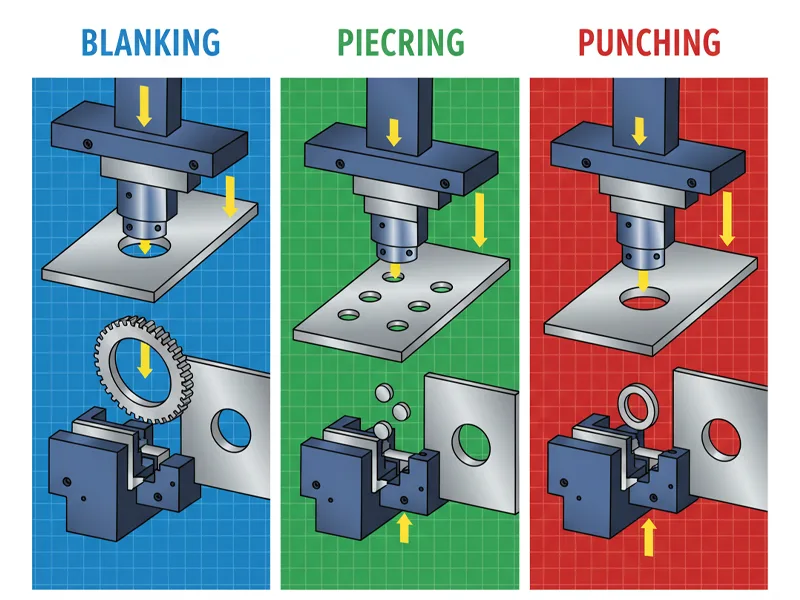

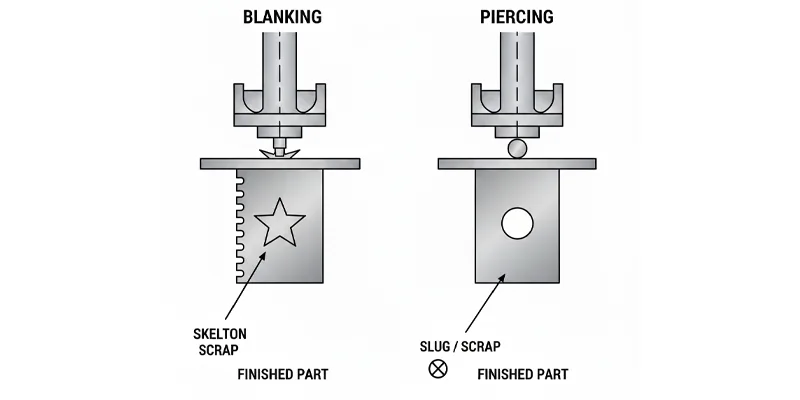

You need to know the main differences between the blanking process, piercing, and punching. This helps you pick the best way to make things. In the blanking process, you cut a piece from a metal sheet, and you keep the piece you cut out as the finished part. Piercing takes out a part of the sheet to make a hole, while punching uses a die to shape metal into objects.

Many companies use these methods:

- In 2023, over 68% of car part makers used fine blanking for smoother edges.

- More than half of European tooling companies got new presses for more exact parts.

Choosing the right process helps you make parts faster and follow industry rules.

Key Takeaways

- Blanking cuts a piece from a metal sheet. The cut piece is kept as the finished part. This process works well for making many parts fast.

- Piercing makes holes in metal sheets. The material taken out is thrown away as scrap. Use piercing to add holes for bolts or wires.

- Punching shapes metal by taking out pieces. The leftover metal is not used as a finished part. Punching helps make different shapes and patterns.

- Picking the right process changes how fast you work. It also changes how much material you use and how good the parts are. Think about your project needs before you choose.

- Blanking works best for simple shapes and high accuracy. Piercing and punching are better for making tricky holes and patterns.

- New tools and machines help blanking, piercing, and punching work better and faster. They also help make parts more exact.

- Always check if your die and punch line up right. This stops damage and helps you get clean cuts.

- Knowing the differences between these processes helps engineers choose the best way to design and make things.

Table of Contents

Key Differences

Definitions

You need to understand the basic definitions before you choose a process. Each method works differently and gives you different results. The table below shows the most accepted definitions in engineering:

| Process | Definition |

|---|---|

| Piercing | A shearing process that creates a hole in raw metal, with the removed metal considered scrap. |

| Punching | A machining process that removes scrap metal from a sheet, creating a shape that matches the die. |

| Blanking | A process that cuts holes in metal, saving the removed piece for use, creating multiple parts. |

When you use blanking, you keep the piece you cut out. Piercing makes a hole, and you throw away the scrap. Punching shapes the metal by removing parts, and the leftover piece matches the die.

What Sets Each Apart

You see big differences in what each process removes and what you keep.

- Blanking gives you a finished part from the cut-out piece. You use this part in your product.

- Piercing creates holes in the metal sheet. The scrap from the hole is not used.

- Punching shapes the metal by cutting out forms. The scrap matches the die, but you do not use it as a finished part.

Tip: If you want to make many identical parts quickly, blanking works best. If you need holes for fasteners or wires, piercing is the right choice. Punching helps you create shapes or patterns in metal sheets.

Blanking, piercing, and punching each change the metal in different ways. Piercing can weaken the area around the hole. Punching may cause edge deformation, which can affect the strength of your part. Blanking keeps the metal strong and works well for high-volume production.

Importance for Engineers

You must know these differences to make smart choices in design and manufacturing.

- Blanking lets you create many parts with strong edges.

- Piercing helps you add holes for assembly or wiring, but you need to check if the metal stays strong enough.

- Punching lets you cut shapes, but you should watch for edge damage.

Recent advancements make these processes even better. Fineblanking presses now reach speeds over 50 strokes per minute. Servo-driven presses give you more control over speed and position. Tooling improvements, like better steels and coatings, help you get cleaner cuts and longer tool life.

The metal stamping market keeps growing. You see more CNC machines and automation in factories. These changes help you make parts faster and with higher precision.

Note: When you pick blanking, piercing, or punching, you decide how your part will look and perform. You also control how fast you can make parts and how much material you use.

Blanking Process

Steps

You need to follow a clear sequence when you use the blanking process. Each step helps you get accurate parts and keeps your production smooth.

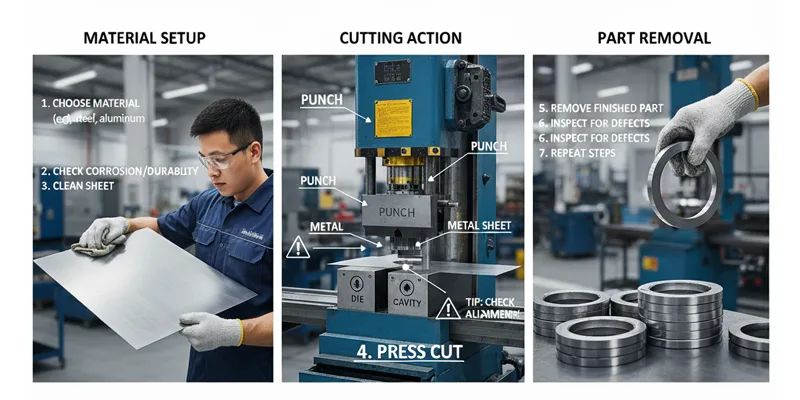

Material Setup

Start by choosing the right material for your project. You look at factors like corrosion resistance and durability. Pick a metal sheet that matches your needs. Clean the sheet to remove any dirt or oil. This step makes sure you get a clean cut and prevents defects. You prepare the metal so the blanking process works well.

Cutting Action

Set up the blanking die in your press. The die has two main parts: a punch and a die cavity. The punch matches the shape you want to cut out. Place the metal sheet on the press bed. The blanking punch moves down and pushes the metal through the die cavity. This shears the metal and creates the part you need. You control the press to make sure the force is enough for the thickness of your material.

Tip: Always check the alignment of your die and punch before you start. Misalignment can damage your tools and ruin your parts.

Part Removal

After the cutting action, you remove the finished part from the die. The blanking process gives you a piece with clean edges and the exact shape you want. You inspect the part for any defects. If you see burrs or rough edges, you may need to trim or finish the part. You repeat these steps for each piece you need.

Tools Used

You use several key tools in the blanking process. Each tool has important specifications that affect your results.

| Specification | Description |

|---|---|

| Tonnage | Maximum force the press can exert (in tons). Determines material thickness. |

| Bed Size | Dimensions of the bolster plate where the die sits. Dictates die size. |

| Stroke Length | Maximum distance the ram travels for tooling setup and part ejection. |

| Shut Height | Distance from the bed to the bottom of the ram at its lowest position. |

| Speed (SPM) | Strokes Per Minute, crucial for throughput, especially on mechanical presses. |

You select your press based on the thickness and size of your metal sheet. The blanking die must fit the bed size. You adjust the stroke length for each job. The shut height helps you set up the tooling. Speed matters when you want to make many parts quickly. You use a blanking punch that matches the shape of your finished part.

Note: Modern presses let you adjust speed and force for different materials. This flexibility helps you get better results and longer tool life.

The blanking process gives you strong, precise parts. You can make many identical pieces in a short time. You need to set up your tools carefully and follow each step for the best outcome.

Piercing and Punching

Piercing Steps

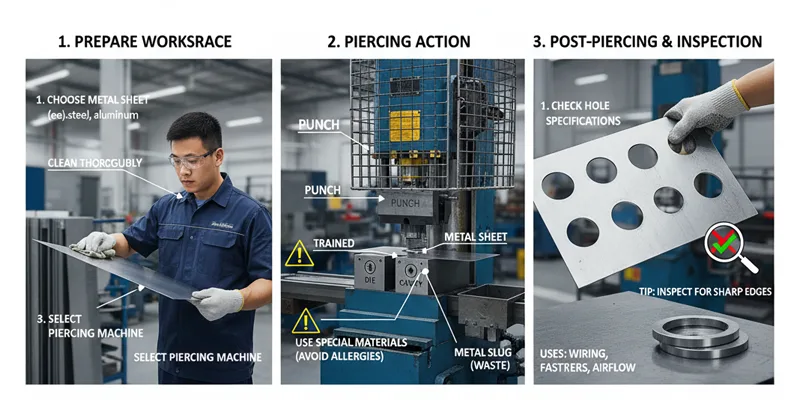

Setup

First, you get your workspace ready. You pick a metal sheet and clean it well. You choose a piercing machine that fits your project. Trained workers often do piercing in factories to keep things safe. If you want to avoid allergies, you use special materials. This step helps you make holes that are just right.

| Step | Description |

|---|---|

| Piercings by licensed nurses | Trained people do the work, so there are fewer problems. |

| Hypoallergenic earrings always | Good materials help stop allergies and infections. |

| Aftercare is not an afterthought | You get tips to help healing and stop problems. |

Hole Creation

You use the piercing machine to push a punch through the metal. The punch knocks out a small piece and leaves a hole. You make sure the holes match your plan. The scrap from the hole is not used. After you finish, you clean the area and check for sharp edges. This keeps your part safe and ready. Piercing is good for making holes for wires, fasteners, or air flow.

Tip: Always check each hole after you finish. Sharp edges can cause trouble when you put parts together.

Punching Steps

Setup

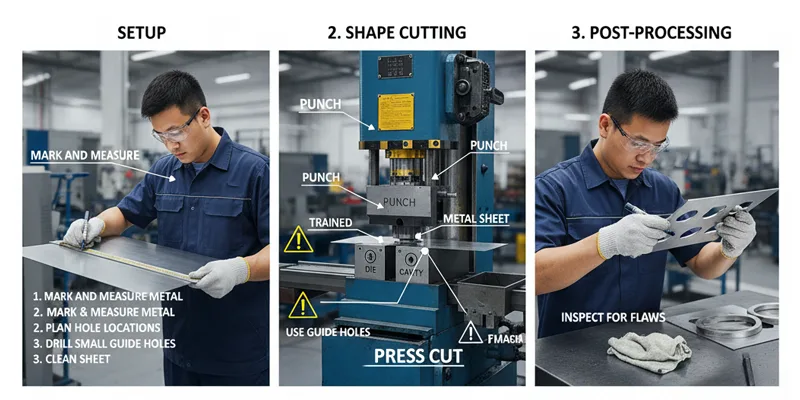

You start punching by marking and measuring the metal. You plan where each hole or shape will go. You use tools to make sure your design is right. Sometimes you drill small holes or make dents to guide the punch. This helps you avoid mistakes and get good results.

Shape Cutting

You put the punch into the hole or dent. The machine pushes the punch through the metal. This cuts out holes or shapes that match your die. You use a tool to smooth sharp edges. You look at each piece to see if it is good. You clean the metal before you move on.

- Marking and Measuring: Mark and measure the metal so punches go in the right place.

- Layout and Drilling: Plan where holes or shapes go, and drill small holes or make dents.

- Punching: Put punches in the holes to make the shapes you want.

- Deburring: Smooth sharp edges on the punched metal.

- Inspection: Check each piece to make sure it is right.

- Cleaning: Clean the metal to get rid of dirt or scraps.

Note: Punching lets you make lots of shapes fast. You can use it to cut holes, slots, or patterns in metal sheets.

Tools

You use different tools for piercing and punching. Each tool is made for a special job. Some punches are best for making holes. Others work better for cutting thick or hard metal. You might use step piercing punches for making holes at different levels. Carbide punches are good for jobs that need high accuracy. Black head annealed punches last longer when you use them a lot. Custom punches fit special projects. D shape HSS punches help you get exact results. Double step punches let you make cool patterns in one try. Metal hole punches work in many jobs. Pilot punches help you put holes in the right spot. Pin punches are good for small parts and lining things up.

| Type of Punch | Description |

|---|---|

| Step Piercing Punches | Makes holes at different levels in one go, so you work faster. |

| Black Head Annealed Punches | Made stronger for tough jobs, so they last longer. |

| Carbide Punches | Very hard and strong, good for jobs that need accuracy. |

| Customized Piercing Punches | Made for special jobs that need a unique punch. |

| D Shape HSS Punches | D-shaped for exact holes when you need them. |

| Double Step Punches | Has two levels for making fancy patterns in one step. |

| HSS Block Punches | Made from strong steel, good for hard jobs and lasts long. |

| HSS Punches | Stays sharp and hard even when used a lot. |

| HSS Step Punches | Has more than one level for better work and speed. |

| Industrial Piercing Punches | Built for big jobs in factories. |

| Long Step Punches | Longer for making deep holes in metal. |

| Metal Hole Punches | Used for making holes in many kinds of metal. |

| Pilot Punches | Helps you put holes in the right spot. |

| Pin Punches | Thin and good for small jobs like taking out pins. |

| Small Step Punches | Small and good for tiny jobs. |

| Square Piercing Punches | Makes square holes with neat edges. |

Tip: Pick your punch based on how thick the metal is and what kind of hole you need. The right tool helps you get clean holes and makes your tools last longer.

Blanking vs Piercing

Material Removal

You see a big difference in how blanking and piercing remove material. In blanking, you cut out a shape from a metal sheet. The piece you remove becomes your finished part. You do not treat this piece as scrap. In piercing, you punch a hole or shape into the metal. The part you remove is just waste, called scrap. You throw it away and keep the sheet with the new hole.

Here is a table to help you compare:

| Process | Purpose of Removed Material | Resulting Scrap |

|---|---|---|

| Blanking | Desired product | Not considered scrap |

| Piercing | Scrap | Considered scrap |

Tip: If you want to keep the cut-out piece, choose blanking. If you only need a hole or opening, use piercing.

Part Focus

Blanking and piercing focus on different results. When you use blanking, you make the outside shape of a part. This part comes from the metal sheet, and you use it in your final product. Piercing works the other way. You use it to make holes or shapes inside a part. The main goal is to create an opening, not to keep the removed piece.

- Blanking produces the outside features of a component.

- Piercing produces internal holes or shapes.

You can also see the difference in this table:

| Process | Primary Focus | Material Removed |

|---|---|---|

| Blanking | Produce a piece part from a stock strip of material | None (produced part) |

| Piercing | Create holes or openings in the piece part | Scrap (slug) |

Note: Blanking focuses on making a new part. Piercing focuses on changing an existing part by adding holes.

Die and Punch Differences

You use different tools for blanking and piercing, even though both use a die and a punch. In blanking, the die matches the shape of the part you want to keep. The punch pushes the metal through the die, and you collect the cut-out piece. In piercing, the punch matches the hole you want to make. The die supports the metal sheet, and the punch removes the scrap.

- In blanking, you design the die for the finished part. The punch helps cut it out.

- In piercing, you design the punch for the hole. The die holds the sheet steady.

You often use the same press for both processes, but you change the die and punch shapes. You can also use punching to make different shapes, but the main idea stays the same: blanking gives you a part, piercing gives you a hole.

Remember: Always check your die and punch setup before you start. The right setup gives you clean parts and less waste.

Comparison

Table

You need to compare blanking, piercing, and punching before you choose a process. Tables help you see the main differences quickly. Look at the factors that matter most in engineering.

| Aspect | Blanking | Piercing | Punching |

|---|---|---|---|

| Material Outcome | You keep the cut-out piece as your part. | You throw away the cut-out piece as scrap. | You remove shapes; scrap matches the die. |

| Dimension Determination | Die size sets the blank’s size. | Punch size sets the hole’s size. | Die and punch shape set the cut-out form. |

| Die and Punch Design | Die matches the finished part’s size. | Punch matches the hole’s size. | Die and punch match the desired shape. |

| Material | Handles many thicknesses and hardness levels. | Works best with thinner or softer materials. | Best for thin or soft materials. |

| Quantity | Good for small batches with high precision. | Works well for large batches. | Suits high-volume production. |

| Complexity | Best for simple shapes. | Makes holes of many shapes and sizes. | Cuts many shapes and patterns. |

| Finishing | Leaves clean edges. | May leave rough edges. | Often leaves rough edges. |

Tip: Use this table to match your project needs with the right process. If you want clean edges and strong parts, blanking works best. If you need many holes, piercing gives you speed. Punching helps you create patterns or slots in metal sheets.

Bullet Points

You can use these main points to guide your decision:

- Blanking gives you the part you need from the metal sheet. You keep the cut-out piece.

- Piercing creates holes in your part. You throw away the scrap from the hole.

- Punching removes shapes from the metal. The leftover scrap matches the die, but you do not use it as a finished part.

- Die size decides the size of the blank in blanking. Punch size decides the size of the hole in piercing.

- Blanking works with many types of metal and thicknesses. Piercing and punching work best with thin or soft materials.

- Blanking is best for small batches where you need clean edges. Piercing and punching suit high-volume jobs.

- You get simple shapes with blanking. Piercing and punching let you make more complex holes and patterns.

- Blanking usually leaves cleaner edges. Piercing and punching may leave rough edges that need finishing.

Note: Always check your material and project needs before you choose a process. The right choice helps you save time, reduce waste, and get better results.

You now have a clear view of how blanking, piercing, and punching compare. Use these tables and points to pick the process that fits your project. This helps you make strong, precise parts every time.

Applications

Blanking

Blanking is used when you need fast and accurate parts. This process cuts shapes from metal sheets. You keep the piece you cut out and use it as your part. Many industries use blanking to make strong and neat parts. Here are some ways blanking is used:

- Automotive Industry: You make metal parts like car panels and engine pieces. These parts must be strong and fit together.

- Electronics: You create small, exact parts like connectors and covers. These must be the right size so devices work.

- Household Appliances: You shape metal for things like fridge doors. These parts need smooth edges to look good and be safe.

- Aerospace: You make parts that are light and strong. Planes and spacecraft need these for safety and to work well.

Blanking gives you parts with smooth edges and the right shape. You can make lots of parts quickly. This process is good for big projects that need many exact pieces.

Piercing

Piercing is used when you need to make a hole in metal. This process lets you add holes for bolts, wires, or air. You push a punch through the metal to take out a small piece. The piece you remove is not used. Piercing is important because it adds features without changing the whole part.

You see piercing a lot in car making. You make holes for bolts or rivets in car panels. Electronics makers use piercing for holes for plugs or cooling. Appliance makers use piercing to make holes for handles or buttons. Piercing helps you add things to metal parts and keep them strong.

Punching

Punching is used to cut shapes or patterns in metal. This process lets you make holes, slots, or designs fast. You can make many shapes by changing the punch and die. Punching is popular because it is quick and gives the same results each time.

Punching is used in many places:

- Automotive Industry: You make brackets, panels, and exhaust parts. These must be strong and fit together.

- Construction: You make building parts and supports. Punching adds holes or slots for putting things together.

- Electronics: You make covers, heat sinks, and board parts. These need the right shapes and holes.

- Industrial Equipment: You make machine parts and safety covers. Punching adds features for safety and use.

- Consumer Goods: You shape kitchen tools and furniture. Punching lets you add cool designs or useful holes.

Punching lets you make many shapes. You can change your tools to fit your job. This process saves time and cuts down on waste.

Industries

Blanking, piercing, and punching are used in lots of industries. These methods help make strong and useful parts for many products. Every industry uses these processes to fix problems and meet special needs.

Here is a table that shows where you use these methods and what you make:

| Industry | Typical Products |

|---|---|

| Electrical and Power | Clips, cups, covers, fasteners, electronic assemblies |

| Construction | Power tools, panel fastening systems, industrial switches, custom assemblies |

| Hardware | Nuts, bolts, screws, hinges, locks, catches, latches, handles, cabinetry essentials |

| Appliances | Ice machines, microwaves, refrigerators, grills, trash compactors, fryers, and griddles |

In electrical and power jobs, you need small metal parts. Blanking helps you make clips and covers that fit well. Piercing adds holes for wires and fasteners. Punching shapes metal for electronic assemblies.

Construction needs tough parts that last long. Blanking cuts panels for power tools. Piercing makes holes for fastening systems. Punching shapes metal for switches and custom assemblies. You get parts that fit together and work on job sites.

Hardware makers use these methods all the time. Blanking makes nuts, bolts, and screws. Piercing adds holes for hinges and locks. Punching shapes latches and handles. You get parts that open, close, and hold things.

Appliance makers want smooth and safe parts. Blanking cuts doors for fridges and grills. Piercing adds holes for buttons and handles. Punching shapes trays and covers for ice machines and fryers. You get parts that look nice and work safely at home or in restaurants.

Tip: Pick the right process by thinking about the product you want. Blanking is best for strong finished parts. Piercing helps you add holes and features. Punching lets you make patterns and shapes.

You also see these methods in other places. Factories use them for car parts, airplane pieces, and machine covers. You find them in electronics, furniture, and toys. Each process helps you solve problems and make products that last.

You can do better work by learning how each industry uses blanking, piercing, and punching. You get better results and make parts that fit your needs. You save time and waste by choosing the right method for your job.

Pros and Cons

Blanking

Blanking is good when you want strong parts with smooth edges. This process is great for making lots of parts fast. You get very accurate shapes and edges. Blanking helps you make the same part over and over. You waste less metal because you keep the cut-out piece. You can use blanking with many kinds of metal. It works well for thick or thin sheets. You get steady results when you make many parts.

Pros:

- You get exact shapes and smooth edges.

- You can make many parts quickly.

- Smooth edges mean less extra work.

- Good for making lots of parts at once.

- Works with different metals and thicknesses.

- You waste less material.

Cons:

- Only works for simple shapes.

- Special tools can cost a lot.

- Not good for adding holes or designs.

- Some metals may need extra finishing.

Think about the good and bad sides of blanking before you pick it. Blanking is fast and accurate, but you might need other methods for tricky shapes.

Piercing

Piercing helps you put holes in metal parts. You use piercing when you want to make parts quickly. This process gives you okay accuracy for basic jobs. Piercing works well for tubes and flat sheets. You spend less money at first and can start fast. Piercing is good for many simple jobs.

Here is a table that shows the main pros and cons of piercing:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Material Quality | Saves money for making tubes | More mistakes from cutting stress |

| Process Reliability | Works fine for most jobs | Walls and surfaces may not be even |

| Application Suitability | Good for simple uses | Not great for parts that need to be perfect |

| Defect Control | Costs less to start | More mistakes and extra work needed |

| Mechanical Strength | Strong enough for normal jobs | May not seal well under pressure |

| Quality Expectations | Meets basic rules for most industries | Not good for jobs that need perfect parts |

Think about the good and bad sides of piercing when you need holes. Piercing is quick, but you might see more mistakes and need extra work.

Punching

Punching lets you make holes, slots, and shapes in metal sheets. You use punching to make lots of parts fast and with good accuracy. This process is great for big jobs and CNC machines. You get the same quality every time and finish quickly. Punching helps you save metal and money on workers. You can punch many types of metal like aluminum and stainless steel.

Here is a table that shows the main pros and cons of punching:

| Advantages | Disadvantages |

|---|---|

| Makes lots of parts very fast | Machines are loud |

| Cuts holes, slots, and shapes in many sizes | Makes scrap that needs cleaning up |

| Very accurate for CNC machines | Needs safety guards and trained workers |

| Same quality in big batches | Sharp edges may need smoothing |

| Saves money for big jobs | CNC machines cost a lot at first |

| Often skips extra drilling or shaping | Needs skilled workers to set up and run |

| Smart layouts save metal | Tools can jam if set up wrong or metal is bad |

| Works with many metals | |

| CNC machines save on worker costs |

Look at the good and bad sides of punching before you start. Punching is fast and accurate, but you need to handle noise, scrap, and safety.

Selection Guide

When you work on a new project, selecting the right process can make a big difference in your results. You need to look at the material, your project needs, and the cost. Each factor helps you decide if blanking, piercing, or punching fits your job best.

Material

You should always start by looking at the material you plan to use. The type and thickness of your metal sheet affect how well each process works. Some metals are soft and easy to cut, while others are hard and need more force. Thicker materials need more clearance between the punch and die. If you use the wrong setup, you might get rough edges or damage your tools.

Here is a table to help you see what matters most:

| Factor | Description |

|---|---|

| Material Properties | The type of metal changes how much force you need and how clean the cut will be. |

| Workpiece Thickness | Thicker sheets need more space between the punch and die for a good cut. |

| Tooling Condition | Sharp, well-kept tools give you better results and longer tool life. |

Tip: Always check your material’s hardness and thickness before selecting the right process. This step helps you avoid mistakes and get clean, strong parts.

Project Needs

Your project goals shape your choice. If you want to create a flat shape from a metal sheet, blanking gives you a fresh part to use in later steps. When you need holes or cutouts in a part, piercing works best. Punching helps you make precise holes or shapes in metal forms. Think about the final use of your part and how many you need to make.

| Process | Description | Application | Characteristics |

|---|---|---|---|

| Blanking | Forms a flat shape from a metal sheet. | Makes blanks for further work. | The cut-out piece becomes your new part. |

| Piercing | Makes holes or slots using a punch and die. | Adds holes or cutouts to parts. | The removed piece is scrap. |

| Punching | Uses a press for precise holes and shapes. | Creates special hole shapes in metal forms. | May separate extra material from the part. |

If you plan on mass-producing parts, selecting the right process early helps you save time and reduce waste. You also get more consistent results.

Cost

Cost plays a big role in your decision. Tooling for blanking can cost more at first, but you get fast and repeatable results. Piercing and punching often use simpler tools, which can lower your starting costs. However, if you need high precision or special shapes, you may need custom tools. Always balance your budget with your quality needs.

- Blanking: Higher tooling cost, but lower cost per part for large runs.

- Piercing: Lower initial cost, good for adding features to existing parts.

- Punching: Flexible and fast, but may need more finishing for clean edges.

Note: Selecting the right process helps you control costs and meet your project goals. Always match your process to your budget and the number of parts you need.

Now you know that blanking, piercing, and punching all do different things. Blanking makes finished parts. Piercing puts holes in metal. Punching shapes the metal sheets. Choosing the right process helps you make strong and correct parts. Look at the tables and guides in this blog to help with your project. For hard jobs, you can:

- Work with engineering companies to get advice

- Bring in experts to help with big workloads

- Hire project managers to help run large projects

You get better results when you ask experts for help with hard choices.

FAQ

Blanking gives you a finished part from the metal sheet. Piercing makes a hole in the sheet, and you throw away the piece you remove.

You can use the same press for all three processes. You need to change the die and punch shapes to match each job.

Blanking creates many identical parts quickly. You get strong edges and save time when you need lots of pieces.

Punching can leave rough edges. You may need to smooth or finish the part after punching to make it safe and look good.

You get the best results with thin or soft metals like aluminum or mild steel. Hard or thick metals may need special tools.

You look at your project needs, the type of metal, and your budget. Use blanking for finished parts, piercing for holes, and punching for shapes.

Blanking usually costs more at first because you need special tools. You save money when you make many parts.

You can make many shapes with punching. Change the punch and die to create holes, slots, or patterns in metal sheets.