services

CNC Turning Service

Whether you are looking for a custom CNC turning parts for a brand or are just looking for a professional CNC turning manufacturer, AFI Industrial Co., Ltd. is your first choice.

Get A Quick ReplyCNC Turning with AFI

With access to a network of over 300 shops, including those with CNC lathes and turning centers, AFI Parts provides you with the capacity and capabilities your project needs, while also delivering the most competitive pricing and lead times. AFI’s machine learning-trained technology platform also provides instant manufacturability feedback to ensure that your part is optimized for the CNC turning process and fits the requirements you need.

Our on-demand manufacturing platform can deliver high-quality metal and plastic CNC turning parts for rapid prototyping or low-to-high volume production runs. Get an instant quote from your 3D CAD file today. The price for your turned prototypes includes tariffs and shipping for standard parcels.

AFI CNC Materials

| Material | Available Varieties |

|---|---|

| Aluminum | Aluminum 5052, Aluminum 7075, Aluminum 7075-T6, Aluminum 6063-T5, Aluminum 7050-T7451, Aluminum MIC-6, Aluminum 6061-T6, Aluminum 2024-T3 |

| Brass/Bronze | Brass C360, Brass 260, C932 M07 Bearing Bronze |

| Copper | EPT Copper C110, Copper 101 |

| Plastics | ABS, Acetal [Delrin], Acrylic, G-10 Garolite, Nylon 6/6, PEEK, Polycarbonate, PTFE [Teflon], Polypropylene, Ultra-High Molecular Weight, Polyethylene |

| Steel | Alloy Steel 4130, Alloy Steel 4140, ASTM A36, Stainless Steel 15-5, Stainless Steel 17-4, Stainless Steel 18-8, Stainless Steel 303, Stainless Steel 304, Stainless Steel 316/316L, Stainless Steel 416, Stainless Steel 420, Steel 1018, Steel A36 |

| Titanium | Titanium Grade 2, Titanium 6Al-4V |

| Zinc | Zinc Sheet Alloy 500 |

Custom Sourced Materials

Various CNC-turned metal and plastic part options are available for an instant online quote. If you cannot find the material you need, please submit your quote with details of the part characteristics, tolerances, inspection requirements, and quantity on the quotation page for review by our expert engineers.

Finishes

The finish option with the quickest turnaround. Parts are left with visible tool marks and potentially sharp edges and burrs, which can be removed upon request. Surface finish is comparable to a 125 uin Ra finish.

The part surface is left with a smooth, matte appearance.

Type II creates a corrosion-resistant finish. Parts can be anodized in different colors—clear, black, red, and gold are most common—and are usually associated with aluminum. Type III is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II.

This is a process where powdered paint is sprayed onto a part, which is then baked in an oven. This creates a strong, wear- and corrosion-resistant layer that is more durable than standard painting methods. A wide variety of colors is available to create the desired aesthetic.

Don’t see the finish you need? Submit an RFQ, and we’ll look into a finishing process for your custom lathe work.

Ready to get started on your CNC turning quote?

Free shipping available for domestic CNC machining orders!

Get Your Instant QuoteApplications of CNC Turning

Rapid Tooling

Because CNC can be applied to virtually any material, it is perfect for rapid tooling, i.e., creating fixtures or molds.

Rapid Prototyping

The range of materials available, low cost per unit, and speed of production make CNC a great option for prototyping.

Serial Production

High-quality finish, vast material options, and precise tolerances have made CNC lathe turning a favorable technology for serial production parts.

Advantages of CNC Turning

Using the latest CNC machines, Xometry produces highly accurate, quick turn parts in as fast as 1 day.

Select from a variety of finishes on solid metal and plastic parts, built to precise design specifications.

Choose from over 50 metal and plastic materials. CNC Machining offers a wide variety of certified materials.

Offers high-precision tolerances ranging from +/-0.001″ – 0.005″, depending on customer specs.

CNC Machining is perfect for the production of 1-10,000 CNC machined parts.

CNC General Tolearances

| Description | General Tolerance |

|---|---|

| Distance Dimensions | For features of size (Length, width, height, diameter) and location (position, concentricity, symmetry) +/- 0.005”. |

| Orientation and Form Dimensions | 0-12″ +/- 0.005″, Angularity 1/2 degree. For 24″ and beyond please consult AFI’s Manufacturing Standards. |

| Edge Condition | Sharp edges will be broken and deburred by default. Critical edges that must be left sharp should be noted and specified on a print. |

What is CNC Turning?

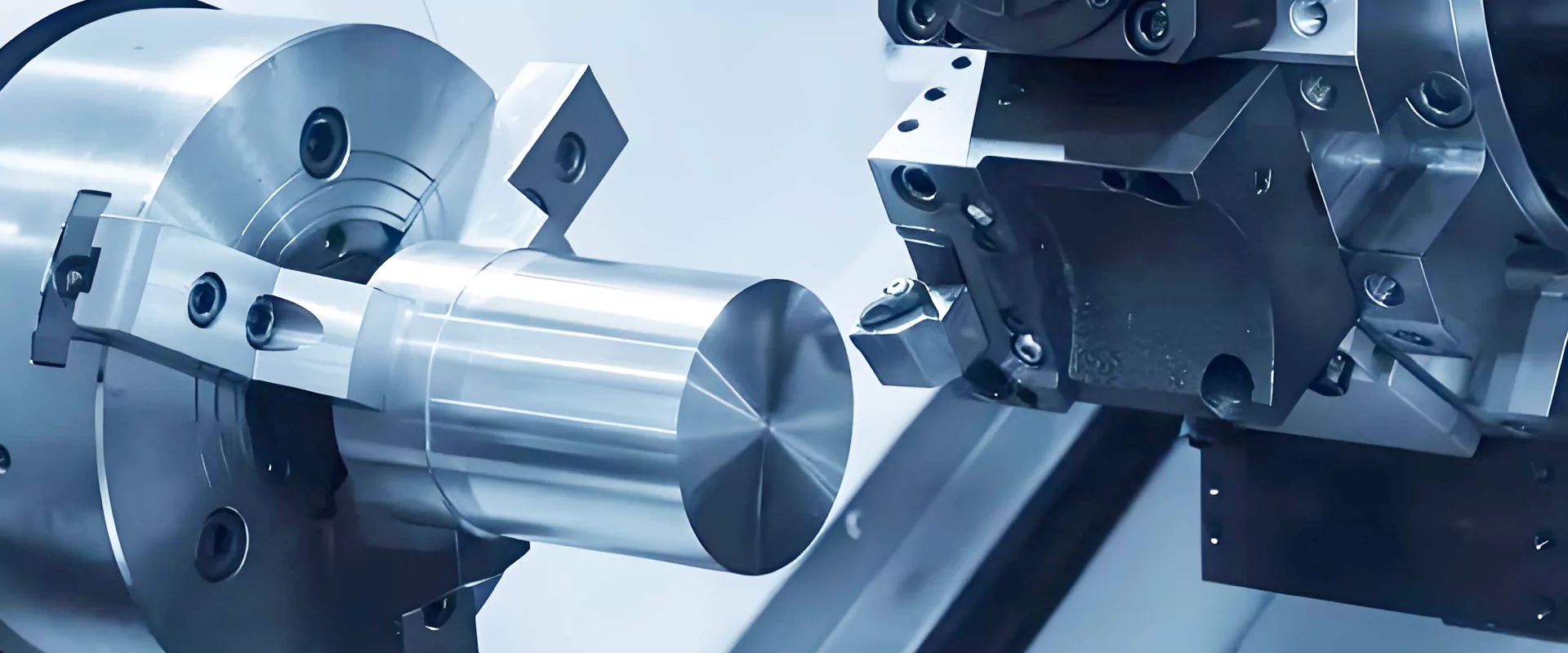

The Basics Of CNC Lathes

A CNC lathe machine, also called live tooling lathes, is ideal for cutting any symmetrical cylindrical or spherical parts. Characteristically, a lathe spins a workpiece on a vertical or horizontal axis, while a fixed shaping instrument moves around it on a more or less linear path. The act of cutting a workpiece on a CNC lathe is called turning.

How CNC Turning Works

CNC lathes use a subtractive method to create the desired shape. With the G-Code created, a blank bar of stock material is loaded into the chuck of the lathe’s spindle. The chuck holds the workpiece in place while the spindle spins. When the spindle is up to speed, a stationary cutting tool is brought into contact with the workpiece to remove material until the desired geometry is achieved.

There are many operations that can be performed on a live tooling lathe, including facing, threading, knurling, drilling, boring, reaming, and taper turning. Different operations require tool changes and can increase cost and set-up time.

When all machining operations are completed, the part is cut from the stock for further post-processing. The CNC lathe is then ready to repeat the operation with little-to-no set-up time in between.

Types Of CNC Lathes

There are many types of lathes, but the most common are 2-axis CNC lathes and Swiss-type lathes. Swiss-type lathes are unique in that stock material is fed through a guide bushing, allowing the tool to cut nearer to the point of support, which makes them particularly useful for long, slender CNC lathe parts and micromachining. Some Swiss-type lathes also come equipped with a second tool head that operates as a CNC mill, allowing them to perform multiple machining operations without having to move the workpiece to a different machine. This makes Swiss-type lathes extremely cost-effective for complex turned parts with CNC lathe services.

Benefits Of CNC Turning

Like CNC mills, CNC lathes can be easily set up for high repeatability, which makes them great for everything from rapid prototyping to low and high-volume production. Multi-axis CNC turning centers and Swiss-type lathes allow for multiple machining operations in one machine. making them a cost-effective option for complex geometries that would otherwise require multiple machines or tool changes in a traditional CNC mill.

CNC Turning Video