You see that 7075 aluminium is special because it is very strong and has a lot of zinc. When you pick 7075 aluminum, you get up to 5.6% zinc. This is much more than most other types:

| Alloy Type | % Zinc (Zn) |

|---|---|

| 7075 Aluminum | 5.6% Zn |

| 6061 Aluminum | N/A |

The high zinc makes 7075 alloy strong but still light. This is important for planes, cars, and defense parts. You can see how important it is in these facts:

- The 7075 aluminum market is growing by 10.1% each year from 2025 to 2032.

- More companies are spending money on better ways to make strong alloys.

Engineers and machinists use 7075 aluminum for parts that need to work well under stress.

Key Takeaways

- 7075 aluminum is special because it has a lot of zinc. This makes it stronger than many other aluminum alloys. This alloy is light but also very strong. It is great for airplanes, cars, and sports gear. 7075 aluminum has a high strength-to-weight ratio. This means it makes strong parts that are not heavy. Engineers like 7075 aluminum for parts under high stress. It is used for things like airplane wings and race car frames. 7075 aluminum is strong but hard to weld. It may need special coatings in tough places. The alloy has zinc, magnesium, and copper. These work together to make it strong and tough. 7075 aluminum is okay to machine. It can be cut and shaped, but you need sharp tools and care. Knowing the properties and limits of 7075 aluminum helps people pick the right material for each job.

Table of Contents

7075 Aluminium Alloy Composition

7075 Aluminum Composition

7075 aluminum is made from a mix of elements. These elements work together to make it strong. The main part of 7075 aluminum is zinc. It also has magnesium, copper, and some other small parts. Here is a table that shows the main chemical composition of 7075:

| Element | Percentage Range |

|---|---|

| Zinc | 5.6–6.1% |

| Magnesium | 2.1–2.5% |

| Copper | 1.2–1.6% |

| Chromium | ~0.23% |

| Others | <0.5% (silicon, iron, manganese, titanium, etc.) |

Zinc Content

Zinc is the most important part of 7075 aluminum. The zinc amount is between 5.6% and 6.1%. This high zinc makes 7075 aluminum very strong. Zinc helps the alloy get stronger by precipitation hardening. This means zinc atoms stop the metal from moving inside. It makes the metal harder to bend or break.

Magnesium and Copper Roles

Magnesium and copper are also important in 7075 aluminum. Magnesium is between 2.1% and 2.5%. Copper is between 1.2% and 1.6%—magnesium and zinc work together to make the alloy harder. Copper gives the alloy more strength and toughness. This helps the alloy hold heavy loads and take hits. When you put these elements together, you get a strong and tough material.

Minor Alloying Elements

There is a little bit of chromium, about 0.23%. There are also small amounts of silicon, iron, manganese, and titanium, each less than 0.5%. Chromium helps control the size of crystals in the metal. This makes the metal more bendable and tough. The other small elements help change the properties a little. But they do not change the main features of 7075 aluminum.

Tip: The exact mix of elements in 7075 aluminum makes it great for parts in planes, cars, and sports gear that need to be strong.

Other Alloys Comparing 7075 Aluminum

7075 aluminum is different from other aluminum alloys. The chemical makeup is not the same. Here is a table that shows how the main elements are different in 7075, 6061, and 2024:

| Alloy Type | Major Alloying Elements |

|---|---|

| 2024 | 3.8-4.9% copper |

| 6061 | 0.6-1.2% copper, 0.6-1.2% magnesium, 0.4-0.8% silicon |

| 7075 | 5.1-6.1% zinc, 2.1-2.9% magnesium |

7075 aluminum has more zinc and magnesium than 6061 or 2024. This is why 7075 aluminum is much stronger.

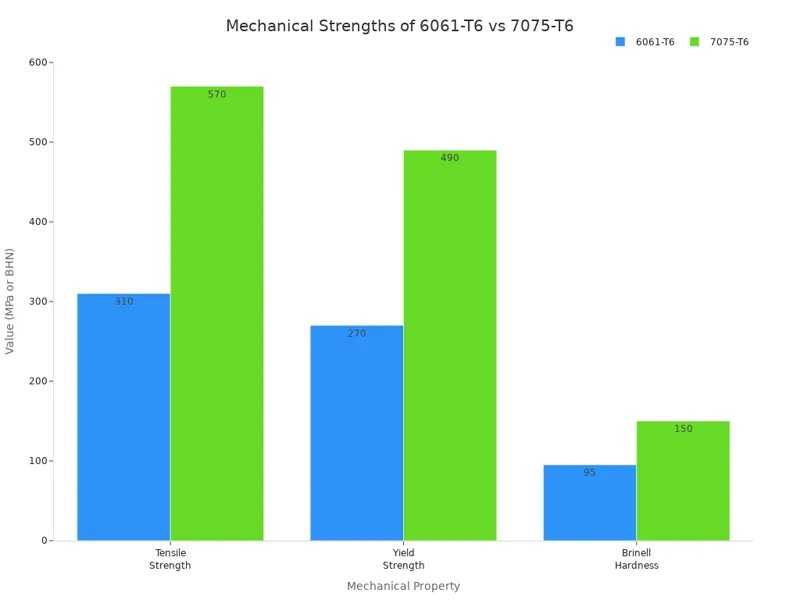

If you look at how strong the alloys are, you see more differences. Here is a table that shows the strength and hardness of 7075-T6 and 6061-T6:

| Property | 6061-T6 | 7075-T6 | Notes |

|---|---|---|---|

| Tensile Strength (MPa) | 310 | 570 | 7075 is nearly 84% stronger |

| Yield Strength (MPa) | 270 | 490 | 7075 is 81% stronger |

| Hardness (Brinell Hardness Number) | 95 | 150 | 7075 is 58% harder |

| Fatigue Resistance | Moderate | Good | 7075 offers better resistance to repeated stress |

| Impact Resistance | Moderate | Good | 7075 generally has better impact absorption |

7075 aluminum is stronger and harder than 6061. If you need a material for high stress, 7075 aluminum is a better pick.

Note: When you compare 7075 aluminum to other alloys, look at both the chemical makeup and the strength. This helps you choose the best material for your job.

7075 Aluminum Properties

When you check the material properties of 7075 aluminum, you see why engineers like it for hard jobs. This high-performance alloy is special because it is very strong, hard, and works well under pressure. Here are the main things you should know.

Mechanical Strength and Hardness

7075 aluminum is well-known for being strong. It is a good choice when you need something that will not bend or break easily. The mechanical properties make it great for parts that carry heavy weights or take hard hits.

Tensile and Yield Strength

Tensile strength shows how much pulling force a material can take before it breaks. Yield strength tells you how much force it can take before it bends and does not return to its original shape. 7075 aluminum has higher numbers than most other aluminum alloys.

Here is a table with the usual numbers for 7075 aluminum:

| Property | Value |

|---|---|

| Brinell Hardness | 150 |

| Tensile Strength: Ultimate | 560 MPa |

| Tensile Strength: Yield | 480 MPa |

If you look at 7075 aluminum and compare it to other alloys, you see it is much stronger. For example:

| Material | Ultimate tensile strength (MPa) | Density (g/cc) | Specific Strength (kN m/kg) |

|---|---|---|---|

| 7075-T6 | 572 | 2.81 | 203.6 |

| 7068-T6511 | 710 | 2.85 | 249.1 |

7075 aluminum gives you a strong and light choice. That is why it is used in airplanes, race cars, and fast bikes.

Hardness Ratings

Hardness tells you how well a material can stop scratches or dents. 7075 aluminum has a Brinell hardness of 150. This means it is harder than many other aluminum alloys. If you need something that will not wear out fast, 7075 aluminum is a good pick.

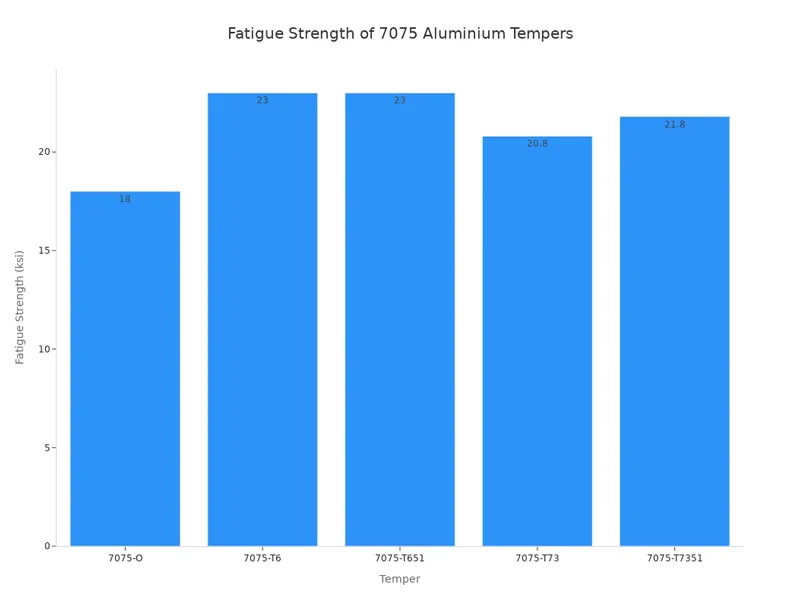

Fatigue and Toughness

Fatigue strength tells you how well a material can handle being bent or moved over and over. Toughness shows how much energy it can take before breaking. 7075 aluminum does well in both.

Here is a table with the fatigue strength for different types of 7075 aluminum:

| Temper | Fatigue Strength (ksi) |

|---|---|

| 7075-O | 18 |

| 7075-T6 | 23 |

| 7075-T651 | 23 |

| 7075-T73 | 20.8 |

| 7075-T7351 | 21.8 |

You can trust 7075 aluminum to last a long time, even if it gets bent or shaken a lot. This makes it great for airplane wings, bike frames, and other moving parts.

Tip: If you want a material that will not break after many uses, 7075 aluminum is a good choice.

Corrosion Resistance

Corrosion resistance is important if you want your parts to last in rough places. 7075 aluminum can resist rust in many places, even with chemicals or bad weather. Here is how it compares to other alloys:

| Alloy | Corrosion Resistance Description |

|---|---|

| 5052 | Especially good against saltwater, great for boats. |

| 6061 | Has good corrosion resistance, used in buildings and structures. |

| 7075 | Resists corrosion in many places, even with chemicals and bad weather. |

You can use 7075 aluminum outside or where it might get wet or dirty. It will stay strong and keep its shape, even in the rain or with chemicals.

Note: 7075 aluminum is good at fighting rust, but you may still want to add coatings or treatments for the toughest places.

Machinability and Workability

When picking a material for parts, you want to know if it is easy to cut and shape. This is called machinability. Workability means how well you can bend or form the metal without it breaking. 7075 aluminum is very strong and has fair machinability. You should know what to expect before you start working with it.

Here is a table that shows machinability ratings for some alloys:

| Alloy | Machinability Rating |

|---|---|

| 7075 | Fair |

| 2024 | Fair |

| 6061 | Good |

| 2011 | Excellent |

7075 aluminum has a fair machinability rating. This means you can cut and shape it, but it is not as easy as 6061 or 2011. 2011 aluminum is the easiest to machine. 6061 is also a good choice if you want something easier to work with.

- 7075 aluminum is fair for machinability, but 2011 is excellent.

- 6061 is known for being good to machine.

- The high strength of 7075 aluminum can wear out tools faster.

When you machine 7075 aluminum, you need sharp tools and careful settings. Its high strength can make your tools dull faster. You may need to change tools more often or use special coatings. If you use CNC machines, you can set the speed and feed rates to get the best results. This helps you make parts that fit well and look smooth.

Tip: If you want to make complex or very precise parts, 7075 aluminum works well with CNC milling and turning. Just plan for tool changes and use the right cutting fluids.

Workability is also important. 7075 aluminum is not as easy to bend as softer alloys like 6061. If you bend it too much, it can crack. Most of the time, you will cut 7075 aluminum into the shape you want instead of bending it. If you need to form it, do it before the final heat treatment, when the metal is softer.

Note: 7075 aluminum is a top pick for planes, race cars, and high-performance parts. You can machine it into very exact shapes. Even though it is not the easiest to work with, its strength and quality are worth the extra effort.

Characteristics of 7075 Aluminum in Real-World Use

Many engineers and makers pick 7075 aluminum for tough jobs. It is special because it is strong and light. It also does well when bent many times. There are some things you should know before using it.

Strength-to-Weight Ratio

You want parts that are strong but not heavy. 7075 aluminum has a high strength-to-weight ratio. The number is about 186.48 MPa/g/cm³. This is much higher than 6061 aluminum. You get strong parts that do not weigh a lot. You can use less material and still get good strength. That is why it is used in planes, race cars, and bikes. These parts stay tough but do not add much weight. This helps save fuel and makes sports gear easier to use.

Tip: If you need something strong and light, 7075 aluminum is great for cars and planes.

Fatigue Resistance

Parts that bend or move a lot need to last. 7075 aluminum can handle being bent many times. Here is a table that shows how it works:

| Aspect | Description |

|---|---|

| Fatigue Life | 7075-T6 aluminum can lose strength after many bends, but it still works well for most uses. |

| Microstructure | How the metal is made changes how it stops cracks. |

| Crack Initiation | Cracks can start near the surface, often where tiny bits are found. |

| Plastic Deformation | Some shapes of 7075 aluminum bend less, so they last longer. |

You can trust 7075 aluminum for parts like wings, bike frames, and car arms. It stays strong even after lots of use.

Note: If you want a part that lasts a long time, 7075 aluminum is a good choice.

Limitations and Weaknesses

7075 aluminum is strong and light, but it has some limits. Here are things to watch out for:

| Limitation/Weakness | Description |

|---|---|

| Susceptibility to Stress Corrosion Cracking | 7075 aluminum can crack when stressed, mostly because it has a lot of copper. |

| Challenges in Weldability | The high zinc makes welding hard and can cause cracks. |

- Most failures in strong aluminum parts happen with 7075-T6.

- The mix of copper and zinc makes it easier to crack if wet or stressed.

You might need special coatings to protect it in tough places. Welding is hard, so you may use bolts or machine the parts instead.

Tip: Think about where you use 7075 aluminum and how you join parts. Knowing what it can and cannot do helps you get the best results.

7075 Aluminum Alloy vs. Other Materials

When you pick a material, you want to know how it matches up with others. Let’s see how 7075 aluminum alloy is different from other common metals.

7075 vs 6061 Aluminum

Both 6061 and 7075 are used a lot. They are both aluminum alloys, but they are not the same. Here is a table to help you see the differences:

| Property/Application | 7075 Aluminium | 6061 Aluminium |

|---|---|---|

| Strength | High strength, for high-stress jobs | Good strength, works for many uses |

| Formability | Limited formability and weldability | Good formability and weldability |

| Corrosion Resistance | Moderate | Good |

| Typical Applications | Aerospace, military, high wear parts | Furniture, automotive, marine, structures |

7075 aluminum is much stronger than 6061. You use it when you need a part that will not bend or break easily. 6061 is easier to weld and shape. It also costs less, so it is used in furniture, cars, and boats. If you need a strong alloy for hard jobs, 7075 is better, but it costs more.

| Alloy Type | Cost Comparison | Strength Characteristics |

|---|---|---|

| 6061 | More cost-effective | Lower strength, easier to weld |

| 7075 | More expensive | Higher strength, best for performance |

Tip: If you want to make strong, complex parts, 7075 aluminum alloy is a great choice. It gives you strength and accuracy, but it costs more and needs careful machining.

7075 vs 2024 Aluminum

2024 and 7075 are both strong, but they are not the same. Here is a table to show the main differences:

| Alloy | Corrosion Resistance | Fatigue Resistance |

|---|---|---|

| 2024 | Poor (high copper) | Superior fatigue life under cycles |

| 7075 | Moderate | Less preferred for fatigue jobs |

You pick 7075 aluminum when you want a high strength-to-weight ratio. This means you can make lighter parts that are still strong. This is important for planes. You also get:

- High strength for important parts

- Good corrosion resistance for tough places

- Flexibility and toughness in different forms

- Many uses in aerospace

- Best for military and aerospace parts where strength is key

2024 is good if you need a part that will bend or move a lot, like airplane wings. But if you want a part that is strong and fights rust, 7075 is better.

7075 Aluminum vs Steel

You might wonder how 7075 aluminum compares to steel. Steel is strong and tough, but it is much heavier. Here is what you should know:

- 7075 aluminum is strong but much lighter than steel.

- You can cut and shape 7075 aluminum more easily than most steels.

- Steel is better at stopping wear and taking hits, but it is heavy.

- For parts that need to be light and strong, like in planes or bikes, 7075 aluminum is often the best pick.

- Steel is best for parts that need to handle lots of wear, heat, or big impacts.

Note: If you want to save weight and still get good strength, 7075 aluminum is a smart choice. It is easy to machine and great for high-performance parts.

Applications of 7075 Aluminium

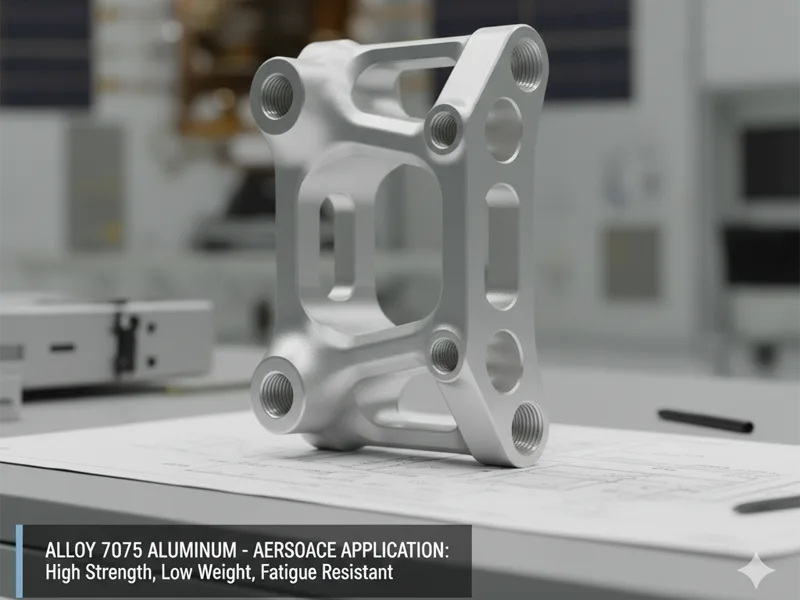

Aerospace and Aviation

You often see 7075 aluminum in aerospace applications. This alloy is a top choice for making airplane parts. You find it in wing spars, fuselage frames, and landing gear. The reason is simple. 7075 aluminum alloy gives you high strength without adding much weight. This helps planes fly farther and use less fuel. In aerospace, every gram matters. Engineers pick this alloy because it keeps planes light and strong. You also see it in spacecraft and satellites. These parts must survive tough conditions. The alloy’s strength and resistance to fatigue make it perfect for these jobs.

Note: When you work in aerospace, you need materials that can handle stress and last a long time. 7075 aluminum is one of the best for this.

Automotive and Motorsport

You find 7075 aluminum in many high-performance cars and racing vehicles. Car makers use it for parts that need to be both strong and light. Here are some common parts made from this alloy:

- Suspension systems

- Chassis parts

- Structural parts

Why do you see it so much in these places? The answer is its high strength-to-weight ratio. This means you can make lighter cars without losing strength. Lighter cars go faster and use less fuel. The alloy also stands up well to repeated stress. This is important for parts that face constant vibrations and loads, like in motorsport. When you use 7075 aluminum, your car can perform better and last longer.

If you want your vehicle to be fast and reliable, this alloy is a smart pick.

Sporting Goods and Recreation

You also see 7075 aluminum in sports and recreation gear. This alloy helps make lighter and stronger equipment. Here are some ways it improves your sports experience:

- It gives you a high strength-to-weight ratio, so your gear is lighter and easier to handle.

- It dampens vibrations, which helps you control your equipment better.

- It has a long fatigue life, so it does not wear out quickly, even with heavy use.

- It is lighter than steel, which helps you move faster and stay agile.

- It is tougher than many plastics, so your gear lasts longer and resists impacts.

You find this alloy in bike frames, climbing gear, baseball bats, and even arrows. When you use equipment made from 7075 aluminum, you get better speed, control, and durability. This makes it a favorite for athletes and outdoor fans.

If you want sports gear that helps you perform your best, look for products made with this alloy.

Industrial and Military Uses

You see 7075 aluminum in many factories and military places. This alloy is strong and light. These features help make parts that can handle stress but are not heavy. In factories, it is used for machines, tools, and frames. In the military, you find it in vehicles, aircraft, and armor.

| Application | Property Description |

|---|---|

| Aircraft Frames and Structures | High strength-to-weight ratio helps planes work better and use less fuel. |

| Fuselage Panels | Gives enough strength for flight stress and keeps the weight low. |

| Wing Components | Handles strong forces from air and stays light. |

| Landing Gear | Has great strength for takeoff and landing impacts. |

| Military Aircraft | Used for many parts to help planes fly better and move faster. |

| Spacecraft | Strong and tough, good for hard space jobs like heat shields and frames. |

7075 aluminum is not just for planes. It is also in spacecraft and military vehicles. Its high strength-to-weight ratio lets you make tough parts that do not slow things down. This matters for vehicles that need to go fast or carry heavy stuff.

Tip: If you work in defense or big factories, 7075 aluminum gives you strength without extra weight.

Machining Applications

If you need to make detailed and exact parts, 7075 aluminum is a good choice. You can shape it into very precise pieces. This is important for aerospace, cars, robots, and electronics. The alloy is almost as strong as steel but much lighter. You get strong parts that are easy to move and put together.

Some reasons why 7075 aluminum is good for machining:

- It is the strongest common aluminum alloy.

- You get steel-like strength with easier cutting and good rust resistance.

- The strength-to-weight ratio keeps parts light and tough.

- You can cut it cleanly for tight fits.

- It works well in CNC machines, robots, and chip-making tools.

When you cut 7075 aluminum, use sharp tools and keep your setup steady. This helps you get smooth surfaces and the right size. Here is a table with tips for machining:

| Machining Practice | Importance of High-Tolerance Parts |

|---|---|

| Sharp, properly designed cutting tools | Needed for smooth surfaces and exact sizes |

| Higher cutting speeds than steel | Helps cut the strong alloy well |

| Moderate feed rates | Stops the metal from getting too hard, keeps the sizes right |

| Proper cooling | Stops heat from hurting the part |

| Rigid setups | Cuts down on shaking, keeps things accurate |

Note: If you want to make exact parts for planes, defense, or advanced factories, 7075 aluminum is a top choice. It keeps its shape and size, even after lots of use.

You see 7075 aluminum in CNC machine parts, robots, and chip-making tools. Its machinability lets you make detailed and strong parts that meet strict rules. This is why engineers and makers like using it for the best results.

You can see why 7075 aluminium is special. It has zinc, magnesium, and copper. These make it strong and not heavy. This helps you build parts that are tough but light. There are some clear benefits. Planes can fly farther and carry more. Cars and bikes get strong parts that can take hits. You can also make tricky shapes because it is easy to machine.

But there are some things to watch out for:

| Limitation | Explanation |

|---|---|

| Difficult to Weld | You need special ways to weld it. |

| Lower Corrosion Resistance | It needs coatings in harsh places. |

| Higher Cost | It costs more than other alloys. |

Knowing these things helps you choose the best material for your project.

FAQ

You get higher strength from 7075 aluminum because it has more zinc and magnesium. These elements work together to make the metal harder than most other aluminum alloys.

You should avoid welding 7075 aluminum. The high zinc and copper content make it prone to cracking. Most people use bolts or machine the parts instead of welding.

You can use 7075 aluminum outdoors. It resists corrosion in many environments. For harsh or salty conditions, you should add a protective coating to keep it strong.

You get almost the same strength as steel but much less weight. 7075 aluminum is easier to machine than most steels. Steel is better for heavy wear or high heat.

You should use 7075 aluminum for airplane parts, racing car frames, bike components, and high-performance tools. It works best when you need strong, light, and precise parts.

You can bend 7075 aluminum, but it is not easy. The alloy is strong and can crack if you bend it too much. You should shape it before the final heat treatment.

You can machine 7075 aluminum with sharp tools and the right settings. It is not as easy as 6061 or 2011, but you can still make very precise parts with CNC machines.

You get a high strength-to-weight ratio with 7075 aluminum. This means you can build lighter planes that still stay strong and safe. That is why engineers pick it for wings, frames, and landing gear.