You can pick from many mild steel finishes in 2025. Some choices are zinc plating, clear passivation, and thick film trivalent coatings. Each finish alters the appearance and durability of your mild steel. Metal finishing helps stop rust. It also keeps the surface strong. The table below shows which finishes follow safety rules:

| Finish Type | Compliance |

|---|---|

| Clear/Blue | Cr III ELV/RoHS compliant |

| Thick film trivalent | Cr III ELV/RoHS compliant |

| Black passivate | Cr VI not ELV/RoHS compliant |

When you choose a mild steel finish, you make it fight rust better. You also make it look nicer. Finishing helps your project follow safety and environmental rules.

Key Takeaways

- Mild steel finishes help stop rust. They also make steel look better and last longer. Pick a finish that fits your project’s needs.

- Self-color mild steel works well inside. But it rusts fast. Add a protective coating to make it last longer.

- Zintec coated steel protects from rust indoors. It may need more treatment for outdoor use.

- Galvanized steel is strong against rust outside. It can handle bad weather. It is good for fences and building frames.

- Zinc plated steel looks shiny indoors. It does not last long outside. Use it for hardware that stays dry.

- Clear passivated steel keeps a clean look. It resists rust fairly well. It works for electronics and panels.

- Powder coating gives a tough and colorful finish. It stops scratches and rust. It is great for furniture and outdoor gear.

- Think about the environment and how much care is needed. This helps your mild steel project last longer.

Table of Contents

Mild Steel Finish Types

Self-Color

Benefits

You get the most natural look with self-color mild steel. This finish shows the raw, untreated surface of the metal. You can see the true texture and color of low-carbon steel. Self-color steel is easy to weld and cut. You can apply other surface finishes later if you want. Many people choose this option for projects that need further metal surface treatment.

Drawbacks

Self-color mild steel rusts quickly. It has no protection from moisture or air. You must store it in a dry place. If you leave it outside, it will corrode fast. You need to add a protective coating or paint if you want it to last longer.

Best Use

Use self-color mild steel for indoor projects. It works well when you plan to add your own finish or coating. Many fabricators pick this option for custom metal finishing procedures.

Zintec Coated

Benefits

Zintec coated mild steel uses a thin layer of zinc applied by electrolysis. This metal finishing process gives you better corrosion resistance than self-color steel. Zintec coating protects the steel during storage and transit. You can machine and press it easily, which makes it great for making white goods like washing machines. The coating provides both active and passive corrosion protection. It also stays flexible and resists shock and vibration. Zintec coated steel works in temperatures from -60°C to +150°C.

Drawbacks

Zintec coated steel does not perform well outdoors in harsh weather. The thin zinc layer can wear away over time if exposed to rain or snow. You may need extra surface treatment for outdoor use.

Best Use

Choose Zintec coated mild steel for indoor products that need some rust protection. It fits well in appliances, pressed parts, and storage containers. You get a good balance of machinability and protection with this mild steel finish.

Galvanized

Benefits

Galvanized mild steel uses the hot-dip galvanizing process. You dip the steel into molten zinc, which forms a thick, protective layer. This finish gives you strong rust resistance. Galvanizing protects the steel metal finishes from harsh weather. You can use galvanized steel outdoors without worry. The zinc layer shields the steel from water and air.

Drawbacks

Galvanized steel can cost more than other types of steel finishes. The thick zinc layer may make welding or painting harder. Sometimes, the finish looks rough or uneven. You may not want this look for decorative projects.

Best Use

Pick galvanized mild steel for outdoor structures. Fences, railings, and building frames last longer with this finish. You get the best protection for high-quality mild steel in tough environments. Galvanizing works well when you need a durable, long-lasting surface finish.

Tip: When treating metal surfaces for outdoor use, always consider the benefits of galvanizing. This method offers the best defense against rust and weather damage.

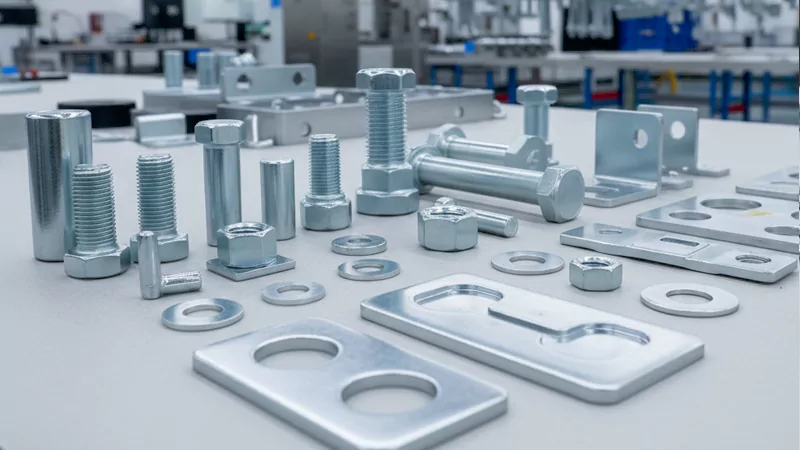

Zinc Plated

Benefits

You get a shiny, smooth finish when you choose zinc plated mild steel. This metal finishing process covers the steel with a thin layer of zinc. The zinc acts as a barrier and helps protect the steel from rust. You can use zinc plated steel for parts that need to look clean and bright. The finish also makes the steel easier to handle and assemble. Zinc plating works well for small parts like bolts, nuts, and brackets.

Drawbacks

Zinc plated mild steel does not last long outdoors. The thin zinc layer wears away if you expose it to rain or harsh weather. You may see white rust form on the surface after some time. You need to use extra surface treatment if you want better protection. Zinc plating is not as strong as galvanizing for outdoor use.

Best Use

You should use zinc plated mild steel for indoor items. It fits best for hardware, fasteners, and tools that need a neat look. This finish works well for parts that will not face heavy moisture or outdoor conditions.

Clear Passivated

Benefits

Clear passivation gives mild steel a special layer that helps fight corrosion. This finishing process forms a passive film on the steel, especially in alkaline solutions. The film develops as iron dissolves and Fe2+ ions form, then changes into an Fe3+ passive layer. The chemical environment, like the presence of sulfide, can change how the steel reacts. You get better corrosion resistance because the passive film blocks moisture and air. Clear passivated steel keeps its natural color and looks clean.

Drawbacks

Clear passivated mild steel may not protect as well as thicker coatings. The passive film can wear away if you scratch or damage the surface. You need to handle the steel carefully to keep the finish strong. This surface finishing works best in controlled environments.

Best Use

You should pick clear passivated mild steel for indoor projects that need good corrosion resistance and a clean look. It fits well for electronics, panels, and parts that need a smooth surface. This finish works best when you want to keep the steel’s natural appearance.

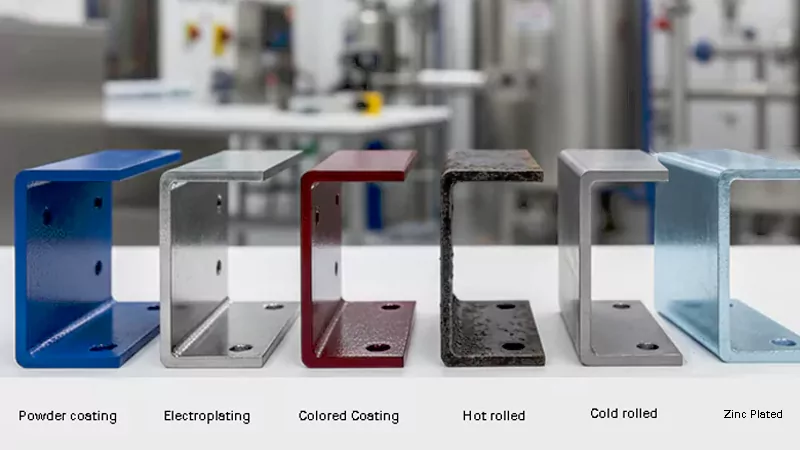

Hot Rolled

Benefits

Hot rolled mild steel uses heat during the metal finishing process. You get steel that is strong and easy to shape. The process makes the steel flexible for bending and forming. Hot rolled steel costs less than cold rolled steel. You can use it for large structures and frames. The finish is rough, but it works well for projects that do not need a smooth surface.

| Characteristics | Hot Rolled Steel | Cold Rolled Steel |

|---|---|---|

| Production Process | Heated above recrystallization temperature, then rolled | Room temperature, followed by annealing and cold drawing |

| Surface Finish | Scale present; rougher finish | Smooth surface; cleaner finish |

Hot rolled steel has a rough surface because scale and oxide layers form during production. You get a strong product for heavy-duty use.

Drawbacks

Hot rolled mild steel does not look as clean as other steel metal finishes. The rough surface can make painting or coating harder. You may need extra surface treatment if you want a smooth finish. The scale can flake off and cause problems in some projects.

Best Use

You should use hot rolled mild steel for construction, beams, and frames. It fits best for projects where appearance does not matter. This finish works well for large parts that need strength and durability.

Cold Rolled

Benefits

You get a smooth and clean surface with cold rolled mild steel. This process shapes the steel at room temperature, which makes the metal stronger and gives it a more precise size. Cold rolled steel has a better appearance than hot rolled steel. You can paint or coat it easily because the surface is even and free from scale. Many people choose this finish when they want tight tolerances and a professional look. You can use cold rolled steel for parts that need to fit together perfectly.

Drawbacks

Cold rolled mild steel costs more than hot rolled steel. The process takes more time and energy, which raises the price. You may also find that cold rolled steel is harder to bend or shape after finishing. If you need to make big changes to the metal, you might need special tools. The surface can rust if you do not add extra protection.

Best Use

You should use cold rolled mild steel for products that need a smooth finish and exact measurements. This type of steel works well for furniture, appliances, and car parts. You get the best results when you want a clean look and strong performance.

Phosphating

Benefits

Phosphating gives mild steel a thin, protective layer that helps prevent rust. The 7-tank phosphating process removes dirt, oxides, and old rust from the metal. It then adds a phosphate coating that sticks well to the steel. This layer makes a great base for paint or other coatings. You get better corrosion resistance and a surface that holds paint longer. Zinc phosphating changes the metal surface into a polycrystalline layer, which helps paint and lubricants stick better. This finish stands up well to alkaline environments and lasts a long time.

- You can use phosphating for:

- Automotive parts and underbody structures

- Industrial machinery and assemblies

- Structural steel in construction

- OEM parts that need reliable coating

Drawbacks

Phosphating does not give as much protection as galvanizing or powder coating. The layer is thin and can wear away if you scratch or rub the surface. You need to handle the steel with care after finishing. If you leave phosphated steel outside without extra paint or coating, it may still rust over time.

Best Use

You should pick phosphating for mild steel parts that need a good base for paint or oil. This finish works best for car parts, machine frames, and steel used in buildings. You get the most value when you use it as a first step before painting or adding other coatings.

Electroplating

Benefits

Electroplating covers mild steel with a thin layer of another metal. You can choose from several metals, each with its own benefits:

- Gold gives you excellent corrosion resistance and high conductivity. You often see it in electronics and aerospace parts.

- Silver offers high conductivity, making it great for electrical uses.

- Copper provides a good base layer and helps with electrical flow.

- Nickel adds hardness and protects against rust, which makes your parts last longer.

- Chromium gives a hard, shiny finish that looks great on car parts.

- Zinc protects against corrosion and is common in galvanizing steel.

You get a finish that looks good and protects the steel. Electroplating also improves the surface for electrical and decorative uses.

Drawbacks

Electroplating can cost more than simple coatings. The process needs special equipment and careful control. If the plating is too thin, it may wear off quickly. Some metals, like gold and silver, are expensive. You need to check the finish often to make sure it stays strong.

Best Use

You should use electroplating for mild steel parts that need a shiny look or special properties. This finish works well for car trim, electrical connectors, and decorative items. You get the best results when you want both protection and a high-quality appearance.

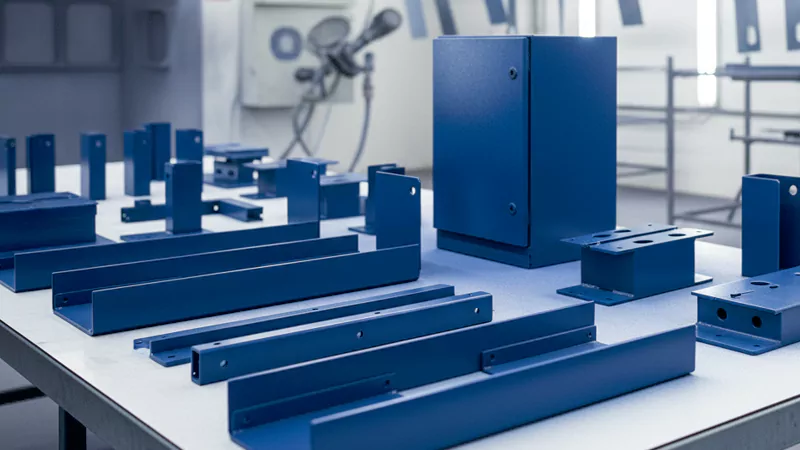

Powder Coating

Benefits

You can use powder coating to give mild steel a strong and colorful finish. This method covers the metal with a dry powder, then you heat it to form a hard layer. Powder coating protects the steel from scratches, chips, and rust. You get a smooth and even surface that looks bright and clean. Many people choose powder coating because it does not use harmful chemicals. You help the environment by picking this metal finishing process.

Powder coating works best when you start with the right type of mild steel. Cold rolled mild steel gives you a clean surface with no mill scale, so the powder sticks well. Hot rolled steel has mill scale that makes the finish rough and less durable. You should check the table below before you start:

| Type of Mild Steel | Characteristics | Recommendation for Powder Coating |

|---|---|---|

| Cold Rolled 1008 | No mill scale, clean surface for better adhesion | Recommended for powder coating |

| Hot Rolled A36 | Has mill scale that affects surface texture and adhesion | Not recommended for powder coating |

| Hot Rolled Pickled and Oiled A36 | Surface preparation may vary, but generally less ideal than cold rolled | Use with caution, surface preparation is crucial |

You get better results when you remove rust inhibitors and oxide layers before finishing. Powder coating gives you a long-lasting mild steel finish that stands up to wear and tear.

Drawbacks

Powder coating needs careful surface preparation. If you leave any rust or oil on the steel, the powder will not stick well. You must clean the metal and remove all oxide layers. Hot rolled mild steel can make this step harder because of the mill scale. You may need extra work to get a smooth finish. Powder coating does not work well on rough or dirty surfaces. You must use the right pretreatment, such as iron or zinc phosphate, to help the powder bond to the steel.

Best Use

You should use powder coating for mild steel parts that need a tough and colorful surface. This finish works well for furniture, tools, and outdoor equipment. You get the best results with cold rolled mild steel. Powder coating is a good choice when you want a clean look and strong protection.

Tip: Always clean the metal before powder coating. Remove rust inhibitors and oxide layers to help the powder stick better.

Anodizing

Benefits

You can use anodizing to make mild steel more resistant to corrosion and wear. This metal finishing process creates a thin oxide layer on the surface. Anodizing gives you a smooth and shiny finish. You get a surface that resists scratches and stains. Many people like anodizing because it adds color and makes the steel look modern. You help protect the steel from moisture and chemicals.

Drawbacks

Anodizing does not work as well on mild steel as it does on aluminum. The process can make the steel brittle if you do not control it carefully. You may see uneven color or spots on the surface. Anodizing costs more than other finishing methods. You need special equipment and chemicals to do it right.

Best Use

You should use anodizing for mild steel parts that need a decorative and protective finish. This method works best for small items, such as panels or trim pieces. You get the most value when you want a colorful and shiny surface.

Passivation

Benefits

Passivation helps mild steel resist rust and corrosion. This finishing process uses chemicals to remove free iron from the surface. You get a clean and smooth finish that lasts longer. Passivation makes the steel less likely to react with moisture or air. Many people use passivation to improve the life of their metal parts. You help keep your mild steel strong and safe.

Drawbacks

Passivation does not add a thick protective layer. The finish can wear away if you scratch or damage the steel. You must handle the metal carefully after finishing. Passivation works best in controlled environments. You may need to repeat the process if the steel gets dirty or rusty.

Best Use

You should use passivation for mild steel parts that need extra protection from rust. This finish works well for medical tools, food equipment, and electronics. You get the best results when you want a clean and safe surface.

Why Finish Mild Steel

Corrosion Protection

You want your mild steel to last a long time. The main reason to finish steel is to stop rust. If you do not treat mild steel, it reacts with water and air. This makes rust form and weakens the metal. Rust can make steel break faster. Finishing blocks water and oxygen from touching the steel.

Many coatings help stop rust. Some finishes, like PVP zinc phosphate, slow down rust a lot. Others, such as MOFs, make a thick layer that protects steel in acid. Superhydrophobic and hybrid coatings keep water away from steel.

| Finish Type | Corrosion Resistance Improvement | Key Findings |

|---|---|---|

| PVP Zinc Phosphate | More than six times lower corrosion rate | Works well in neutral environments |

| MOFs | Dense protective layer | Best for acidic media |

| Various Coatings | Surface modification | Superhydrophobic and hybrid compounds prevent corrosion |

Tip: Pick a finish that fits where you use your steel. Outdoor steel needs strong protection to last longer.

Appearance

You want your steel project to look nice. The finish you pick can change the color and shine. Some finishes make steel smooth and bright. Others add texture or special colors. You can choose a finish that matches your style.

Electroplating gives you many colors and changes how steel looks. Anodizing makes steel bright and smooth. Powder coating gives lots of colors and textures. Brushing adds texture but has fewer color choices.

| Finish Type | Aesthetic Impact | Color Options |

|---|---|---|

| Electroplating | Changes the look of metal surfaces | Many colors |

| Anodizing | Makes steel look vibrant and smooth | Uniform, bright finishes |

| Powder Coating | Durable, smooth, and colorful | Many colors and textures |

| Brushing | Adds unique texture | Mostly metallic colors |

Note: A good finish protects steel and makes it look better. This helps you sell your product more easily.

Durability

You want your steel to be strong and last. Finishing helps steel resist scratches and damage. A tough finish keeps steel safe from bumps. It also helps your product last longer and saves money.

Some finishes make steel harder to wear out. Powder coating and anodizing make the surface stronger. Phosphating and passivation help steel last by stopping rust. These finishes work well for tools, furniture, and equipment.

- Benefits of finishing for durability:

- Stops scratches and dents

- Makes products last longer

- Lowers repair costs

- Keeps steel looking new

If you want steel to last, pick a finish that fits how you use it. Strong finishes give you the best value.

Standards

You want your mild steel project to meet the right standards. Standards help you make sure your steel finish is safe, strong, and ready for its job. When you follow these rules, you protect your work from problems like rust, weak spots, or unsafe chemicals. You also show your customers and partners that you care about quality.

Industry standards guide you on how to finish mild steel the right way. These rules tell you which steps to follow and what results to expect. You can find standards for many finishing processes. Each process has its own set of rules. Some standards come from groups like ASTM, MIL, or AMS. These groups test and update their rules often to keep up with new technology.

Here is a table of common finishing processes and their main standards in 2025:

| Process | Standards |

|---|---|

| Acid Etching | AMAT 0190-00144 |

| Anodizing | ASTM B580, MIL-A-8625 |

| Bright Nickel Plating | ASTM AMS-2403, ASTM AMS-2423, QQ-N-290 |

| Chemical Cleaning | AMAT 0250-09720, AMAT 0250-20000 App A & D, AMAT 0250-70351, AMAT 0250-31176 |

| Chromate Conversion Coating | ASTM B449, MIL-C-5541E, MIL-DTL-5541F |

| Electroless Nickel Plating | MIL-C-26074, MIL-DTL-32119, ASTM B733 Type V, SAE AMS-C-2404 |

| Passivation | AMS-2700, ASTM A380, ASTM A967, QQ-P-35 |

| Powder Coating | Internal specification |

| Tin Plating | ASTM B545, MIL-T-10727 |

| Zinc Plating | ASTM B633, QQ-Z-325 |

You should check which standard fits your project. For example, if you use zinc plating, ASTM B633 gives you the steps and tests for a good finish. If you want to anodize steel, ASTM B580 or MIL-A-8625 will guide you. These standards help you pick the right chemicals, thickness, and safety steps.

Note: Following standards can help you pass inspections and sell your products in more places. Many buyers and builders ask for proof that you meet these rules.

You also protect the environment and people’s health when you use the right standards. Some rules limit harmful chemicals or require safe waste handling. You help keep your workplace safe and your steel strong.

To sum up, standards give you a clear path to a better finish. You save time, avoid mistakes, and build trust with your customers. Always check the latest standards before you start your next mild steel project. 🛠️

Comparing Types of Steel Finishes

Corrosion Resistance

You want your project to last a long time. Protecting steel from rust is very important. Some finishes work better in tough places. Galvanized steel uses a thick zinc layer. This layer keeps water and air away from the metal. Powder coating also protects steel well. It makes a hard shell that blocks moisture.

Phosphating helps protect steel, but it works best under paint or oil. It does not last as long as galvanizing or powder coating. Scientists test how coatings work in labs. Salt spray tests show how long a finish stops rust. Galvanized steel is not always tested this way. It forms zinc carbonates outside in nature. Phosphated steel gets tested for short times, like 8 or 24 hours. Zinc-nickel and zinc flake coatings last much longer in these tests.

| Coating Type | Testing Method | Corrosion Resistance Notes |

|---|---|---|

| Phosphated Mild Steel | Salt Spray Test | Tested for short periods (8 or 24 hours) |

| Galvanized Mild Steel | Not generally used | Hot-dip galvanizing forms zinc carbonates in natural environments |

| Zinc-Nickel Coatings | Salt Spray Test | Can last up to 720 hours |

| Zinc Flake Coatings | Salt Spray Test | Can last up to 1000 hours |

Tip: For outdoor use, pick galvanized or powder coated steel. These finishes give the best protection from rust.

Aesthetics

You want your project to look nice. The finish changes the color, shine, and feel of steel. Powder coating gives you lots of color choices. You can pick bright, dull, or bumpy looks. Electroplating makes steel shiny. It can use metals like nickel or chrome for a mirror look. Anodizing makes the surface smooth and colorful. It works better on aluminum than steel.

Hot rolled steel looks rough and strong. Cold rolled steel looks smooth and clean. Phosphating makes steel gray and dull. This is good under paint. Galvanized steel looks silver with spots. Each finish gives steel a different style.

- Powder coating: Many colors and textures

- Electroplating: Shiny, metallic look

- Anodizing: Smooth, colored surface

- Hot rolled: Rough, industrial texture

- Cold rolled: Smooth, clean appearance

- Galvanized: Spangled, silver finish

Note: Pick a finish that matches your design. A good look helps your product get noticed.

Cost

You want to save money. The price of finishing steel depends on the process and materials. Hot rolled steel costs less because it needs less work. Cold rolled steel costs more because it needs extra steps. Galvanizing costs more but protects steel well. Powder coating costs more than paint. It lasts longer and needs less fixing.

Electroplating and anodizing cost the most. They need special chemicals and tools. Phosphating is cheap and works well under paint. Zintec coating gives some protection at a fair price.

| Finish Type | Cost Level | Notes |

|---|---|---|

| Hot Rolled | Low | Basic protection, rough surface |

| Cold Rolled | Medium | Smooth finish, higher price |

| Galvanized | Medium-High | Best for outdoor use |

| Powder Coating | Medium-High | Durable, colorful, long-lasting |

| Electroplating | High | Shiny, decorative, expensive metals |

| Anodizing | High | Best for aluminum, costly for steel |

| Phosphating | Low | Good base for paint, affordable |

Tip: Think about cost and how well the finish works. Spending more now can help you save money later on repairs.

Suitability

When you choose a mild steel finish, you need to think about your project. Each finish works best for certain jobs and places. You should ask where you will use the steel. Think about how much it will get used and how often you can fix it.

Some finishes protect steel outside in tough weather. Other finishes are better for inside or for decoration. Look at the table below to see which finish matches your project:

| Steel Finish | Characteristics | Best Suited For |

|---|---|---|

| Weathering Steel | Makes a rust layer that protects, needs less care, looks cool | Landscaping, outdoor sculptures |

| Stainless Steel | Stops rust well, needs little care, good for salty places | Coastal projects, outdoor use |

| Galvanized Steel | Saves money, fights rust, lasts 40-50 years if cared for | General outdoor applications |

| Carbon Steel | Needs paint to stop rust, saves money | Budget projects with maintenance |

If you need steel for outside, galvanized steel is a strong choice. It protects against rain and snow. You can use it for fences, gates, and frames. Weathering steel is good for art and gardens. It makes a rust layer that keeps the metal safe and looks special.

Stainless steel does not get ruined by salty air or water. Use it for buildings near the coast, bridges, and outdoor chairs. It stays shiny and needs little work for many years.

For inside jobs, you have more options. Cold rolled steel is smooth and works for furniture and machines. Powder coating adds color and keeps steel safe in homes and offices. Electroplating makes steel shiny for decorations.

If you want to spend less, carbon steel is a smart pick. You must paint it or add a coating to stop rust. You need to check it often and fix it, especially if you use it outside.

You should also think about how much the steel will get used. Powder coating and anodizing make steel strong for tools and equipment. Phosphating is good for car parts and machine frames. Passivation helps keep medical tools and food machines safe.

Tip: Always pick a finish that fits where you use the steel. Steel outside needs strong protection. Steel inside can look nice and feel smooth.

Ask yourself these questions:

- Will the steel be in rain, snow, or salty air?

- Do you want it shiny, colorful, or with texture?

- How much fixing can you do?

- Is your project for looks, building, or machines?

When you answer these questions, you can choose the best finish for your mild steel. Your project will last longer and look nicer. 😊

Choosing a Mild Steel Finish

Project Needs

You should always start by thinking about what your project requires. Every project has different needs. Some projects need a strong surface. Others need a shiny look. You might want a finish that makes your steel last longer or look better.

When you choose a finish, ask yourself these questions:

- Does your project need corrosion protection?

- Do you want a smooth or rough surface?

- Will the steel be visible or hidden?

- How fast do you need the parts finished?

Different finishes give you different results. For example:

- Hot-rolled, annealed, and pickled steel has a dull, rough finish.

- Cold-rolled steel with a 2B finish looks smooth and reflective.

- Brushed finishes give a polished look with a visible grain.

You also need to think about the properties of the material. Some finishes act as a sacrificial coating. This means they protect the steel by wearing away first. Other finishes improve the appearance of the base metal. Passivation types can boost corrosion resistance. If you want the best finish for metal, match the finish to your project’s needs.

Tip: Make a list of what matters most for your project. This helps you pick the right metal finishing process.

Environment

The place where you use your steel changes what finish you should pick. Humidity, rain, temperature, and pollution all affect how steel lasts. High humidity speeds up rust. If you live near the coast, the air is often humid for most of the year. Climate change can make these problems worse.

| Environmental Factor | Influence on Corrosion Behavior |

|---|---|

| Relative Humidity | Big effect on corrosion, especially in dry areas |

| Rainfall | Can speed up or slow down rust, depending on how much and how often it rains |

| Temperature | Affects rust more when humidity is high |

| Atmospheric Pollutants | Make rust and damage happen faster |

If you use steel outside, you need a finish that stands up to weather. High humidity and pollution make steel rust faster. Pollutants in the air can make the surface break down. You need a finish that gives strong corrosion protection. For indoor projects, you can use a lighter finish.

Note: Always check the environment before you choose a finish. The right choice helps your steel last longer.

Budget

Your budget plays a big role in your decision. Some finishes cost more because they need special tools or materials. Others are quick and cheap. You need to balance cost with how long you want your steel to last.

Here are some things to think about:

- Hot-rolled finishes cost less but look rough.

- Cold-rolled and powder-coated finishes cost more but look better and last longer.

- Galvanizing costs more upfront but saves money on repairs.

- Simple coatings like phosphating are affordable and work well under paint.

You should also think about production speed. Some finishes take longer to apply. If you need your project done fast, pick a finish that fits your timeline and budget.

Tip: Spending a little more on finishing now can save you money on repairs later.

Maintenance

You want your mild steel project to last as long as possible. Maintenance plays a big role in how well your steel finish performs over time. Each finish needs a different level of care. Some finishes protect steel for years with little effort. Others need regular checks and cleaning to stay strong.

You should think about how much time and money you can spend on upkeep. If you pick a finish that needs less maintenance, you save effort and lower costs. If you choose a finish that needs more attention, you must plan for inspections and cleaning.

Here is a table that shows how often you should check and clean some popular mild steel coatings:

| Coating Type | Visual Inspection Frequency | Routine Cleaning Frequency | Detailed Assessment Frequency | Professional Evaluation Frequency |

|---|---|---|---|---|

| Series 1095 Endura-Shield | Quarterly | Every 6-12 months | Annually | Every 2-3 years |

| Series 1071 Fluoronar | Annually | Every 2-3 years | Every 5 years | Every 5-10 years |

You see that some coatings, like Series 1095 Endura-Shield, need more frequent checks. You should look at the steel every three months. You clean it once or twice a year. You do a detailed assessment every year. You call a professional every few years. Other coatings, like Series 1071 Fluoronar, need less frequent care. You inspect once a year. You clean every few years. You do a deep check every five years. You get a professional evaluation every five to ten years.

Tip: If you want less work, pick a finish that needs fewer inspections and cleanings. This helps you save time and money.

You should also think about the environment. Steel outside in rain or snow needs more care. Steel inside stays cleaner and needs less attention. If your project faces harsh weather, you must check for rust and damage more often.

Here are some simple steps you can follow to keep your steel finish in good shape:

- Wipe down the surface with a soft cloth to remove dust.

- Use mild soap and water for cleaning.

- Check for scratches, chips, or rust spots.

- Touch up damaged areas with paint or coating.

- Schedule regular inspections based on your finish type.

You help your steel last longer when you keep up with maintenance. You avoid big repairs and keep your project looking good. If you plan ahead, you make sure your steel finish stays strong for years.

Note: Always read the manufacturer’s care instructions for your chosen finish. Following these steps helps you get the best results and longest life from your mild steel.

Trends in Types of Metal Finishes

Sustainability

More companies now care about the earth when picking a finish. Today, you can choose from many green options. These new choices help nature and keep people safe. Here are some big trends in eco-friendly metal finishing:

- You see more metals with green labels. These metals come from places that try to hurt nature less.

- Many factories use metals that have been recycled. This step means less digging and saves power.

- Some companies try out new materials that break down or are light. These work well and are better for the planet.

- You notice more safe coatings and water-based cleaners. These choices cut air pollution and protect workers.

🌱 Tip: When you pick a finish, look for green labels. This helps you make a smart and earth-friendly choice.

Technology

New technology is changing how you finish mild steel. These changes help you get better results and save money. For example, powder coating and nanocoatings last longer and protect better. Some coatings can even fix small scratches by themselves. This means you spend less time and money fixing things.

- Nanotechnology coatings make surfaces tougher and stop rust.

- Self-healing coatings fix tiny damage on their own.

- Special thermal sprays help steel handle high heat.

- New ways to coat use less energy and fewer chemicals.

You can also use smart tools to check your finish. These tools help you find problems early and keep your products strong.

Industry

Many industries now follow strict rules for safety and the environment. In the United States, groups like the EPA and OSHA make these rules. These rules push companies to use safer and greener ways to finish metal.

- Factories spend money on research to meet ASTM safety rules.

- Green coatings are used more because of new laws.

- Self-healing materials help products last longer and cost less to fix.

- Nanotechnology and smart coatings give new ideas for cars, buildings, and machines.

You see that metal finishes keep changing as industries look for better ways to protect and make steel look good. When you learn about these trends, you can make better choices for your projects and the planet.

Mistakes with Mild Steel Finish

Application

You can make mistakes when you finish mild steel. These mistakes can affect how your project looks and lasts. You should know the most common problems so you can avoid them.

- Choosing the Wrong Type of Mild Steel

You might pick the wrong kind of steel for your project. MS plates and MS sheets have different uses. If you do not check your project needs, you may end up with steel that does not work well. Always ask your supplier if you are not sure. - Using Improper Welding Techniques

Welding mistakes can make your steel weak. If you use the wrong welding method, your steel may bend or break. You should learn the right way to weld mild steel before you start. - Skipping Surface Preparation

If you do not clean the steel before finishing, the coating may not stick. Dirt, oil, or rust can cause problems. You should always clean and dry the steel first. - Applying Coatings Too Thick or Thin

If you put on too much coating, it may crack or peel. If you use too little, the steel may rust. You should follow the instructions for each finish.

Tip: Take your time with each step. Careful work helps you get the best results.

Cost

You may face cost overruns if you do not plan well. Delays and mistakes can make your project more expensive. You should watch out for these common cost problems:

| Factor/Strategy | Description |

|---|---|

| Increased Labor Costs | Delays can make workers wait or switch jobs, which raises costs. |

| Extended Equipment Rentals | If you keep equipment longer than planned, you pay more. |

| Impact on Subsequent Trades | Delays can push back other jobs, making the whole project cost more. |

| Effective Planning | Good planning helps you finish on time and avoid extra costs. |

| Early Supplier Engagement | Talking to suppliers early helps you get materials when you need them. |

| Strong Supplier Relationships | Good relationships with suppliers help prevent delays and misunderstandings. |

| Use of Technology | Technology helps you track progress and spot problems early. |

| Buffer Time | Adding extra time to your schedule helps you handle surprises. |

| Quality Control | Checking your work helps you avoid mistakes that need fixing. |

Note: Careful planning and strong supplier relationships help you control costs.

Compatibility

You need to match your finish to your steel and your project. If you do not, you may see problems later.

- Some finishes do not work well with certain types of mild steel. For example, powder coating sticks better to cold rolled steel than hot rolled steel.

- If you use the wrong finish, your steel may rust or peel. Always check if your finish matches your steel type.

- Some finishes react with chemicals or other materials. You should test a small area before you finish the whole project.

🛠️ Tip: Ask your supplier or a metal finishing expert if you are unsure about compatibility. This step helps you avoid costly mistakes.

You can avoid most mistakes by learning about your steel, planning your work, and checking compatibility. Careful choices help your project look better and last longer.

You have many choices when you select a mild steel finish. Each type offers different levels of protection, looks, and cost. You should match the finish to your project needs. Think about how the environment, use, and budget affect your decision. The right types of metal finishes help your mild steel last longer and look better. If you want expert advice, reach out to a metal finishing specialist for guidance.

FAQ

You should choose galvanized or powder-coated finishes for outdoor use. These finishes protect steel from rain, snow, and sun. Galvanizing adds a thick zinc layer. Powder coating creates a hard, colorful shell. Both options help your steel last longer outside.

Yes, you can paint over many mild steel finishes. You should clean the surface first. Phosphated and cold rolled steel work well as a base for paint. Avoid painting over oily or dirty surfaces. Always follow the paint manufacturer’s instructions.

You can stop rust by adding a protective finish. Use zinc plating, powder coating, or galvanizing. Keep steel dry and clean. Store it indoors when possible. Regularly check for scratches or chips and repair them quickly.

Powder coating and water-based coatings are more eco-friendly. These finishes use fewer harmful chemicals. Many companies now use recycled metals and green processes. Look for products with eco-labels or certifications.

Yes, you need to check and clean mild steel regularly. Wipe off dust and dirt. Inspect for damage or rust. Touch up any scratches with paint or coating. Proper care helps your steel last longer.

You should think about where you will use the steel, how it will look, your budget, and how much care it needs. Make a list of your needs. Compare finishes based on protection, appearance, and cost.

You can anodize mild steel, but it works better on aluminum. Anodizing steel can cause uneven color and brittleness. If you want a colorful or shiny finish, consider powder coating or electroplating instead.

Hot rolled steel has a rough, scaly surface. It costs less and works well for strong structures. Cold rolled steel looks smooth and clean. It fits best for projects that need a neat appearance or tight measurements.