In the world of precision manufacturing, procurement managers and mechanical engineers often face a dilemma: Should you stick with cost-effective standard 3-axis machining, or invest in advanced 5-axis CNC machining services?

For simple, flat parts, 3-axis is undoubtedly the economic choice. However, as modern component designs become increasingly intricate – especially in aerospace and medical device manufacturing – standard machining often falls short due to accumulated tolerance errors from multiple setups and extended lead times.

As a CNC machining manufacturer with extensive experience, we understand the nuances between these technologies. This article breaks down the technical differences to help you calculate the “total manufacturing cost” rather than just looking at the hourly machine rate.

What is the Core Difference Between 3-Axis and 5-Axis Machining?

What are 3-Axis and 5-Axis?

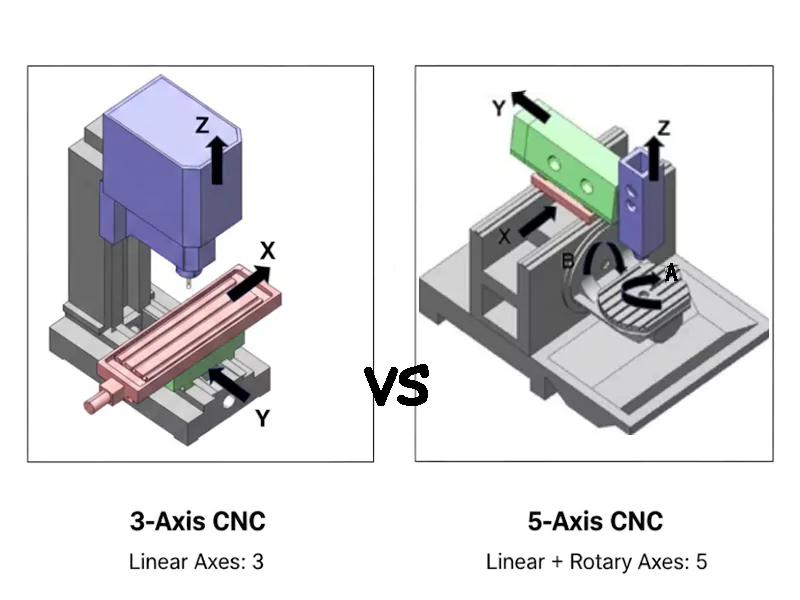

To understand the benefits, we first need to look at how the machine axes move.

3-Axis Machining: The cutting tool moves along the X(left-right), Y(front-back), and Z(up-down) linear axes. The workpiece remains stationary during cutting. This is best suited for planar surfaces, drilling, and simple contours.

5-Axis machining: In addition to X, Y, and Z, 5-axis machines utilize two additional rotary axes(typically A and B, or A and C). This allows the cutting tool to approach the workpiece from almost any direction.

Pro Tip: 5-axis machining is categorized into”3+2 Axis”(Positional) and “Simultaneous 5-Axis”(Continuous). The former is used for positioning the tool at a fixed angle, while the latter is used for machining complex, contoured surfaces.

Key Differences Table

It is important to know the main differences between 3-axis vs 5-axis CNC machining before you pick a CNC machine for your job. The table below shows how each CNC machine works for complexity, cost, accuracy, and setup:

| Feature | 3-Axis CNC Machine | 5-Axis CNC Machine |

|---|---|---|

| Movement Capability | Moves on X, Y, and Z axes | Moves on X, Y, Z, A, and B axes |

| Setup Time | Needs many setups for hard parts | Can finish many sides in one setup |

| Achievable Geometries | Can only make 90-degree angles | Can make hard parts with undercuts and odd angles |

| Accuracy | Good for simple parts | Great for tight fits and detailed shapes |

| Cost | Costs less to buy and run | Costs more to buy, program, and run |

| Operator Skill | Needs basic skills | Needs advanced skills and special training |

| Surface Finish | Gives a normal finish | Gives a better finish with less shaking |

Note: The biggest difference between 3-axis vs 5-axis CNC machining is how each CNC machine handles hard parts and setup time.

Think about how hard your parts are, your budget, and how many you need before you choose. The right CNC machine will help you save time and avoid expensive errors.

How to Choose 3-Axis or 5-Axis CNC Machining?

1. Single Setup Efficiency

In 3-axis machining, producing a complex part with features on multiple sides requires manual flipping. You might need to flip the part 6 or more times. Each flip requires re-fixturing and recalibration of coordinates.

- The pain point: Every manual re-fixturing introduces human error and consumes significant machine downtime.

- The 5-axis solution: A 5-axis machine can process 5 sides of a part in a single setup(excluding the bottom holding face). This “Done-in-One” capability drastically reduces lead time and improves positional toler

2. Part Complexity and Geometry

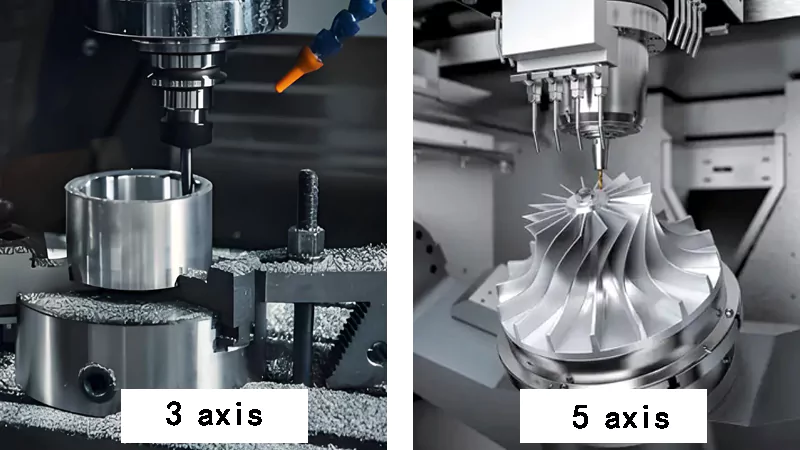

For parts with undercuts, deep cavities, or continuous curved surfaces(like turbine impellers), standard 3-axis tools simply cannot reach the target area without interference. 5-axis machines can tilt the tool or the workpiece to easily avoid collisions, enabling complex geometry.

Here is a table that shows what parts are best for 5-axis CNC machining:

| Suitable Parts for 5-Axis CNC Machining | Examples of Parts |

|---|---|

| Undercuts or multi-sided features | Medical implants |

| Deep cavities or internal features | Robotics components |

| Complex contours or 3D profiles | Tooling for automated systems, Precision prototypes with critical design tolerances |

Tip: If your part has more than two sides or needs curved shapes, 5-axis kinematics will give you better results.

3. Multi-Sided and Curved Features

It is hard to make parts with many sides or curves. 3-axis machining can do simple shapes, but you must set up the part many times. This takes longer and can cause mistakes. Each setup can make the part less accurate.

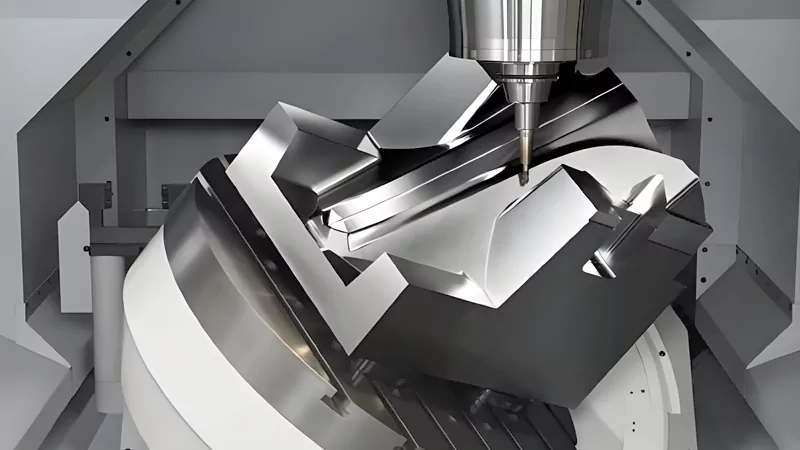

5-axis machining fixes these problems. You can work on all sides and curves at once. This gives you more control over the tool and helps you make hard shapes easily. You also get a smoother finish, and your tools last longer.

The table below shows how each CNC machine works with multi-sided and curved parts:

| Feature | 3-Axis CNC Machining | 5-Axis CNC Machining |

|---|---|---|

| Ability to machine complex geometries | Limited | High |

| Setup requirements | Multiple setups | Single setup |

| Surface finish quality | Moderate | Superior |

| Tool life | Standard | Enhanced |

| Cycle times | Longer | Reduced |

| Undercut capabilities | Challenging | Easy |

| Overall accuracy | Lower | Higher |

Note: You save time and get better parts when you use 5-axis machining for parts with many sides or curves.

4. Precision and Surface Quality

When machining deep cavities with 3-axis, long tools re required to avoid collision, which leads to tool vibration(chatter) and poor surface quality.

5-axis machines allow the use of shorter, more rigid cutting tools because the head can lower closer to the part. This significantly reduces vibration, resulting in a lower surface roughness(Ra value) and reducing the need for secondary manual polishing.

If you need your part to be very exact or look shiny, pick 5-axis CNC machining. For easy jobs, 3-axis machining costs less and works fine.

Tip: Always choose the right cnc machining for your part’s shape and quality needs. This helps you avoid mistakes and makes your project go well.

5. Extended Tool Life

By maintaining optimal chip load and cutting angles, 5-axis machining reduces anomalous tool wear. This is particularly beneficial when cutting hard-to-machine materials like Titanium or Stainless Steel, directly saving you money on tooling consumables.

6. Cost and Efficiency Factors

You need to think about both the starting price and future costs when picking between 3-axis machining and 5-axis machining. A new high-end 5-axis CNC machine costs about $108000 in 2025. In comparison, the purchase and maintenance costs of three-axis machine tools are much lower. And running costs over time and different too. You pay more each hour to use a 5-axis machine, but it works faster for tough jobs. The table below shows how the costs compare:

| CNC Type | Cost per Hour | Machine Cost Range | Efficiency in Handling Complex Geometries |

|---|---|---|---|

| 3-Axis | $20–$40 | $25K–$50K | Limited; needs more setups for hard parts |

| 5-Axis | $75–$150+ | $80K–$500K or more | High; can make tough shapes with fewer setups |

Note: 5-axis machining costs more, but it saves time and cuts mistakes on hard jobs.

7. Setup Reduction and Cycle Time

You should think about how setup and cycle time change your work. 5-axis CNC machining lets you finish a part in just one setup. This means less moving and fewer mistakes. You get better accuracy and faster results.

The table below compares setup and machining time:

| Factor | 3-Axis | 5-Axis |

|---|---|---|

| Setup Time | Medium | Very Low (1-setup) |

| Tolerance Range | ±0.1 mm | ±0.01 mm or tighter |

| Machining Time | Medium | Fastest (optimized tool paths) |

With 3-axis machining, you need to set up the part many times for hard jobs. This takes longer and can cause mistakes. 5-axis machining makes things easier and is great for jobs that need to be very exact.

Tip: Pick 5-axis cnc machining for parts with tight fits or tricky shapes to work faster and more accurately.

7. Production Volume Impact

How many parts do you make changes to determine which CNC machine is best for saving money? 5-axis mills need fewer setups for hard parts. This means better accuracy and less work for people. When you make more parts, the price for each part drops a lot.

- The price for each part can drop by half if you make five instead of one.

- Big orders, like over 1,000 parts, can make the price five to ten times lower for each part.

- Fewer setups with 5-axis machining mean less work and faster jobs.

If you want to make lots of parts, 5-axis CNC machining is better for hard designs. For easy, small jobs, 3-axis machining is still a good way to save money.

Remember: Choose your machine based on how hard your parts are and how many you need. This helps you save money and work faster.

Industry Applications and Use Cases

Not every part requires a 5-axis. However, in the following industries, it is practically the standard for high-precision CNC machining:

Aerospace Industry

Essential for machining turbine blades, blisks, and complex airframe structures requiring simultaneous motion for aerodynamics and lightweighting.

Medial Devices

Human bones and organs are not geometric planes. 5-axis is the optimal choice for manufacturing orthopedic implants(like hip joints) and surgical instruments.

High-Performance Automotive

Used for engine ports, intake manifolds, and transmission housings that require optimized fluid dynamics.

Prototyping vs Mass Production

Prototyping and mass production need different things. For prototypes, you want speed and easy changes. 5-axis machining works with many materials. You can make hard shapes fast and test new ideas. This lowers mistakes and gives good results.

For mass production, you need every part to be the same. 5-axis machining lets you make many parts with fewer setups. You save time and lower costs for each part. 3-axis machining is good for simple, high-volume items. You switch to 5-axis machining for advanced designs or less manual work.

- 5-axis machining gives better accuracy and flexibility.

- You make hard shapes with high precision.

- This technology helps with small batches and prototypes.

Tip: Use 5-axis machining for fast prototyping and making many complex parts. For simple, repeatable items, 3-axis machining is still a good way to save money.

Pitfalls and Hidden Costs

When you pick between 3-axis and 5-axis machining, watch out for extra costs and mistakes. Many projects have problems because people forget about setup, programming, maintenance, or picking the right specs. If you want your CNC machining project to work well, you need to know about these risks.

Setup and Programming Challenges

Setup and programming might seem easy at first, but they can get tricky fast. With 3-axis machining, you work with basic shapes and need less training. You set up the machine quickly and use simple programs. If you switch to 5-axis machining, setups get harder. You need advanced programming skills and more training for workers. The table below shows how these challenges are different:

| Aspect | 3-Axis CNC Machines | 5-Axis CNC Machines |

|---|---|---|

| Complexity | Simpler, suitable for basic shapes | More complex, handles intricate geometries |

| Programming Skills | Basic programming skills required | Advanced programming skills needed |

| Setup Time | Generally quicker setup | More time-consuming setup due to complexity |

| Training Requirements | Minimal training for operators | Significant training required for operators |

If you do not plan for these extra steps, you might have delays and spend more money. Make sure your team has the right skills before starting with 5-axis machining.

Maintenance and Downtime

All CNC machines need regular care. If you skip maintenance, machines can break, and you lose time. 5-axis machines have more moving parts and are more complicated. You need to check and fix these machines more often. If you forget, you might have longer downtime and bigger repair bills. 3-axis machines are easier to take care of, but you still need a schedule.

Set up a maintenance plan for every CNC machine. This keeps your work going and helps you avoid surprise costs. If you plan for downtime, you can keep your project moving.

Tip: Regular maintenance saves money and stops sudden breakdowns. You protect your machines and keep your cnc machining running well.

Over- or Under-Specifying

When you set rules for your CNC machining project, you need to find the right middle ground. If you ask for very tight tolerances, costs go up fast. You need better machines and strict checks. The link between tolerance and cost is not simple. Tighter tolerances can make costs jump much higher than you think.

- Use normal tolerances when you can to keep costs low and jobs faster.

- Costs go up a lot when you move from normal to very tight tolerances because jobs get harder.

- Tight tolerances make production more expensive since you need better machines and careful checks.

- The link between tolerance and cost is not straight; tighter tolerances can make costs rise much faster.

- Asking for too-tight tolerances is a common mistake that can make projects cost more and take longer.

- Picking tolerances wisely can save you lots of money and time.

If you ask for tolerances that are too loose, your parts might not fit or work right. If you ask for tolerances that are too tight, you waste money and time. Match your rules to what your project really needs. This helps you avoid costly mistakes and keeps your CNC machining working well.

Supplier Evaluation and Cost-Effectiveness

Supplier Experience

When you pick a CNC machining supplier, check if they know both 3-axis and 5-axis machining. Suppliers with lots of experience can help you avoid problems and delays. You want someone who knows how to make hard parts and can meet tight rules. Skilled suppliers know how to use fewer setups, which saves you time and money. They also give you better finishes and faster work.

As an honest manufacturing partner, we don’t recommend 5-axis for every project. 3-axis is more cost-effective for:

- Simple Geometries: Parts with only flat surfaces, right angles, and standard holes.

- Budget Constraints & Standard Precision: If the part does not require tight positional tolerances across multiple faces, the lower rate of 3-axis is preferable.

- High volume, Low complexity: For rapid production of washers, brackets, or simple plates, 3-axis combined with automated fixtures is highly efficient.

Why Choose AFI Industrial Co., Ltd. for Your Next Project?

Owning a 5-axis machine doesn’t guarantee 5-axis capability – it requires experienced CAM programmers and skilled operators.

At AFI Industrial Co., Ltd, we are equipped with advanced Mazak 5-axis machining centers and backed by an engineering team that understands design. We review your CAD drawings to provide Design for Manufacturability(DFM) feedback, helping you optimize costs at the design stage.

Summary

- Pick a 3-axis CNC machine for easy parts and lower cost. It works well for simple jobs and small budgets.

- Choose a 5-axis CNC machine for hard shapes and high accuracy. It is great for making detailed surfaces and tight fits.

- 5-axis machining can cut cycle time and setup time a lot. This makes it good for big production runs.

- Think about how hard your parts are. Use a 3-axis for simple designs. Use a 5-axis for tricky shapes with undercuts.

- Look at your budget closely. 3-axis machines cost less at first. 5-axis machines save time and lower mistakes later.

Ready to get started? Don’t compromise on precision for your complex designs. Contact our engineers for a free DFM review and a competitive quote for 5-axis machining.

FAQ

3-axis machining is good for easy parts with straight cuts. 5-axis machining is better for making hard shapes or curved surfaces. The extra axes help you reach more angles in one setup.

Pick 5-axis machining for parts with undercuts or many sides. It is best for jobs that need tight fits and smooth finishes. Aerospace, medical, and car projects often use 5-axis machining.

Yes, 5-axis machining costs more than 3-axis machining. The machine is advanced and needs skilled workers. You pay more, but you get faster work and better accuracy for tough jobs.

You can use 3-axis machining for simple prototypes. If your prototype has many sides or curves, use 5-axis machining. It saves time and gives better results.

CNC machining makes cuts very precise and repeatable. You get smoother surfaces and tighter fits, especially with 5-axis machining. You avoid mistakes and do less manual work.

You can use metals like titanium, aluminum, and stainless steel. Plastics and composites also work well. 5-axis machining handles tough materials and hard shapes easily.

Look at your part’s shape, how many you need, and your budget. Pick 5-axis machining for complex shapes or big batches. For simple jobs, 3-axis machining is a good choice.

Tip: Always talk to your supplier before you choose. You get expert help and avoid expensive mistakes.