You can use a black oxide finish on steel to protect it from rust, improve grip, and make surfaces look sleek. This finish also helps reduce friction and glare. Many industries choose black oxide finish because it offers strong corrosion resistance, lasts a long time, and keeps parts the right size. The process saves energy, works well for high-volume jobs, and costs just a few cents per pound. If you want to learn how to black oxide steel at home or in a shop, you will find practical steps easy to follow.

Key Takeaways

- Black oxide finish helps stop steel from rusting and makes it look better. This is why many industries use it. The process puts a thin layer of magnetite on steel. This keeps the parts the same size and shape. It also helps stop corrosion. There are different black oxide processes like hot, mid-temperature, and cold. Each one lasts a different amount of time and costs a different amount. You can pick the one that fits your needs best. After treatment, adding oil or wax helps stop corrosion even more. This makes steel parts last longer in hard conditions. Black oxide coating also helps you grip tools better. This makes them safer and easier to use, even if your hands are slippery. You need to take care of the finish by cleaning and oiling it gently. This keeps it looking nice and working well for a long time. Picking the right steel, like carbon or stainless steel, is very important. This helps you get the best results with black oxide finishing. Always follow the proper safety protocols and procedures during the black oxide process. This helps you get a strong and even finish.

Table of Contents

What is a black oxide finish

Definition

You can use a black oxide finish to help steel parts last longer and achieve a dark appearance. This finish is a thin layer on steel. It does not change how big or shaped your parts are. The main chemical in this finish is magnetite. Magnetite sticks to steel when you use special solutions. You often see black oxide finish on tools, fasteners, and machine parts. It helps these items stay strong and look nice.

Tip: Black oxide finish is good for parts that must keep their size and shape.

How it works

The black oxide process turns the outside of steel into magnetite (Fe3O4). This new layer keeps steel safe from rust and damage. You do not need to worry about your parts getting bigger or heavier. The process uses a strong liquid with chemicals like sodium hydroxide, nitrates, and nitrites. You put steel parts in this liquid at different temperatures, depending on the way you choose.

- The process can use hot, medium, or cold liquids.

- Magnetite sticks to steel when oxidized salts are present.

- This layer helps stop rust and keeps parts looking good.

Types of black oxide

There are three main kinds of black oxide processes. Each kind works best for different jobs and costs.

| Process Type | Temperature Range (°C) | Time Required (minutes) | Finish Type | Durability | Sludge Production | Fume Production |

|---|---|---|---|---|---|---|

| Hot Black Oxide | 140.556 | 10 – 20 | Glossy Blue-Black | Longer lasting | Less | More |

| Mid-Temperature | 107.222 – 123.889 | 30 – 45 | Glossy Black | Less lasting | More | Less |

| Cold Black Oxide | Room Temperature | Faster | Thinner, Less Durable | Less durable | N/A | N/A |

- Hot black oxide gives a shiny blue-black look that lasts longer. You need high heat and there are more fumes.

- Mid-temperature black oxide uses lower heat. It is less strong and good for parts that cannot take high heat. It balances cost and strength.

- Cold black oxide uses a special liquid at room temperature. This way is fast and cheap. The coating is thin and does not last as long as hot black oxide.

Note: Cold black oxide is best when you need speed and low cost more than strength.

Black oxide coating benefits

Corrosion resistance

You want your steel parts to last as long as possible. Black oxide coating gives you a strong layer of protection against rust. This layer forms a barrier that keeps moisture and air away from the steel. When you use black oxide coating, you improve the corrosion resistance of your parts. This means your tools, fasteners, and machine parts stay in good shape for a longer time.

You can see the difference in corrosion resistance when you compare black oxide coating to untreated steel. The salt spray test is a common way to measure this. Here is a simple table that shows how long each type lasts in a salt spray test:

| Coating Type | Salt Spray Test Duration (hours) |

|---|---|

| Black Oxide | 100 |

| Untreated Steel | 96 |

Black oxide coating does not stop all rust, but it slows it down. If you add oil or wax after the coating, you get even better corrosion resistance. This extra step helps your steel parts last longer, even in tough conditions.

Tip: Always use a post-treatment like oil or wax to boost corrosion resistance and keep your steel looking new.

Durability

You want your steel parts to handle daily use without wearing out fast. Black oxide coating adds a thin but tough layer to the surface. This layer does not chip or peel like paint. It bonds with the steel, so it stays in place even when you use the part a lot.

Black oxide coating helps your parts keep their strength and shape. You do not have to worry about the coating making your parts too thick or changing how they fit together. This means you get both durability and precision. Your tools and machine parts will last longer and work better.

Lubricity and reduced friction

Black oxide coating gives your steel parts a smooth surface. This smoothness helps reduce friction when parts move against each other. The coating holds oil well, so the surface stays slippery. When you use black oxide coating, the oil seeps out and forms a thin film. This film can cut the friction by half or more.

- The oil film from black oxide coating lowers the coefficient of friction by 50% or more.

- Black oxide coating gives you a surface with less friction than untreated steel, especially when you use oil.

- You will notice less wear and tear on your parts. The coating helps them slide smoothly and last longer.

You get better performance from your tools and machines. Black oxide coating also helps prevent parts from sticking or seizing up. This makes your work easier and keeps your equipment running smoothly.

Improved grip

You want your tools to feel safe in your hand. Black oxide coating helps you hold them better. The surface gets a little rougher than plain steel. This means your fingers do not slip as much. This is important for tools like wrenches or pliers.

- Black oxide coating makes moving parts slide easier.

- The coating makes iron products harder and keeps them from rusting.

When you use black oxide coating, parts do not feel slippery. The finish holds oil well, so you can keep a good grip. This makes your work safer and more comfortable. It helps if you use tools for a long time. You can trust your grip even if your hands are sweaty or oily.

Tip: Pick black oxide coating for tools and machine parts that need a strong grip.

Appearance

You want your steel parts to look nice and work well. Black oxide coating gives them a dark finish that looks good. This finish is smooth and even. It makes your tools look professional.

| Advantage | Description |

|---|---|

| Decorative Finish | Makes things look nice and neat. |

| Corrosion Resistance | Stops rust and damage. |

| Dimensional Stability | Keeps shape even under pressure. |

| Improved Lubricity | Helps moving parts work better. |

| Anti-Galling | Stops wear when parts touch. |

| Reduced Glare | Cuts down on shiny spots. |

| Pre-treatment for Paint | Gets surfaces ready for paint. |

| Reduced Conductivity | Lowers electricity flow if needed. |

| No Embrittlement | Keeps the metal strong. |

| No Welding Gases | Safe for many uses. |

| Cost Effectiveness | Saves money on finishing. |

Black oxide coating is used by many people and companies. They like it for its good looks and useful features. You see this finish on scissors, knives, and other tools. It gives a matching look and hides small marks or scratches. Black oxide coating keeps your things looking new, even after lots of use.

The black oxide finish is great for tools like scissors and knives. It gives them a matching look and hides small marks, so your tools look better.

Reduced reflection

You might use steel parts outside or in bright light. Black oxide coating helps by cutting down glare. The finish makes a dull surface that does not shine. This helps you see your work better and keeps bright spots away.

| Finish Type | Surface Reflection | Additional Notes |

|---|---|---|

| Black Oxide | Low | Matte finish cuts glare, good for some jobs. |

| Polished Steel | High | Very shiny, can be too bright. |

| Untreated Steel | Moderate | Shiny but not as much as polished steel. |

The matte finish of black oxide coating lowers light reflection a lot. This is good for tools or equipment where glare is a problem. You get a deep black or gray-black color that looks smooth. Many people pick black oxide coating for this reason. It helps when you need to see clearly and focus.

- The matte finish of blackened steel cuts down glare.

- Black oxide coating is best when you want less light reflection.

Note: If you work in bright places or need less glare, black oxide coating is a good choice for your steel parts.

Cost-effectiveness

You want to protect steel parts without spending a lot. Black oxide coating gives strong protection for less money than other finishes. The process uses less energy and fewer materials, so you save more. Many shops use black oxide coating for big jobs. You can finish lots of parts fast and keep costs low.

Here is a table that shows how black oxide coating costs compare to other finishes:

| Finishing Method | Cost Comparison |

|---|---|

| Black Oxide Coating | Relatively low cost |

| Zinc Plating | Higher cost |

| Powder Coating | Higher cost |

Black oxide coating works well for tools, fasteners, and machine parts. You get a classic look and strong protection without spending much. You do not need fancy equipment or long wait times. This makes black oxide coating a smart pick for small shops and big factories.

Tip: If you want to save money and protect steel parts, choose black oxide coating for your next project.

Dimensional accuracy

You need steel parts to fit together just right. Black oxide coating helps because the finish is very thin. The process does not add a thick layer or change part size. You can use black oxide coating for small parts and precision tools. The finish bonds with steel, so you do not risk warping or distortion.

Check this table to see why black oxide coating is good for high-precision work:

| Evidence Description | Key Point |

|---|---|

| Black oxide doesn’t leave a thick film on the surface | Excellent finish for tightly toleranced parts |

| Less risk of part distortion or dimensional change | Ideal for small parts and high-precision applications |

| Minimal Dimensional Impact | Ensures minimal effect on the part’s dimensions, crucial for precision components |

You get the same results every time. Black oxide coating keeps your parts the right size and shape. You do not have to worry about fitting problems or extra work. This makes black oxide coating perfect for gears, shafts, and other parts that need exact measurements.

Note: Pick black oxide coating when you want to protect steel and keep your parts accurate.

How to black oxide steel

Materials and safety

Before you start, you need the right materials and safety gear. You want to protect yourself and get the best results. Here is a table that shows common materials used for black oxide finish:

| Material | Description |

|---|---|

| Carbon Steel | Used for tools and machine parts. Durable and strong. |

| Stainless Steel | Good for harsh environments. Resists rust even more. |

| Copper | Used for plumbing and decorative items. |

| Zinc | Common for hardware and car parts. |

| Brass | Gives a unique look for decorations. |

| Aluminum | Adds a nice finish and extra protection. |

You must also use safety equipment. Always wear gloves, goggles, and a long-sleeve shirt. The chemicals can burn your skin or eyes. Work in a place with good airflow. If you use hot solutions, keep a fire extinguisher nearby. Never mix chemicals unless you know it is safe.

Tip: Always read the labels on your chemicals. Follow the instructions to stay safe.

Surface preparation

You want your black oxide finish to stick well and last long. Clean steel parts are the key. Dirt, oil, or rust can ruin the finish. Here is a table that shows the main steps for surface preparation:

| Step | Description |

|---|---|

| Cleaning | Use a strong cleaner to remove oil and dirt. Hot, soapy water works for small jobs. |

| Acid Activation | Use an acid bath to remove rust or scale. This step helps the finish stick better. |

| Rinsing | Rinse parts in clean water after each step. This keeps chemicals from mixing. |

| Solution Care | Check the temperature and strength of your black oxide solution. This gives you even results. |

You should always make sure your parts are very clean. If you skip cleaning, the black oxide finish may not cover the steel. Rinse your parts in distilled water to remove any leftover cleaner. If you see rust or scale, use a pickling solution to remove it. Rinse again before moving to the next step.

Note: Clean parts give you a smooth, even black oxide finish every time.

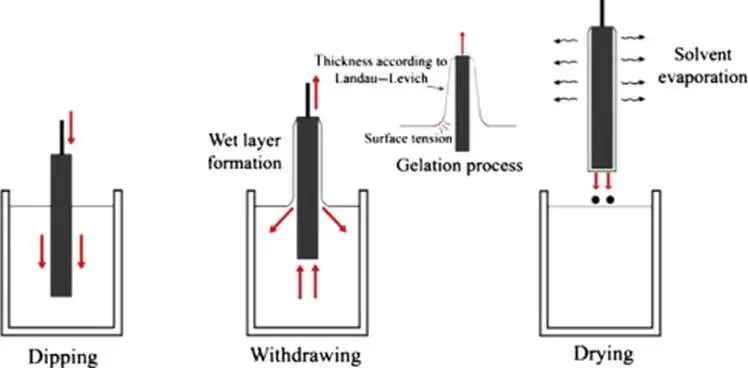

Application steps

Now you are ready to learn how to black oxide steel. Follow these steps to get a strong, lasting finish:

- Clean the steel

Remove all dirt, oil, and grease. Use a cleaner like E-Kleen 148E for 2-5 minutes at 120˚ to 150˚F. This helps the finish stick. - Rinse in cold water

Rinse the part for 30-60 seconds. This removes any leftover cleaner. - Activate the surface

If your steel is hard to coat, use an activator like E-Prep 258. Rinse again after this step. - Apply the black oxide finish

Place the steel in the black oxide solution, such as InstaBlak 333, for 2-4 minutes. Keep the temperature and time steady for the best results. - Rinse again

Rinse the part in cold water for 30-60 seconds. This stops the chemical reaction. - Seal the finish

Dip the part in a sealant like E-Tec for 1 minute. This step protects against rust and makes the finish last longer. - Let the finish set

Let the part sit for a few hours. The sealant will make the black color deeper and stronger.

You can use these steps at home or in a shop. Always check the instructions for your chemicals. If you want to know how to black oxide steel the right way, follow each step closely. You will get a smooth, dark finish that protects your steel.

Tip: If you want the best results, do not rush. Take your time with each step.

You now know how to black oxide steel using safe and simple steps. Clean parts, careful rinsing, and the right chemicals give you a strong black oxide finish. This process works for tools, machine parts, and even decorative items. If you follow these steps, you will see why many people choose black oxide finish for lasting protection.

Post-treatment

After you finish the black oxide process, you need to protect your steel parts. The black oxide layer gives some rust resistance, but you can make it much stronger with post-treatment. You have several options for sealing and protecting the finish. Each method works best for different needs.

Here is a table that shows common post-treatment methods and what they do:

| Post-Treatment Method | Description |

|---|---|

| Water Soluble Oil Light | Dries quickly and gives mild protection. |

| Water Soluble Oil Regular | Standard oil treatment for better rust resistance. |

| Water Displacing Oil Regular | Pushes away moisture and boosts protection. |

| Water Displacing Oil Heavy | Leaves a thick oil film for strong protection. |

| Rust Inhibitor | Special formula to stop rust from forming. |

| Water Soluble Wax | Dries to the touch and works as an oil alternative. |

| Water Soluble Acrylic | Clear coating for when you do not want an oily surface. |

You can choose oil, wax, or acrylic depending on your project. Oil treatments work well for tools and machine parts. Wax gives a dry finish and still protects against rust. Acrylic is good if you want a clear, non-oily surface.

Tip: Always use a post-treatment after black oxide. This step helps your steel last longer and keeps the finish looking new.

You should let the post-treatment dry fully before using the part. This makes sure the protective layer sticks well and gives the best results.

Maintenance

You want your black oxide coated steel to last as long as possible. Good maintenance keeps the finish strong and looking good. You can follow these steps to care for your parts:

- Use mild detergents. Clean with gentle soap and warm water. Avoid rough scrubbing pads.

- Wipe with a soft cloth. Choose a lint-free cloth or sponge to protect the finish.

- Dry parts well. Use a clean cloth to remove all water and prevent spots or rust.

- Avoid harsh chemicals. Stay away from strong solvents and acidic cleaners.

- Inspect parts often. Look for signs of wear or damage.

- Store in a controlled environment. Keep parts away from moisture and corrosive agents.

- Lubricate moving parts. Use suitable oils to reduce friction and wear.

- Protect from impacts. Use covers when moving or storing parts.

- Do not overload. Use parts within their design limits to avoid stress.

Note: Regular care helps your black oxide finish stay strong and keeps your steel parts working well.

You can keep your steel looking dark and smooth with simple cleaning and careful storage. If you follow these steps, your black oxide coated steel will last for years.

Black oxide finish vs other coatings

Zinc plating

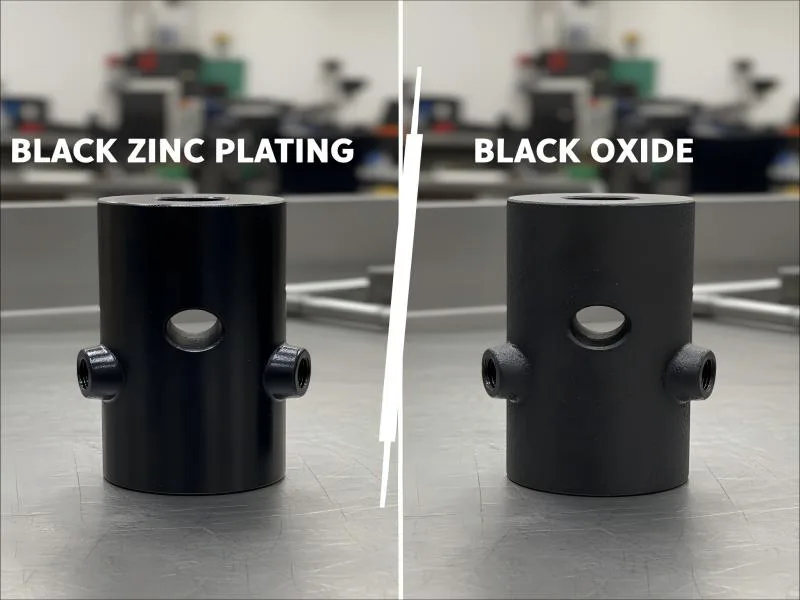

You may wonder how black oxide finish and zinc plating compare. Both protect steel, but they do it in different ways. Black oxide makes a thin, dark layer on steel. Zinc plating puts a layer of zinc metal on top.

Zinc plating protects steel from rust better. The zinc layer will rust first and saves the steel. Black oxide only gives a little protection unless you add oil or wax. If you want strong rust protection, zinc plating is a better choice.

Black oxide finish usually costs less than zinc plating. You can use black oxide for many parts and save money. Zinc plating costs more because it uses more material and takes longer to do.

Here is a table to help you compare:

| Feature | Black Oxide | Zinc Plating |

|---|---|---|

| Corrosion Resistance | Mild (needs oil/wax) | Excellent (sacrificial) |

| Cost | Lower | Higher |

Tip: Pick zinc plating if you need strong rust protection. Choose black oxide if you want to save money and keep part size the same.

Paint and powder coat

Paint and powder coat are also used to protect steel. You see these finishes on things like furniture, tools, or car parts. Paint and powder coat make a thick, colorful layer on steel. Black oxide keeps the steel almost the same size.

Black oxide finish costs less than paint or powder coat. It gives a thin layer that does not change how parts fit. Paint and powder coat give you more color choices and a thicker, tougher finish. Powder coat lasts longer and does not scratch as easily as black oxide.

Here is a table to show the main differences:

| Advantages of Black Oxide Finish | Disadvantages of Black Oxide Finish |

|---|---|

| Cost-competitive | Very mild corrosion resistance |

| Adds minimal thickness | Needs post-treatment for protection |

Powder coating gives a strong, nice-looking finish in many styles. Black oxide can wear off if you do not seal it. You need oil or wax to help black oxide last longer.

| Advantages of Powder Coating | Disadvantages of Black Oxide Finish |

|---|---|

| More durable finish | Mild corrosion resistance |

| Many color and style options | Can be easily rubbed off |

Note: Use black oxide when you want a thin, low-cost finish. Pick powder coat for color, style, and extra toughness.

Bluing and phosphating

Bluing is often used on guns or tools. Phosphating is common for car parts and fasteners. Black oxide, bluing, and phosphating all use chemicals to protect steel, but they are different.

Black oxide uses a hot alkaline solution. Bluing is like black oxide but is mostly for guns. Phosphating uses an acid to make a thicker, gray layer.

Phosphating protects steel from rust better, especially with oil. The coating is thicker and can change the size of the part. Black oxide keeps the steel almost the same size. Black oxide gives a matte black look. Phosphating looks gray and is not as even.

Here is a table to compare them:

| Feature | Black Oxide Finish | Phosphate Coating |

|---|---|---|

| Application Process | Alkaline solution at high temperature | Acidic solution forms a crystalline layer |

| Corrosion Resistance | Moderate, better with oil | High, especially with oil |

| Thickness | 0.5–1.5 microns, keeps tolerances | Up to 25 microns, can change size |

| Aesthetic Appeal | Matte black, good for decoration | Gray/dark, less uniform |

| Applications | Tools, firearms, decorative hardware | Fasteners, engine parts, hydraulic systems |

Tip: Pick black oxide for a thin, dark finish on small, precise parts. Use phosphating if you want more rust protection and do not mind a thicker layer.

When to choose black oxide

You want to pick the right finish for your steel parts. Black oxide stands out in several situations. You should know when this finish works best for your needs.

Many industries use black oxide when they need to control costs and keep parts precise. The finish adds almost no thickness, so your parts fit together perfectly. You do not have to worry about changing the size or shape of your steel. This makes black oxide a smart choice for gears, fasteners, and small machine parts.

You often see black oxide on steel that stays indoors. The finish gives mild protection against rust. If your parts will not face rain or harsh chemicals, black oxide works well. You save money and still get a good-looking surface.

Appearance matters for many products. Black oxide gives steel a deep black color that looks professional. You see this finish on decorative hardware, consumer electronics, and display items. The dark surface hides fingerprints and small scratches. Your products look new and clean for longer.

Industry experts suggest black oxide in these scenarios:

- You need to keep costs low and maintain tight tolerances.

- Your steel parts stay indoors and do not need heavy-duty rust protection.

- You want a classic, dark look for visible components.

- You need a finish that does not change the size or fit of your parts.

- You want to improve grip and reduce glare on tools or equipment.

Tip: Black oxide works best for indoor projects, decorative items, and precision tools. If you want a finish that looks good and keeps your parts accurate, choose black oxide.

Here is a table to help you decide if black oxide is right for your project:

| Situation | Is Black Oxide a Good Choice? |

|---|---|

| Tight dimensional requirements | ✅ Yes |

| Need for low cost | ✅ Yes |

| Indoor use | ✅ Yes |

| High corrosion resistance needed | ❌ No |

| Outdoor exposure | ❌ No |

| Decorative appearance important | ✅ Yes |

You should also think about maintenance. Black oxide needs oil or wax to boost rust protection. If you can care for your parts and keep them dry, black oxide will last a long time.

You get a finish that looks sharp, feels smooth, and keeps your steel parts working well. Black oxide gives you a balance of cost, appearance, and precision. If these features match your needs, black oxide is the right choice.

Common issues

Incomplete coverage

Sometimes, the black oxide finish does not cover steel parts evenly. This can make your parts look spotty or leave them open to rust. Many things can cause this problem. You can stop most of these issues by following the right steps.

Here is a table that shows what causes incomplete coverage and how to fix it:

| Cause of Incomplete Coverage | Prevention Strategy |

|---|---|

| Residual salts | Proper processing and immediate sealing |

| Insufficient sealing | Ensure adequate sealing protection |

| Process control failures | Maintain precise temperature and chemical concentrations |

| Mechanical abrasion | Use thicker coatings or protective measures |

| Environmental exposure | Regular maintenance and protective coatings |

If you see spots or lines on your steel, check your steps. Clean and seal your parts right after coating. Keep your chemicals at the right heat and strength. Protect finished parts from scratches and rough places. These steps help you get a smooth black oxide finish every time.

Surface contamination

Surface contamination is a big reason for a bad black oxide finish. Dirt, oil, or leftover chemicals can stop the coating from sticking well. You must clean your steel parts very well before you start.

- Good cleaning removes oils and grease for a nice finish.

- If you do not rinse enough, leftover chemicals can cause uneven color.

- Rinse your parts under running water to wash away all residue.

Surface contamination blocks the reaction needed for a good black oxide layer. If you do not clean your parts, the finish may look weak or patchy. Always use a strong cleaner and rinse with lots of water. This helps the black oxide stick better and last longer.

Tip: Clean and rinse your steel parts well before black oxide. This step gives you a strong, even finish.

Poor adhesion

Poor adhesion means the black oxide coating does not stick well to steel. This can make the finish flake off or wear away too soon. You can stop this problem by following these steps:

- Control your process: Keep the temperature, chemical strength, and time just right. For example, alkaline black oxide works best between 285°F and 295°F.

- Prepare the surface: Clean your parts with alkaline or acid pickling to remove all dirt and grease.

- Maintain your bath: Test and refresh your black oxide solution often. Check the pH and add new chemicals when needed.

- Use post-treatment: Apply oil or wax after black oxide to boost corrosion resistance. Sealed coatings can last over 100 hours in salt spray tests.

- Inspect your work: Check your parts for defects before and after coating. Quality control helps you catch problems early.

- Choose the right use: Know where black oxide works best. Use extra protection if your parts face tough conditions.

If you follow these steps, your black oxide finish will stick well and last longer. Regular checks and good cleaning help your coating stay strong.

Troubleshooting

When you black oxide steel, you might face problems like uneven color, thin coatings, or spots. You can fix most of these issues by following a few simple steps. Start by checking your process from start to finish. Each step matters for a strong, even finish.

Common Troubleshooting Steps:

- Always clean your parts well before you begin. Use soap to remove grease and dirt. Rinse with water. For tough grime, use an acid bath. If you want the best results, sandblast the surface with fine grit and then use an ultrasonic cleaner. This removes even tiny particles.

- Never touch cleaned parts with your bare hands. Oil from your skin can cause spots or poor adhesion. Use clean gloves or tongs to handle the steel.

- Make sure you keep the oxidizing tank at the right temperature. If the tank is too cool or too hot, the coating may turn out thin or patchy. Use a thermometer to check the temperature before you dip your parts.

- Space your parts out in the tank. If you crowd them together, the chemicals cannot reach every surface. This can lead to incomplete coverage or streaks.

- Time your dipping step carefully. Leave the steel in the solution for the recommended time. If you rush, the coating may not form well. If you wait too long, the finish can become uneven.

- After coating, rinse your parts right away. This stops the chemical reaction and helps the finish set evenly.

- If you see spots, streaks, or thin areas, do not worry. Clean the part again and repeat the process. Many problems go away with a second try.

Tip: Use a checklist to track each step. This helps you spot where things might go wrong.

Here is a quick troubleshooting table to help you solve common problems:

| Problem | Likely Cause | Solution |

|---|---|---|

| Thin or patchy coating | Low tank temperature | Adjust temperature to the correct range |

| Spots or streaks | Dirty or oily surface | Clean and degrease thoroughly |

| Incomplete coverage | Parts too close together | Space parts out in the tank |

| Poor adhesion | Touching with bare hands | Use gloves or clean tools |

| Discoloration | Incorrect dipping time | Follow recommended timing |

You can avoid most problems by working carefully and following each step. If you run into trouble, review your process and try again. With practice, you will get a smooth, dark black oxide finish every time. 😊

Tips for best results

Steel selection

Choosing the right steel makes a big difference in your black oxide finish. You want steel that works well with the process and gives you strong protection. Here are some types you should consider:

- Carbon steel works best for black oxide finishing. You get a tough surface that lasts a long time. Machine parts, tools, and fasteners made from carbon steel hold up well and resist rust.

- Stainless steel is another good choice. Many people use it in harsh environments. The black oxide coating adds even more corrosion resistance, so your parts stay strong.

Pick steel that matches your project needs. If you want a finish that looks good and stays tough, start with carbon or stainless steel.

Bath control

Controlling your bath is key to getting a smooth, even black oxide coating. You need to watch the temperature and chemical concentration. These factors change how your finish looks and how well it protects your steel.

The hot black oxide process uses high heat. You get a fast coating, but you also see more fumes. The medium-temperature process takes longer, but you get fewer fumes and a finish that looks just as good. Temperature control helps you avoid problems like uneven color or weak protection.

| Factor | Effect on Coating Quality |

|---|---|

| Bath Temperature | Influences uniform coverage, color, and corrosion resistance |

| Chemical Concentration | Affects overall performance and uniformity of the coating |

You should keep your bath at the right temperature for your process. Hot baths work fast but need careful handling. Medium-temperature baths are safer and still give you a strong finish. Always check your chemical levels to make sure your coating comes out even and resistant to water.

- Hot black oxide process: Heated to a boil, faster (under 10 minutes), but produces undesirable fumes.

- Medium-temperature process: Below boiling, takes 20 to 60 minutes, fewer fumes produced.

Test your bath often. Adjust the temperature and chemicals as needed. This helps you get the best results every time.

Sealing methods

You need to seal your black oxide finish to keep your steel safe from rust. The sealing step is easy to miss, but it is very important. You have a few choices for sealing your parts.

The final step, and one of the most important and overlooked, is that the parts receive an after-finish sealant. Most often this is simply oil, but wax is also common. In any case, the parts must be coated to protect them from rusting. Without this finishing step, black oxide parts can rust just as quickly as bare steel.

Oil works well for most tools and machine parts. Wax gives you a dry finish that still protects against moisture. Some people use acrylic for a clear, non-oily surface. Always let your sealant dry before you use the part. This makes sure the protective layer sticks and lasts.

Seal your black oxide finish every time. You get better rust protection and a finish that stays dark and smooth.

Black oxide finish helps protect steel parts from rust. It also makes them easier to hold and gives them a nice dark color. Your parts will move smoothly and not rub together as much. This finish is best for things you use inside or in safe places. Always put a seal on your parts after you coat them. This helps them last longer and stay strong. If you do each step, your results will be good every time.

| Drawback | Black Oxide Coated Steel | Modern Alternatives (Anodizing, Powder Coating) |

|---|---|---|

| Toxicity | Highly toxic processes | Safer processes |

| Finish Consistency | Inconsistent finishes | Smooth, consistent finishes |

| Color Options | Limited to black | Wide variety of colors available |

Tip: Pick black oxide if you want to save money and keep parts the right size. Always use post-treatment to protect your steel.

FAQ

You get the best results with carbon steel. Stainless steel also works well. Avoid using aluminum or non-ferrous metals. These metals do not react properly with black oxide solutions.

You can apply black oxide at home using cold solutions. Always wear gloves and goggles. Work in a well-ventilated area. Follow all safety instructions on the chemical labels.

Black oxide protection lasts for years indoors. You must use oil or wax after coating. Outdoor use shortens the lifespan. Regular maintenance helps keep the finish strong.

You do not need to worry about part size. Black oxide forms a thin layer. The process keeps your parts accurate. You can use it for precision tools and machine parts.

You should use oil, wax, or acrylic sealants. Oil works best for tools. Wax gives a dry finish. Acrylic is good for a clear, non-oily surface. Always let the sealant dry before use.

You can paint over black oxide. Clean the surface first. Use a primer for better adhesion. Painting adds extra protection and color options.

You should not use black oxide on food-contact items. The chemicals in the process are not food-safe. Choose stainless steel or food-grade coatings for kitchen tools.

You can fix uneven coverage by cleaning the part again. Remove all oil and dirt. Repeat the black oxide process. Use gloves to avoid fingerprints. Always rinse and seal the part after coating