemical jobs. People use it for tanks, pipes, and trays that hold or move chemicals. Magnesium in alloy 5052 helps stop rust from water and weak chemicals. You can trust it to protect against rust in many places.

If you compare alloy 5052 to stainless steel, you see some differences. Stainless steel is better with strong acids and bases. Alloy 5052 is good near the ocean but not as good with strong alkalis or halide acids. You should always check what chemicals you use before picking a metal.

| Material | Corrosion Resistance in Chemical Handling | Notes |

|---|---|---|

| Alloy 5052 | Good in marine environments, but less resistant to strong alkalis and halide acids | Susceptible to strong alkalis (NaOH) and halide acids (HCl, HBr) |

| Stainless Steel | Superior corrosion resistance in harsh chemical environments | Grades like 316 endure chlorides and brines, suitable for chemical handling applications |

You see alloy 5052 in water treatment, food processing, and mild acid equipment. It is light and easy to shape into different forms. It also costs less than stainless steel, so you save money. If you need to handle strong acids or bases, pick stainless steel instead.

Tip: Always check your chemicals before using alloy 5052 for tanks or pipes. This helps you keep your equipment safe and avoid damage.

Pressure Vessels

Alloy 5052 is used for pressure vessels that hold gases and liquids. This metal gives you strength and stops rust. You can make tanks, pipes, and hydraulic lines with it. Alloy 5052 is good for vessels that do not need very high pressure.

You might want to know how much pressure alloy 5052 can take. Here are some common numbers:

- Yield strength for 5052-O is about 13,000 psi.

- Thin-walled pressure vessels made from alloy 5052 can handle about 2,400 psi.

- In hydraulic systems, 5052-O tubing works up to 1,500 psi.

- High-pressure lines made from alloy 5052 can reach up to 3,000 psi.

You get strong and safe tanks and pipes for water, food, and low-pressure hydraulic systems. You can weld alloy 5052 easily, so your joints stay strong. The metal also resists rust, so your pressure vessels last longer.

Note: For very high-pressure jobs, you should use other alloys or materials. Alloy 5052 is safe and strong for medium pressure needs.

Consumer Applications

Appliances

Alloy 5052 is used in many home appliances. Companies pick this metal because it is tough and does not rust. You can find it in freezers, washing machines, and air conditioners. The smooth surface makes cleaning simple. You do not have to worry about stains or rust, even if you use it every day.

This metal helps appliances last a long time. It makes strong covers that protect the inside parts. You can bend or shape it, and it will not crack. You see it in fridge doors, microwave cases, and dishwasher panels. It is also used in electronic boxes to keep out water and dust.

Tip: Buying appliances with alloy 5052 means you get products that work well for many years.

Beverage Cans

You drink from cans made with alloy 5052 often. This metal makes cans strong and keeps your drinks safe. It stops cans from rusting, even with fizzy or sour drinks.

Here is a table that shows why alloy 5052 is good for cans:

| Feature | Description |

|---|---|

| Corrosion Resistance | Great at stopping rust, even with salt water and wet places. |

| Strength | Stronger than 1100 and 3003, so cans do not dent easily. |

| Workability | Easy to shape, so making cans is quick and simple. |

You get cans that do not leak or rust. Your drinks stay fresh and clean. These cans are also easy to recycle, which helps the planet.

- Known for stopping rust very well.

- Does not rust in salty or wet places.

- Used a lot for cans that hold drinks.

Note: Alloy 5052 makes cans strong and safe, so your drinks are always good.

Storage Tanks

You use storage tanks made from alloy 5052 at home and work. These tanks hold water, chemicals, and food. The metal does not rust, so tanks last a long time.

- 5052 aluminum does not rust, so tanks last longer.

- It can be welded well, so tanks keep their shape and strength.

- 5052 aluminum fights rust, which helps tanks last.

- It is strong, so tanks can handle stress again and again.

- Good welds mean tanks stay safe and do not leak.

You get tanks that do not rust, even with water or chemicals inside. The welds are strong, so tanks do not leak. You see these tanks used for rainwater, food, and chemicals at home and in businesses.

Tip: Pick storage tanks made with alloy 5052 if you want them to last and stay safe.

Alloy 5052 is used in many things you use every day. It is strong, does not rust, and is easy to take care of. This means your products last longer and need less work.

Home and Kitchen Uses

You see alloy 5052 in many places around your home and kitchen. This metal helps you enjoy products that last longer and stay looking new. You benefit from its strength and resistance to rust every day.

Many kitchen products use alloy 5052 because it stands up to moisture, heat, and daily wear. You find it in cabinets, appliances, and even small items like clock boards. The metal does not stain or corrode easily, so you spend less time worrying about damage.

Here is a table that shows some common kitchen products made from alloy 5052 and the advantages they offer:

| Kitchen Products | Advantages |

|---|---|

| Electronic shell | Excellent corrosion resistance |

| Kitchen cabinet | High tensile strength and elongation |

| Electrical appliance | Rust resistance |

| Fan and fan blade | Suitable for various applications |

| Household freezer | Durable and long-lasting |

| Clock board | Versatile for different kitchen uses |

| Fence | Provides structural integrity and support |

You notice that alloy 5052 helps your kitchen stay clean and safe. Cabinets made from this metal do not warp or crack. Freezers and refrigerators use alloy 5052 for their outer shells. You get appliances that work well for years without rust or dents.

You also find alloy 5052 in fans and fan blades. These parts need to be light and strong. The metal keeps them working smoothly and quietly. You enjoy cool air in your kitchen without worrying about broken blades.

Many electronic devices in your kitchen use alloy 5052 for their shells. This metal protects the inside parts from moisture and dust. You get reliable performance from your microwave, toaster, and other gadgets.

Tip: Choose kitchen products made with alloy 5052 if you want items that resist rust and last longer.

You see fences and supports made from alloy 5052 around your home. These structures stay strong even in wet or humid conditions. You do not need to paint or treat them often. The metal keeps its shape and supports your kitchen setup.

You benefit from alloy 5052 in many ways. You save money because your products last longer. You spend less time cleaning and repairing. You enjoy a kitchen that looks good and works well every day.

Alloy 5052 gives you peace of mind. You know your kitchen products will stand up to daily use and keep their shine. You make a smart choice when you pick items made from this reliable metal.

Alloy 5052 vs Other Alloys

5052 vs 6061

You may wonder how alloy 5052 compares to alloy 6061. Both are popular choices, but they have different strengths. If you need a metal for heavy-duty jobs, 6061 might be the better pick. It is harder and works well for machining. You can use it for parts that need to hold up under pressure.

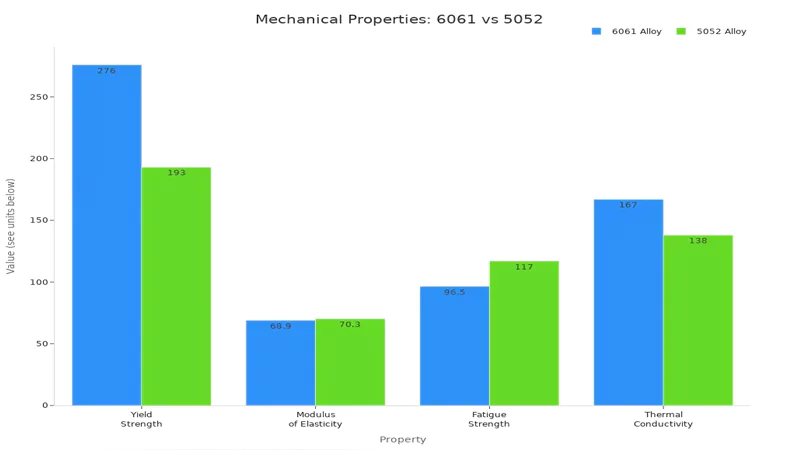

Here is a table that shows the main mechanical differences:

| Property | 6061 Aluminum Alloy | 5052 Aluminum Alloy |

|---|---|---|

| Yield Strength | 276 MPa | 193 MPa |

| Modulus of Elasticity | 68.9 GPA | 70.3 GPA |

| Fatigue Strength | 96.5 MPa | 117 MPa |

| Thermal Conductivity | 167 W/m-K | 138 W/m-K |

You see that 6061 has higher yield strength. This means it can handle more force before it bends. 5052 has better fatigue strength, so it lasts longer when bent or shaped many times. You also get better elasticity with 5052, which helps you form it without breaking. If you need a metal for welding or sheet metal work, 5052 is easier to use.

Note: 5052 resists corrosion better than 6061 because it has less copper. You can use it near water or in harsh weather.

When you look at cost, 5052 is usually less expensive than 6061. You save money if you do not need the extra strength of 6061.

- 6061 is harder and best for machining.

- 5052 is better for welding and forming.

- 5052 lasts longer under repeated stress.

5052 vs 3003

You might also compare alloy 5052 with alloy 3003. Both are easy to shape, but they have different uses. 3003 is softer and more formable. You can bend it into complex shapes without cracking. If you need a metal for simple jobs, 3003 works well.

Here are some things to think about:

- 5052 has higher tensile and yield strength than 3003. You get more durability for tough jobs.

- 5052 offers excellent corrosion resistance, especially in marine environments. You can use it for boats and docks.

- 3003 is easier to weld. If welding is important, you may choose 3003.

- 3003 is more affordable than 5052. You save money for everyday projects.

Tip: Pick 5052 for strength and corrosion resistance. Choose 3003 for easy forming and lower cost.

Selection Tips

You want to choose the right alloy for your project. Here are some tips to help you decide:

- If you need high strength and durability, go with 6061 or 5052.

- For projects near water or chemicals, 5052 is the best choice because it resists corrosion.

- If you need to bend metal into complex shapes, 3003 is easier to form.

- For welding, 3003 is simpler to use, but 5052 also works well for many jobs.

- Think about your budget. 3003 is the cheapest, 5052 is in the middle, and 6061 costs the most.

Remember: Match the alloy to your needs. Consider strength, corrosion resistance, formability, weldability, and cost. This helps you get the best results for your project.

Fabrication and Care

Cutting and Forming

You can cut and shape alloy 5052 easily. This metal bends and stretches without breaking. You can make many shapes with it. CNC machines help you cut it very accurately. These machines let you make detailed parts and waste less metal. The 5052-H32 temper is good for welding and cutting.

Here is a table that shows the main features when cutting alloy 5052:

| Attribute | Description |

|---|---|

| High precision | Cutting error can be controlled within ±.005″, meeting precision needs. |

| High speed and efficiency | Faster than traditional methods, suitable for mass production. |

| Smooth cuts | Cut edges are neat and burr-free, often requiring no additional grinding. |

| Flexible and diverse | Supports processing of complex shapes like curves and special parts. |

| Small heat-affected zone | Reduces material deformation and maintains mechanical properties. |

| Non-contact processing | No mechanical stress, preventing deformation or surface scratches. |

When you cut 5052 aluminum, the edges are smooth and clean. You do not have to grind them after cutting. Laser, waterjet, and CNC cutting work best for this metal. These ways keep the metal strong and stop it from bending. You can also bend and roll 5052 aluminum without it cracking. This makes it great for panels, covers, and special parts.

Tip: Use CNC machines for very accurate cuts and less waste. The right tools help you save time and material.

Surface Treatments

You want your alloy 5052 items to last a long time. Surface treatments help protect the metal from rain, scratches, and fading. You can pick different ways to make it stronger and look better.

Here is a table of common surface treatments for alloy 5052:

| Surface Treatment | Description |

|---|---|

| Anodizing | Creates a durable, corrosion-resistant surface ideal for harsh weather and salt-laden environments. |

| Painting | Uses high-quality acrylic or epoxy paints with UV resistance, requiring a primer for adhesion. |

| Powder Coatings | Meets AAMA standards, resists chipping, scratching, and fading. |

| Electrophoretic Coating | Forms a corrosion-resistant coating through chemical reaction, keeping luster over time. |

| Electroplating | Produces a smooth metal film with strong abrasion and corrosion resistance. |

| Passivation | Creates a protective film to prevent mold and oxidation on aluminum alloys. |

Anodizing is good if you need strong protection from salt and rain. Painting and powder coating add color and block sunlight. Electrophoretic coating and electroplating make the metal shiny and tough. Passivation helps stop mold and keeps the metal clean.

Note: Pick the right surface treatment for where you use the metal. Outdoor use needs more protection than indoor use.

Cleaning

You can keep alloy 5052 looking nice with easy cleaning. Cleaning removes dirt, dust, and stains. You do not need special cleaners for most jobs. Use mild soap and warm water for daily care. Soft cloths or sponges work best so you do not scratch the metal.

Follow these steps to clean alloy 5052:

- Mix mild soap with warm water.

- Wipe the metal with a soft cloth or sponge.

- Rinse with clean water to wash off the soap.

- Dry with a soft towel to stop water spots.

For tough stains, use a cleaner that does not scratch. Do not use steel wool or strong chemicals. These can scratch or hurt the metal. If you see any rust spots, clean them right away to stop more damage.

Tip: Clean alloy 5052 often to keep it shiny and strong. Taking care of it helps your products last longer.

You find alloy 5052 in lots of industries. It does not rust easily, so it lasts a long time. It is strong and you can bend it without trouble. People use it for boats, cars, and things at home.

- It stays tough and you do not need to fix it often.

- You can weld and shape it without problems.

- It helps you save money because it lasts many years.

Learning about alloy 5052 helps you pick the best metal for your job. Think about alloy 5052 if you want something that works well and lasts a long time.

FAQ

You get better corrosion resistance and formability with Alloy 5052. This alloy bends easily and does not rust in wet or salty places. You can use it for many jobs where other alloys might fail.

Yes, you can weld Alloy 5052 using common methods like MIG or TIG welding. You do not need special equipment. Always clean the metal before welding for the best results.

You can safely use Alloy 5052 for food and water tanks. The metal does not react with most foods or water. Many companies use it for kitchen equipment and storage tanks.

Use mild soap and warm water to clean Alloy 5052. Wipe with a soft cloth or sponge. Avoid harsh chemicals or steel wool. Dry the surface to prevent water spots.

You find Alloy 5052 in boats, car parts, building panels, and kitchen appliances. It also appears in beverage cans and storage tanks. Its strength and rust resistance make it popular in many industries.

Yes, you can paint or coat Alloy 5052. Use a primer for better paint sticking. Powder coating and anodizing also work well. These finishes protect the metal and add color.

Alloy 5052 does not rust like steel. It forms a protective layer that stops corrosion. You can use it outdoors or near water without worry.

You can buy Alloy 5052 sheets in many thicknesses. Common sizes range from 0.032 inches to 0.125 inches. Thicker sheets give more strength, while thinner sheets bend more easily.