Imagine you finish a part and see sharp edges. These edges can hurt quality and safety. You must pick advanced deburring tools. The right tool keeps your product safe and teaches you how to use a deburring tool effectively. It also makes your work faster.

- Pick a deburring tool that fits your material. This helps remove burrs without damaging your workpiece.

- The shape of your part helps you choose your deburring method, which also changes how your part looks at the end.

- How many parts you make affects your equipment choice, which can help you work faster.Burrs can slow down robots in factories and cause mistakes. If you learn how to use a deburring tool properly, your parts stay strong and reliable.

Key Takeaways

- Pick a deburring tool that works with your material. This helps stop damage and gives better results. Think about the shape of your parts before you pick a deburring method. The shape can change how the finished part looks. Check how many parts you need to make. This helps you choose between manual tools or machines for faster work.

- Always try your deburring process on one sample part first. This makes sure you get the finish you want before making more. Take care of your deburring tools often. This helps them last longer and work well every time. Follow safety rules like wearing safety gear and keeping air moving in your work area. Learn about new deburring technologies to make your work better and meet industry rules. Ask suppliers for help to find the best tools and ways for your needs.

Table of Contents

Application

To pick the right deburring tool, you must know your job. Look at what material you have. Think about the shape of your parts. Count how many parts you will make. These things change how you remove burrs. They help you stop problems like rough edges or scratches.

Material

Materials act differently when you deburr them. You need to match your tool and media to your material. This gives you the best results.

Metals

Metals like steel, aluminum, and titanium are used a lot. Hard metals need strong deburring media. Soft metals need a gentle touch. The table below shows which media work best for each material:

| Deburring Media | Commonly Used For |

|---|---|

| Ceramic | Hard metals like titanium, stainless steel, and tough metals; also used for soft metals and plastics. |

| Plastic | Fragile metals like magnesium, zinc, brass, aluminum; also for plastic parts. |

| Organic | Natural, biodegradable materials. |

| Steel | Many materials; good for light deburring jobs. |

Ceramic media is good for hard metals and gives different finishes. Steel media is best for light deburring and keeps your area clean. Pick the media that matches your metal’s hardness and the finish you want.

Plastics

Plastics can be soft or break easily. Use plastic or ceramic media for these. Plastic media comes in different types. You can pick the one that fits your job. Using the wrong tool can melt or break your parts. Always test on a sample first.

Composites

Composites mix things like carbon fiber and resin. These parts have tight spaces and special shapes. Synthetic media with abrasives in a soft base works well. It shows new abrasives as it wears down. This gives you a smooth finish every time.

Part Geometry

The shape of your parts changes how you deburr them. Simple shapes are easy to work on. Hard shapes need more care. You may have problems like:

- Many shapes and sizes in one batch

- Changing tools often, which slows you down

- Mixing materials in one group

- Small batches that make machines too costly

- Keeping all parts the same quality

If your parts have small spaces or tiny features, use small, careful deburring tools. Custom holders help with odd shapes. But they can move out of place. This can leave burrs or make the finish uneven.

Tip: Always check your holders and tool setup before you start. This helps you avoid mistakes and keeps your work smooth.

Production Volume

How many parts you make changes what you need. If you make a lot, use machines. These include mass finishing, where you do many parts at once, and machines with brushes or belts for flat parts.

| Method | Description |

|---|---|

| Mass Finishing | A batch process using abrasive media to deburr and finish many parts at the same time. |

| Powered Brush, Belt, and Disc | Machines that use spinning abrasive tools for flat materials. |

If you only make a few parts, hand tools may be better. If you start making more, machines save time and keep your work the same.

Surface Finish

Surface finish is important for every job. You want your parts to look nice and work well. The right deburring tool helps you get the best surface finish. You need to think about how smooth or rough your part should be. Some jobs, like in airplanes or hospitals, have strict rules for surface texture. These rules help you pick the right tool and method.

| Standard | Description |

|---|---|

| ISO 1302 | Shows surface texture in product drawings, important for engineers and designers. |

| ISO 25178 | Gives rules for 3D surface texture, used in 3D printing. |

You see these rules in drawings and reports. They tell you how smooth your part must be after deburring. If you do not follow them, your part might not work right. You should check these rules before you start.

The deburring tool you pick changes your surface finish. You can use hand tools, vibration machines, or SPINner deburring systems. Each tool gives a different result.

- Hand tools let you control the finish, but take more time.

- Vibration machines are fast for many parts, but may leave a dull look.

- SPINner deburring systems are fast and give good quality.

You need to match your tool to your material, part size, and shape. This helps you get the best finish for your job. If you use the wrong tool, you might get scratches, rough spots, or uneven edges.

Tip: Always try your deburring process on a sample part first. This lets you see the finish before you do all your parts.

You can check surface finish with gauges or microscopes. These tools show if your part meets the rules. If you see problems, you can change your tool or method. This helps you fix mistakes and get better results.

Some parts need to be shiny and smooth. Others need a dull or rough finish for grip. You choose what is best for your job. You should talk to your customer or check the drawing to know what finish they want.

Surface finish changes how your part fits, moves, and lasts. A smooth finish lowers friction and wear. A rough finish can help paint or glue stick. You need to think about these things when you pick your deburring tool.

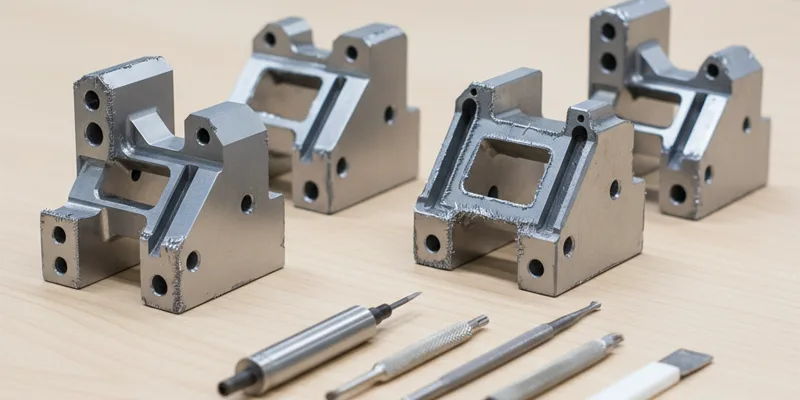

Deburring Tools

When you pick deburring tools, you need to match them to your job. There are many types of tools. Each type has its own strengths. The table below shows the main types:

| Type of Deburring Tool | Description |

|---|---|

| Handheld Tools | Manual tools like knives, scrapers, files, and brushes for small lots and intricate parts. |

| Machine-Mounted Tools | Integrated into CNC equipment for high-volume manufacturing with rotary burrs and abrasive wheels. |

| Automated Systems | Robotic cells and thermal/electrochemical systems for batch processing with high efficiency. |

Manual Tools

Manual deburring tools give you control and let you be flexible. You use these tools for small jobs or detailed work. They help you reach tight spots and work on delicate parts.

Edge trimmer

An edge trimmer takes off burrs from straight or curved edges. It fits in your hand and is easy to guide. You can make the edge smooth and clean with little effort. Edge trimmers work best for plastics, soft metals, and thin sheets.

File

A file shapes and smooths rough edges. You can pick different shapes and sizes for your part. Files work well for metals and hard plastics. You need to use steady strokes to keep the surface even. Files help you reach corners and small features.

Sandpaper/emery cloth

Sandpaper and emery cloth help you finish surfaces and take off small burrs. You can wrap them around a block or use them by hand. You can choose different grits for rough or smooth finishes. These tools work for metals, plastics, and composites. Some types can be reused, so they are better for the environment.

Scraper

A scraper takes off tough burrs and cleans flat surfaces. You hold it at an angle and push it along the edge. Scrapers work well for metals and hard plastics. They let you control the process and help you avoid damage.

Manual deburring tools cost less and are easy to use. You can see their good and bad points in this table:

| Advantages | Disadvantages |

|---|---|

| Low cost and simple operation | Low efficiency and high labor intensity |

| Allows for fine, detailed deburring on complex shapes or specific locations | Precision may be lower, leading to uneven deburring results |

| High flexibility and adaptability | Requires skilled workers, and improper handling may result in secondary damage |

Tip: Manual deburring works best for prototypes, repairs, or small jobs. You can change tools fast and work on many shapes.

Electric/pneumatic tools

Electric and pneumatic deburring tools help you work faster and more accurately. You use these tools for medium-sized jobs or when you need more power. Electric tools use motors and give steady results. Pneumatic tools use air and respond quickly. Both types help you finish parts faster than by hand. You can use them for metals, plastics, and composites. These tools help you use new deburring methods and save effort and waste.

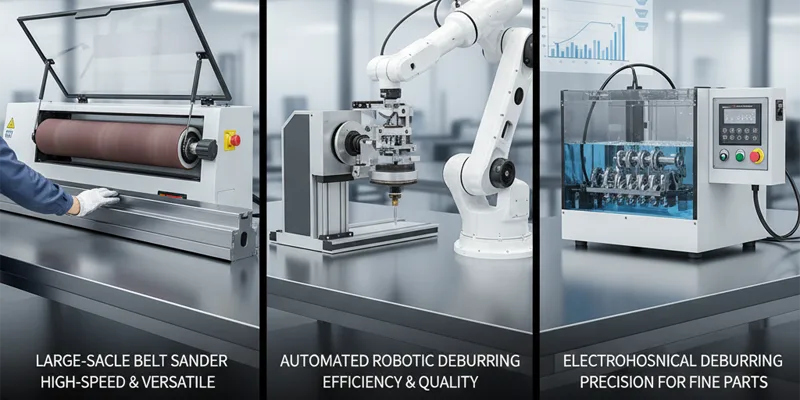

Automated Deburring Methods

Automated deburring methods help you handle lots of parts and keep results the same. You use these systems to work faster and make fewer mistakes. These systems use advanced tools and new deburring methods.

Drum/vibratory finishing machines

You put your parts and abrasive media in a drum or bowl. The machine shakes or spins, and the media rubs the parts. This method works well for many small parts at once. You save time and get even finishes. Drum and vibratory machines can use media again, which is better for the environment.

Thermal deburring (TEM)

Thermal deburring uses heat to burn away burrs. You put your parts in a chamber, fill it with gas, and light it. The heat removes burrs from hard-to-reach places. This method works well for tricky shapes and inside features. You get fast and clean results.

Electrochemical deburring (ECD)

Electrochemical deburring uses electricity and chemicals to take off burrs. You set up electrodes and run a current through the part. This process removes burrs without touching the surface. ECD works best for metals and gives you good control. You use this method for parts that need to be very exact.

Plasma deburring

Plasma deburring uses a strong plasma jet to remove burrs. You point the jet at the part, and it burns away the extra material. This new method works for metals and special materials. You get fast and accurate results and can use machines to do the work.

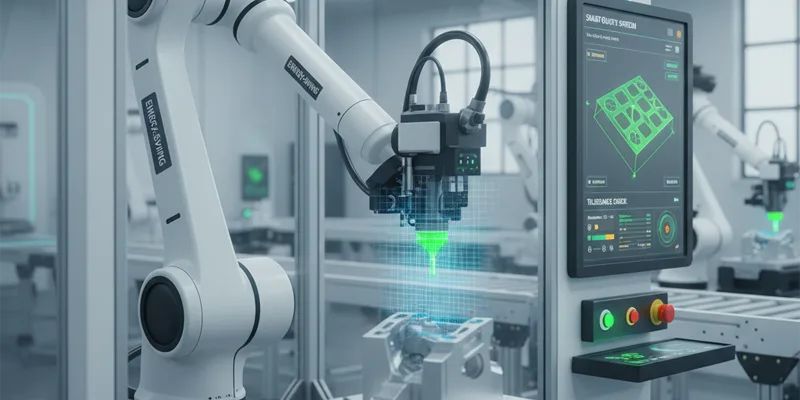

Automation in deburring is growing quickly. Many factories now use robots and smart machines for deburring. These systems use sensors and AI to watch the process and change settings as needed. You get better quality, fewer mistakes, and use less material.

Note: Automated deburring tools help you meet strict quality rules and are better for the environment because they use less energy and make less waste.

CNC and Robotic Tools

You can make your factory better by using CNC and robotic deburring tools. These systems help you get very smooth parts every time. They also make sure each part is made the same way. With CNC deburring, machines do the hard work for you. This means your parts have smooth edges every time.

CNC machines follow a set path to move deburring tools. You tell the machine where to go, how fast, and how hard to press. The machine does not get tired or make mistakes. Robotic deburring tools work almost the same way. Robots use sensors and smart controls to change what they do. They can use different deburring tools and work on many shapes.

Here are some reasons to use CNC and robotic deburring tools:

- Every part gets the same finish.

- You can make more parts in less time.

- You lower the chance of getting hurt from manual work.

- You save money on workers and make fewer mistakes.

Tip: If you want your factory to run well, try cnc deburring systems. These machines work all day and night and give you good results.

Let’s see how these systems help your business. The table below shows the main benefits:

| Benefit | Description |

|---|---|

| Consistent finish | Robots keep the same pressure and speed, so all parts look the same. |

| Higher throughput | More factories use deburring robots now, so you can finish parts faster. |

| Reduced injury risk | Manual deburring is hard work and can hurt people; robots help stop this. |

| Lower operating cost | Robots work all the time, so you spend less on workers and injuries. |

With CNC deburring, you can set the machine for different materials and shapes. You pick the right deburring tools for each job. The machine changes tools by itself, so you do not have to stop and switch. This saves time and keeps your parts moving.

Robotic deburring tools can reach small spaces and tricky shapes. You can trust them with delicate parts and they will not break them. These systems use cameras and sensors to watch the part as they work. If they see a problem, they fix it right away.

Factories now use smart tech to check when tools wear out and need fixing. This helps you stop problems before they happen and keeps your CNC machines working fast. You can connect these systems to your computer and watch how they work from anywhere.

If you want to be better at making things, you should try cnc and robotic deburring tools. They help you meet tough quality rules and keep your costs down. You get more control over your work and better results for your customers.

How to Use a Deburring Tool

Selection Checklist

Choosing the right tool is the first step in learning how to use a deburring tool effectively. You need to match your tool to your job. Use this checklist to help you decide:

| Criteria | Description |

|---|---|

| Range of Solutions | Make sure your supplier offers different deburring options, not just one type of machine. |

| Understanding Requirements | Work with your supplier to clarify your needs, such as space and production speed. |

| Sample Provision | Give sample parts to your supplier so they can suggest the best deburring solution for you. |

Tip: Always test a tool on a sample part before starting full production. This helps you avoid costly mistakes.

Step-by-Step Guide

You can follow these steps to master how to use a deburring tool and get the best results:

- Choose the Appropriate Deburring Tool

Look at your part’s material and shape. Pick a tool that fits your needs. For example, use a file for metal edges or a scraper for flat surfaces. - Make Ready the Workpiece

Clean your part. Remove dirt or oil. If needed, use a file to take off rough spots before you start deburring. - Begin Deburring

Hold the tool firmly. Move it along the edge or surface with steady pressure. Keep your motion smooth and even. - Check the Workpiece

Inspect your part for leftover burrs. If you see any, repeat the process. Make sure the finish matches your requirements.

Note: Regularly replace or sharpen your deburring tools. Dull tools can cause uneven results and damage your parts.

You can avoid common mistakes by understanding your material. For example, stainless steel needs a different approach than plastic. Adjust your machine settings or hand pressure to match the material and the finish you want. If you treat deburring as an important step, you will improve your product quality and save time.

Safety Tips

Safety is a key part of learning how to use a deburring tool. You protect yourself and your team by following these tips:

- Wear protective gear like gloves, safety glasses, and a dust mask.

- Work in a space with good airflow to keep dust and fumes away.

- Check your part for sharp edges or dangerous spots before you start.

- Use the right tool for your material to avoid accidents.

- Follow the manufacturer’s instructions for each tool.

- Keep children and pets out of the work area.

- Obey speed limits for electric or pneumatic tools. Never push a tool past its safe speed.

- Do not use too much pressure with power brushes. This can damage the tool and your part.

- Maintain your tools. Clean and check them often to make sure they work safely.

Remember: Safe habits help you avoid injuries and keep your workspace running smoothly.

If you follow these steps and tips, you will know how to use a deburring tool safely and get the best finish for your parts. Good deburring practices lead to better products and a safer shop.

Manufacturing Efficiency

Tool Performance

Picking the right deburring tool helps you work faster. Automatic deburring machines make your job easier and improve quality. You get better results when you match the tool to your needs. Belt sanding machines are fast and can do many jobs. They work well for big factories.

Electrochemical deburring machines are good for small, detailed parts. You should check how strong the deburring force is and how smooth the surface looks. The TOPSIS method helps you choose the best settings. This makes your work more reliable and keeps quality high. Watching these numbers helps you make every part the same.

Tip: Always check surface finish and deburring force. This helps you keep your work safe and high quality.

Cost vs. Benefit

You need to think about both cost and benefit when picking a deburring tool. Manual deburring looks cheap at first, but costs can go up fast. You need more workers when things get busy, which costs more money. Automated cryogenic deburring is clean and saves money over time. It gives you the same good results every time. Even if machines cost more at first, you save money later.

Automated deburring machines need fewer workers and help keep people safe. They also make sure every part is made the same way. Some companies spend over $300,000 a year on manual deburring with lots of workers. If you use automated deburring, you might not need a whole shift. Skilled workers can do other important jobs. Buying automated machines can save money quickly. For example, one machine may only need two workers. The machine could pay for itself in a year.

- Manual deburring costs more and slows down work.

- Automated deburring makes work faster, safer, and better for the planet.

- You get better quality and reliability with machines.

- Using machines helps you waste less and use less energy.

Maintenance

Taking care of your deburring tools helps them last longer. Clean your tools often with air or a brush to get rid of dirt. Keep abrasive tools in a dry place so they do not rust. Check your tools for damage and change them if needed. Turn off machines before cleaning. Use a vacuum or air to clean out dirt. Wipe surfaces with mild soap and water. Put oil on moving parts as the maker says. Checking and fixing tools often helps you find problems early. This keeps your work running smoothly.

Note: Good maintenance helps you work faster and better. You stop problems, make better parts, and help your tools last longer.

You help the planet by keeping tools clean and using less energy. These steps help you work faster and reach your sustainability goals. You protect your tools and make sure every part is good and reliable.

Quality and Reliability

1. Eliminate Functional Defects

Improve Fitting Accuracy: Burrs affect dimensions and appearance, preventing parts from seating properly during assembly. Deburring ensures a perfect fit and improves assembly yield.

Ensure Sealing: Even tiny burrs on surfaces or openings that require sealing can damage gaskets or O-rings, causing leaks. Thorough deburring is a prerequisite for ensuring sealing performance.

Improve Fluid Flow: In hydraulic or pneumatic systems, burrs can obstruct or disrupt the flow of fluid, affecting system efficiency and response time.

2. Improve Surface and Appearance Quality

Improve Aesthetics: Clean, smooth edges give products a more refined and professional appearance.

Eliminate Safety Hazards: Sharp burrs are a leading cause of operator injury during handling, assembly, and use. Deburring directly improves product and operational safety.

Ease Subsequent Processing: A clean surface (free of burrs or flash) ensures uniform adhesion during subsequent surface treatments (such as plating, painting, and coatings), improving adhesion and final quality.

Improved Reliability

1. Reduces Fatigue and Stress Concentration

Eliminates Stress Concentration Points:

Burrs are essentially tiny cracks or sharp points on the edge of a material. These sharp geometric shapes create areas of stress concentration. When a product is subjected to cyclic loads (such as vibration or fatigue), cracks often initiate and propagate from these points, leading to premature fatigue failure. Deburring smoothes or chamfers the edge, significantly dissipating stress.

Improves Structural Strength:

Chamfering and rounding enhance the edge strength of parts, making them more resistant to impact and fatigue.

2. Reduces Wear and Secondary Contamination

Prevents Abrasive Wear:

If burrs break off during use, these metal debris (abrasive particles) can enter the system (e.g., bearings, gearboxes, hydraulic valves). These hard debris can cause severe abrasive wear, accelerating the failure of other critical components.

Extending System Life:

Deburring ensures that no loose metal particles circulate in the system during dynamic operating environments, thereby extending the life of the entire system.

3. Improving Dynamic Balance

For high-speed rotating parts (such as turbine blades and rotors), even small burrs can disrupt dynamic balance. Deburring ensures even weight distribution, reduces vibration and noise, and improves reliability.

Leading Options 2025

Manual Solutions

Manual deburring tools will still be useful in 2025. They work best for small jobs, repairs, or tricky shapes. Many shops pick brands like Klein Tools and Vermont American. These brands are cheap and easy to use. You do not need much training to use them. The handles are made to fit your hand well. This helps you work longer without getting tired. You can finish your work faster and with less effort.

- Klein Tools and Vermont American are good for small jobs.

- Handles that fit your hand help you work without getting tired.

- Easy tools mean you do not spend much time teaching new workers.

Manual deburring tools let you control your work. You can reach small spaces and work on delicate parts. These tools are a smart pick for custom jobs or when you need to change things quickly.

Power and Pneumatic

Power and pneumatic deburring tools will be more common in 2025. You will see these tools in places that need very careful work, like car and airplane factories. More people are buying automatic deburring tools now. You need these tools to make sure your parts are smooth and the right size.

- Power deburring tools help you make smooth and exact parts.

- Pneumatic deburring tools are strong and last a long time.

- These tools can do hard jobs in tough places.

- Airplane and car companies like these tools for big jobs.

Power and pneumatic deburring tools help you work faster. You can finish more parts in less time. You also get better results with less hard work.

Automated Innovations

Automated deburring tools will change how factories work. New machines will save energy and need less hand work. Many companies use robots with sensors to make parts more exact. You will see more green abrasives and smart systems that check quality as you work. The table below shows some top new ideas for 2025:

| Innovation | Description | Materials Used | Sustainability Features | Projected Market Impact |

|---|---|---|---|---|

| Automated Deburring Systems | Machines that work fast and need fewer workers | Aluminum, Steel | Save energy, recycle leftover bits | Make more parts, spend less on workers |

| Eco-friendly Abrasives | Abrasives that are better for the planet | Recycled Glass, Natural Minerals | Break down naturally, make less pollution | Good for buyers who care about the earth |

| Robotic Deburring Tools | Robots with sensors for exact and repeatable work | Carbon Fiber, Alloys | Less waste because of careful cutting | Fewer mistakes, less fixing needed |

| AI-Powered Quality Control | AI checks parts while you work | Metals, Plastics | Less waste by fixing problems right away | Fewer bad parts, more even results |

| Multifunctional Deburring Tools | Tools that do many deburring jobs at once | Titanium, Composites | Last longer, waste less material | Save money for small and medium shops |

Automated deburring tools help you make better parts and save money. Smart tech helps you meet tough rules and waste less. These new ideas will help you keep up in a fast-changing world.

Specialty Tools

Specialty deburring tools help with tough jobs. In 2025, these tools are used in places that need careful work and quick changes. You use specialty tools when regular deburring does not work well. These tools help with tricky materials, odd shapes, and strict rules.

You see specialty deburring tools in aerospace, medical, and electronics factories. These places need perfect finishes and must follow hard rules. Specialty tools use smart technology to help you do this. Many tools now have AI and IoT. You can watch how your tool works and know when it needs fixing. This keeps your factory working and stops long breaks.

These tools work with many materials and sizes. You can change jobs fast. You do not have to buy new machines for every job. This helps you keep up with new orders and changes.

Caring for the planet is important now. You see green deburring methods like waterjet and plasma. These use less power and make less trash. You help your company save money and meet earth-friendly goals.

Specialty tools also work with Industry 4.0. You connect your deburring tools to other machines. This makes your work faster and better. You can check data, change settings, and fix problems without stopping.

Here is a table that shows how specialty deburring tools help in 2025:

| Aspect | Details |

|---|---|

| Advancements in Technology | AI and IoT let you watch tools and fix them before they break. |

| Customization | Tools work with many materials and sizes, so you can do many jobs. |

| Sustainability | Waterjet and plasma deburring use less energy and make less waste. |

| Industry Integration | Tools work with Industry 4.0, making your work faster and better. |

You see some trends with specialty deburring tools:

- More machines use automation and give better quality.

- Custom tools help you change jobs quickly.

- High prices make it hard for small companies to buy new tools.

Tip: Pick specialty deburring tools that fit your work goals. Think about smart tech, flexibility, and caring for the planet. This helps you do better work and stay ahead.

You use specialty tools for jobs that regular tools cannot do. You get more control, better parts, and faster work. Specialty deburring tools help you do well in today’s factories and get ready for new challenges.

Picking the right deburring tool helps your product look better. It also makes your work easier and faster. You need to match your tool to the material you use. Think about the shape of your part. How many parts you make matters too. The finish you want is important. Use a checklist and a decision chart to help you choose. Try out tools on sample parts before making all your products. Ask suppliers for advice if you are not sure. Test new ideas to see how they work in real life.

Tip: Check your process often. New deburring technologies can help you keep up with others and follow new rules in your industry.

FAQ

Pick a tool that matches your material. Hard metals need tough abrasives. Soft plastics need gentle tools. Always test on a sample part first so you do not damage it.

Look at your tools before you use them. Change or sharpen them if they look dull or make uneven results. Clean and store your tools the right way to help them last longer.

You might need different tools for tricky shapes. Use small or bendy tools for tight spots. For flat parts, use files or sandpaper. Always pick a tool that fits your part’s shape.

Automated systems help you save time and keep your work the same. If you make lots of parts or need high quality, automation can lower costs and stop mistakes over time.

Always wear safety glasses, gloves, and a dust mask. Good airflow keeps dust and fumes away from you. Follow all safety rules for your tools.

Use gauges or microscopes to look at your parts. Compare the finish to standards like ISO 1302 or ISO 25178. If you see rough spots, change your process.

You can use reusable media, eco-friendly abrasives, and machines that save energy. Automated systems often make less waste and use less energy. Ask your supplier about green choices for your shop.