If you want metal that does not rust, pick 316 stainless steel. If you want metal that is easy to shape and costs less, pick 416 stainless steel. When considering 316 vs 416 stainless steel, you should choose based on where you use the part. Think about how much money you want to spend. Also, consider what you need the metal to do. Many businesses use these steels for different jobs.

| Industry/Area | Applications |

|---|---|

| Food Processing Equipment | Parts that stay clean and do not rust |

| Firearms and Defense | Strong hammers and triggers that are easy to make |

| Medical | Tools and implants that do not rust |

| Heavy Industries | Tanks and pipes for hard work |

Think about what matters most to you. Is it stopping rust, shaping the metal, or saving money? This will help you pick between 316 vs 416 stainless steel quickly.

Key Takeaways

- Pick 316 stainless steel for great rust protection. It works well in places with lots of water or chemicals.

- Use 416 stainless steel if you want to save money. It is easy to cut and shape.

- Think about how you will use the steel. 316 is best for food and medical uses because it does not rust easily.

- Check your budget before you choose. 416 stainless steel costs less, so it is good for cheaper projects.

- Know that 316 stainless steel is stronger and harder. It is better for tough jobs.

- Choose 416 stainless steel for making many parts fast. It helps tools last longer.

- Always pick the right steel for your project. This helps your project last and work well.

- Ask suppliers or engineers for help if you are not sure which steel to use.

Table of Contents

Quick comparison

316 vs 416 stainless steel summary

When you look at 316 and 416 stainless steel, you see they are different. Their chemical makeup and how they work are not the same. 316 stainless steel has more chromium and nickel. It also has molybdenum. This helps it fight rust, even in salty or wet places. 416 stainless steel has less chromium and almost no nickel. It has sulfur, which makes it easier to cut and shape. But the sulfur makes it not as good at stopping rust.

Here is a quick look at their main differences:

| Property | 316 Stainless Steel | 416 Stainless Steel |

|---|---|---|

| Chromium Content | 16-18% | 12-14% |

| Nickel Content | 10-14% | Lacks significant amounts |

| Molybdenum Content | 2-3% | None |

| Sulfur Content | None | Present (improves machinability) |

| Corrosion Resistance | High (especially in chloride environments) | Moderate (compromised by sulfur) |

You can see that AISI 316 is very good at stopping rust. This makes it great for tough places. AISI 416 stainless steel is better if you need to cut or shape metal fast.

Key features

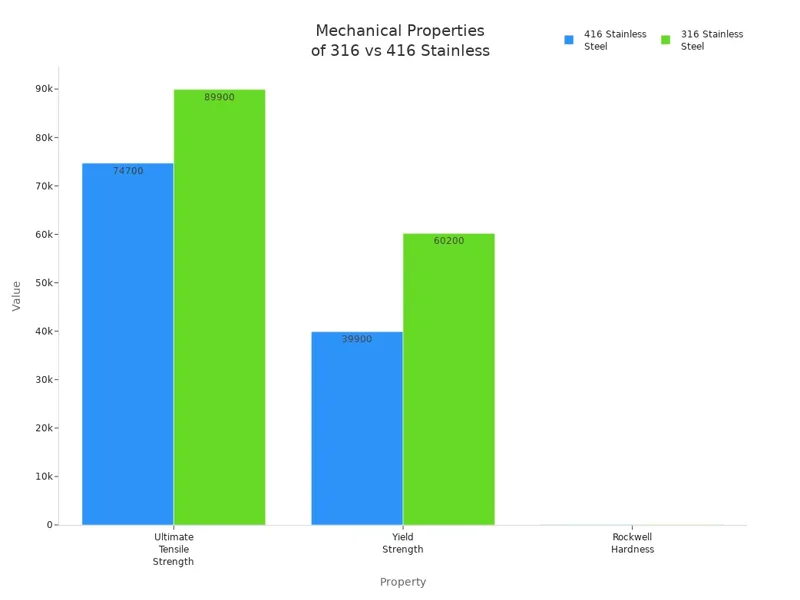

You should also check how strong and hard these steels are. 316 stainless steel is stronger than 416 stainless steel. It can take more force before it bends or breaks. The Rockwell hardness scale shows 316 stainless steel is harder too.

| Property | 416 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Ultimate Tensile Strength, psi | 74,700 | 89,900 |

| Yield Strength, psi | 39,900 | 60,200 |

| Rockwell Hardness | B82 | B91 |

416 stainless steel is much easier to machine. The sulfur helps tools cut it faster. This can save time and money if you make lots of parts. 316 stainless steel costs more. But you get better rust protection and strength.

Tip: If you need metal for boats, food, or medical things, pick 316 stainless steel. If you want to save money and need easy cutting, choose 416 stainless steel.

Comparing the two steels helps you pick the right one. Always match the steel to your project. Use this comparison to think about rust protection, strength, and how easy it is to shape. This way, you get the best steel for your job.

Key differences

Corrosion resistance

When you look at 316 and 416 stainless steel, you see a big difference. 316 stainless steel is much better at stopping rust. It has molybdenum, which helps it fight rust and damage from chemicals. You will find 316 stainless steel in places with saltwater, chemicals, or lots of moisture.

- 316 stainless steel is used in:

- The ocean

- Chemical plants

- Buildings near the coast

It can stop chloride attacks and pitting. It also resists crevice corrosion. This makes it great for boats and chemical jobs. 416 stainless steel does not have molybdenum. It has sulfur, so it is easier to cut. But it does not stop rust as well. You should not use 416 stainless steel in wet or salty places. It can rust faster there.

| Property | 316 Stainless Steel | 416 Stainless Steel |

|---|---|---|

| Molybdenum Content | 2-2.5% | N/A |

| Corrosion Resistance | High, especially in acidic environments | Inferior, particularly in chloride-rich areas |

| Pitting Resistance | Excellent | N/A |

| Temperature Resilience | Improved resilience under extreme temperatures | N/A |

Note: Pick 316 stainless steel for boats, pools, or chemical tanks. It is best for stopping rust.

Strength and hardness

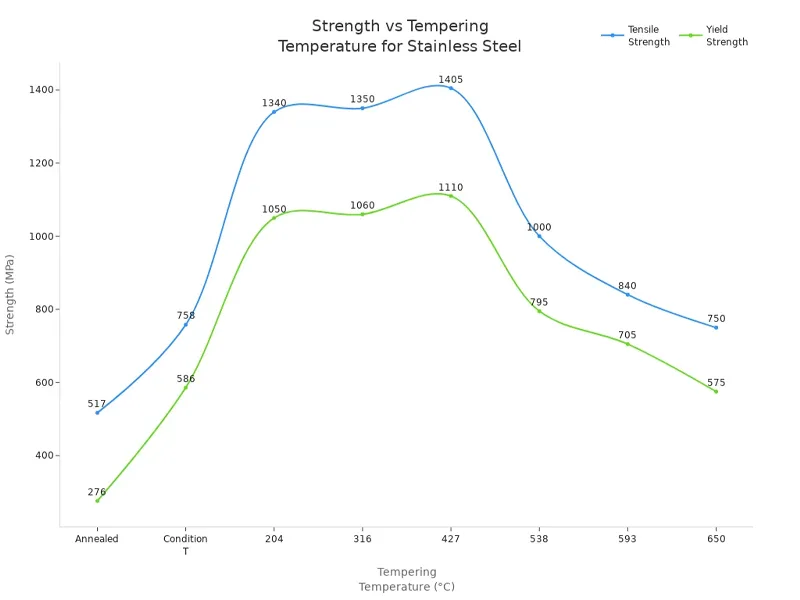

You should also think about strength and hardness. 316 stainless steel is stronger and harder than 416 stainless steel. It can take more force before it bends or breaks. You can see this in their tensile and yield strength numbers.

| Tempering Temperature (°C) | Tensile Strength (MPa) | Yield Strength 0.2% Proof (MPa) |

|---|---|---|

| Annealed (316) | 517 | 276 |

| Annealed (416) | 758 | 586 |

| 204 | 1340 | 1050 |

| 316 | 1350 | 1060 |

| 427 | 1405 | 1110 |

| 538 | 1000 | 795 |

| 593 | 840 | 705 |

| 650 | 750 | 575 |

316 stainless steel works better for tough jobs. It keeps its strength even when it gets hot. 416 stainless steel is softer. It can wear out faster if you use it for heavy work.

Machinability

Machinability means how easy it is to cut or shape the metal. 416 stainless steel is much easier to machine. It has sulfur, so you can cut it faster and use cheaper tools.

| Material | Machinability Index | Comparison to Mild Steel |

|---|---|---|

| 416 Stainless Steel | 90 | 100 |

| 316 Stainless Steel | N/A | N/A |

You can use high-speed steel or carbide tools for 416 stainless steel. You can cut it at speeds up to 500 SFM with carbide tools. For 316 stainless steel, you must go slower. You should cut at only 50-70 SFM with high-speed steel tools.

| Stainless Steel Type | Recommended Cutting Speed (SFM) | Tooling Type |

|---|---|---|

| 316 | 50-70 | HSS |

| 416 | 500 (Carbide) / 120 (HSS) | Carbide / HSS |

- Carbide tools work best for 416 stainless steel.

- You save time and money when you machine 416 stainless steel.

If you need to make many parts fast, pick 416 stainless steel. If you want more rust protection and strength, choose 316 stainless steel. It is harder to machine, but it lasts longer.

Cost

When you choose between 316 and 416 stainless steel, cost plays a big role. You want to get the best value for your project. The price of stainless steel changes based on the type, the market, and the amount you buy.

You will notice that 316 stainless steel usually costs more than 416 stainless steel. The reason is simple. 316 stainless steel has extra elements like molybdenum and nickel. These elements give it high corrosion resistance, but they also make it more expensive to produce.

Here are some recent prices for stainless steel in the United States:

- The average price for 316 stainless steel solid scrap was $1.14 USD per pound as of September 20, 2023.

- The average price for 316 stainless steel secondary scrap was $0.50 USD per pound as of August 28, 2025.

- The average price for general stainless steel scrap was $0.47 USD per pound on October 3, 2025.

You can see that 316 stainless steel sits at the higher end of the price range. If you need high corrosion resistance, you will pay more for 316. This extra cost makes sense if you use the steel in places with water, salt, or chemicals. You get better protection and longer life.

416 stainless steel costs less. It does not have the same level of corrosion resistance as 316. You save money if you use 416 for dry or indoor projects where rust is not a big problem. Many machine shops pick 416 when they need to make lots of parts quickly and want to keep costs down.

Tip: If your project needs strong rust protection, spend more for 316 stainless steel. If you want to save money and do not need high corrosion resistance, 416 stainless steel is a smart choice.

Always match your budget to your needs. Think about where you will use the steel and how much you want to spend. This way, you get the right balance between cost and performance.

Key similarities

Stainless steel basics

You will find that both 316 and 416 belong to the same family. They are both types of stainless steel. This means they share some important qualities. Both resist rust better than regular steel. You can use them in places where you need strength and a clean look. Both types have chromium in their mix. Chromium forms a thin layer on the surface. This layer helps stop rust and stains. You can count on both to last longer than plain steel in most environments.

Magnetic properties

You may notice that not all stainless steels act the same around magnets. The difference comes from their internal structure. Here is how 316 and 416 compare:

- 416 stainless steel is magnetic because it has a martensitic structure.

- The martensitic structure forms when carbon and chromium mix in a certain way.

- 316 stainless steel is usually non-magnetic. It has an austenitic structure.

If you need a metal that sticks to magnets, you should pick 416. If you want a metal that does not react to magnets, 316 is a better choice.

Tip: Always test your material with a magnet if magnetic properties matter for your project.

Heat resistance

Both 316 and 416 can handle high temperatures. You can use them in places where heat is a concern. However, their limits are not the same. The table below shows the maximum service temperatures for each type:

| Stainless Steel | Maximum Service Temperature (Continuous) | Maximum Service Temperature (Intermittent) |

|---|---|---|

| 416 | 675 °C (1250 °F) | 760 °C (1400 °F) |

| 316 | 870 °C (1600 °F) | 925 °C (1700 °F) |

You can see that 316 handles higher heat than 416. If your project faces extreme temperatures, 316 gives you more safety. Both types keep their strength and shape well under heat, but you should always check the limits before choosing.

316 vs 416 stainless steel uses

Marine and corrosive settings

You need metal that does not rust in salty or wet places. Saltwater and chemicals can ruin most metals fast. 316 stainless steel is the best choice for these jobs. People use it to build boats and docks. It works well on offshore platforms, too. This metal fights rust better than most others. It stays strong even in tough weather.

- Grade 316 works great where there is saltwater or strong chemicals.

- You see it in boat hulls, railings, and marine hardware.

- Oil and gas platforms use it for walkways and handrails.

- Ships use it for pipes, hinges, and fasteners.

- Docks use it for bolts, washers, and signs.

- Water plants pick it for pipes under the sea.

Pick 316 stainless steel if you want metal that lasts in harsh places. It keeps your things safe from rust and damage.

Tip: If your project is near the ocean or uses chemicals, pick 316 stainless steel. It helps your stuff last longer and need less fixing.

Food and medical

Food and medical jobs need very clean and safe metal. 316 stainless steel is good for this because it does not react with food or medicine. It stands up to acids, salt, and strong cleaners. You see it in milk factories, drug storage, and medical tools. This metal keeps food and medicine safe.

| Grade | Best For | Why? |

|---|---|---|

| 316 Stainless Steel | Dairy processing, pharmaceutical storage, marine applications | Superior resistance to acids, salt, and harsh chemicals |

ASTM International makes rules for safe medical tools. ASTM F899-20 lists what stainless steel must have for surgical tools. 316 stainless steel meets these rules and keeps things safe.

- ASTM F899-20 checks the safety of surgical tools.

- 316 stainless steel is best for food and medical jobs.

Use 316 stainless steel if you need metal that is safe and does not rust in food or medical places.

Note: Always check the rules for your job. 316 stainless steel meets top safety and cleanliness needs.

Firearms and precision parts

Firearms and small machine parts need metal that is easy to shape and strong. 416 stainless steel is good for these jobs because it is easy to cut. People use it for nuts, bolts, and studs. This metal has sulfur, so you can shape it faster. It also wears down slowly, especially after heat treatment.

| Stainless Steel Grade | Key Characteristics | Common Applications |

|---|---|---|

| 316 | Excellent corrosion resistance; not easy to harden | Trigger guards, floorplates |

| 416 | Excellent machinability; added sulfur for improved machining | Nuts, bolts, studs |

- Grade 316 is used for trigger guards and floor plates because it does not rust.

- Grade 416 is used for nuts, bolts, and studs because it is easy to machine.

You can make 416 stainless steel even tougher with heat. This makes it good for valves, shafts, and gears. It works well up to 1400°F (760°C), so it is good for hot parts.

| Property | Description |

|---|---|

| Heat Treatment Effects | Makes it stronger and harder, but less tough. |

| Composition | More manganese and chromium make it better. |

| Carbon Content | Helps it resist wear and damage. |

| Applications | Good for valves, shafts, and gears that need to last. |

| Temperature Resistance | Stays strong up to 1400°F (760°C) and 1247°F (675°C). |

| Machining Properties | Does not stick to tools and is easy to cut. |

Pick 416 stainless steel for small parts that need easy cutting and good wear resistance. If your parts will get wet or touch chemicals, use 316 stainless steel.

Tip: For guns and small machine parts, 416 stainless steel saves time and money. For parts that get wet or touch chemicals, 316 stainless steel protects better.

Machining and manufacturing

You want to pick the right stainless steel for machining and manufacturing jobs. The choice between 316 and 416 stainless steel can change how fast you work and how much you spend on tools. If you need to make many parts quickly, 416 stainless steel stands out. This metal is known as a free-machining grade. It has added sulfur, which makes it much easier to cut and shape. You can use standard tools and run machines at higher speeds. This means you finish jobs faster and your tools last longer.

| Stainless Steel | Machinability Rating | Tool Life Characteristics |

|---|---|---|

| 316 | Poor | Shorter tool life due to specialized tools |

| 416 | Easy | Longer tool life due to easier machining |

- 416 stainless steel lets you machine parts with less effort.

- You get higher productivity and save money on tool replacements.

- 316 stainless steel needs special cutting tools. You must go slower, and your tools wear out faster.

The 416 stainless steel helps you keep costs down in busy shops. You can make more parts in less time. If you use 316 stainless steel, you get better corrosion resistance, but you spend more time and money on machining.

Tip: Choose 416 stainless steel for high-volume manufacturing where speed and tool life matter most. Pick 316 stainless steel if your parts will face harsh chemicals or need to last in tough environments.

Budget projects

When you work on budget projects, you want to save money but still get good results. The cost of stainless steel depends on the type you pick and how you use it. 416 stainless steel is the more affordable choice. It has less nickel and no molybdenum, so the raw material costs less. You also spend less on machining because it is easy to cut. This means you pay less for labor and tools.

Here is a table to help you compare the costs:

| Cost Aspect | 416 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Initial Material Cost | Lower — less nickel and molybdenum | Higher — premium alloying elements |

| Machining Cost | Lower — easy to machine, less tool wear | Higher — slower machining, more tool wear |

| Production Lead Time | Shorter — faster machining | Longer — careful processing needed |

| Maintenance Costs | Higher — may need more repairs or replacements | Lower — lasts longer in tough environments |

| Total Cost of Ownership | Best for dry, indoor, or short-term projects | Best for harsh, wet, or marine environments |

- 416 stainless steel helps you finish projects on a tight budget.

- You get fast production and lower upfront costs.

- 316 stainless steel costs more at first, but it saves money over time if you need strong corrosion resistance.

You should think about what your project needs most. If you do not need top-level rust protection, 416 stainless steel is a smart pick for saving money. If your project faces water, chemicals, or marine conditions, 316 stainless steel gives you better value in the long run.

Note: Always match your steel choice to your project’s needs. Saving money now can cost more later if you pick the wrong grade for the job.

Decision checklist

Corrosion resistance needs

First, think about how much rust protection you need. Some jobs need metal that can handle tough places. If your project is near saltwater, chemicals, or outside, you need strong corrosion resistance.

- Saltwater can cause pitting and fast rusting.

- If you weld different stainless steels, bimetallic corrosion can happen.

- Humidity or pollution can also cause rust that you do not expect.

Look at what is in the alloy. Stainless steel with more chromium, molybdenum, and nickel protects better. Grade 316 has molybdenum, so it is great for marine and chemical jobs. Grade 304 works for many things, but does not fight chlorides as well.

Tip: Pick 316 stainless steel if your project is near the ocean, in a pool, or in a chemical plant. It gives the best rust protection.

Machining needs

Next, think about how easy it is to cut and shape the metal. Some stainless steels are much easier to machine than others. If you need to make lots of parts fast, machinability is important.

Here is a simple table to help you compare:

| Stainless Steel Grade | Machinability Considerations | Additional Properties |

|---|---|---|

| 316 | Needs special tools and slower speeds to avoid hardening | Strong and durable due to higher nickel content |

| 416 | Easy to machine because of added sulfur | Ferritic steel with good machinability |

You can save time and money by picking the right grade for machining. 416 stainless steel lets you cut parts faster, and your tools last longer. 316 stainless steel is harder to machine, but it is stronger.

Note: For fast machining or making many parts, 416 stainless steel is the better pick.

Budget

You should also look at your budget before you choose. The price of stainless steel can change your whole plan. If you do not need the best protection, you can save money with 416 stainless steel.

- Check your budget and how much you can spend.

- If you want to save money and do not need top rust protection, 416 stainless steel is a smart choice.

- If your project needs to last in tough places, spending more on 316 stainless steel can save money later.

Remember: Saving money now can mean higher repair or replacement costs later if you pick the wrong steel.

Application

When you choose between 316 and 416 stainless steel, you need to think about how you will use the metal. The application decides which grade works best for your project. You want to match the steel to the job so you get the best results.

Start by asking yourself these questions:

- Where will you use the part?

- Will the part touch water, chemicals, or food?

- Does the part need to last a long time?

- Do you need to make many parts quickly?

- Is saving money your main goal?

Use the table below to help you decide:

| Application Type | Best Stainless Steel | Why It Works Well |

|---|---|---|

| Marine (boats, docks) | 316 | Fights rust from saltwater |

| Food & Medical | 316 | Safe for food, resists chemicals |

| Firearms & Precision | 416 | Easy to machine, strong after heat |

| High-Volume Machining | 416 | Fast to cut, saves tool costs |

| Budget Projects | 416 | Lower price, quick production |

| Chemical Plants | 316 | Handles acids and harsh cleaners |

| Outdoor Hardware | 316 | Stays strong in rain and humidity |

| Indoor Fixtures | 416 | Good for dry, low-risk settings |

You should pick 316 stainless steel if your project faces water, salt, or chemicals. This grade keeps your parts safe from rust and damage. You see 316 in places like swimming pools, kitchens, and hospitals. It also works well for outdoor signs and railings.

If you need to make many parts fast, 416 stainless steel helps you save time and money. You can cut and shape it easily. Machine shops use 416 for bolts, nuts, and gears. Firearm makers choose 416 for triggers and barrels because it is easy to work with and strong after heat treatment.

Tip: Always match the steel to your project’s needs. If you want long life and rust protection, choose 316. If you want easy machining and lower cost, pick 416.

Think about the environment. Wet, salty, or chemical-heavy places need 316. Dry, indoor, or low-risk jobs can use 416. You should also look at how many parts you need. High-volume jobs often use 416 to save money.

You make the best choice when you match the steel to your application. This helps your project last longer and cost less. If you are not sure, ask a supplier or engineer for advice. They can help you pick the right grade for your job.

Note: The right stainless steel makes your project safer, stronger, and more affordable. Always check your application before you decide.

When you compare 316 vs 416 stainless steel, you see clear differences. You get better corrosion resistance with 316 stainless steel. You find easier machining and lower cost with 416 stainless steel. Both types belong to the stainless steel family and offer good strength. Use the checklist to match your needs. Your project will work best when you pick the right grade for your environment and budget.

FAQ

You get better rust protection with 316 stainless steel. The molybdenum in 316 helps it resist saltwater and harsh chemicals. You can use it for boats, docks, and marine hardware.

You may find welding 416 stainless steel difficult. The added sulfur improves machinability but can cause cracks during welding. If you need to weld, choose 316 stainless steel for better results.

You should not use 416 stainless steel for food or medical equipment. The sulfur in 416 can contaminate food. For safe food contact, pick 316 stainless steel.

416 stainless steel is magnetic. It has a martensitic structure. 316 stainless steel is usually non-magnetic because it has an austenitic structure.

Think about your needs. If you want rust protection, pick 316. If you need easy machining and lower cost, choose 416. Match the steel to your environment and budget.

You can use 416 stainless steel outdoors in dry areas. It may rust quickly in wet or salty places. For outdoor projects with moisture, 316 stainless steel works better.

Yes, you pay more for 316 stainless steel. The extra nickel and molybdenum increase the price. You get better corrosion resistance and longer life for the higher cost.

You can use high-speed steel or carbide tools for 416 stainless steel. The added sulfur makes cutting easier. You save time and reduce tool wear.