Metal fusion plating uses heat and pressure to stick a metal layer onto another material. This makes a strong and protective surface. You can find this process in places that need strong and dependable parts. Car, airplane, and electronics companies use it to help products last longer. The worldwide market for these companies was $18.3 billion in 2022. It may grow to $27.2 billion by 2032.

| Year | Market Size (in billion USD) | CAGR (%) |

|---|---|---|

| 2022 | 18.3 | N/A |

| 2032 | 27.2 | 4 |

Key Takeaways

- Metal fusion plating uses heat and pressure. It bonds a metal layer to another material. This makes a strong and protective surface.

- Many industries use this process. These include automotive, aerospace, electronics, and medical devices. It helps things last longer and resist damage.

- Preparing the surface is very important. Cleaning and pre-treatment help make a strong bond. They stop problems like peeling.

- The process needs careful control of heat and pressure. This helps get the best results. Mistakes can cause weak bonds or defects.

- Metal fusion plating lets you design many shapes. You can make light and detailed structures. Traditional methods cannot do this.

- Picking the right metal is very important. Metals that do not match can rust or make weak bonds. Always check if metals work well together.

- After plating, cooling and checking are needed. These steps help make sure the parts are good and last long.

- Knowing the good and bad sides of metal fusion plating helps you choose well for your needs.

Table of Contents

Metal Fusion Plating Basics

What Is Metal Fusion Plating

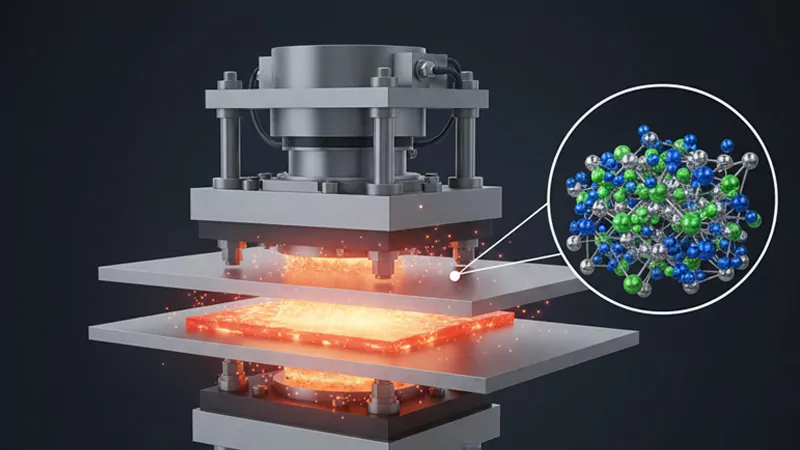

You might ask how metal fusion plating is different. It uses heat and pressure to join a metal layer to another material. This makes the bond strong and long-lasting. Many industries use this method for tough surfaces. Metal fusion plating gives surfaces that resist wear, heat, and corrosion.

Key Principles

To know how metal plating works, you need to learn the science. There are several ideas about how metals stick together:

- Film Theory: When you press and heat two metal surfaces, new metal spots touch and join.

- Energy Barrier Theory: You need enough energy, like heat, for metals to bond, even if they are clean.

- Diffusion Bonding Theory: Atoms move across the edge between metals and make a tight bond.

- Recrystallization Theory: Metals form new crystal shapes at the bond, which makes it stronger.

These ideas show why metal fusion plating makes surfaces tough and reliable.

Metal Fusion Plating vs. Other Metal Plating Methods

There are different ways to plate metals. Each way has good and bad points. Here is a quick look at how metal fusion plating compares to other methods:

| Method | Efficiency | Durability |

|---|---|---|

| Metal Fusion Plating | Simple and cheap, used a lot in factories | Gives extra hardness and stops corrosion |

| Electroplating | Cheap, good for lots of parts | Not always even, can build up on high spots |

| Electroless Plating | Harder to do, makes better surfaces | More even, strong, and thinner than electroplating |

Metal fusion plating is good when you want something simple and strong. Electroplating is fast for many parts but can be uneven. Electroless plating gives a smooth finish but takes more time and skill.

Tip: When picking a metal plating method, think about the part, how much protection you need, and your budget.

If you follow the basic steps, you will get good results. Here is an easy order to follow:

- Clean the surface to get rid of dirt and oil.

- Treat the surface with chemicals to help the metal stick.

- Get the plating bath ready with the right temperature and pH.

- Use electrodeposition to add the metal layer (for electroplating).

- Finish with treatments after plating to help the surface last longer.

When you know these basics, you can pick the best metal plating method for your needs.

Metal Fusion Plating Process

Surface Preparation

Before you start the metal plating process, you need to prepare the surface. This step helps you get a strong and lasting bond. If you skip or rush this part, you may see weak spots or peeling later.

Cleaning

You must remove all dirt, oil, and other unwanted materials from the surface. These contaminants can stop the metal layer from sticking well. Common problems include:

- Oils and greases from machines or hands

- Salts left after rinsing

- Dust and small particles from the air

- Rust from old or poorly stored parts

- Residue from packaging or adhesives

You also need to watch out for:

- Particulate matter from sanding or grinding

- Contaminated tools or equipment

- Die-lube, mold release agents, and leftover millings

If you leave any of these on the surface, the metal plating process will not work as it should. You may see rough spots or weak bonds.

Pre-Treatment

After cleaning, you move to pre-treatment. This step prepares the surface for the metal fusion plating. You may use chemicals or special tools to make the surface ready. Industry standards help guide you in this step. Here is a table of common standards:

| Standard | Description |

|---|---|

| SSPC-SP-1 | Solvent Cleaning: Removes soluble substances using solvents. |

| SSPC-SP-2 | Hand Tool Cleaning: Uses non-power tools to remove loose contaminants. |

| SSPC-SP-3 | Power Tool Cleaning: Uses power tools for cleaning. |

| NACE No. 1/SSPC-SP-5 | White Metal Blast Cleaning: Removes all foreign matter for a clean surface. |

| NACE No. 3/SSPC-SP-6 | Commercial Blast Cleaning: Removes visible contaminants, minor stains allowed. |

| NACE No. 4/SSPC-SP-7 | Brush-Off Blast Cleaning: Cleans but allows some tightly stuck contaminants. |

| NACE No. 2/SSPC-SP-10 | Near-White Metal Blast Cleaning: Limits staining to five percent of area. |

| SSPC-SP-11 | Power Tool Cleaning to Bare Metal: Prepares surfaces to bare metal. |

| NACE No. 8/SSPC-SP-14 | Industrial Blast Cleaning: Allows some residue, with limits on staining. |

You should pick the right standard for your metal plating process. This choice depends on the type of metal, the part, and the final use.

Fusion and Bonding

Once you finish surface preparation, you move to the main part of the metal plating process. This is where you join the metal layer to the base material.

Heat Application

You use heat to help the metals bond. The right amount of heat lets atoms move and mix at the surface. This step is key in the metal fusion plating process. If you use too little heat, the bond will be weak. Too much heat can damage the part.

Pressure Application

You also need to apply pressure. Pressure pushes the metal layer onto the base material. This helps the metals touch closely and form a strong bond. In the metal plating process, you must control both heat and pressure for the best results.

Post-Treatment

After you finish bonding, you need to treat the part again. This step helps the new metal layer last longer and work better.

Cooling

You must cool the part after the metal fusion plating. The cooling rate changes the final properties of the metal layer. If you cool too fast, the layer may become hard but brittle. If you cool too slowly, the layer may lose hardness. Studies show that a slower cooling rate can lower hardness. For example, hardness dropped from 243 HV to 221 HV as cooling slowed. The cooling rate also changes the microstructure and strength of the metal plating process.

Inspection

You need to check the finished part. Inspection helps you find any problems like cracks, weak spots, or uneven layers. You may use tools to measure thickness, hardness, and surface quality. Post-treatment steps can also include heat treatment, polishing, or coating. Here is a table of common post-treatment processes:

| Technique | Post-Treatment Process |

|---|---|

| Powder Bed Fusion (PBF) | Heat Treatment, Hot Isostatic Pressing, Surface Polishing, Machining, Coating |

| Binder Jetting (BJT) | Sintering, Infiltration, Surface Coating |

| Metal Filament Extrusion | Sintering, Machining, Surface Smoothing, Coating |

| Directed Energy Deposition | Machining, Heat Treatment, Surface Finishing |

Tip: Careful inspection and post-treatment help you get the most from your metal plating process. You can improve strength, appearance, and lifespan.

When you follow each step in the metal plating process, you get a strong, reliable finish. You also avoid common problems and make sure your parts last longer.

Types of Metal Plating

Fusion Plating

Fusion plating makes metals stick together very well. You use heat and pressure for this method. First, you press a metal layer onto another material. Heat helps atoms move and mix at the surface. Pressure pushes the metals close together. This creates a strong bond that does not wear out easily. It also stops rust and damage.

Fusion plating is good for parts that get used a lot or face tough conditions. You see it in airplanes, cars, and big machines. Fusion plating is different because it does not need electricity or chemical baths. You can change the temperature and pressure to control the bond. You can use metals like steel, titanium, and nickel. These metals are strong and last a long time. Fusion plating gives you a finish that works well for hard jobs.

Electroplating

Electroplating is a common way to plate metals. You use electricity to put a thin metal layer on a part. You put the item in a liquid with metal ions. Then, you connect it to a power source. The electric current moves metal ions onto the part’s surface. This lets you control how thick and smooth the coating is. Electroplating can make things look better, stop rust, and make them harder.

Many industries use electroplating. Car makers, electronics companies, and jewelry makers use it a lot. You can pick from many metals for electroplating:

- Chromium Plating: Stops rust and looks shiny. You see it on cars and fixtures.

- Nickel Plating: Makes things harder and stops rust. Used in electronics and vehicles.

- Copper Plating: Conducts electricity well and stops rust. Found in electronic parts.

- Gold Plating: Stops rust and looks bright. Used in jewelry and electronics.

- Silver Plating: Conducts electricity very well. Used for electrical contacts.

- Zinc Plating: Protects metal by letting itself rust first. Seen on car parts.

Electroplating is flexible. You can coat shapes that are hard to cover. You can also control how the finish looks. You must watch the liquid and the electric current to get good results.

Electroless Plating

Electroless plating is a different way to plate metals. You do not use electricity. You use a chemical reaction to put metal on a surface. The plating bath has a reducing agent. This agent makes metal ions stick to your part. You get an even coating, even on tricky shapes. Electroless plating is good for electronics, medical tools, and small parts.

You need several chemicals for electroless plating:

- Metal salts

- Reducing agents

- Complexing agents

- Buffers

- pH adjusters

- Stabilizers

- Accelerators

- Wetting agents

- Brighteners

Electroless plating uses a redox reaction. The reducing agent changes metal ions into solid metal. You get a smooth and even layer. You do not need to worry about electricity or uneven coatings. Electroless plating lets you control thickness and quality. You can use it for parts that need to be exact and resist rust.

Tip: Pick the metal plating method that fits your part, the place it will be used, and the finish you want.

Immersion Plating

Immersion plating lets you coat metals without electricity. You use a chemical reaction to add a thin metal layer. This method works well for parts that need to be flat. It also helps when you need tight tolerances. You often see immersion plating in electronics. It is common for printed circuit boards (PCBs). Immersion plating is different from electroplating and fusion plating.

You begin by dipping your part into a solution. The solution has metal ions inside. These ions react with your part’s surface. The reaction forms a thin metal layer. You do not need a power source for this process. The process stops when the base metal is covered. You get a smooth layer, but it cannot be very thick.

Immersion plating is used to coat copper with tin, silver, or gold. It is good when you want a lead-free finish. Many companies choose immersion plating to follow safety rules. You get a flat surface, which helps with soldering on PCBs. The process gives tighter tolerances for plated holes. You can use it for press-fit applications. These need a smooth and reliable surface.

When you compare immersion plating to other methods, you see differences. Electroplating makes thicker layers but needs electricity. Fusion plating uses heat and pressure for a strong bond. Immersion plating uses only chemistry. You do not need extra equipment. The finish works well for electronics and small parts.

Let’s look at the pros and cons of immersion plating versus fusion plating:

| Advantages | Disadvantages |

|---|---|

| Flat surface for soldering | Handling can damage the PCB |

| Lead-free and RoHS compliant | Soldering problems |

| Tighter tolerances for holes | Tin whiskers |

| Good for press-fit applications | Shorter shelf life than ENIG |

Immersion plating gives you a flat surface and meets safety rules. It is good for soldering and is affordable. You do not need to worry about lead. This helps you follow RoHS rules. You can mount small parts easily because the surface stays flat.

Note: Immersion plating is best for flat, lead-free surfaces in electronics. Handle parts gently because the coating can get damaged.

You should know the disadvantages too. Immersion plating can cause tin whiskers. These are tiny metal hairs that can create problems. The coating does not last as long as other methods. You may see corrosion if tin is exposed. The process uses chemicals like thiourea, which can be harmful. It is hard to measure the coating thickness. If you need to rework or assemble parts many times, immersion plating may not be the best choice.

When you pick a metal plating method, think about your needs. Electroplating gives thicker layers and more control. Fusion plating gives a strong bond for tough jobs. Immersion plating gives a flat, lead-free surface for electronics. The process is simple and meets many safety standards.

Immersion plating helps you follow environmental rules. It gives a reliable finish for electronics. You see it used for PCBs, connectors, and small parts. You should look at the pros and cons before you choose. If you need a flat surface and tight tolerances, immersion plating is a good choice. If you need more durability, try fusion plating or electroplating.

Benefits of Metal Fusion Plating

Durability

You want your parts to last a long time. Metal fusion plating gives you that strength. When you use this method, you get a surface that stands up to heavy use. The bond between the metal layer and the base stays strong, even when you put it under stress. You see less cracking and fewer chips. Metal plating with fusion techniques helps your tools and machines work longer without breaking.

Laboratories use several tests to check how tough these surfaces are. You can look at the table below to see how experts measure durability:

| Test Type | Purpose |

|---|---|

| Salt Spray Testing | Simulates corrosive environments to assess resistance to rust and degradation. |

| Adhesion Testing | Evaluates how well a coating bonds to a substrate, indicating potential for peeling. |

| Hardness Testing | Measures resistance of a coated surface to indentation and wear. |

| Wear Resistance Testing | Assesses the surface’s ability to withstand mechanical wear from abrasion and impact. |

These tests show you how metal plating stands up to real-world conditions. You can trust fusion plating to protect your parts from damage.

Tip: If you need parts for tough jobs, choose metal plating with fusion. You get a finish that lasts and keeps working.

Corrosion Resistance

Rust and corrosion can ruin your equipment. Metal fusion plating helps you fight these problems. The process creates a barrier that blocks water, chemicals, and air. You see less rust on your parts, even in harsh places. Metal plating with fusion works well for outdoor tools, car parts, and machines that face moisture.

Salt spray tests help you see how well the coating protects against corrosion. You can use these results to pick the best metal plating for your needs. Fusion plating gives you a layer that does not break down easily. You spend less money on repairs and replacements.

You also get better results when you use the right metals. Nickel, titanium, and stainless steel all resist rust. When you use fusion plating, you make your parts last longer in wet or salty places.

Adhesion

You need a coating that sticks well. Metal fusion plating gives you strong adhesion. The heat and pressure in the process help the metal layer bond tightly to the base. You do not see peeling or flaking. Your parts stay smooth and safe.

Adhesion testing checks how well the coating sticks. You can use these tests to make sure your metal plating will not fail. Fusion plating creates a bond that holds up under stress. You can use your parts in machines, vehicles, and electronics without worry.

Good adhesion means you get a surface that stays in place. You do not have to fix or replace coatings often. Metal plating with fusion helps you save time and money.

Note: Strong adhesion keeps your equipment working. You get better results with fusion plating.

Design Flexibility

Metal fusion plating lets you try new designs. You get more choices than with old metalworking ways. You can make parts with shapes that are hard to do with older tools. This process works for tricky designs, thin parts, and fragile shapes.

You can see how this helps in many ways:

| Aspect | Description |

|---|---|

| Intricate Geometries | Lets you make shapes that old methods cannot do. |

| Conformal Cooling Channels | Helps you cool parts right where you need it. |

| Lightweight Structures | Lets you design lighter parts that work well. |

You can make parts with special shapes. This means you can add curves, holes, or patterns as needed. You do not have to worry about what cutting or casting cannot do. Metal fusion plating works with 3D printing. You can print a base and add metal on top for strength. This way, you can make special parts for different jobs.

You can also put cooling channels inside your parts. These channels move heat away from hot spots. Your tools and machines stay cooler and last longer. You can put these channels just where you want them. Other ways cannot do this as well.

Making lighter parts is another big plus. You can take away extra material and keep only what you need. This makes your parts lighter but still strong. Lighter parts save energy and help things go faster, like cars and planes.

Here are some ways metal fusion plating gives you more design options:

- You get more freedom when you use 3D printing to make special parts.

- You can make parts that are just right for the job, better than old ways.

- You can build thin or tricky shapes in new ways.

Note: Metal fusion plating lets you use different metals in one part. You can pick the best metal for each area. This helps you save money, lower weight, and keep things strong.

You can also change your design without starting over. If you need to fix a part, you can change the shape or thickness of the metal layer. This saves time and money when you are making new things.

With metal fusion plating, you do not have to give up on your ideas. You can try new things in manufacturing. Your products can work better and look different from others.

Limitations of Metal Fusion Plating

Material Compatibility

Not all metals work well with metal plating. Some metals can react and cause problems. If you use the wrong metals together, you might get rust or weak bonds. This happens with metal fusion plating and also with electroplating. You need to check if metals match before you start. The table below shows which metals do not go together and why:

| Incompatible Metals | Reason for Incompatibility |

|---|---|

| Aluminum and Copper | Aluminum reacts with copper and rusts fast in wet places. |

| Zinc and Steel (Stainless/Galvanized) | Zinc reacts with stainless or galvanized steel and rusts quickly. |

| Steel and Brass/Bronze | Steel reacts with brass or bronze and rusts when they touch. |

| Magnesium and Any Other Metal | Magnesium reacts with almost any metal and rusts easily. |

| Carbon Steel and Stainless Steel | Carbon steel reacts with stainless steel and rusts a lot. |

You should not use these metal pairs for metal plating. If you use electroplating, you need to check for these problems too. Picking the right metals helps your parts stay strong and last longer.

Process Complexity

Metal fusion plating is hard to do sometimes. You must control heat and pressure very carefully. If you make a mistake, the metal plating can break or crack. You might see weak spots or uneven layers. Electroplating has steps too, but metal fusion plating needs more care with heat and force. You need special machines and tools for this job. Workers may need training to do it right. If you skip a step or rush, you can ruin the part.

Here are some reasons why the process is tricky:

- You must keep the temperature just right.

- You need to use the right pressure.

- You have to check the surface before and after plating.

- You may need extra steps like cooling or polishing.

- You must watch for mistakes at every step.

Electroplating can be quicker, but it also needs careful control. Both methods need skill and good planning.

Tip: Always follow each step for metal plating. Careful work helps you get better results and fewer problems.

Environmental Impact

Metal plating can hurt the environment. When you use metal fusion plating or electroplating, you may make waste and use chemicals. You must follow rules to keep water and air clean. In the United States, 40 CFR Part 438 sets standards for metal shops. These rules cover wastewater and limit what you can put in rivers or drains. You must use the best control technology for your shop. New factories must follow even stricter rules.

- 40 CFR Part 438 lists rules for metal shops.

- The rules set limits for wastewater from metal plating.

- You must use the best control technology and meet new standards.

If you do not follow these rules, you can get fined or lose your license. Both metal fusion plating and electroplating need safe ways to handle waste. You should always check local and national laws before you start metal plating.

Note: Good planning and safe waste handling help protect the environment and keep your business safe.

Applications

Automotive

Engine Parts

Metal plating is used a lot in cars. Engine parts need to last and handle heat. Metal plating makes them stronger. Electroplating adds nickel or chromium to parts like pistons and valves. This layer keeps them safe from rust and wearing out. With metal plating, engine parts do not break as fast. They can handle friction and heat better. You do not have to fix or change them as often.

Exterior Trim

Metal plating is also on the outside of cars. Door handles and grilles need to look nice and stay shiny. Chrome electroplating gives them a bright look. It also protects them from rain, salt, and dirt. Metal plating helps car trim look new for longer. You do not see rust or dull spots quickly.

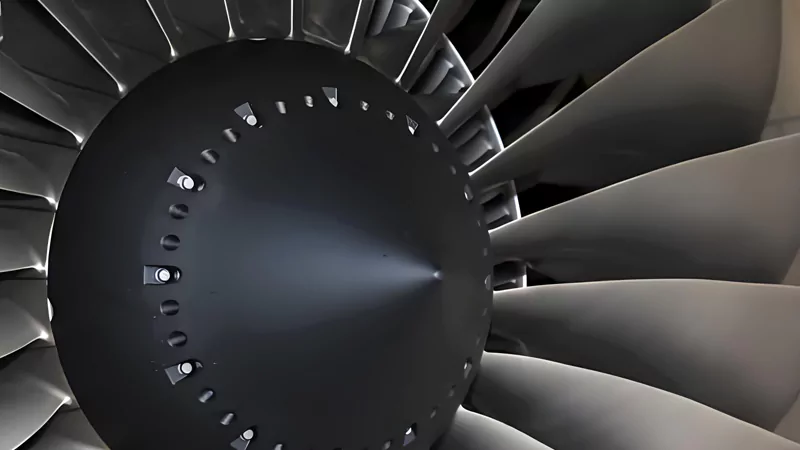

Aerospace

Aircraft Components

Aerospace parts must be strong for hard jobs. Metal plating, mostly electroplating, helps make them tougher. Chrome plating protects engine parts and landing gear. This layer stops wear and rust. Every part must work well when you fly. Metal plating helps you trust your plane. Chrome plating keeps parts working longer in bad weather or stress. These parts must be reliable. If one fails, it can cause big trouble.

Protective Coatings

Metal plating is used for protective coatings in planes. Electroplating and electroless plating help parts last longer. These coatings stop rust and damage from chemicals or water. Metal plating keeps planes safe and ready to fly. The coating helps new technology grow in aerospace. You get better parts that last longer.

Electronics

Circuit Boards

Metal plating is important in electronics. Circuit boards need good connections and must not rust. Metal fusion plating is used for this. It helps connect layers and makes electricity flow better. Electroplating is used for finger plating and through-hole plating. These methods give low resistance and strong boards. Metal plating helps electronics work better and last longer.

- Finger plating uses gold for strong contacts.

- Through-hole plating adds a film and uses heat to set it.

- Reel linkage selective plating and brush plating coat only needed areas.

Connectors

Connectors must stay clean and conduct electricity well. Metal plating, often with gold or silver, helps them work. Electroplating gives a smooth layer that stops wear and rust. Metal plating on connectors gives better signals and fewer problems. Devices stay reliable even after many uses.

Tip: Using metal plating in electronics makes them work better and last longer. It also helps devices meet high quality standards.

Medical Devices

Surgical Tools

Metal plating is used on many surgical tools. Doctors need tools that stay sharp and strong. Metal plating makes the surface hard and stops scratches. It also helps stop rust. Electroplating is common for scalpels, forceps, and scissors. This process puts a thin metal layer on the tool. The layer can be chromium or nickel. It helps the tool last longer and makes cleaning easier. You can sterilize these tools many times. The surface does not get damaged. Metal plating keeps tools looking new. This is important in hospitals.

Implants

Implants must work well inside the body. Metal plating helps make implants safe and strong. You want implants that do not rust or break. Electroplating and other methods add a protective layer. This layer goes on hip joints, dental screws, and pacemaker cases. It helps the implant work better with your body.

Metal’s electro-dynamic properties help cells stick to the implant. This helps healing and keeps the implant in place. You get better results after surgery. Metal plating meets strict healthcare rules. This keeps patients safe.

Here is a table showing the main benefits of metal plating for implants:

| Benefit | Description |

|---|---|

| Durability | Makes medical devices last longer. |

| Biocompatibility | Helps implants fit better with the body. |

| Compliance with Standards | Follows healthcare rules for safety. |

You can see more good things about metal plating for implants:

- Stops rust better

- Helps the body accept implants

- Makes implants last longer

These benefits make metal plating a good choice for medical devices. Electroplating helps you make implants that last and work well inside the body.

Industrial Equipment

Metal plating is used in many machines. Factories, power plants, and chemical plants use it. Electroplating protects gears, pumps, and valves. It stops rust, heat, and chemicals from hurting parts. This process adds a strong layer. It keeps parts working in tough places.

Corrosion-resistant materials are important for equipment. Machines face chemicals, high heat, or saltwater. Metal plating gives protection. You lower the risk of equipment breaking. You keep your workplace safe. In important jobs, metal plating adds reliability. You avoid costly breakdowns. Your operations run smoothly.

Metal plating can save you money. The protective layer makes parts last longer. You do not need to replace them often. Electroplating works for many shapes and sizes. You can trust metal plating to keep equipment strong.

Tip: Pick metal plating for industrial equipment if you want it to last longer and need fewer repairs.

You now know that metal fusion plating uses heat and pressure. This makes strong bonds that last a long time. The process gives surfaces that do not rust easily. You can also change designs to fit your needs. Some metals do not mix well, so you must be careful. The process needs close control to work right. Metal fusion plating is used in cars, planes, electronics, and medical tools. The table below explains why this method is important for making things today:

| Benefit | Description |

|---|---|

| Enhanced Quality | Makes parts stronger and work better. |

| Performance | Helps parts last longer and saves money. |

| Customization | Lets you pick the finish for each part. |

| Cost Efficiency | Cuts mistakes and helps you spend less. |

| Faster Turnaround | Makes products faster and ships them sooner. |

| Compliance | Follows rules and stops problems with recalls. |

Knowing about metal fusion plating helps you pick better designs and make good products.

FAQ

You can use metals like steel, titanium, nickel, and copper. These metals stick well and do not wear out fast. Always make sure your base material matches the plating metal. This helps you avoid problems.

Metal fusion plating makes a layer that blocks water and air. This layer keeps rust from starting. Your parts last longer, even in wet or salty places.

Yes, you can use metal fusion plating for medical tools and implants. The process makes surfaces smooth and strong. It also helps meet safety rules for healthcare.

You cannot use fusion plating right on plastic. The process uses heat and pressure that plastic cannot take. You should pick other plating methods for plastic parts.

You can use tests like salt spray, adhesion, and hardness checks. These tests show if the metal layer sticks well and does not get damaged. Always look at your parts after plating.

Fusion plating can cost more because it needs special machines and careful work. You may save money later since your parts last longer and need fewer fixes.

You see metal fusion plating in cars, planes, electronics, medical, and factory equipment. These industries need parts that are strong and do not wear out or rust.

You can recycle many metal-plated parts. Take off the plating layer before recycling. Always follow local rules for recycling metal and handling waste.