When you use metal in tools, machines, or buildings, you want it to be strong and reliable. Heat treatment of metals means you heat and cool the metal in a careful way to improve its properties. This process makes metal harder, tougher, or easier to shape. Most heat treatment happens with steel—about 80% of these processes help steel products. With heat treatment, you can increase hardness, boost toughness, and keep the metal stable for longer use. These changes help make metal safer and last longer in daily life.

Key Takeaways

- Heat treatment makes metal better by heating and cooling it in a special way. This process helps metal become stronger, harder, and last longer for daily use. Some common heat treatment methods are annealing, hardening, and tempering. Picking the right heat treatment helps metal parts work well and stay good for a long time. Heat treatment can stop problems like cracking and bending in metal. You can find heat-treated metal in tools, machines, and things like car parts. Knowing heat treatment words helps you understand how metal changes during the process. Good heat treatment saves money because it means fewer repairs and replacements.

Table of Contents

Heat Treatment of Metals Defined

What Is Heat Treatment

You can think of heat treatment of metals as a way to change how metal acts and looks inside. When you heat and cool metal in a controlled way, you change its structure and improve its properties. Metallurgists describe heat treatment as a series of steps that use heat, soaking, and cooling to create special microstructures. You use heat treating to make metal stronger, harder, or more flexible. The IFHTSE says heat treating uses thermal cycles and sometimes chemicals to change the structure and properties of metal. You see these changes in heat-treated metals every day, from tools to car parts.

Heat treatment is not just about making metal hot and cold. You use it to create the right balance of strength, toughness, and flexibility for each job.

- Heat treatment involves heating and cooling operations to get the properties you want.

- You can use heat treatment to make metal last longer and work better.

How Heat Treatment Works

You follow a few main steps when you use heat treatment. Each step helps you control the final result.

1. Heat the metal to a specific temperature.

2. Hold the metal at that temperature for a set time.

3. Cool the metal in a certain way, like in air, water, or oil.

When you heat metal, you change its internal structure. You see new phases form, like austenite or martensite. These phases affect how tough or hard the metal becomes. The way atoms move and spread out, called diffusion, helps make the metal more even inside. You can control how cracks start and grow by changing the microstructure. If you want more strength, you can create a high dislocation density in martensite. If you need more toughness, you can adjust the transformation temperatures with alloying.

Tip: The cooling step is just as important as heating. Fast cooling can make metal hard but brittle. Slow cooling can make it softer and easier to shape.

Key Terms

You will see many special words when you learn about heat treatment. Here are some common terms and what they mean:

| Term | Definition |

|---|---|

| Cryogenic Treatment | You expose steel to very low temperatures to make it more stable and sometimes harder. |

| Decarburization | You lose carbon from the surface of steel when you heat it in air, which makes it softer on the outside. |

| Diffusion | Atoms move from crowded areas to less crowded areas inside the metal, making it more even. |

| Drawing | You reheat hardened steel to make it less hard but more flexible. |

| Ductility | The ability of metal to stretch or bend without breaking. |

| Hardening | You make metal harder by heating and cooling it in a special way. |

| Martensite | A hard, needle-like structure formed when you cool steel quickly. |

| Austenite | A phase of iron and carbon that forms when you heat steel above a certain temperature. |

| Case Hardening | You make the surface of metal much harder than the inside. |

| Controlled Cooling | You cool metal in a planned way to avoid cracks or damage. |

| Grain | Small crystals inside metal that affect its strength and toughness. |

| Fatigue | Metal breaks after being bent or stretched many times. |

| Forging | You shape metal by hammering or pressing, often with heat. |

| Induction Hardening | You heat only the surface of metal with electromagnetic waves, then cool it quickly to make it hard. |

| Nitriding | You add nitrogen to the surface of steel to make it harder. |

| Bainite | A tough structure formed when you cool steel at a certain rate. |

Note: Learning these terms helps you understand how heat treatment works and what results you can expect.

Purpose of Heat Treatment

Why Heat Treatment Is Used

Heat treatment helps metal work better in daily life. You can change how strong, hard, or tough metal is. This lets you pick the best mix for each job. Companies use heat treatment because it:

- Makes metal harder and stronger.

- Helps metal last longer and not wear out fast.

- Lets metal handle heavy hits and loads.

- Stops metal from rusting so it lasts longer.

- Changes how metal acts with magnets for special jobs.

Heat treatment also saves money. Better metal means less extra work and fewer repairs. You do not need to replace parts as often.

Desired Changes in Metals

Heat treatment helps metal act the way you want. You can make metal strong, bendy, or tough. The process helps you get these results:

| Property | Description |

|---|---|

| Increased Hardness | Metal does not scratch or wear down easily. |

| Improved Strength | Metal can hold heavy things without breaking. |

| Enhanced Toughness | Metal can take hits and not crack. |

| Controlled Grain Structure | Metal works better inside because grains are improved. |

| Optimized Ductility | Metal bends or shapes without snapping. |

| Reduced Internal Stresses | Metal does not crack or warp when used or made. |

| Improved Machinability | You can cut or drill metal more easily. |

| Resistance to Wear and Abrasion | Metal lasts longer when it moves or rubs. |

| Enhanced Corrosion Resistance | Metal does not rust or get damaged in bad places. |

| Tailored Electrical and Magnetic Properties | Metal works well in electronics or magnets. |

| Improved Fatigue Resistance | Metal does not break after lots of use. |

| Customization for Specific Applications | Metal fits jobs in cars, planes, and other things. |

You can use annealing, hardening, tempering, or normalizing to get these changes. Annealing makes steel softer and easier to bend. Hardening makes metal tougher and harder to wear out. Tempering gives tough metal more strength. Normalizing helps metal be strong and hard.

Problems Solved by Heat Treatment

Metal can have problems when you use it. Heat treatment fixes many of these problems:

- Distortion: Metal can bend or twist if heated wrong. Heat treatment keeps metal in the right shape.

- Cracking: Fast heating or stress can make cracks. Heat treatment stops cracks and keeps metal whole.

- Hardness Issues: Metal that is too soft or hard does not work well. Heat treatment helps you get the right mix.

Heat treatment also takes away stress in metal. This makes metal last longer and work better. You can make metal softer or harder, stronger, and better at handling wear. Your products stay safe and work well, even when things get tough.

Tip: Picking the best heat treatment helps metal parts do their job and not break.

Heat Treatment Processes

Annealing

Annealing makes metal softer and easier to use. You heat the metal to a high temperature. Then you keep it hot for a while. After that, you let it cool down slowly. This helps steel and other metals bend without breaking. Annealing has three main steps: recovery, recrystallization, and grain growth. Recovery takes away stress inside the metal. This stops cracks from forming. Recrystallization makes new grains inside the metal. These new grains help the metal bend more. Grain growth happens if you keep heating. The grains get bigger, and the metal gets even softer.

| Stage | What Happens | Result for Metal |

|---|---|---|

| Recovery | Internal stresses get removed | Metal becomes more ductile |

| Recrystallization | New grains form and replace old ones | Grain structure improves |

| Grain Growth | Grains get bigger if heating continues | Metal softens, ductility rises |

Tip: Annealing helps you cut, bend, or shape metal more easily. It also helps stop cracks when making things.

Hardening

Hardening is a common way to treat metal. You use hardening to make metal strong and hard to scratch. First, you heat the metal above a certain temperature. Next, you cool it very fast in water or oil. This quick cooling is called quenching. Quenching changes the inside of the metal. The metal gets a hard surface that does not dent easily. Hardening is good for steel tools and machine parts.

- Hardening makes metal stronger and harder.

- It helps metal last longer and not wear out.

- You usually harden metal before tempering.

| Feature | Hardening |

|---|---|

| Process | Heat → Quench |

| Purpose | Increase hardness and strength |

| Temperature | High (above critical temperature) |

| Effect | Wear resistance goes up |

| Used In | Tools, machine parts, car parts |

Note: Hardening can make metal brittle. You often need another step to fix this.

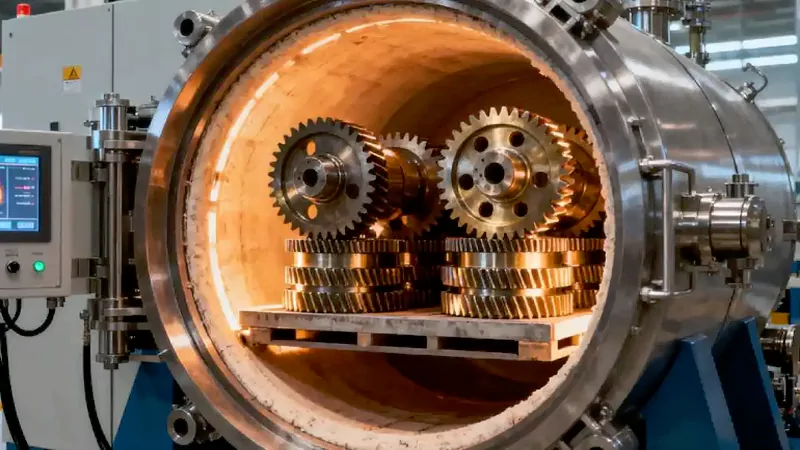

Tempering

Tempering comes after hardening. It makes metal less brittle and more tough. You heat the metal again, but not as hot as before. Then you let it cool down slowly. This step takes away stress and makes the metal tougher. Tempering keeps the metal hard but adds flexibility. You use tempering for springs, knives, and gears.

| Feature | Tempering |

|---|---|

| Process | Reheat → Slow Cool |

| Purpose | Improve toughness, reduce brittleness |

| Temperature | Lower (150–650°C) |

| Effect | Metal stays hard but gains toughness |

| Used In | Springs, knives, gears |

Tip: Always temper metal after hardening. This makes metal last longer and work better.

Hardening, annealing, and tempering are used a lot in metal work. Each one changes metal in a special way. You can make metal soft, hard, or tough for different jobs. Heat treatment helps you build things that are strong and last a long time.

Normalizing

Normalizing gives you a way to make metal strong and even. You use this heat treatment process when you want metal to have a uniform structure inside. You start by heating the metal above a certain temperature. You keep it hot for a short time. After that, you let it cool down in air. This process helps you fix problems that happen during forging or rolling. You see normalizing used for steel parts that need to be tough and reliable.

When you normalize metal, you make the grains inside smaller and more even. Small grains help metal resist breaking and bending. You also remove stresses that build up during shaping. This makes the metal easier to cut, weld, or machine. You use normalizing for gears, axles, and other parts that need to work hard every day.

Tip: Normalizing works well when you want metal to have a balance of strength and softness. You get better results if you use normalizing after forging or welding.

Here is a simple table to show what normalizing does for metal:

| Step | What You Do | Result for Metal |

|---|---|---|

| Heating | Heat above critical temp | Grains change |

| Soaking | Hold at high temp briefly | Stress removed |

| Air Cooling | Cool in air | Uniform structure |

Normalizing helps you prepare metal for other heat treatment steps like hardening or tempering. You get metal that is easier to work with and lasts longer.

Other Methods

You can use other heat treatment methods to change how metal acts. Each process gives you special results for different jobs. Here are some common methods you might use:

- Case Hardening: You make the surface of metal very hard while keeping the inside soft. You use this for gears and tools that need a tough outside.

- Induction Hardening: You heat only the surface of metal with electromagnetic waves. You cool it quickly to make it hard. This process works fast and gives you a strong surface.

- Nitriding: You add nitrogen to the surface of steel. This makes the metal harder and more resistant to wear.

- Cryogenic Treatment: You cool metal to very low temperatures. This process makes metal more stable and sometimes harder.

- Austempering and Martempering: You use special cooling steps to get a mix of hardness and toughness. These methods help you avoid cracks and make metal last longer.

Note: You should pick the right heat treatment process based on what you need the metal to do. Each process changes the metal in a unique way.

You see these methods used in car parts, cutting tools, and machine components. You get metal that fits the job and stays strong under stress. You can combine different processes to get the best results for your project.

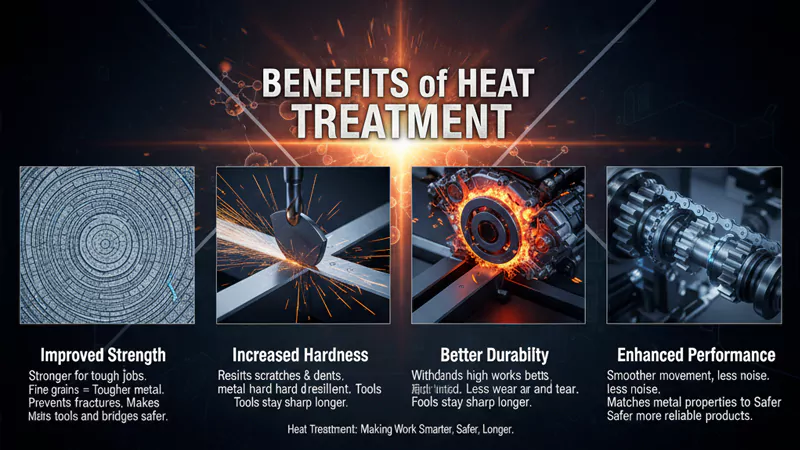

Benefits of Heat Treatment

Improved Strength

Metal parts need to be strong for hard jobs. Heat treatment helps metal get stronger. You heat and cool metal in a careful way. This changes the inside of the metal. The grains inside become smaller and more even. Small grains make metal tough and less likely to break. You see this in steel beams and car axles. Strong metal makes bridges safer and tools last longer. Machines work better with strong metal.

Tip: Strong metal parts stop sudden breaks. They help your equipment work well.

Increased Hardness

Hardness helps metal resist scratches and dents. Heat treatment makes metal harder for tools and machines. Quenching and tempering are important steps. Quenching cools metal fast from high heat. This turns austenite into martensite and makes metal hard. Tempering comes after quenching. It uses lower heat to keep hardness and add toughness.

- Quenching changes metal’s structure and makes it strong.

- Tempering keeps metal hard and stops brittleness.

- Cryogenic treatment makes metal even harder and stable.

Tempering forms tiny carbides in tool steels. These carbides have molybdenum and vanadium. Carbides help metal stay hard after lots of use. Tools cut better and last longer. Hard metal parts do not get damaged easily. You spend less time fixing or replacing them.

| Process | What Happens | Result for Metal |

|---|---|---|

| Quenching | Cool metal quickly | High hardness |

| Tempering | Reheat at lower temperature | Toughness, hardness |

| Cryogenic | Treat with extreme cold | Extra hardness |

Better Durability

Durability means metal parts last longer and work better. Heat treatment makes engine parts and gears more durable. Hardening and tempering make metal strong for heat and pressure. Heat-treated metal does not wear out or rust fast.

- Engine parts handle high heat and heavy loads.

- Wear resistance keeps metal safe during use.

- Fatigue strength helps metal survive many stress cycles.

- Less risk of failure means fewer repairs.

You see these benefits in cars, trucks, and machines. Durable metal parts keep equipment safe and reliable. You get longer life and better performance from your products.

Note: Picking the right heat treatment gives you the best metal parts.

Enhanced Performance

When you use metal parts in machines, cars, or tools, you want them to work well every time. Heat treatment helps you get the best performance from metal. You see the difference in how metal parts move, last, and handle stress.

Heat treatment lets you match metal to its job. You can make metal strong for heavy loads or flexible for bending. You get metal that does not crack or wear out fast. This means your tools cut better, your car runs smoother, and your machines work longer.

Tip: Heat-treated metal gives you smoother movement and less noise in engines and gears.

How Heat Treatment Boosts Performance

- Better Fit for Purpose: You choose the right heat treatment to match what you need. For example, you want hard steel for cutting tools and tough steel for springs.

- Less Wear and Tear: Heat-treated metal resists scratches and dents. You spend less time fixing or replacing parts.

- Stable Shape and Size: Metal keeps its shape even when hot or under pressure. You get parts that fit and work every time.

- Improved Safety: Stronger metal means fewer breaks or failures. You stay safe when using heat-treated products.

Real-Life Examples

| Product | How Heat Treatment Helps | Performance Benefit |

|---|---|---|

| Car Engine Parts | Withstand high heat and pressure | Smoother running, longer life |

| Cutting Tools | Stay sharp after many uses | Cleaner cuts, less effort |

| Bicycle Frames | Resist bending and cracking | Safer rides, more comfort |

| Construction Beams | Hold heavy loads without bending | Stronger buildings |

You see heat treatment in sports equipment, kitchen knives, and even electronics. Metal parts work better and last longer because of these processes.

Why Performance Matters

You rely on metal every day. When metal performs well, you save money and time. You avoid sudden breaks or failures. You get products that do their job without problems.

Note: Choosing the right heat treatment helps you get the most from your metal parts.

Key Performance Gains

- Faster machines and engines

- Quieter operation in moving parts

- Fewer repairs and replacements

- Better results in sports and work

Heat treatment gives you metal that fits your needs. You get stronger, safer, and more reliable products. Next time you use a tool or ride a bike, remember that heat treatment helps it perform at its best.

Applications of Heat Treatment

Everyday Uses

You find heat-treated metal in many things you use daily. When you buckle your seatbelt, the clasp stays strong in a crash. This strength comes from heat treatment. Cooking tools like spatulas and knives do not bend easily. They last longer because the metal is heat treated. Your car uses heat-treated parts to keep you safe and moving.

- Seatbelt clasps stay strong during accidents.

- Cooking utensils last longer and do not wear out fast.

- Car parts like gears and axles work better and last longer.

Heat treatment helps make everyday items safer and more reliable for you and your family.

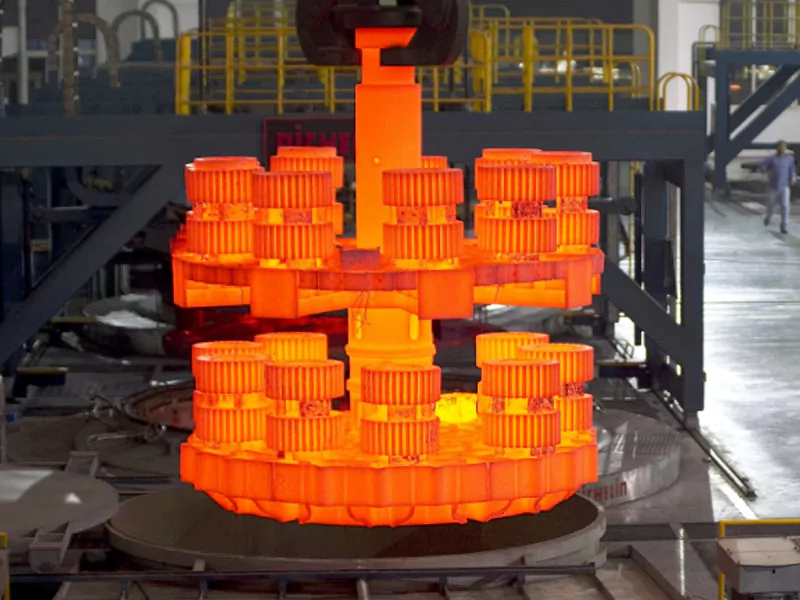

Industrial Uses

Factories and workshops need heat treatment for their machines. You see heat-treated metal in engines, pumps, and heavy equipment. Heat treatment changes how metal acts and makes it stronger. Workers heat, hold, and cool metal to fit each job.

You get these benefits from heat treatment in industry:

- Metal parts in machines get stronger and last longer.

- Iron, steel, and titanium are heat treated for tough jobs.

- Equipment works well and does not break easily.

When you use machines at work or see construction sites, you count on heat-treated metal to do the job.

Heat treatment has three main steps:

- Heating: Make the metal hot to a set temperature.

- Holding: Keep the metal hot so it can change inside.

- Cooling: Lower the temperature to keep new properties.

Product Examples

Some products need special heat treatment to work their best. Gears, shafts, and bearings in cars and machines go through processes like carburizing and nitriding. Carburizing adds carbon to the surface to make it harder. Nitriding uses nitrogen to make metal stronger and resist wear.

Here is a table that shows how heat treatment matches products and temperature ranges:

| Heat Treatment Process | Notable Products/Applications | Temperature Range (°F) |

|---|---|---|

| Carburizing | Gears, shafts, camshafts | 1562 to 1832 |

| Nitriding | Gears, crankshafts, bearings | 752 to 1094 |

You use these products every day, like driving your car or using tools at home.

Heat treatment helps metal parts last longer, work better, and keep you safe.

Choosing Heat Treatment Methods

Factors to Consider

When you choose a heat treatment method, you need to look at several important factors. Each factor helps you decide which method works best for your project. You want your metal to have the right properties and last a long time. Here is a table that shows what you should think about:

| Factor | Description |

|---|---|

| Metal Alloy | The type of metal changes which heat treatment you can use. Different alloys react in unique ways. |

| Desired Properties | You need to know if you want your metal to be harder, tougher, or easier to shape. |

| Part Geometry | The size and shape of your part affect how evenly the heat treatment works. |

| Equipment Availability | You must check if you have the right tools and machines for the process. |

| Cost | You want a method that gives good results without costing too much. |

Tip: Always match your goals with the right method. This helps you get the best results and saves money.

Matching Process to Metal

You need to match the heat treatment process to the type of metal you use. Each metal reacts differently when you heat and cool it. Metallurgists use special steps for each kind of metal. Here is how you can match the process:

- For cast iron, carbon steel, martensitic stainless steel, and tool steel, you can use hardening, annealing, normalizing, stress relieving, case hardening, nitriding, and tempering.

- For copper and copper alloys, you can use annealing, ageing, and quenching.

- For aluminum, you can use annealing, solution heat treatment, and natural or artificial ageing.

The heat treatment process has three main stages: heating, soaking, and cooling. Each stage helps you get the properties you want in your metal.

You need to pick the right process for your metal. This helps you avoid problems and get strong, reliable parts.

Common Mistakes

You can make mistakes during heat treatment if you do not follow the right steps. These mistakes can cause problems with your metal parts. Here is a table that shows common mistakes, their causes, effects, and how you can prevent them:

| Mistake | Cause | Effects | Prevention |

|---|---|---|---|

| Distortion | Uneven heating or cooling, poor fixturing | Parts do not fit right | Use good fixturing and control cooling rates |

| Grain Growth | Too much time at high temperature | Weaker metal, less stable size | Watch heating times and use proper cooling |

| Quench Cracking | Cooling too fast | Cracks form, metal breaks easily | Pick the right cooling method and preheat metal |

| Surface Oxidation | Metal touches air during heating | Bad surface, rusts faster | Use clean surfaces and control the atmosphere |

| Soft Spots | Uneven heating or not enough soaking time | Metal fails under stress | Heat evenly and test hardness after treatment |

Note: You can avoid most mistakes by following the right steps and checking your work. Good planning keeps your metal strong and safe.

You use heat treatment to make metal act differently. This process helps metal get stronger and tougher. It also makes metal better for many jobs. You can see these changes in cars, tools, and buildings. Factories use heat treatment to make products safe and last longer.

| Benefit | Why It Matters |

|---|---|

| Better performance | Metal works well in tough conditions |

| Longer lifespan | Parts last longer and need less repair |

| Cost savings | Fewer replacements and lower expenses |

You count on heat treatment every day at home and at work.

FAQ

Heat treatment changes how metal acts. You make metal harder, stronger, or easier to shape. You also help metal last longer and resist wear.

You can heat treat many metals like steel, iron, copper, and aluminum. Each metal needs a special process. Some metals do not change much with heat treatment.

Cooling sets the new structure inside the metal. Fast cooling makes metal hard. Slow cooling makes metal soft. The way you cool metal decides its final properties.

Heat treatment can help metal resist rust, but it does not make it rust-proof. You often need extra coatings or special alloys for full rust protection.

You look at the type of metal and what you want it to do. You choose a process that gives you the right mix of hardness, strength, and toughness.

You should not try heat treatment at home. The process needs high temperatures and special equipment. You can get hurt or damage the metal without proper tools.

If you skip heat treatment, metal parts may break, bend, or wear out quickly. You risk having tools and machines that do not work well or last long.

Heat treatment time depends on the metal and the process. Some steps take minutes. Others need hours. You must follow the right timing for good results.