Services

ServicesOur services

What we offer

We combine manufacturing expertise with advanced equipment to deliver precise, cost-effective metal parts on time, every time.

Services provided

We provide a full range of custom metal parts manufacturing services, including CNC turning and milling, sheet metal fabrication, stamping, bending, and assembly. Working directly from your drawings and 3D models, our engineering and production teams ensure each component meets your dimensional, material, and functional requirements.

With stable quality, clear communication, and flexible lead times, we help you simplify your supply chain, reduce total cost, and keep your projects and production lines running smoothly.

“AFI Parts quickly understood our drawings and application. They suggested practical design optimizations that reduced cost without affecting performance, and the first batch passed inspection with no issues. They’ve become one of our most dependable metal parts suppliers.”

Daniel K.

Operations Manager

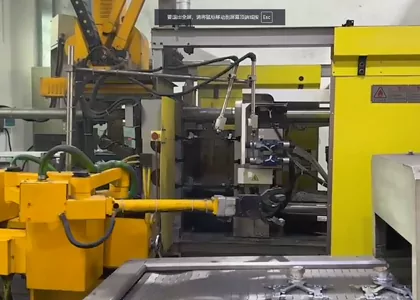

Machining

CNC Turning

High-precision turned components for shafts, bushings, and custom round parts with tight tolerances.

CNC Milling

Accurate milled parts for complex geometries, pockets, and contours in a wide range of metals.

Sheet Metal

Custom sheet metal parts formed, punched, and bent to match your enclosure and bracket designs.

Metal Stamping

High-efficiency stamping for repeatable metal parts, ideal for medium to large production volumes.

Tube Bending

Precision tube and pipe bending for fluid, air, and structural applications with clean, consistent radii.

Gear Hobbing

Custom gears and splines produced with stable tooth accuracy for reliable power transmission.

Welding

Strong, clean welds for assemblies and frames, ensuring structural integrity and long-term durability.

Metal Cutting

Flexible cutting solutions for plates, bars, and profiles, ready for downstream machining or fabrication.

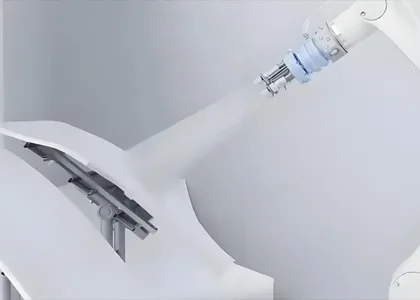

Grinding

Fine surface finishing and tight-tolerance grinding for critical fit, wear resistance, and smooth operation.

Heat Treatment

Quenching

Controlled quenching to increase hardness and strength for parts working under heavy load and wear.

Metal Tempering

Tempering services to balance hardness and toughness, improving performance and extending part life.

Casting

Lost Wax Casting

Complex, near-net-shape cast parts with fine detail, ideal for precision metal components.

Die Casting

High-volume die cast parts with excellent dimensional stability and smooth surfaces for finishing.

Sand Casting

Versatile sand casting for larger or less intricate parts with robust mechanical properties.

Powder Metallurgy

Net-shape metal parts with uniform properties and material efficiency through powder metallurgy processes.

Forging

Forged components with superior strength and grain flow for demanding structural and mechanical applications.

Surface Treatment

Anodizing

Protective and decorative anodized finishes that enhance corrosion resistance and surface hardness on aluminum parts.

Electroplate

Electroplated coatings for improved conductivity, corrosion resistance, and appearance on functional components.

Spray Painting

Durable spray-painted finishes matched to your color standards for branded or protective surfaces.

Powder Coating

Thick, impact-resistant powder-coated layers for long-lasting protection in tough working environments.

Brushed

Brushed metal textures that reduce visible scratches and deliver a clean, high-end appearance.

Sandblasting

Sandblasted surfaces for uniform texture, better coating adhesion, and an industrial matte look.

Polishing

Polished finishes that enhance appearance, smooth roughness, and improve cleanability for visible parts.

Need custom metal parts? Let’s build them.

We combine manufacturing expertise with advanced equipment to provide fast, accurate, and dependable production.

(0086) 139-2924-0170

No matter what kind of metal component you need, our skilled machining and fabrication team is here to help.

From prototypes to full-scale production, we’ll deliver consistent, high-quality parts that match your drawings and deadlines. Have a project in mind? Contact us today and let us take care of the manufacturing.

Schedule an Appointment