Precision in straight turning affects how good each part is. If you pay attention to accuracy, you make parts the same every time. This also helps you make fewer mistakes and get smoother surfaces. Look at the table below to see the benefits:

| Benefit | Description |

|---|---|

| Precision | CNC turning machines can be very exact, up to ±0.0001 inches. |

| Repeatability | You get parts that look the same, no matter how many you make. |

| Reduced Human Error | There are fewer mistakes and less wasted material. |

| Improved Surface Finish | Better finishes mean you may not need extra work. |

AFI Industrial Co., Ltd. helps machinists meet these goals. They use advanced CNC turning operations and strong quality checks. You can use these tips if you are new or have lots of experience.

Key Takeaways

- Make sure your machine is set up tightly. This helps you get better results and fewer errors.

- Hold your workpiece firmly so it does not move when you cut it.

- Use sharp tools to stop chatter. Change the speed or feed if needed.

- Give your workpiece good support. This stops it from bending and keeps your cuts exact.

- Pick the best cutting tool material for your job.

- Line up your lathe tool with care. This helps you make straight cuts and accurate parts.

- Take care of your CNC lathe often. This stops it from breaking and keeps your work precise.

- Watch your cutting speed and feed. This helps your surface look better and your tool last longer.

Table of Contents

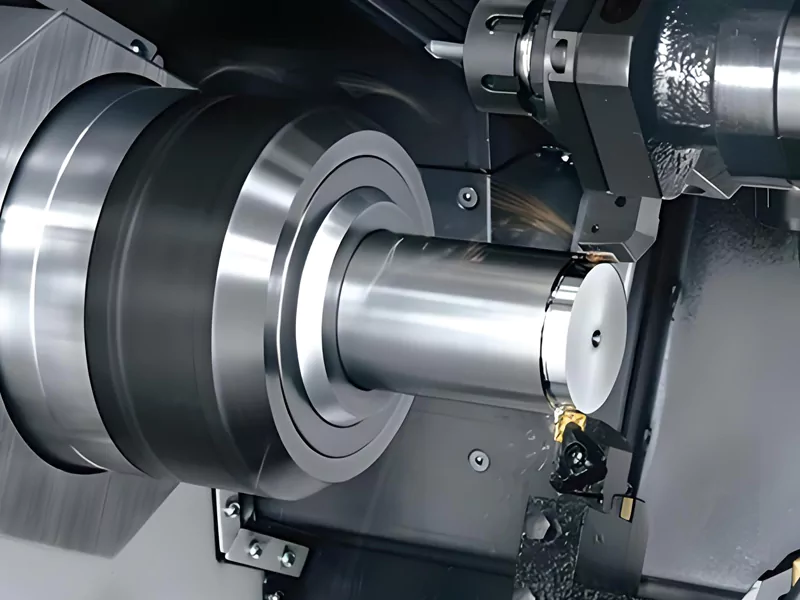

Straight Turning Setup

Getting your machine ready is the first thing to do. A good setup helps you avoid mistakes. It also keeps your parts the same every time. Here’s what you should pay attention to.

Rigid Machine Setup

A strong machine setup is very important for good turning. If your machine does not move, you get better results. You will also have fewer problems.

Secure Clamping

You need to clamp your workpiece tightly. If it is loose, it can move while cutting. This can cause mistakes and a rough surface. Always check if your chuck or fixture holds the material well. If you see any movement, stop and fix the clamping.

Tip: Before you start, shake your setup gently. If something moves, make it tighter.

Minimize Chatter

Chatter is a vibration that can mess up your workpiece. It sounds loud and high-pitched. Chatter can make the surface rough and wear out your tool faster. You can stop chatter by making your setup stronger and using sharp tools.

- Chatter often happens because of self-excited vibrations.

- Chatter can ruin the high precision of CNC lathes.

- Vibrations during cutting can lower accuracy and hurt the surface.

If you hear chatter, slow down the speed or change the feed rate. Sometimes, using a new tool or a different insert helps.

Workpiece Support

Supporting your workpiece is just as important as clamping it. If you do not support it enough, the material can bend or shake while cutting.

Reduce Unsupported Length

Keep the part that sticks out as short as you can. If it is too long, it can bend or shake. This can make the size and shape wrong.

- Material can bend during cutting if the unsupported length is too long.

- Problems can also happen if the machine or tool is not lined up right.

Use Steady Rest

A steady rest gives extra help to long or thin workpieces. It holds the material still while you turn it. This stops bending and helps you keep tight tolerances.

Note: AFI Industrial Co., Ltd. uses advanced setups and steady rests to make sure every part is made right.

Common Setup Errors to Avoid

Many mistakes can hurt your precision. Watch out for these common problems:

- Bed saddle shaking during heavy cutting

- Tool going in too deep during cut-off

- Gaps in the lead screw or nut

- Datum not lined up right

- Positioning mistakes in sub-production

- Sliding head guide bush not tight enough

If you focus on a strong setup and good support, you will do well. AFI Industrial Co., Ltd. uses these tips in every CNC turning job. This helps you get the best precision.

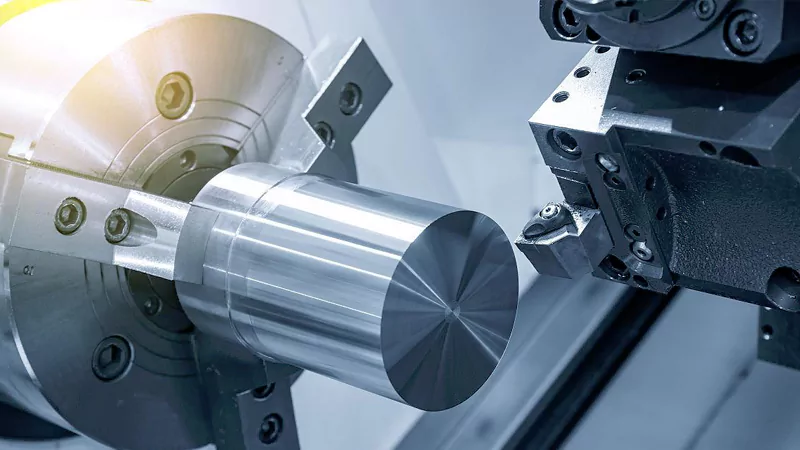

Cutting Tool Selection

Choosing the right cutting tool is one of the most important steps in straight turning. The cutting tool you select affects the accuracy, surface finish, and overall quality of your parts. An effective tooling strategy can help you turn more precise parts. You need to think about both the material and the geometry of the cutting tool. AFI Industrial Co., Ltd. uses advanced CNC turning machines and can work with many types of materials, always keeping tight tolerances.

Tool Material

The material of your cutting tool decides how well it cuts and how long it lasts. You want a cutting tool that matches your workpiece and your job needs.

Carbide vs. HSS

You will often choose between carbide and high-speed steel (HSS) for your cutting tool. Carbide tools are harder and keep their shape better. They help you hold tight tolerances and get smoother surfaces. Carbide cutting tools work well for steel and tough materials. You can expect surface roughness between 32-63 microinches with carbide, while HSS tools usually give you 63-125 microinches. HSS cutting tools are tough and resist breaking, but they wear out faster and may not keep precision over long runs.

If you want high precision and a great finish, use carbide cutting tools. For softer materials or short jobs, HSS cutting tools can be a good choice.

When you pick a cutting tool, think about these factors:

- Hardness vs. toughness: Harder cutting tools cut cleaner, but tougher cutting tools last longer.

- Workpiece material: Match your cutting tool to the material. Carbide is best for steel, while high-toughness carbide works for stainless steel.

- Cutting speed and feed rate: Set these right to avoid tool failure.

- Coatings: Coated cutting tools last longer and reduce friction.

Tool Geometry

The shape of your cutting tool and insert affects how it cuts and the finish you get. You need to look at the nose radius and rake angle of your insert.

Nose Radius

The nose radius is the rounded tip of your cutting tool insert. A larger nose radius gives you a smoother surface and helps your cutting tool last longer. If you use a smaller nose radius, you can make sharper details, but your cutting tool may wear out faster. Changes in nose radius can affect surface roughness and precision. Always pick the nose radius that matches your job needs.

| Nose Radius | Surface Finish | Tool Life | Detail Level |

|---|---|---|---|

| Large | Smoother | Longer | Lower |

| Small | Rougher | Shorter | Higher |

Positive Rake Inserts

A positive rake insert has a cutting edge that slices through the material easily. This design helps chips curl and move away from the workpiece. You get thin, curled chips that do not clog your machine. Positive rake inserts also lower the cutting force by up to 25%. You can remove more material with less resistance, which improves chip flow and surface finish. This makes your straight turning more precise.

Tip: Use positive rake inserts for ductile materials. You will see better chip control and smoother finishes.

AFI Industrial Co., Ltd. uses many types of cutting tools and inserts to match different materials and jobs. Their team reviews every drawing and selects the best cutting tool and insert for each part. This helps you get the tight tolerances and high quality you need.

Lathe Tool Setup

Setting up your lathe tool the right way makes a big difference in straight turning. You can avoid mistakes and get better results by focusing on alignment, overhang, and clamping.

Tool Alignment

You need to align your lathe tool with care. Good alignment helps you cut straight and keeps your parts accurate.

Center Height

Check the center height before you start. The cutting edge of your tool should match the center line of the lathe. If the tool sits too high or too low, you may see poor surface finish or uneven cuts. You can use a simple ruler or a center gauge to check this. Many machinists use these steps to get the best alignment:

- Mount the lathe on the floor.

- Level the lathe.

- Align the headstock.

- Align the tailstock to the headstock using a dial indicator.

- Adjust the tailstock with shim stock if needed.

You should also use a precision level to check the lathe bed. Make sure the lathe sits on a solid base. If you see wear on the bedways, adjust them before you begin.

Overhang

Tool overhang means how far the tool sticks out from the holder. If the tool extends too far, it can bend under pressure. This bending causes vibration and makes your cuts less accurate. You may see rough surfaces and wrong sizes on your workpiece. Try to keep the tool overhang as short as possible. Here are some things to watch for:

- Excessive tool overhang increases bending.

- Bending leads to inaccuracies in machining.

- Longer overhang causes more vibration.

- Vibration can make the tool deflect and lose precision.

You can reduce overhang by using the right tool holder and setting the tool close to the holder. This helps you get better results on your lathe.

Secure Clamping

Clamping your tool the right way is just as important as alignment. If you clamp the tool unevenly, the workpiece can deform. You might see an oval shape instead of a round one. Dimensional accuracy can drop by up to 15% if clamping is poor. Always make sure the clamping force is even. Check the tool holder and tighten all screws. If you see movement, stop and fix the clamping before you continue.

Tip: Uniform clamping keeps your workpiece round and helps you hold tight tolerances.

You can use these steps every time you set up your lathe tool. Good alignment, minimal overhang, and secure clamping help you get the best results in straight turning. AFI Industrial Co., Ltd. uses these practices to deliver high-precision parts with their CNC turning service.

Machine Condition

You need to keep your CNC lathe in good shape. This is important for making straight turning precise. Check and take care of your machine often. This helps you stop mistakes and keeps your parts right. AFI Industrial Co., Ltd. checks their machines carefully. They follow strict steps to make sure each machine works well.

Maintenance

Doing regular maintenance helps your lathe work smoothly. You should have a plan to find problems early. This can stop your machine from breaking down.

Lubrication

Lubrication helps your machine move easily. You should check oil levels every day. If oil is low, parts can wear out fast. Add oil when needed and use the right kind. Good lubrication stops metal parts from rubbing together. This keeps your lathe working well and makes it last longer.

Tip: Make a daily list to check oil and lubrication spots. This helps you remember what to do.

Slideway Cleaning

Slideways help your lathe parts move. Dirt and chips can build up on slideways. This can make movement rough. Clean slideways every week. Use a soft cloth to wipe away dust and dirt. If you see sticky spots, clean them right away. Clean slideways help your lathe move well and keep your cuts straight.

| Frequency | Maintenance Tasks |

|---|---|

| Daily | Check oil, look at tool holders and bearings, check coolant. |

| Weekly | Clean, check lubrication, and look for worn parts. |

| Monthly | Do deep checks and fix any problems you find. |

| Quarterly | Check everything, including axis drive and alignment. |

| Semi-Annual | Do careful checks to make sure everything works right. |

| Annual | Do big maintenance jobs to keep your machine working well. |

Follow this schedule to keep your machine in great shape.

Tool Inspection

Checking your tools helps you find wear before it causes trouble. Look for damage and change tools when needed.

Wear Indicators

Look for signs of wear on your cutting tools. These can be chips, cracks, or dull edges. If you see these, your tool may not cut well. Checking tools often helps you find problems early. This keeps your parts the right size and stops mistakes.

- Checking tools often keeps them in good shape.

- Finding wear early helps you avoid errors.

- Good tools help your machine and make parts more accurate.

Replacement

Change tools that show signs of wear. Do not wait until they break. Worn tools can make rough surfaces and wrong sizes. Keep extra tools ready. Change them as soon as you see wear. This helps you keep your turning accurate and your machine safe.

Note: AFI Industrial Co., Ltd. checks every tool and machine part before starting. This makes sure every part meets high standards and tight tolerances.

You can keep your CNC lathe accurate by following these care and check steps. Regular care helps you stop mistakes and keeps your turning jobs precise.

Cutting Parameters

Choosing the right cutting parameters helps you get the best results in straight turning. You need to set the speed, feed, and depth of cut for each job. These settings affect surface finish, tool life, and accuracy. If you adjust cutting parameters carefully, you can improve your work and keep your tools in good shape.

Speed and Feed

Speed and feed are two main cutting parameters. You control how fast the cutting tool moves and how much material it removes. If you set these right, you get a smooth surface and longer tool life.

Surface Finish

Surface finish depends on how you set the feed rate and cutting speed. If you use a high feed rate, you get a rough surface. Lower feed rates make the surface smoother. You should start with a low feed rate and increase it slowly. This helps you control chips and get a better finish.

| Parameter | Effect on Surface Finish |

|---|---|

| Feed Rate | Higher feed rate leads to rougher surface finish due to increased scallop marks. Lower feed rate yields smoother finish. |

| Cutting Speed | Must be optimized to balance material removal and tool wear. |

- A high feed rate results in a rough cut.

- For rough turning, the feed rate is usually 0.1-0.3 mm/rev.

- For finishing, you can use a feed rate of 0.01-0.05 mm/rev.

- Higher feed rate increases material removal rate.

- Lower feed rate gives you a smoother surface.

If you want a shiny finish, use a low feed rate and set the cutting speed to match your material. You can test different settings to see what works best. AFI Industrial Co., Ltd. uses advanced CNC machines to set cutting parameters for each job. This helps you get the right surface finish every time.

Tool Life

Tool life depends on how you set speed and feed. If you use a high cutting speed, your tool can wear out faster. Lower speeds help your tool last longer. You should watch for signs of wear and change your cutting tool when needed. If you set the feed rate too high, you can damage the cutting edge. You can keep your tool life long by using the right cutting parameters.

Tip: Start with a low feed rate and cutting speed. Increase them slowly to find the best balance between surface finish and tool life.

If you see chips building up or the surface getting rough, lower the feed rate. This helps you protect your cutting tool and keep your work accurate.

Depth of Cut

Depth of cut is another important cutting parameter. It tells you how deep the cutting tool goes into the material. You need to set this carefully to avoid problems.

Tool Pressure

If you use a deep depth of cut, you increase cutting forces. This can cause the cutting tool to bend or vibrate. Vibrations can make your workpiece less accurate. You should use shallow cuts for finishing passes. This helps you get tight tolerances and a smooth surface.

- A deeper depth of cut increases cutting forces.

- More force can cause tool deflection and vibrations.

- Vibrations can hurt dimensional accuracy.

- Shallower cuts help you get better surface finishes.

- Increasing depth of cut raises cutting forces due to a larger contact area.

You can start with a small depth of cut and increase it if your machine stays stable. If you see vibrations, lower the depth of cut. This helps you keep your cutting tool safe and your work precise.

Note: AFI Industrial Co., Ltd. sets cutting parameters for each job. Their team checks speed, feed, and depth of cut to make sure every part meets high standards.

If you pay attention to cutting parameters, you can improve your results in straight turning. You get better surface finishes, longer tool life, and more accurate parts.

Heat and Chip Control

Getting good precision in straight turning means you must handle heat and chips well. If you do not, your tool can get damaged. The surface may look bad, and it can even be unsafe. You can do better work if you use the right coolant and chip control.

Coolant Use

Coolant is important for keeping your turning steady. It cools the cutting spot and helps move chips away. This keeps your tool sharp and your part the right size.

Types

There are different coolants for CNC turning. Each one works best for certain jobs.

- Flood coolant is good with carbide tools. It covers the cutting area and stops sudden heat changes. This helps you keep tight tolerances and stops your tool from breaking.

- Mist coolant sprays a light mist on the tool and part. It helps your tool last longer and does not make a big mess. Mist coolant is good if you want to use less coolant.

- High-pressure coolant shoots coolant hard at the cutting spot. It breaks chips and cools fast. This is needed for tough materials like titanium or Inconel.

Coolant also keeps the temperature steady in your part and machine. This helps you keep tight tolerances, even if you run the job for a long time.

Delivery

How you put coolant on matters too. You want the coolant to hit the cutting spot. This gives you the best cooling and chip removal.

| Evidence | Explanation |

|---|---|

| Coolant lowers heat at the cutting spot | Less heat makes your tool last longer and helps you work better. |

| Too much heat can hurt your tool | More friction and heat can break your tool. |

| Good coolant use gives lube and cooling | This helps your tool work better, even when cutting is hard. |

| High-pressure coolant breaks chips well | This helps your tool last and keeps your part from bending. |

| Cooling is needed for tough materials | Hot and sticky metals like Inconel and titanium need coolant or your tool will break. |

Tip: Always check your coolant nozzles. Make sure they point at the cutting edge for the best results.

Chip Breaking

Chips come off when you cut metal. If you do not control them, they can wrap around your part or tool. This can scratch your part or even cause an accident.

- Chip breakers help you make chips small. Small chips are easy to clean up.

- Good chip control keeps your work area safe. You do not get long, sharp chips that can hurt you or your machine.

- The right chip breaker makes your surface look better. It also helps your tool last longer.

- You need to pick the chip breaker that fits your material. Each material needs a different chip breaker shape.

- Bad chip control can make your tool wear out and can be dangerous.

Note: Always use chip breakers that fit your material and cutting job. This keeps your turning safe and accurate.

If you focus on heat and chip control, you protect your tools. You get a better surface and keep your work area safe. These steps help you get the precision you want in straight turning.

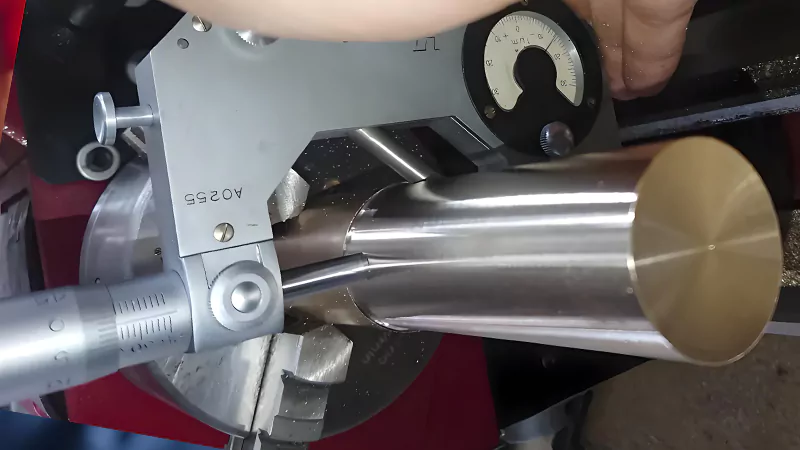

Measurement and Inspection

You need to check your work often during straight turning. This helps you keep every part within the right size and shape. If you measure and inspect at each step, you catch mistakes early. You can fix problems before they get worse. AFI Industrial Co., Ltd. uses strict checks to make sure every part meets high standards.

In-Process Checks

You should measure your parts while the machine is running. This helps you see if the tool is cutting the right size. If you find a problem, you can stop and fix it right away. You do not have to wait until the end.

Micrometers

A micrometer is a tool that measures small sizes very well. You use it to check the diameter of your part. Hold the micrometer around the part and read the number. This tool helps you see if your part is too big or too small. You can use a micrometer many times during turning. This keeps your work close to the right size.

Dial Indicators

A dial indicator is another tool you use for checking straightness and runout. Place the tool against the part and watch the needle move. If the needle jumps, your part is not straight. You can use this tool to check if the tool is set up right. You also use it to see if the part moves while turning.

Tip: Use both micrometers and dial indicators during turning. This helps you catch mistakes early and keep your parts within tight limits.

Here are some best practices for in-process measurement:

| Best Practice | Description |

|---|---|

| Automated Probing | Automated probing systems help you keep each part within the right size. You do not need to check by hand as much. |

| Real-time Monitoring | Real-time data lets you see problems as they happen. You can fix them before they cause bad parts. |

- Real-time monitoring lets you track the process as it happens.

- You can spot quality issues right away.

Final Inspection

After you finish turning, you need to check your part one last time. This makes sure the tool did its job well. You look at the size and the surface finish. You want every part to match the drawing.

Tolerance

Tolerance means how close your part is to the right size. You want every part to be as close as possible. Modern CNC turning can hold tight tolerances. Here are some standard tolerances you can expect:

| Source | Standard Tolerance |

|---|---|

| Fractory | +/- 0.005″ (0.127 mm) |

| 3ERP | ±0.005″ (tight tolerance) |

| Protolabs | +/- 0.005 in. (0.13mm) |

AFI Industrial Co., Ltd. keeps tolerances as tight as ±0.01mm. This means your parts will fit and work every time.

Surface Finish

You also need to check the surface finish. This tells you how smooth the part feels and looks. A good surface finish means less friction and less wear. It also helps your part last longer. If you get a fine surface finish, your part will resist rust and stress better.

- Smoother surface finishes lower friction and wear. This helps parts like bearings and pistons last longer.

- Finer finishes spread out stress. This makes your part stronger and stops early failure.

Surface finish measurement is key for part quality. It affects how well your part works in machines. You want to check the surface finish after turning to make sure it meets your needs.

Note: AFI Industrial Co., Ltd. checks every part for size and surface finish. Their team uses the right tool for each job. This keeps every part within tight limits and high quality.

You should always measure and inspect your work. This helps you keep your turning jobs precise and your parts ready for use.

You can get steady precision in straight turning by using these seven tips. Each tip helps you stop problems like vibration, heat, and rough surfaces. The table below lists some problems you might see and ways to fix them:

| Challenge | Solution |

|---|---|

| Workholding | Use collets for a strong grip. Machine jaws to match your part size. |

| Insert Selection | Choose the right insert shape. Higher lead angles make the surface smoother in straight turning. |

| Surface Finish | Wiper inserts help you get a smoother finish when turning. |

| Chatter | Change speeds and feeds. Make your setup stronger to lower vibration in straight turning. |

| Heat Management | Use coolant to keep your tool and part cool while turning. |

You can make your work better by using these steps every time you turn parts. AFI Industrial Co., Ltd. gives you good CNC turning and precise manufacturing. Share your own tips or stories in the comments. Your ideas help everyone learn more about turning.

FAQ

Straight turning means you cut along the length of a workpiece to make it smooth and even. You use a lathe for this job. You get parts with the same diameter from end to end.

You can tighten your setup, use sharp tools, and adjust speed or feed. Try to keep the tool overhang short. If you hear vibration, slow down the spindle or change the insert.

Tool alignment helps you cut straight. If your tool sits too high or low, you get rough surfaces and wrong sizes. Always check the center height before you start.

You use micrometers for diameter checks. Dial indicators help you see straightness and runout. Automated probing systems can give you real-time data for better control.

AFI Industrial Co., Ltd. can machine aluminum alloys, titanium alloys, and engineering plastics. You get parts for automotive, aerospace, and medical devices.

AFI Industrial Co., Ltd. holds tolerances as tight as ±0.01mm. You get parts that fit and work every time.

Coolant keeps your tool and part cool. It helps chips move away. You get better surface finishes and longer tool life.

You should check your tools before every job. Look for wear, chips, or cracks. Replace worn tools to keep your parts accurate.