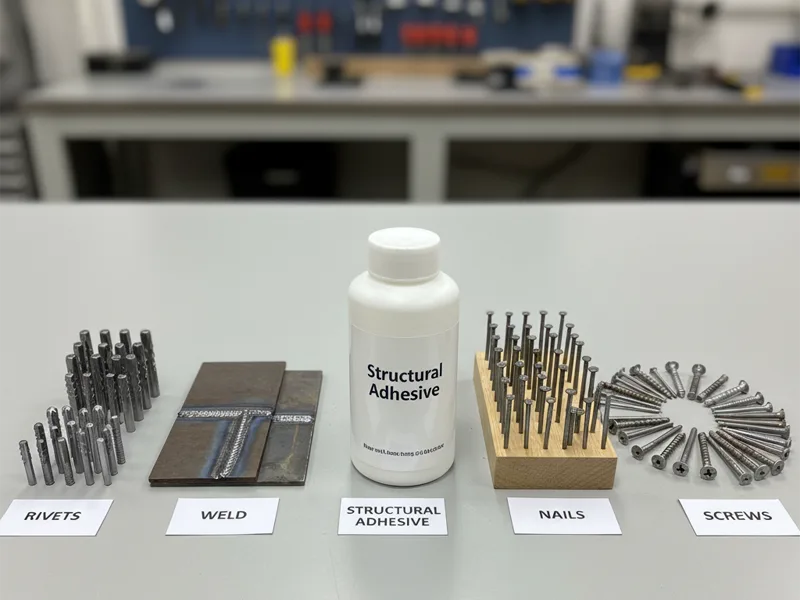

If you want your project to last, you need strong choices. Here are five permanent fasteners that always hold tight: rivets, welds, structural adhesives, nails, and screws. You can trust these options when you need things to stay together. Think about your project and picture how each fastener can help you build something that lasts.

Key Takeaways

- Pick permanent fasteners like rivets, welds, structural adhesives, nails, and screws for strong and lasting holds. Think about what materials you are joining. Some fasteners work better with wood, metal, or plastic. Check how much weight and stress your project will have. Use high-tensile fasteners for heavy things. Rivets are good for metal joints that need to stay together, even if there is a lot of shaking. Welding makes a bond as strong as the materials you join, so it is great for tough jobs. Structural adhesives are flexible and can join different materials without the use of fasteners. Nails are fast to use and work best for wood, giving strong side-to-side strength. Screws hold things tight and work with many materials, so they are a good choice.

Table of Contents

Types of Permanent Fasteners

Common Types of Fasteners

When you build something that should last, you need the right fasteners. Permanent fasteners help make strong connections that stay together. These fasteners are hard to take out. You use them when you want your project to last a long time.

Permanent fasteners make a joint that is not easy to undo. They give strength and keep things stable for a long time. Temporary fasteners are simple to remove and are good for short jobs.

Here is a quick way to see the differences:

| Type of Fastener | Characteristics |

|---|---|

| Temporary Fasteners | Simple to remove, used for short-term joints, examples are bolts and screws. |

| Permanent Fasteners | Used once, makes a joint that stays, examples are welding and soldering. |

You can find many fasteners in building and making things. Some are for quick repairs, and others are for strong holds. The five main permanent fasteners in this post are:

- Rivets

- Welds

- Structural adhesives

- Nails

- Screws

These fasteners are very strong and are used in many jobs. You can see them in bridges and also in furniture. There are other fasteners like bolts, nuts, and anchors, but these five work best for permanent jobs.

Selection Criteria

You should think about a few things before picking a fastener. Every project is different. Here are some questions to help you choose:

- What materials are you joining? Some fasteners are better for metal, others for wood or plastic.

- How much weight or stress will the joint have? Heavy loads need stronger fasteners.

- Will the joint face water, heat, or chemicals? Some fasteners can handle tough places better.

- Do you want the joint to stay or come apart? Permanent fasteners are best if you do not want to take them apart.

There are many fasteners you can buy. Each one has its own good points. When you know the differences, you can pick the best one for your job. Permanent fasteners help you feel sure your project will stay strong.

Rivets

Features

Rivets are a type of permanent fastener that you use to join two or more materials together. You install a rivet by placing it through a hole and then deforming the tail end. This action creates a tight clamping force that holds the materials in place. Rivets work well in high-vibration environments because they do not loosen over time. You can use rivets with metal, wood, or plastic. They create a very tight fit, called an interference fit, which helps them carry more of the load in a joint than loose fasteners.

Here are some features that make rivets strong and reliable:

- You use rivets only once. After installation, you cannot remove them easily.

- Rivets distribute loads evenly across the joint, which makes them good for high-stress applications.

- Structural rivets resist vibration and can handle high shear and tensile loads.

- Rivets work well in places where you need a permanent and secure hold.

You often see rivets used when you need a joint that will not come apart. Their mechanical properties make them one of the strongest types of fasteners available.

Uses

You find rivets in many industries and projects. They are popular because they create strong and lasting connections. Some common uses for fasteners like rivets include:

- Aircraft assembly, where rivets must withstand high shear and tensile forces.

- Construction projects, such as bridges and steel buildings.

- Boiler tanks, where hot rivets seal joints against leaks.

- Ornamental ironwork adds both strength and style.

- Renovation projects, especially when you want to match existing structures.

Rivets play a key role in aerospace engineering. You need to understand the tensile and shear strength of rivets before choosing them for these jobs. Shear strength helps rivets resist sliding forces, while tensile strength shows how much force is needed to pull them apart.

When to Use

You should choose rivets when you want a permanent connection that will last. Rivets work best when you need to join metal parts, but you can also use them with wood or plastic. If your project will face vibration or heavy loads, rivets are a smart choice. You might use rivets in places where other fasteners could loosen or fail over time.

Tip: Use rivets when you need a joint that will not come apart, even in tough conditions.

Rivets are not easy to remove, so you should use them only when you are sure you want a permanent bond. If you need to take things apart later, you might want to look at other types of fasteners.

Welds

Features

Welding gives you one of the strongest ways to join materials. You use heat or pressure to fuse two pieces. The result is a solid bond that acts like a single piece. Welds do not rely on extra fasteners. You create a joint that is almost impossible to undo without cutting or grinding.

Here are some features that make welds stand out:

- You get a super-strong and permanent connection between steel components.

- Welds ensure durability and reliability in high-stress jobs.

- The fusion process means the joint can handle heavy loads and tough conditions.

- Welds do not loosen over time, even with vibration or movement.

Welding creates a bond that is stronger than many other types of fasteners. You can trust welds when you need a joint that will last for years.

Uses

You see welds in many industries. Welding plays a key role in building and repairing large structures. You find welds in places where strength and safety matter most.

Some common uses for welds include:

- Aerospace: You need welding to fuse metals in aircraft manufacturing and repair. Methods like GMAW and electrical arc welding help create strong joints.

- Construction: Over half of the world’s steel goes into construction. MIG welding is popular because it works fast and needs little maintenance compared to other fasteners.

- Railroads: Welding helps make compartments and join rails. Spot welding is effective for these jobs.

- Shipping: You use welding to build ships and containers. Welds make these structures lightweight and easy to maintain.

- Manufacturing: MIG welding is used in many manufacturing sectors. It is fast and cost-effective.

Welds give you reliable connections in heavy industry and infrastructure projects. You see welds in bridges, pipelines, and steel frames. These applications need joints that will not fail under stress.

When to Use

You should choose welding when you want a permanent bond that will not come apart. Welding works best for joining metals, especially steel and aluminum. If your project needs to handle heavy loads, vibration, or harsh weather, welds are a smart choice.

Consider welding for these situations:

- You need a joint that will last for decades.

- Your project faces high stress or heavy use.

- You want a smooth finish without extra fasteners showing.

- You work with steel frames, pipelines, or automotive parts.

Welding is not easy to undo. You should use it only when you are sure the joint will stay in place. If you need to take things apart later, you might want to look at other types of fasteners.

Tip: Use welding for permanent connections in projects that demand strength and durability. Welds give you peace of mind in critical applications.

Structural Adhesives

Features

You can use structural adhesives to make strong bonds. These adhesives include things like epoxy and construction glue. You do not need holes or extra parts to use them. You put them on as a liquid or paste. They harden and make a solid connection.

Structural adhesives use chemical bonding. This means they hold things together at a tiny level. The joint can handle heavy loads and lots of stress. Many adhesives stay flexible after they harden. They can bend and move without breaking.

Here is a table that shows why structural adhesives are a good choice for permanent fastening:

| Property | Description |

|---|---|

| Bond Strength | Moderate-to-high bond strength, forming permanent, high-strength bonds. |

| Flexibility | Excellent flexibility and elongation, allowing for movement without failure. |

| Impact Resistance | Good impact resistance, crucial for load-bearing applications. |

| Environmental Resistance | Resistant to moisture, chemicals, and temperature fluctuations. |

| Adhesion to Dissimilar Materials | Can bond materials like glass-to-metal or plastic-to-wood effectively. |

| Shear and Peel Strength | Excellent shear and peel strength, ensuring durability under stress. |

| Curing Characteristics | Long pot life with slower curing, allowing for adjustments during application. |

| Toughness | High toughness and peel strength, enhancing durability. |

| UV and Chemical Resistance | Strong resistance to UV light and chemicals, ensuring longevity. |

| Electrical Insulation Properties | Good electrical insulation properties, beneficial in electronics applications. |

| Performance in Harsh Environments | Long-lasting performance in harsh environments, suitable for various industries. |

You can see that structural adhesives have many good points. Other fasteners may not give you these benefits.

Uses

You will see structural adhesives used in many jobs. They work well for joining wood, metal, and plastics. These adhesives help you stick things together that are hard to join with nails or screws.

Here is a table that shows some common materials you can bond with structural adhesives:

| Material | Description |

|---|---|

| Wood | A renewable and recyclable resource, ideal for construction due to its structural properties. |

| Aluminum | Requires proper preparation; commonly bonded using anaerobic, cyanoacrylate, and epoxy adhesives. |

| Plastics | Acrylic and polyurethane adhesives are used for high-strength bonding and environmental resistance. |

You might use adhesives in furniture, cars, and electronics. Sometimes, strong adhesives can hold better than nails or screws. This is true for big surfaces. For example, Fusionbond is a new adhesive. It has over 50 J of impact resistance. It has a shear strength above 3,500 psi for steel-to-steel bonds. This makes it great for tough jobs.

When to Use

You should pick structural adhesives when you want a neat look and a strong bond. Adhesives work best for joining different materials. They are good when you do not want to drill holes. You can use them where vibration, water, or chemicals might hurt other fasteners.

Tip: Use structural adhesives for projects that need a smooth finish, strong hold, and resistance to harsh conditions.

You will find adhesives helpful in building cars and electronics. They help you make joints that last, even in hard places. If you want a permanent fix that spreads stress out, adhesives are a smart choice.

Nails

Features

You see nails as one of the oldest and most trusted fasteners in woodworking. People have used nails for over 5,000 years, which shows their reliability. You can choose from many types of nails, each designed for specific tasks. Nails come in different lengths, gauges, and shapes, so you always find one that fits your project.

- Nails work best for wood because they bond well with wood fibers.

- You install nails quickly, which saves you time on large jobs.

- Nails cost less than screws, making them a practical choice for many projects.

- You get better shear strength with nails, so they handle sliding pressure better than screws.

- Some nails, like LIGNOLOC® wooden nails, use heat to bond with wood, creating a strong and permanent connection.

- Nails do not corrode or react with certain woods, so your project stays strong for years.

Tip: You should use nails when you want a fast, strong, and lasting hold in wood.

Uses

You find nails in almost every part of residential and commercial construction. Nails help you build sturdy frames, attach sheathing, and secure roofing materials. You also use nails in furniture making and home repairs. Nails work well for outdoor structures because they resist weather and hold up over time.

Here are some common uses for nails:

- Framing: You join studs, plates, and joists to form the skeleton of a building.

- Sheathing: You attach plywood or OSB to framing for extra strength.

- Roofing: You secure shingles and underlayment to keep out water.

- Woodworking: You assemble furniture and create strong joints.

- Home repairs: You fasten loose boards and hang pictures.

- Outdoor structures: You build fences, decks, and garden features.

- Temporary fixtures: You put together supports and temporary structures.

Nails give you a reliable way to connect wood in many applications. You can trust nails to hold strong in both indoor and outdoor projects.

When to Use

You should choose nails when you need a quick and permanent connection in wood. Nails work best for framing, decking, and fencing. You get strong holding power and good withdrawal resistance, which means nails stay in place even when the wood expands or contracts.

You see that nails hold well in many types of wood. You should use nails for fast, permanent assemblies, especially when you need to secure trim or build frames. Nails give you a strong joint that lasts, even in tough conditions.

Note: You should pick nails for wood projects that need speed, strength, and reliability. Nails remain one of the most popular fasteners for wood because they work well in so many applications.

Screws

Features

You can count on screws as one of the most versatile fasteners for your projects. Screws have a unique design with threads that grip into the material. This threading lets you create a strong hold without needing to tap threads first. When you drive a screw into wood, metal, or plastic, it forms its own internal threads. This feature makes screws adaptable for many jobs and reduces the need for extra tools.

Screws offer high tensile strength. This means they resist being pulled apart better than nails. The threading also gives screws a better grip, so they stay in place even when the material moves or vibrates. You will find that screws are more difficult to remove than nails, which adds to their reliability in permanent applications. Many people choose screws when they want a fastener that lasts a long time.

Tip: Use screws when you need a strong, lasting connection that will not loosen easily.

Uses

You see screws in almost every type of construction and repair work. Their versatility makes them a top choice for many tasks. Here are some of the most common uses for screws:

- Wood screws help you build furniture, cabinets, and other wood projects.

- Machine screws hold together machinery, appliances, and electronic devices.

- Self-drilling screws let you fasten metal and wood quickly, and are often used in metal buildings and roofing.

- Self-tapping screws work well for metal, plastic, and wood, creating threads as you drive them in.

- Sheet metal screws secure thin metal sheets, such as in HVAC systems and car assembly.

- Drywall screws attach drywall sheets to wooden or metal studs in walls and ceilings.

You can see that screws work in many different materials and settings. This makes them one of the most popular types of fasteners for both professionals and DIYers.

When to Use

You should choose screws when you want a permanent solution that offers both strength and durability. Screws work best when you need a joint that can handle pulling forces, such as in shelving, decking, or framing. Their high tensile strength means they last longer in demanding jobs compared to nails. However, nails have better shear strength, so they bend under pressure instead of breaking.

Here is a table to help you compare screws, nails, and rivets:

| Fastener Type | Tensile Strength | Shear Strength | Durability |

|---|---|---|---|

| Screws | Higher than nails | Lower than nails | Longer lifespan in high-stress jobs |

| Nails | Lower than screws | Higher than screws | More elastic, can bend under load |

| Rivets | Not specified | Not specified | Not specified |

You should use screws for projects where you want a secure, long-lasting hold. Screws are harder to remove than nails, so they keep your work together even when it faces stress or vibration. If you need a fastener that adapts to many materials and holds strongly, screws are a smart choice.

Note: Screws give you the flexibility to work with many types of fasteners and materials. They help you build projects that last.

Comparison Table

Strengths

It is important to pick the right fastener for your project. Each type has its own strong points. The table below shows how they are different:

| Fastener Type | Strengths |

|---|---|

| Rivets | High strength for metal connections. Excellent for vibration resistance. |

| Welds | Creates a joint as strong as the base material. Handles heavy loads and harsh conditions. |

| Structural Adhesives | Bonds dissimilar materials. Spreads stress evenly. Resists moisture and chemicals. |

| Nails | Greater shear strength in wood. Quick to install. Good for large projects. |

| Screws | High tensile strength. Strong grip. Easy to use in many materials. |

Tip: Make sure the fastener’s strength matches your project’s needs for the best results.

Weaknesses

All fasteners have some weak points. Knowing these can help you avoid mistakes. Here are the most common problems and ways fasteners can fail:

- Rivets: Hard to take out. They might fail from getting tired or rusting over time.

- Welds: Needs special tools and skills. It can break from cracks or stress.

- Structural Adhesives: Needs clean surfaces. Might get weak in high heat or if not set right.

- Nails: Can pull out if pulled hard. It can rust if not coated. Might split wood if not placed right.

- Screws: Can break from side pressure. Threads can strip in soft stuff. It can fail from repeated stress.

Note: Fasteners often fail from getting tired, breaking, or rusting. You should check your materials and where you will use them before picking.

Best Uses

You want your project to last a long time. The table below shows the best ways to use each fastener:

| Fastener Type | Best Use Scenario | Material Considerations | Load Requirements |

|---|---|---|---|

| Rivets | Permanent fastening in bridges, aircraft, and metalwork | Works best with metals, some plastics | High load, vibration |

| Welds | Steel frames, pipelines, automotive, and heavy industry | Metals like steel and aluminum | Very high load |

| Structural Adhesives | Furniture, composites, electronics, mixed materials | Bonds wood, metal, plastic, glass | Moderate to high load |

| Nails | Framing, decking, fencing, and woodworking | Best for wood | Shear loads, quick jobs |

| Screws | Bonds: wood, metal, plastic, glass | Wood, metal, plastic | Tensile loads, moderate |

- Use rivets and welds for strong, permanent metal joints.

- Structural adhesives are good for joining different materials or when you want a smooth look.

- Nails are best for quick and strong wood jobs.

- Screws work well in many materials and are easy to put in.

Remember: The best fastener depends on your project’s materials, how much weight it will hold, and where you use it. You get the best results when you pick the right fastener for the job.

Choosing Permanent Fasteners

Project Materials

You need to pick the right fastener for your materials. Every material needs something different. Wood, metal, and plastic react in their own ways to stress and weather. You should think about what kind of fastener you use, what it is made of, and how it looks when finished.

- Type of fastener: Pick bolts, screws, rivets, or anchors for your job.

- Material selection: Choose stainless steel, carbon steel, or special alloys for strength.

- Size: Make sure the fastener fits well for a tight hold.

- Coating: Use coatings to stop rust and wear.

- Drive type: Pick a drive that works with your tools and is easy to use.

- Aesthetic considerations: Think about how the fastener looks if you can see it.

If you work with wood, nails and screws are used a lot. For metal, rivets and welds make strong bonds. If you join different materials, structural adhesives help. Always check that your fastener matches your material for the best results.

Load and Stress

You need to know how much weight and force your joint will take. Some projects must hold heavy things or resist strong forces. High-tensile fasteners are best for these jobs. They last longer and do not break easily.

| Advantages of Rivets | Applications |

|---|---|

| Make strong joints that resist vibration. | Used in aircraft assembly. |

| Good for places with high heat. | Used in metal bridges and structures. |

| Work well for joining metal pieces. | Used in industrial machines. |

- High-tensile fasteners resist pulling and stress.

- They last longer than regular fasteners.

- You see them in cars, buildings, and energy projects.

If your project faces shaking or heavy use, pick a fastener that can handle it. Rivets and welds are good for metal jobs. Screws and nails work for wood, but use the right size and type for the load.

Environment

You need to think about where your project will be. The place affects how long your fasteners last. Water, chemicals, and temperature changes can hurt them over time.

- Water with sulfur, sodium, or chlorine causes rust.

- High humidity makes steel fasteners rust faster.

- Extreme heat or cold makes materials change size, which can loosen fasteners.

- Chemicals can break down fasteners.

- Shaking can loosen joints, so use locks if needed.

- Sunlight can damage fasteners outside.

You should use coatings to protect against rust and wear. Stainless steel and coated fasteners last longer in tough places. If your project faces bad weather or chemicals, pick materials and coatings that resist damage. Check your fasteners often to find problems early.

Tip: Always match your fastener to the project’s materials, how much weight it will hold, and the place it will be. This helps your permanent fastener stay strong for a long time.

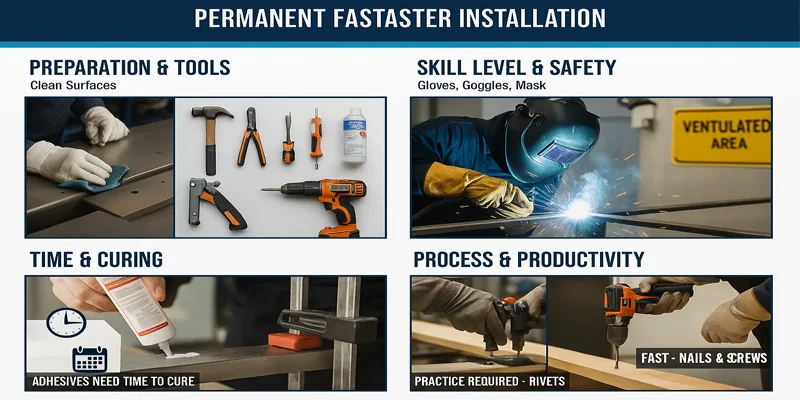

Installation

You need to think about how you will install each type of permanent fastener. The right installation method helps you get a strong and lasting joint. Each fastener has its own steps and tools. If you follow the correct process, your project will stay together for a long time.

Here are some important things to consider during installation:

- Preparation

Clean the surfaces before you start. Dirt, oil, or rust can weaken the bond. For adhesives, make sure the surfaces are dry and free from dust. For welding, remove paint and rust for a better weld. - Tools and Equipment

Use the right tools for each fastener. You need a hammer for nails, a screwdriver or drill for screws, and a rivet gun for rivets. Welding needs special equipment and safety gear. Adhesives may need clamps to hold parts together while they cure. - Skill Level

Some fasteners need more skill than others. You can drive nails and screws with basic tools. Riveting takes practice to get a tight fit. Welding needs training and safety knowledge. Adhesives require careful mixing and application. - Safety

Always wear safety gear. Use gloves, goggles, and masks when needed. Welding and adhesives can give off fumes. Work in a well-ventilated area. - Time and Curing

Some fasteners hold right away, like nails and screws. Adhesives need time to cure. Welding cools down before you can move the parts. Plan your work so you do not rush the process.

Tip: Take your time during installation. Rushing can lead to weak joints or mistakes.

Comparison Table: Installation Needs

| Fastener Type | Tools Needed | Skill Level | Time to Complete |

|---|---|---|---|

| Nails | Hammer | Low | Fast |

| Screws | Screwdriver/Drill | Low | Fast |

| Rivets | Rivet Gun | Medium | Medium |

| Welds | Welding Machine | High | Slow |

| Structural Adhesives | Applicator/Clamps | Medium | Slow (needs curing) |

You should match your skills and tools to the fastener you choose. If you want a quick job, nails or screws work best. For a strong metal joint, welding or riveting is better, but you need more skill. Adhesives are good for smooth finishes, but you must wait for them to cure.

Remember: Good installation makes your fasteners work their best. Take care with every step for a strong, lasting result.

You now know about five permanent fasteners. These are rivets, welds, structural adhesives, nails, and screws. Each one makes strong connections that last a long time. Picking permanent fasteners helps stop things from breaking. It also keeps your project safe.

- Good permanent fasteners help prevent accidents. They work well even in tough places.

- Using the right fastener, like in big buildings, keeps things steady and strong.

- Do not make mistakes like using too much weight or the wrong size.

Look at the comparison table and tips before you begin. Ask questions or share your stories in the comments!

FAQ

A permanent fastener makes a joint that is hard to take apart. You cannot remove it without hurting the materials. People use these fasteners when they want their project to last for years. They also use them when the joint needs to stay strong under pressure.

You can take out some permanent fasteners, but it is not easy. You might break the parts or the fastener when you do this. For example, you have to drill out rivets or cut welds. Think carefully before you use these fasteners.

You should pick stainless steel screws or galvanized nails for outside jobs. These fasteners do not rust and can handle rain and sun. Structural adhesives are also good if you want a neat look and a strong hold.

You need to check your materials, how much weight it will hold, and where you will use it. Look at the comparison table in this blog for help. Pick the fastener that fits your project’s needs for strength and lasting power.

Structural adhesives can be very strong, especially on big surfaces or when joining different materials. But metal fasteners like rivets and welds are usually better for heavy loads or metal-to-metal joints.

You only need simple tools for nails and screws, like a hammer or screwdriver. Rivets need a rivet gun. Welding needs special machines and safety gear. Adhesives may need clamps to hold things while they dry.

Yes, you can use more than one fastener for extra strength. For example, you might use screws and adhesives together. This makes your joint stronger and more dependable.

Most fasteners fail because they rust, get too much stress, or are not put in right. You should always follow the right steps and use the best materials to keep your project safe and strong.