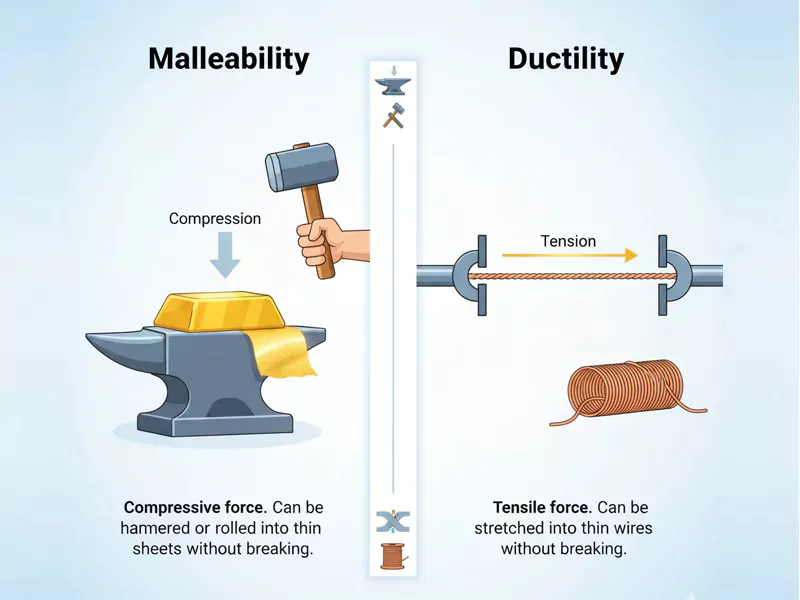

You might ask about the difference between malleability and ductility. Malleability indicates whether you can press or hammer a material into thin sheets without it breaking. On the other hand, ductility refers to the ability to pull a material into a thin wire.

| Property | Simple Definition |

|---|---|

| Malleability | Can be pressed into sheets without breaking |

| Ductility | Can be pulled into wires without snapping |

Understanding the difference between malleability and ductility is essential for selecting the best material for a job. For example:

- Copper is excellent for wires because it is ductile.

- Tin is used for cans because it is malleable.

- Gold is unique because it is both malleable and ductile.

Key Takeaways

- Malleability lets materials be pressed into thin sheets. They do not break when pressed.

- Ductility lets materials be stretched into thin wires. They do not snap when stretched.

- Copper is a good example of a ductile metal. People use copper for electrical wiring.

- Gold is malleable and ductile. This makes gold great for jewelry and electronics.

- Heating metals makes them more malleable and ductile. It is easier to shape metals when they are heated.

- Knowing these properties helps you pick the right metal. You can choose the best metal for your project.

- Ductile metals take in energy and stop sudden breaks. This makes things safer to use.

- Malleable metals help make smooth surfaces and detailed designs. They are important for many creations.

Table of Contents

Difference Between Malleability and Ductility

Ductility vs. Malleability

You may ask how ductility and malleability are not the same. Both show how a material can change shape. They react to different kinds of force. Ductility means you can stretch something into a wire, and it does not snap. Malleability means you can press or hammer something into thin sheets, and it does not break.

Here is a simple table to help you see how ductility and malleability are different:

| Property | Definition | Example |

|---|---|---|

| Malleability | Can be shaped into thin sheets by pressing. | Gold |

| Ductility | Can be stretched into wires by pulling. | Copper |

Gold is a good example of malleability. Copper is a good example of ductility. These properties help you pick the right material for what you need.

Physical Stress Types

When you test ductility and malleability, you use different forces. Ductility checks how much you can stretch a material by pulling. This pulling is called tensile stress. If you pull on copper wire, you test its ductility. The wire gets longer before it breaks.

Malleability checks how much you can flatten a material by pressing or hammering. This pressing is called compressive stress. If you hammer gold into a thin sheet, you test its malleability. The gold spreads out and does not crack.

- Ductile materials stretch a lot before breaking.

- Malleable materials flatten or bend when pressed.

- Ductility helps you make wires. Malleability helps you make sheets.

Tip: To remember the difference, think about the force. Pull for ductility. Press for malleability.

Key Distinction

The main difference between ductility and malleability is the force you use. Ductility is about pulling or stretching. Malleability is about pressing or hammering. Both mean the material changes shape and does not go back to how it was.

Here is a table with more details:

| Characteristic | Ductility | Malleability |

|---|---|---|

| Type of Stress | Pulling (tensile) | Pressing (compressive) |

| Form of Deformation | Permanent shape change | Permanent shape change |

| Applications | Making wires | Making thin sheets |

| Measuring Techniques | Stretching tests | Pressing or hardness tests |

| Materials | Gold, silver, platinum | Gold, aluminum, copper |

| Process | Stretching, drawing | Rolling, hammering, stamping |

| Temperature Dependence | More ductile when hot | More malleable when hot |

| Crystal Structure | Atoms can move past each other | Atoms can move past each other |

You use ductility and malleability to pick the best material for a job. For example, copper is good for wires because it is ductile. Gold is good for jewelry that needs thin sheets because it is malleable. Knowing the difference helps you understand why some metals are better for certain things.

Ductility and Malleability Explained

Ductility

You notice ductility when you stretch a metal wire. Ductility tells how much you can pull a material into a wire before it breaks. To test ductility, you use a pulling force. This pulling force is called tensile stress. If you pull on copper, it stretches a lot before it breaks. This means copper has high ductility.

Ductility is important for many things. You need ductile metals to make wires, chains, and springs. Ductility is about stretching and making wires, not sheets. Some metals like nickel and bismuth are also ductile. You can measure ductility with bend or stretch tests in a lab.

Malleability

Malleability happens when you press or hammer a metal into a sheet. You test malleability by pushing or pressing the metal. This pushing force is called compressive stress. If you hammer gold, it spreads into a thin sheet and does not crack. Gold, silver, and aluminum are known for being very malleable.

You need malleable metals to make coins, foils, and sheets. Malleability helps you shape metals flat or curved. Malleability does not mean a metal can be made into a wire. Some metals are malleable but not ductile. Heat also changes malleability. Heating metals makes them easier to shape.

Testing Methods

You can test ductility and malleability in a lab with different ways. For ductility, scientists use stretching, elastic recovery, and strength tests. These tests show how far a material can stretch before it breaks or how much it goes back after being pulled.

| Method | Description | Standards/Conditions |

|---|---|---|

| Stretching Test | Measures how far a sample can stretch in water. | ASTM D 113, DIN 52 013, JIS K 2207, AASHTO T51; 5 cm/min, 25 °C |

| Elastic Recovery Test | Checks how much a stretched sample returns after being cut. | ASTM D6084 (10 cm, 60 min), EN 13 398 (20 cm, 30 min); 5 cm/min, 25 °C |

| Ductility Strength Test | Tests how much force a sample can take before breaking. | EN 13589, EN 13703, AASHTO T300; 5 cm/min, 4 °C (AASHTO), 5 °C (EN) |

For malleability, you use pressing tests, heating, and mixing metals. These tests show how much pressure a metal can take before it breaks and how heat or mixing changes how easy it is to shape.

| Method | Description |

|---|---|

| Compressive Stress | Shows how much pressure a metal can take before breaking. |

| Temperature | Heating metals makes them more malleable by changing their structure. |

| Alloying | Mixing metals controls grain size and helps shape metals better. |

You can compare ductility and malleability for metals in this table:

| Basis for Comparison | Ductility | Malleability |

|---|---|---|

| Basic | Change into wires | Change into sheets |

| Nature | Stretching | Deforming |

| External stress | Tensile | Compressive |

| Changed to | Wires, chains | Sheets, papers |

| Measurement | Bend test | Pressure test |

| Variation | Ductile materials show high malleability | Malleable materials do not always show good ductility |

| Effect of temperature | Decreases with heat | Increases with heat |

| Examples | Copper, Bismuth, Nickel | Gold, Silver, Aluminum |

Note: Testing methods have some limits. Results depend on sample size, temperature, and how fast you use force. Machine mistakes or sample problems can change results. Sometimes, it is hard to get a sample that shows what the whole metal is like.

When you learn about ductility and malleability, you see why metals act differently. You can pick the right metal for wires, sheets, or other things. Knowing how to test these properties helps you make better choices in science and engineering.

Common Materials

Metals with High Ductility

You see ductile metals in many things every day. These metals can be stretched into wires and do not break. You find them in lots of products around you. New science studies show which metals are most ductile. Here are some of the most ductile metals:

- Gold

- Silver

- Copper

- Palladium

These metals bend and stretch without much effort. Scientists now use new computer methods to guess ductility. This helps you know why some metals stretch more than others. Ductile metals are used in jewelry, electronics, and wires. You need them to make long, thin shapes.

Metals with High Malleability

You use malleable metals when you want to shape or flatten something. These metals let you press, roll, or hammer them into thin sheets. Gold is very malleable and stands out the most. You can hammer gold so thin that light goes through it. Silver and aluminum are also very malleable. You see malleable metals in coins, foils, and decorations. You pick malleable metals for projects that need bending or shaping without breaking. Heat makes these metals even easier to shape. You find malleable metals in art, packaging, and building things.

Tip: If you need a metal for shaping or forming, pick malleable metals. They help you make smooth surfaces and detailed designs.

Both Properties

Some metals have both high ductility and high malleability. You find these metals helpful in many jobs. You see them in things that need both stretching and shaping. The table below shows two metals with both properties and what they are used for:

| Metal | Malleability | Common Uses |

|---|---|---|

| Gold | High | Jewelry, electronics |

| Copper | High | Electrical wiring, plumbing |

You use gold for jewelry because it bends and stretches without breaking. You use copper for wires and pipes because it forms them easily. These metals help you solve problems in design and making things. You choose them when you need both flexibility and strength.

Knowing about ductility and malleability helps you pick the right metal for your needs. You can choose ductile metals for wires, malleable metals for sheets, or metals with both for special projects.

Real-World Uses

Everyday Applications

You see ductility and malleability in daily life. You might not notice them. When you use a spoon or fork, these properties helped shape them. Ductile metals let factories stretch metal into shapes. Malleable metals let them press metal into thin pieces.

Here is a table with products made from ductile metals:

| Product Type | Examples |

|---|---|

| Utensils | Spoons, forks, knives |

| Hardware | Screws, nails, bolts |

| Appliances | Refrigerators, ovens |

You use utensils made from ductile metals every day. Screws and nails bend but do not snap. Appliances like ovens use metal parts shaped by both properties. These features help make strong and safe products for your home.

Tip: When you use metal things, remember ductility and malleability shaped them.

Industrial Examples

Factories need these properties to make good products. Many jobs use ductility in workshops. Here are ways companies use ductile and malleable metals:

- Steel uses both properties to make beams and car parts.

- Aluminum shapes easily, so workers roll it for cans and planes.

- Wire drawing stretches gold and platinum for electronics and jewelry.

- Solders made from ductile alloys join parts in electronics and plumbing.

- Jewelry makers use ductile metals like gold and silver for rings and necklaces.

Gold is a great example of malleability. You can hammer gold into sheets so thin that light goes through. This helps make pretty jewelry with tiny details. Gold’s malleability helps in electronics, too. It makes small, exact parts. Gold bends and stretches well, so it looks nice and works well.

Malleability helps shape metals into thin sheets or detailed forms. Ductility helps stretch metals into wires or bend them without breaking. These properties make metals useful for art, machines, and airplanes.

Factors Affecting Properties

Atomic Structure

You can learn why metals act differently by looking at their atoms. The way atoms are arranged in a metal changes how you can shape or stretch it. Some metals have a face-centered cubic (FCC) structure. This structure lets atoms move in many ways. FCC metals like gold and copper are very ductile. Their atoms slide past each other easily.

- FCC metals have more ways to move, so they bend without breaking.

- Free electrons help the layers of atoms slide. This makes metals more malleable.

- You can hammer or roll FCC metals into thin sheets. Their atoms can slide without breaking apart.

- When you pull metals into wires, atoms move past each other. The metallic bond stays strong.

You see that how atoms are packed changes a metal’s properties. Metals with hexagonal close-packed (HCP) structures do not stretch or flatten as well. You should pick FCC metals for jobs needing high ductility or malleability.

Temperature

You notice that heat changes how metals behave. When you heat a metal, its atoms move faster. This extra energy helps atoms slip past each other. Metals are easier to shape when hot. Malleability goes up because atoms move more freely. Ductility also gets better since metals are less likely to snap. You can shape, roll, or draw metals more easily when they are warm. Factories heat metals before working with them. This makes the job easier and safer.

Tip: If you want to shape or stretch a metal, heat it first. Warm metals bend and stretch better than cold ones.

Alloying

You can change a metal’s properties by mixing it with other elements. This is called alloying. Adding different atoms changes how the metal’s atoms move. Some alloys get stronger but less ductile. Others are easier to shape. Alloying helps you balance strength, ductility, and malleability.

Here is a table that shows how these properties help with recycling:

| Property | Effect on Recycling | Example Use Case |

|---|---|---|

| Malleability | Lets you shape metal by pressing or rolling. | Aluminum can be pressed into thin sheets for packaging. |

| Ductility | Lets you stretch metal into wires without breaking. | Copper can be drawn into wiring for electrical systems. |

You see that alloying helps recycle metals more easily. You can press, roll, or stretch recycled metals into new things. This saves resources and helps the planet.

Choosing Materials

Application Needs

When you pick a material for a project, you must think about what the material will do. Some jobs need metals that can stretch without breaking. Other jobs need metals that can flatten into thin sheets. You should match the property to the job.

- If you want to make wires, choose a ductile metal like copper.

- If you need thin sheets for cans or foils, pick a malleable metal like aluminum.

- For jewelry, gold works well because it is both ductile and malleable.

You also need to look at how the metal will be shaped. Factories use malleable metals for stamping and rolling. Ductile metals work best for drawing and bending. You can see how these properties help in different tasks.

Tip: Always ask yourself, “Will this metal need to bend, stretch, or flatten?” Your answer will guide your choice.

Here is a table that shows how engineers look at different properties when choosing materials:

| Property | Description | Importance in Engineering Applications |

|---|---|---|

| Ductility | Ability to stretch under pulling forces | Needed for energy absorption and flexibility |

| Malleability | Ability to form under pressing or hammering | Helps with shaping in manufacturing |

| Cost | How much the material costs | Must fit the project budget and last a long time |

| Safety | Can the material handle stress without breaking? | Keeps products safe and reliable |

| Material Composition | What elements are in the metal? | Changes how the metal acts in different situations |

Safety

Safety should always come first when you choose a material. You want to make sure the metal will not break or fail during use. Ductile metals can stretch and absorb energy. This helps prevent sudden breaks. Malleable metals can bend without cracking. This is important for parts that get pressed or hit.

You should think about where and how the metal will be used. For example, bridges and buildings need metals that can handle heavy loads. Wires in electronics must not snap when bent. If you pick the wrong metal, things can break and cause harm.

- Use ductile metals for parts that need to bend or stretch.

- Use malleable metals for parts that need to be shaped or pressed.

Note: Always check if the metal can handle the stress it will face. This keeps people and products safe.

Cost

Cost matters in every project. You want a material that fits your budget but still works well. Some metals cost more because they are rare or hard to shape. Gold is expensive but has great properties. Aluminum costs less and is easy to shape.

Engineers balance cost with performance. They look for metals that last long and do not break easily. Sometimes, mixing metals (alloying) gives you the right balance of cost, strength, and shape.

Here are some ways to save money when choosing materials:

- Pick common metals like aluminum or copper for most jobs.

- Use alloys to get the best mix of properties.

- Think about how easy it is to recycle the metal.

Tip: Do not pick the cheapest metal if it will not last. A good material saves money over time because it needs fewer repairs.

By thinking about application needs, safety, and cost, you can choose the best material for your project. This helps you build things that are strong, safe, and affordable.

You now know how malleability and ductility are different. Each property helps you pick the right metal for your project. This difference is important for many reasons.

- Malleability lets you press metals into shapes.

- Ductility lets metals stretch and not break.

- Companies use these properties to make products that last longer.

| Aspect | Explanation |

|---|---|

| Material Selection | Knowing about malleability and ductility helps engineers choose the best metal for each job. |

| Manufacturing Processes | Factories use malleable and ductile metals to make strong and useful things. |

| Product Performance | These properties change how well products work in real life. |

You can make smarter choices when you think about these properties before picking materials.

FAQ

You check malleability by pressing or hammering metal into sheets. You check ductility by pulling metal into wires. Each property uses a different kind of force.

Some metals have both properties. Gold and copper are good examples. You use them for jewelry, wires, and thin sheets.

Ductile metals stretch without breaking. Copper and aluminum are great for electrical wires. These metals bend and twist easily.

Malleable metals are used for coins, foils, and art. Gold and aluminum can be pressed into thin sheets. Factories use these metals for packaging and decorations.

You test ductility by pulling a sample until it breaks. Scientists measure how far the metal stretches. Bend or stretch tests show the results.

Mixing metals changes their properties. Alloying can make metals stronger or easier to shape. You pick the right mix for your project.

Tip: Always check the metal’s properties before starting your project. This helps you choose the best material.