You get new challenges in hard turning each year. To do well, you need to use new techniques and better tools. Modern technology lets you work smarter and quicker. Stay active and keep learning new things. You can make your process better by trying new ways and watching your results. > Remember: Always improving gives you the best results.

Key Takeaways

- Tool wear is a big problem in hard turning. Check tools often and change them when needed. This helps keep work fast and easy.

- The quality of the surface finish affects how well the part works. Change cutting speed and feed rate for smoother surfaces.

- Hard turning needs a steady machine setup for accuracy. Use strong clamping and pick the right tool to lower mistakes.

- Managing heat is very important. Use sharp tools and the right cutting speeds to lower heat. This helps tools last longer.

- Good chip control stops tool wear and machine stops. Use chip breakers and keep the workspace clean.

- Pick the best tools and coatings for your materials. This helps tools work better and last longer.

- Watch your tools with real-time systems. Finding wear early can stop costly stops and make work more accurate.

- Check and fix machines often to keep them working well. Follow a regular plan to stop surprise breakdowns.

Table of Contents

Hard Turning Challenges

Tool Wear

Causes

Tool wear is a big problem in hard turning. Fast cutting speeds and feeds make the tool wear out faster. Hard workpieces also make the tool wear down quickly. If you use the wrong tool materials or coatings, the tool gets worse faster. Bad heat control makes the tool last even less time.

| Findings | Description |

|---|---|

| Tool Wear Influence | Fast cutting and feeding make the tool wear more. |

| Chip Formation | Faster speeds and feeds make rough, saw-like chips. |

| Cost Analysis | Using coated carbide tools keeps costs low for each part. |

Impact

Tool wear hurts how much you can get done and how much you spend. Worn tools make rough surfaces and parts that are not the right size. You will need to stop more often to change tools, which slows you down. If you ignore tool wear, you will throw away more parts and do worse in hard turning. Using coated carbide tools saves money and helps you make more good parts, so they are better than grinding.

Tip: Check your tools often to keep things working well and avoid surprises.

Surface Finish

Factors

Surface finish is very important for hard turning quality. Many things change how smooth your parts are:

- Cutting speed: Going faster can make the surface smoother.

- Feed rate: Feeding faster can make the surface rougher.

- Tool geometry: The shape and sharpness of your tool matter.

- Machine rigidity: A strong setup stops shaking and noise.

| Challenge | Description |

|---|---|

| Surface Finish | Getting a smooth surface is key because it affects part quality. |

| Chatter | Wrong speeds, feeds, or weak setups cause shaking that ruins the surface. |

Defects

Bad surface finish causes big problems. You might see more rubbing, rust, and damage in your parts. Rolling contact fatigue can make bearings wear out faster. Cracks under the surface can grow and break the part. These problems make your parts less reliable and hurt your hard turning results.

Note: Always look for shaking and noise, since these show surface finish issues.

Accuracy

Sources

Keeping accuracy in hard turning means watching for mistakes. Machine rigidity is very important. If your setup is weak, you get tool wear and bad surfaces. Shaking from the machine or part can make things wrong. Picking the wrong tool or holding the part badly makes more mistakes.

- Flatness and rough surfaces often come from bad machine setups.

- Shaking makes you throw away more parts and lowers quality.

Solutions

You can get better accuracy by making your setup strong and holding parts tight. Use collets to grip parts better. Pick the right tool for each job. Watch for shaking and change speeds or feeds if needed. These steps help you make fewer mistakes, throw away less, and do better in hard turning.

Success in hard turning comes from controlling tool wear, surface finish, and accuracy. Stay alert and fix problems early for the best results.

Heat

Effects

Hard turning makes a lot of heat. The cutting edge gets hot very fast. This heat can hurt your tool and the workpiece. When it gets too hot, your tool wears out faster. The workpiece might change shape or get softer. You may see cracks or burns on the finished part.

Researchers have looked at how heat changes tool life and workpiece quality. The table below shows what they found:

| Study Title | Key Findings |

|---|---|

| The Effects of Heat Generation on Cutting Tool and Machined Workpiece | Tool life and cutting accuracy depend a lot on heat. Heat moves between the tool and workpiece. Finite element modeling helped show how heat spreads in the tool. |

| Numerical Investigation of Heat-Induced Effects on Steel Workpieces During Hard Turning Machining Process | This study shows heat affects the workpiece surface and inside layers. Finite element models helped check temperature changes with different settings. |

| Measurement and Numerical Simulation of the Cutting Temperature in Cutting Tool During Turning Operation | This research used tests and computer models to study cutting temperature. They found a 96% match between the two. Heat has a big effect on tool life and workpiece quality. |

High heat in hard turning makes tools wear out and parts worse. You must control heat to keep things working well.

Reduction

You can lower heat by using the right ways. Pick sharp tools and strong tool holders. These help stop friction. Use good cutting speeds and feeds to keep heat down. Sometimes, you can use coolants, but many jobs run dry. In those cases, focus on tool material and machine setup.

- Pick tools that can handle heat.

- Keep your machine strong to stop shaking.

- Change your cutting settings if you see overheating.

Tip: Watch for color changes on your tool or part. This can mean too much heat.

Chip Control

Issues

Chip control is hard in hard turning. Chips form fast and can cause trouble if not managed. Bad chip control makes tools wear out, stops machines, and ruins surfaces. Chips can pile up and trap heat, making tools break early.

Recent studies show the main chip control problems:

| Problem | Description |

|---|---|

| Chip Buildup | Stops the tool from cutting right and makes more heat. This wears out the tool. |

| Heat Generation | Long chips trap heat and can reach 700-900°C. This makes inserts fail early. |

| Tool Geometry Issues | Bad chip pockets make chips nest and stop the machine. |

| Material Properties | Ductile alloys make sticky chips. Hard materials make brittle chips that clog. |

| Vibration | Chip piles cause shaking and ruin the surface. |

| Associated Costs | Downtime from chips can take 10-12% of machine time. This makes more scrap. |

Note: If you see long chips or chip nests, fix it fast to stop problems.

Management

You can control chips better with the right tool shape. Use inserts with chip breakers made for hard turning. Change your speed and feed to break chips into small pieces. Keep your work area clean to stop chip piles. Use air or chip conveyors if you can.

- Check your chips often. Short, curled chips are best.

- Change your tool if you see chip nests or piles.

- Keep your machine and tool holders clean.

Good chip control keeps your work safe and smooth. Your tools last longer and your parts look better.

Tool and Material Selection

Picking the right tools and materials is very important. You need to match your cutting tool to the workpiece. Choose coatings that help your tools work better. Good choices help you stop tool wear. They also make surfaces smoother and keep your process steady.

Cutting Tool Materials

CBN Tools

Cubic boron nitride (CBN) tools are very hard. They resist wearing out and keep their shape. You use CBN tools for cutting hardened steels and superalloys. These tools work well at high temperatures. This means they last longer and make better parts. CBN is best for fine finishes on very hard materials.

Ceramic Inserts

Ceramic inserts cut fast and handle heat well. You can use them to cut hard materials quicker than carbide tools. Ceramic tools have alumina, silicon nitride, or sialon. They help you work faster because they run at higher speeds. Ceramics can break easily, so you need a strong setup.

- Here are some good cutting tool materials for hard turning:

- Cemented carbides: Tungsten carbide, titanium carbide, tantalum carbide

- Ceramics: Alumina, silicon nitride, sialon

- Superhard materials: CBN and polycrystalline diamond (PCD)

Tip: Use ceramic tools to go faster and work better. Always check if your machine is strong enough.

Coatings

Benefits

Coatings on cutting tools help lower friction. They also help tools last longer and make smoother surfaces. Coatings like TiN, AlCrN, AlTiN, TiAlN, and TiAlSiN protect tools from heat and rust. This lets you use your machines longer without changing inserts.

Selection

Pick coatings based on your workpiece and how you cut. Hard coatings are good for hard turning. They keep your tool sharp and steady. Coated tools wear less and make smoother parts. This helps your process stay strong and work well.

| Coating Type | Main Benefit | Typical Use Case |

|---|---|---|

| TiN | Reduces friction | General hard turning |

| AlTiN | Heat resistance | High-speed applications |

| TiAlSiN | Wear resistance | Tough workpieces |

Workpiece Materials

Hardness

Turning very hard materials is tough. High hardness makes cutting harder and causes more friction. This can wear out tools and make bad surfaces. You need the right tools and coatings for these jobs.

Strategies

You can use different ways to get better results with hard workpieces:

- Green machining: Cut the part before it gets hard to make cutting easier.

- Minimize deflection: Keep overhangs short and use the right tool size.

- Rigid clamping: Hold your workpiece and tool tight to stop shaking.

- Two-pass strategy: Do a rough cut first, then a finish cut for better accuracy.

These ways help you stop shaking, make parts more accurate, and help tools last longer. You get better parts and throw away less when you use these steps.

Hard Turning Parameters

Speed

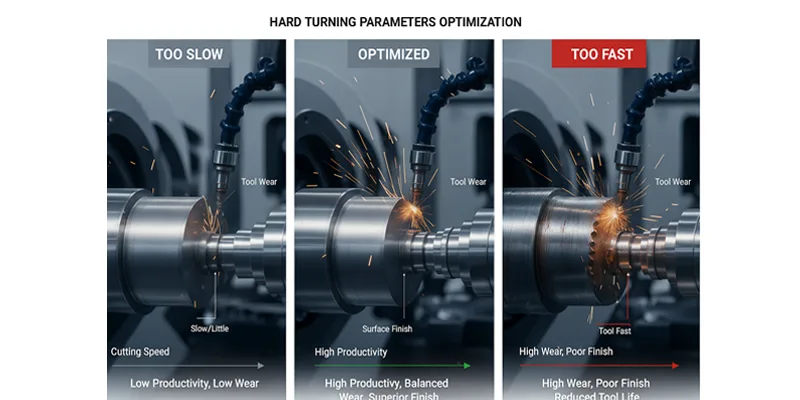

Optimization

You must choose the right cutting speed for hard turning. The speed affects how fast you finish a job and how long your tool lasts. If you set the speed too high, your tool wears out quickly. If you go too slow, you waste time and lower productivity. You should start with the recommended speed for your tool and material. Then, watch the tool and surface quality. Adjust the speed if you see problems like rough surfaces or fast tool wear.

Tip: Always monitor the cutting zone for signs of overheating or excessive wear.

Effects

Cutting speed changes tool life and surface quality. When you increase speed, the temperature at the cutting edge rises. This leads to more wear and can damage the tool. You may see flank wear, which is common in hard turning. Flank wear changes the shape of the cutting edge and makes the surface rougher. Studies show that cutting speed has a bigger impact on tool life than feed rate.

| Finding | Description |

|---|---|

| Tool Wear Importance | Tool wear significantly affects cutting edge geometry and surface quality. |

| Dominant Wear Type | Flank wear is the primary wear type in hard turning of AISI 52100. |

| Temperature Effects | Higher temperatures in the cutting zone lead to adhesion and abrasion wear. |

| Cutting Speed Impact | Higher cutting speeds lead to increased tool wear due to thermal instability and abrasion effects. |

| Tool Life Comparison | Cutting speed has a more significant impact on tool life than feed rate. |

| Wear Mechanisms | Tool flank wear is influenced by contact stress and cutting temperature. |

Note: Lower speeds help your tool last longer, but you must balance speed with productivity.

Feed

Balance

Feed rate controls how much material you remove with each pass. You need to find a balance between speed and surface quality. If you set the feed rate too high, you get rough surfaces and lose accuracy. If you set it too low, you waste time and may burnish the surface, which also hurts accuracy. The best feed rate gives you a smooth surface and keeps your part size correct.

Adjustment

You should adjust the feed rate based on your material and tool. Start with the recommended value, then check the surface roughness and part size. If you see poor accuracy or rough surfaces, change the feed rate. Experimental studies show that a feed rate of 0.16 mm/rev gives the best accuracy and surface finish in hard turning.

| Feed Rate (mm/rev) | Surface Roughness (μm) | Dimensional Accuracy Behavior |

|---|---|---|

| 0.08 | Increased deviation | Poor accuracy due to burnishing |

| 0.16 | Decreased to 6.93 | Best accuracy achieved |

| 0.32 | Increased deviation | Significant decrease in accuracy |

Tip: Check your parts after each run. Adjust the feed rate if you see changes in surface or size.

Depth

Selection

Depth of cut decides how much material you remove in one pass. You must pick a depth that matches your tool and machine strength. If you cut too deep, you risk vibration and tool breakage. If you cut too shallow, you slow down production. Start with the recommended depth for your material, then test and adjust as needed.

- Select initial depth based on material and tool.

- Run test cuts and observe vibration or tool wear.

- Adjust depth to balance productivity and tool life.

Impact

The right depth of cut helps you work faster and keeps your tool safe. Studies show that for AISI 4140 steel, a depth of 2.0–3.0 mm maximizes material removal rate (MRR) and keeps tool life steady. For Inconel 718, use 0.3–0.8 mm for finishing and 1.0–2.0 mm for roughing. Shops often adjust depth to reduce vibration and maintain good results. New technologies like advanced coatings and AI systems help you optimize depth and make real-time changes.

| Study | Material | Recommended Cutting Depth | Notes |

|---|---|---|---|

| Smith et al. (2020) | AISI 4140 steel | 2.0–3.0 mm | Maximizes MRR while maintaining tool life |

| Lee and Kim (2022) | Inconel 718 | 0.3–0.8 mm (finishing), 1.0–2.0 mm (roughing) | Minimizes tool wear and achieves surface roughness < 0.8 µm |

Note: Use technology to help you find the best depth. Adjust as needed for each job and material.

Coolant

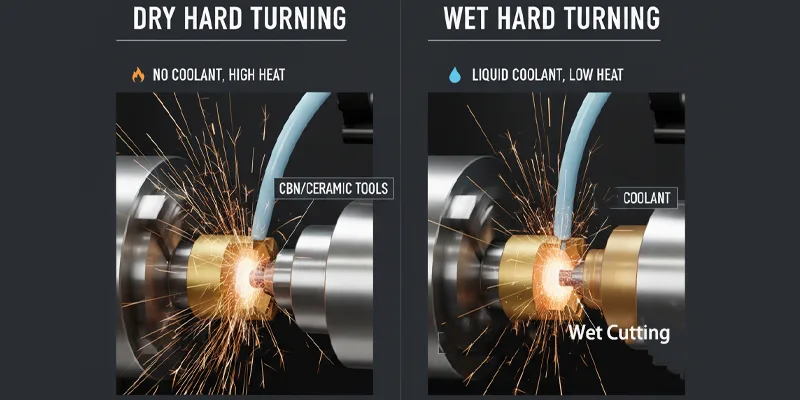

Dry vs Wet

You have to pick between dry and wet coolant in hard turning. Each way has its own good points. Dry cutting means you do not use any coolant. You depend on the tool and machine to handle heat. Dry cutting works best with CBN or ceramic tools. These tools can take more heat and last longer. If you set the right speed and feed, your tools last longer and cost less.

Wet cutting uses liquid coolant to cool things down. You pour coolant over the cutting area. This keeps things cooler and makes smoother parts. Wet cutting also helps your tools last longer. But, you pay more for coolant and have to throw it away safely. You also need to think about the environment and safety rules.

Studies have looked at dry and wet cutting. The table below shows what is good and bad about each:

| Coolant Strategy | Benefits | Drawbacks |

|---|---|---|

| Dry | Tools wear less and last longer if you use the right settings | Surface finish may not be as good as with wet cutting |

| Flooded | Smoother surfaces and longer tool life | Costs more, can hurt the environment, and is harder to get rid of |

Tip: Pick dry cutting if you want to save money and make tools last. Use wet cutting if you need the smoothest surface.

Delivery

If you use wet cutting, you must put coolant in the right place. How you add coolant changes your results. Flood coolant covers the whole cutting area with liquid. This cools the tool and part fast. You get smoother parts and your tools last longer. But, you have to watch the flow and clean up after.

High-pressure coolant shoots liquid right at the cutting spot. This cools things fast and pushes chips away. It keeps the tool sharp and stops chips from piling up. You also get less shaking and better accuracy.

Some shops use minimum quantity lubrication (MQL). This sprays a little oil very fast. It costs less and is better for the environment. You still get good cooling and chip control.

Check your coolant system often. Clean the filters and nozzles to keep the flow strong. Move the nozzle so it hits the cutting edge. Watch for leaks or clogs. Good coolant delivery stops overheating and tool breaks.

- Use flood coolant for most hard turning jobs.

- Try high-pressure coolant for tough work and hard parts.

- Use MQL if you want to help the environment.

Note: The right way to use coolant keeps your work steady and your parts looking good. Always pick the best coolant method for your job.

Technology in Hard Turning

Smart Machines

Adaptive Control

Smart machines help you do precise work. Adaptive control lets machines change settings while working. This helps when the material gets harder or the tool wears out. The machine can find problems and fix them fast. You get better results and fewer mistakes. Your process stays steady and works well.

Precision

Smart machines help you make very accurate parts. They have special features to control heat and shaking. These features are important for good results. Look at the table below to see how smart machines help:

| Feature | Description |

|---|---|

| Thermal Stability | Machines must control heat to keep accuracy in hard turning. |

| Vibration Suppression | Strong machine design helps stop shaking, which is needed for precision. |

| High Precision Positioning | Tools and spindles move on their own, so parts are more accurate. |

With these features, you can make every part with high precision. Your work is more reliable and you waste less material. Smart machines help you get the best results every time.

Monitoring

Tool Wear Detection

You need to check your tools often in precision machining. New monitoring systems help you find tool wear before it causes trouble. Some systems stop the machine to check the tool. Others watch the tool while it works. Real-time monitoring is the best way. You can fix problems right away and keep your work on track.

Sensors

Sensors are important in precision machining. They collect data about heat, force, and shaking. This helps you find tool wear early. The table below shows the main ways to watch tool health:

| Technology Type | Description | Effectiveness |

|---|---|---|

| Offline TCM | Stops work to check tools with special equipment like microscopes. | Reliable but slow and costs more because work stops. |

| Online TCM | Checks tools at set times without stopping work. | Faster than offline but not always real-time. |

| Real-time TCM | Watches tools all the time and fixes problems fast. | Very good for stopping tool failure and keeping accuracy high. |

| Direct Measurement | Uses cameras and microscopes to measure tool wear. | Reliable but expensive and cannot find sudden damage. |

| Indirect Measurement | Looks at things like force and torque to guess tool health. | Cheaper but not as exact; needs smart computers to work better. |

These systems help your work go smoothly. Real-time monitoring is best for most shops. It stops tool failure and keeps parts accurate.

Automation

Tool Change

Automation makes changing tools easier and faster. Robots switch tools quickly and make fewer mistakes than people. You save time and avoid errors that can ruin parts. Here is how automation helps:

- Automated systems save money and cut down on waste.

- They lower mistakes that can cause bad parts.

- Robots work all day and night, so you make more parts.

Automation keeps your work moving and helps you finish more parts on time.

AI Maintenance

AI maintenance helps you keep machines running well. Predictive maintenance uses sensor data to find problems early. You can plan repairs and stop sudden breakdowns. This keeps machines working longer and helps you avoid delays. Uptime can get better by up to 20%. Automation also stops surprise breakdowns that slow you down.

- Automation makes work faster and helps plan repairs.

- Predictive maintenance can make machines work 20% longer.

- Maintenance automation stops surprise breakdowns that hurt productivity.

Adam Coulston, a former Automation Department Manager, said, “When employees are constantly being pulled from elsewhere to ‘fight fires,’ that erodes the innovation mindset and motivation.”

These tools help you keep your work steady and efficient. Automation and AI let you focus on making better parts, not just fixing problems.

Setup and Maintenance

Rigidity

Stability

You need a strong machine for good accuracy in hard turning. Machine Dynamic Stiffness (MDS) shows how much force moves the machine. If MDS is high, your machine does not shake or move much. This helps you get smooth surfaces and keeps your tools working longer. When your machine is stiff, small movements do not cause mistakes. You can make parts that fit well and look good.

- Strong machines help you stay precise in hard turning.

- Less shaking means smoother parts and longer tool life.

Tip: Check your machine’s stiffness before each job. A stiff setup gives better results.

Upgrades

You can make your machine stronger by adding new parts. Use good modular tooling to stop shaking. Dual-contact spindle and tool holders help you be more accurate. Vibration damping tools, like Smart Damper, soak up shakes. These upgrades help you stay steady, even with long tools or tough materials.

| Upgrade Type | Benefit |

|---|---|

| Modular Tooling | Less shaking, more strength |

| Dual-Contact Holders | Better accuracy |

| Damping Technologies | Smoother surfaces |

Workholding

Chucks

Picking the right chuck keeps your part steady. You need workholding that fits your part’s size and shape. Good fixturing holds your part close to the table. This stops movement and controls cutting forces. If you use the wrong fixture, your part may shake, especially if it is thin or shaped oddly.

- Match chucks to your part’s shape for best results.

- Hold parts near the table to keep them steady.

Vibration

Shaking can mess up your part. Good modular tooling and dual-contact holders help stop shaking. Vibration damping tools soak up shocks and keep your work accurate. Always set up your part the right way to stop movement. If you see shaking, check your setup and fix it.

Note: Good workholding and less shaking protect your tools and make better parts.

Maintenance

Inspections

Checking your machine often keeps it working well. Look at important parts for wear or damage. Condition monitoring gives you live data about your machine. This helps you find problems early and fix them fast. Inspections stop surprise breakdowns and keep your work smooth.

- Check machines often for damage or wear.

- Use condition monitoring for quick alerts.

Preventive Routines

Make a regular maintenance plan using the maker’s advice. This helps you stop big problems and keeps your machine working well. A reliability program finds possible failures and helps you fix them before they happen. Predictive maintenance uses data to make your work better and save money.

| Maintenance Practice | Purpose |

|---|---|

| Preventive Schedule | Stops big problems before they start |

| Reliability Program | Keeps machines working well |

| Condition Monitoring | Helps you fix problems fast |

🛠️ Regular maintenance makes your machine last longer and helps you do better hard turning.

Troubleshooting

Tool Life

Failure

Sometimes your cutting tools do not last long. Many things can cause this problem. Hard workpieces make the tool get hot fast. High heat wears out the tool quickly. You spend more money on new tools. You also lose time and make fewer parts. Tool wear can make a white layer on the part. This layer makes the part weaker and less reliable.

Common reasons for short tool life are:

- Too much heat at the cutting edge

- Hard or rough workpiece materials

- Wrong cutting speeds or feeds

- Bad tool material or coating choice

If your tools wear out fast, check your cutting settings and tool type first.

Solutions

You can make tools last longer by doing a few things. Watch the cutting temperature during work. Use systems that show tool wear early. Pick tools with special coatings that fight heat and wear. Change your speed and feed to lower heat. Keep your machine setup strong to stop shaking. This helps your tools last longer.

Quick tips to improve tool life:

- Use coated tools made for hard turning

- Check tool health with sensors or software

- Change speeds and feeds to lower heat

- Keep your machine and setup steady

Surface Quality

Defects

Surface problems can look different. You may see rough spots, scratches, or tiny cracks. Sometimes, a white layer forms and makes the part weaker. Bad surface quality can make parts wear out faster. It can also cause rust or even break the part.

| Defect Type | Impact on Part |

|---|---|

| Rough Finish | Hurts how the part works |

| Cracks | Makes the part weaker |

| White Layer | Lowers fatigue strength |

Corrections

To fix surface problems, check your tool first. Change worn or broken inserts right away. Adjust cutting speed and feed for a smoother finish. Make sure your machine is steady and the part is held tight. Use the right tool shape for your material. If you see a white layer, lower the cutting temperature. You can do this by changing settings or using a better tool coating.

Check your process often and make small changes to keep surface quality good.

Downtime

Causes

Downtime can happen for many reasons in hard turning. Tool failure is a big cause. Machines can break down or chip control can be bad. Setup mistakes also stop work. Sometimes, you lose time changing tools or fixing surface problems.

Recovery

You can cut downtime by planning ahead. Use smart maintenance to find machine problems early. Keep extra tools ready for quick swaps. Teach your team to spot trouble before it gets worse. Use machines and sensors to warn you when something is wrong. Check your process often and make it better.

- Do regular maintenance checks

- Keep your workspace neat

- Use sensors for early warnings

Being ready helps you avoid delays and keeps your hard turning work smooth.

You can do well in hard turning by thinking about what went wrong and learning from it. You get better when you set clear goals and try to always improve. It helps to have people around you who support you. You should also learn new technology fast. Success means you keep learning and changing as things change. Working well with your team and staying calm when things are hard helps you do well for a long time.

- Think about mistakes to understand them better.

- Find out what you learned from each problem.

- See problems as chances to do better.

- Try to learn from mistakes and see them as ways to win.

- Have people you trust to help you.

- Change quickly when things are new to keep doing well.

Learning new things and changing with the times help you do well in hard turning. Keep learning and try new ways to work.

FAQ

Hard turning is a machining process where you cut hardened steel or similar materials using a single-point cutting tool. You use this method to replace grinding and finish parts with high precision.

You may use the wrong tool material or coating. High cutting speeds and heat also cause fast wear. Check your tool choice and monitor cutting temperature to extend tool life.

You should use sharp tools and set the correct speed and feed. Keep your machine rigid and stable. Always check for vibration and adjust your setup if you see rough surfaces.

Use inserts with chip breakers designed for hard turning. Adjust your speed and feed to break chips into small pieces. Keep your work area clean to prevent chip buildup.

You can use dry or wet cutting. Dry cutting works well with CBN or ceramic tools. Wet cutting gives a smoother finish but costs more. Choose the method that fits your job and tool.

You need a rigid machine and strong workholding. Use modular tooling and vibration-damping holders. Always check your setup before starting to keep vibration low.

You can use sensors and real-time monitoring systems. These tools track tool wear and alert you to problems. This helps you avoid tool failure and keeps your process running smoothly.