You use the extruding metal process to shape metal by pushing it through a die. This creates long pieces with the same shape throughout. The extruding metal process is very important in many industries. It helps you make strong and light parts while also generating less waste. The global market for this process continues to expand, demonstrating how useful the extruding metal process is:

- The global aluminum extrusion market was valued at USD 94,194.5 million in 2022 and may grow to USD 146,816.8 million by 2030.

- The metal extrusions market size was USD 138.56 billion in 2024 and may reach USD 192.67 billion by 2033.

The extrusion method you select affects cost, quality, and design. By choosing the right extruding metal process, you can save money while achieving fast production and consistent quality.

Key Takeaways

- Metal extrusion changes metal by pushing it through a die. This makes long pieces that all look the same. Choosing the right extrusion method can help save money. It can also cut down on waste and make things faster. Direct extrusion is good for making long, straight pieces. Indirect extrusion gives smoother surfaces and better accuracy. Hydrostatic extrusion uses liquid pressure to shape hard metals. This makes it good for tricky designs. Cold extrusion works at room temperature. It saves energy and makes strong parts with smooth surfaces. Micro-extrusion helps make tiny, exact parts. These are important in medicine and electronics. Knowing about each extrusion type helps you pick the best one. Think about cost, energy use, and material type when choosing. This will help you get the best results.

Table of Contents

Metal Extrusion Overview

Extruding Metal Process

You use the extruding metal process to make metal into long shapes. You start with a solid piece called a billet. You put the billet inside a chamber. You often heat the billet so it gets soft. When the billet is ready, you push it through a die. The metal comes out shaped like the die.

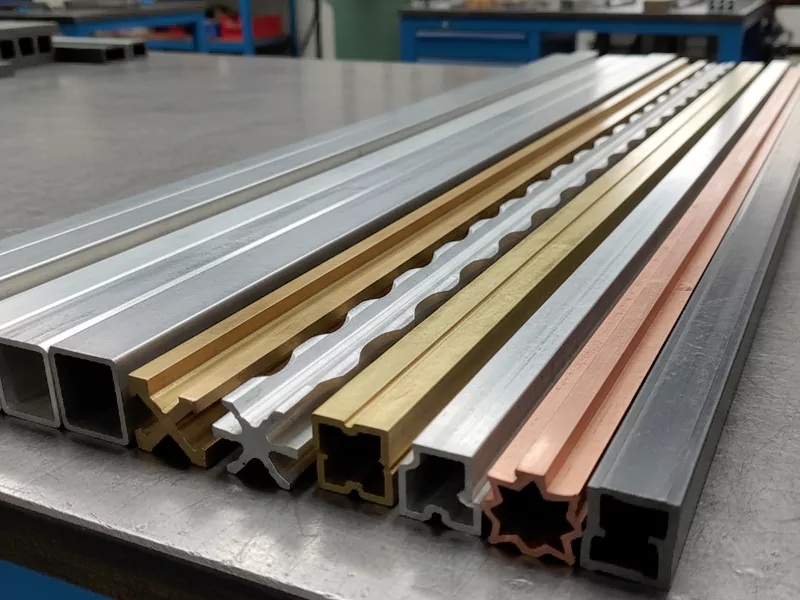

The extruding metal process helps you make parts with tricky shapes. These shapes are hard to make with other methods. You can use this process for metals like aluminum, copper, and steel. The extruding metal process makes strong and light parts. You waste less metal because you only shape what you need.

Here are the main steps in the extruding metal process:

- Put a round billet in a chamber.

- Heat the billet so it gets softer.

- Push the billet through the die with a press.

- Collect the metal that comes out in the die’s shape.

You can use the extruding metal process for easy or hard designs. This process lets you make many different shapes. It helps you meet many design needs.Metal Extrusion Process

The metal extrusion process is important in manufacturing today. You use the metal extrusion process because it has many good points. The extrusion process saves money by using less material and making less waste. You get strong and light parts that work in many industries. The metal extrusion process lets you make special shapes and designs. You have more choices for your projects.

- You save money by wasting less material.

- You get strong and light parts.

- You can make special shapes and designs.

- You help the planet by using recyclable materials.

You see the metal extrusion process in cars, buildings, and electronics. The extrusion process helps you make things faster and better. You can pick the right extruding metal process for your needs. You can make simple rods or tricky shapes. The metal extrusion process lets you control the shape, strength, and look of your final product.

Types of Metal Extrusion

Direct Extrusion

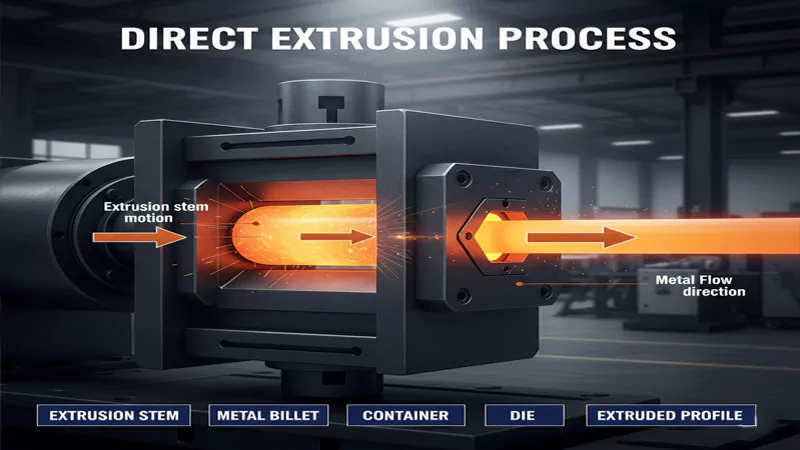

Direct extrusion is the most used metal extrusion process. You push a hot billet through a die that does not move. The metal moves in the same way as the force you use. This method works for many metals like aluminium alloys, copper alloys, stainless steel, and magnesium alloys.

Here is a simple table to help you see the steps in direct extrusion:

| Step | Description |

|---|---|

| Billet preparation | You heat the metal so it gets softer and easier to shape. |

| Container and die assembly | You put the billet in a container with a die at one end. |

| Extrusion process | You push the billet through the die with a ram or screw. |

| Cooling and cutting | You cool the metal and cut it to the size you need. |

You can use direct extrusion to make rods, bars, tubes, and other long shapes. This process saves money and works fast. You get parts with the same shape all the way through and strong properties. Many industries use direct extrusion for aluminium alloys and copper alloys because it makes good parts with less waste.

Tip: If you want to make long, straight pieces with the same shape, direct extrusion is a smart choice.

Indirect Extrusion

Indirect extrusion is not the same as direct extrusion. In this process, the die moves toward the billet, which stays still. The metal moves the other way from the force you use. This way, there is less friction between the billet and the container.

Here is a table that shows how direct and indirect extrusion are different:

| Aspect | Direct Extrusion | Indirect Extrusion |

|---|---|---|

| Process Mechanics | You push the billet through a die that does not move | The die moves toward a billet that does not move |

| Friction | There is more friction with the container walls | There is less friction because the billet does not move |

| Force Requirement | Needs more force | Needs less force |

| Surface Finish | The surface may have marks | The surface is smoother |

| Dimensional Accuracy | Not as precise | More precise |

| Energy Efficiency | Uses more energy | Uses less energy |

| Application Suitability | Good for big, tricky shapes | Good for parts that need high accuracy |

You should use indirect extrusion when you want a smoother surface and better accuracy. This process is good for making parts from titanium alloys and other hard metals. You also save energy because you do not need as much force.

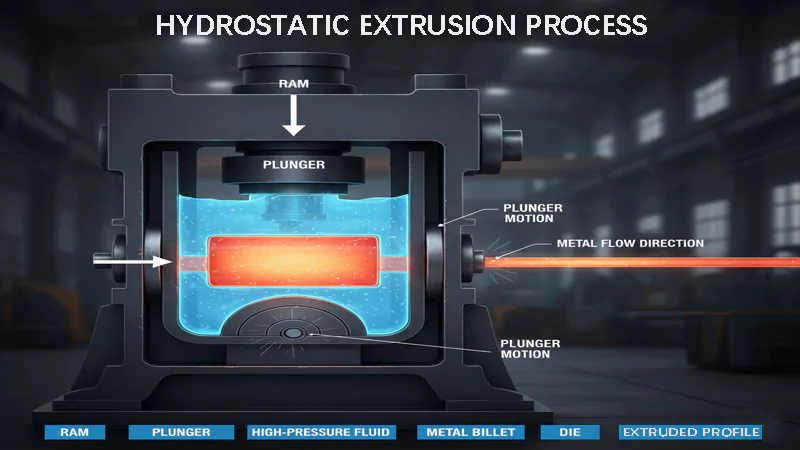

Hydrostatic Extrusion

Hydrostatic extrusion is a special kind of metal extrusion. You use a liquid, like oil or water, to press on the billet. The fluid pushes the metal through the die. This method helps you shape metals that are hard to extrude with other ways.

Hydrostatic extrusion works well for big billets and tricky shapes. You can use it for many metals, like copper alloys and aluminium alloys. The fluid pressure helps stop cracks and problems in the metal.

Here is a table that shows what is good and not so good about hydrostatic extrusion:

| Advantages of Hydrostatic Extrusion | Limitations of Hydrostatic Extrusion |

|---|---|

| You can extrude big billets and cross-sections | You must shape the billet to fit the die |

| The pressure is even, so you do not need to straighten billets | You often need to machine the billet to fix problems |

| No metal sticks to the container walls | It is hard to keep the fluid inside at high pressure |

| You need extra steps to handle the fluid | |

| It is harder to control the speed and stopping | |

| The process is not as good for some shapes | |

| It can be tricky when it is very hot |

Note: Hydrostatic extrusion is helpful when you need to shape tough metals or make special shapes. You should think about the extra steps and tools you need for this process.

Each type of metal extrusion has its own good points. You should pick the right process based on the metal, the shape you want, and the quality you need.

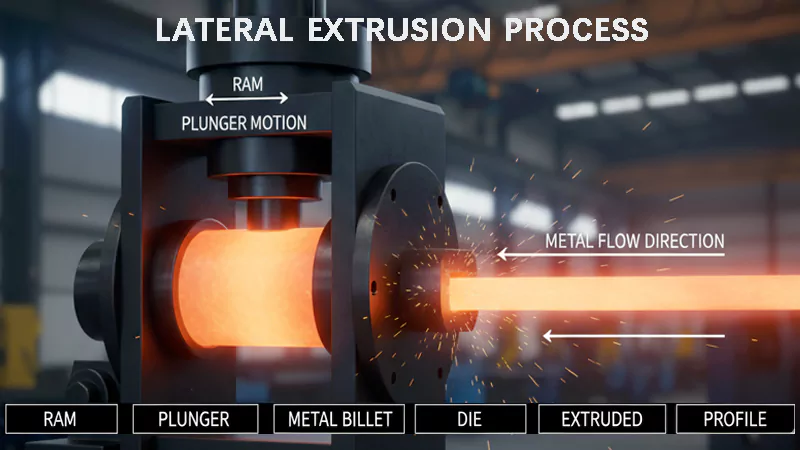

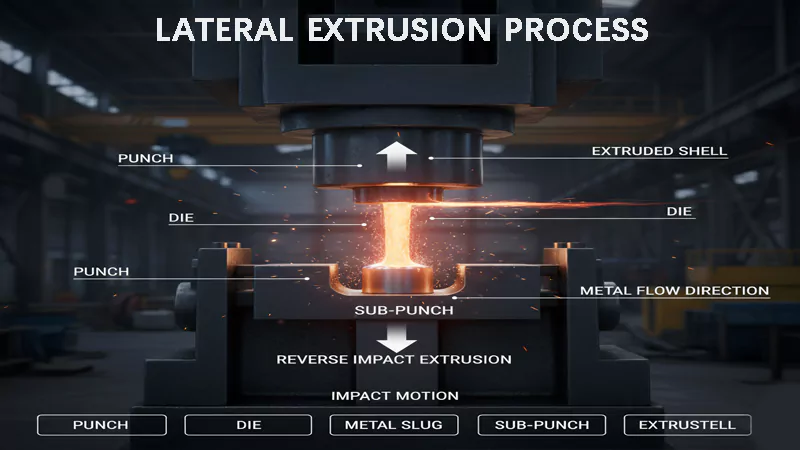

Lateral Extrusion

You use lateral extrusion to make shapes that are hard to create with other methods. In this process, you push metal sideways through a die. This helps you form parts with tricky shapes and cross-shaped pieces.

Lateral extrusion works well for parts that need side openings or special edges. You can make hollow bodies and add features without extra steps. This process saves you time and effort.

Lateral extrusion is smart for parts with tough designs. You can make pieces with holes along their length or openings on the sides. You also get parts with grooves or dips around the edges. Hollow shafts with inside structures are possible, too. If you need features that move force or fluids sideways, lateral extrusion lets you do that.

Here are some times when you might pick lateral extrusion:

- You want to make tricky shapes or cross-shaped pieces.

- You need parts with side openings or edge webs.

- You want hollow bodies with built-in features.

- You need parts for moving force or fluids sideways.

You see lateral extrusion in industries that need special designs and functions. This process helps you meet unique needs and make products work better.

Impact Extrusion

You use impact extrusion to make hollow parts fast and with less metal. In this process, you put a slug of metal in a die and hit it with a punch. The force pushes the metal into the die shape in one quick move.

Impact extrusion helps you save metal and get exact shapes. You often do not need extra steps because the parts come out even and smooth. The metal grains line up, so the parts are strong.

Here are some good things about impact extrusion:

- You save metal compared to cutting or casting.

- You get parts with exact size and even thickness.

- You often skip extra finishing.

- You get strong parts because of grain alignment.

- You can make many shapes and sizes.

- You work quickly and easily.

You find impact extrusion in many fields:

- Cars

- Planes

- Electronics

- Building

- Packaging

This process lets you make light and strong parts for cars, planes, and devices. You also use it for packaging, like cans and tubes. Impact extrusion gives you speed and choices, so you can meet different needs.

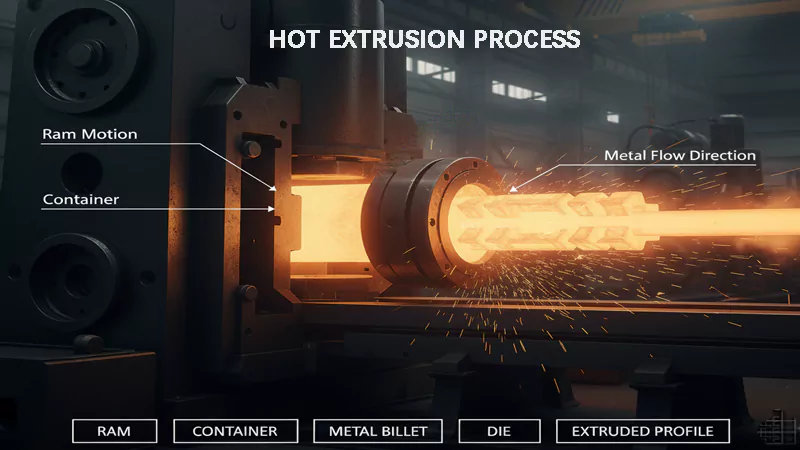

Hot Extrusion

You use hot extrusion to shape metals at high heat. In this process, you heat the billet until it gets soft and easy to push through the die. The temperature is usually between 300°C and 440°C, depending on the metal.

Hot extrusion changes how the metal acts. When you heat the billet, it bends better and moves heat faster. You also change how it carries electricity. If the temperature goes above 650 K, the metal gets softer and loses some hardness. Higher heat makes the metal carry electricity better.

Here is a table that shows how heat changes the metal:

| Temperature Range (°C) | Effect on Bending Strength | Effect on Electrical Conductivity | Effect on Thermal Conductivity |

|---|---|---|---|

| 300 | Bends better | Fewer carriers | Moves heat better |

| 440 | Bends better | Carriers move faster | Moves heat better |

You use hot extrusion for metals like aluminum, copper, and magnesium. This process lets you make strong and bendy parts. You can shape metals that are hard to work with when cold. Hot extrusion helps you get smooth surfaces and exact sizes.

Tip: If you want parts with special shapes and strong features, hot extrusion is a good pick. You can change the heat to get the best results for your project.

You see hot extrusion used in cars, planes, and buildings. This process helps you meet tough design and strength needs.

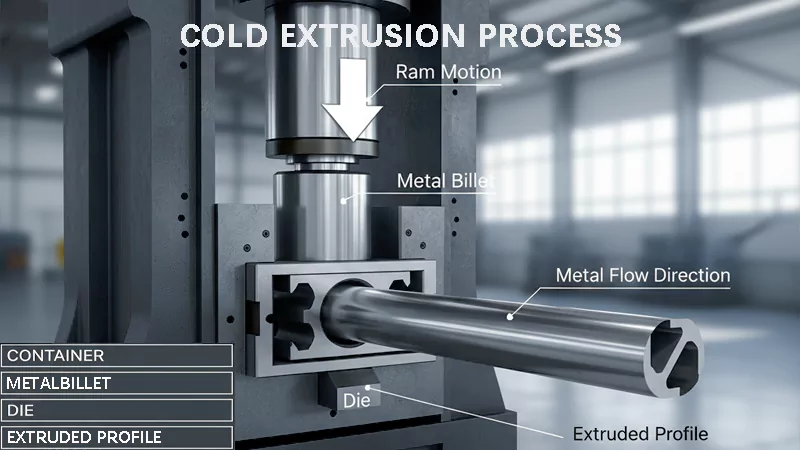

Cold Extrusion

You use cold extrusion to shape metal at room temperature. This process does not need heat. You save energy and work faster. You push metal through a die with high force. The metal changes shape but stays cool. You use cold extrusion for aluminum, copper, lead, steel, and tin.

Cold extrusion makes strong parts with smooth surfaces. The metal keeps its structure. This gives better strength and toughness. You waste less material. You can make tubes, rods, cans, and small car and electronic parts.

Cold extrusion helps you make parts fast and with less energy. You do not heat the metal, so you save money and time.

Here is a table that shows how cold extrusion and hot extrusion are different:

| Feature | Cold Extrusion | Hot Extrusion |

|---|---|---|

| Temperature | Forms material at or near room temperature | Requires preheating to a specific high temperature |

| Force Requirement | Requires greater force for deformation | Requires less force due to material pliability |

| Energy Efficiency | More energy efficient, no heating required | Higher energy consumption due to heating |

| Material Properties | Enhances microstructural properties and integrity | Improves flexibility and deformation velocity |

| Production Speed | Higher output due to faster production capabilities | Slower output compared to cold extrusion |

You use cold extrusion when you want high output and strong parts. You get better microstructure and save energy. You also make parts with smooth surfaces and exact sizes.

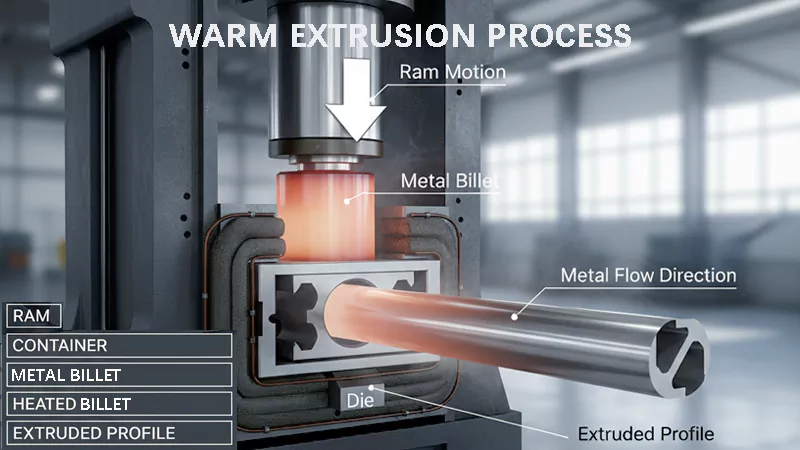

Warm Extrusion

Warm extrusion uses some heat, but not as much as hot extrusion. You heat the metal to a medium temperature, between 200°C and 500°C. The metal gets softer than in cold extrusion, but not as soft as in hot extrusion.

You use warm extrusion for aluminum and copper. You can make aluminum extruded tubing, rectangular tubing, and square tubing. You also use warm extrusion for mining tools, hardware joints, fluid and gas pipes, building frames, lighting fixtures, light poles, and heat shields.

- Aluminum extruded tubing

- Aluminum rectangular tubing

- Aluminum square tubing

You pick warm extrusion to balance strength and easy shaping. Warm temperatures help you get smooth surfaces and strong parts. You use less force than cold extrusion, so you save energy. You also get better shapes and sizes.

Warm extrusion is smart for making parts that need strength and easy shaping. You use it for building frames, mining tools, and light poles.

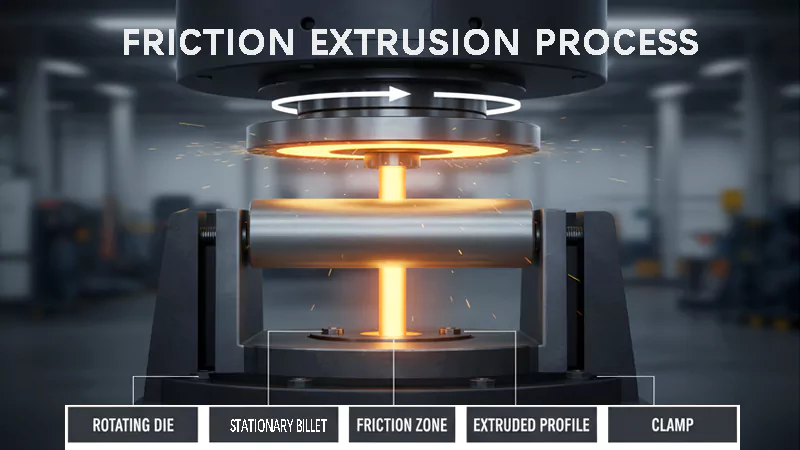

Friction Extrusion

Friction extrusion is a special metal extrusion process. You spin the metal charge while pushing it through the die. The spinning creates stress and changes the metal near the die. This makes heat inside the metal, so you do not need to preheat. You save energy and work faster.

Friction extrusion helps you weld powders together. You get better material and strong parts. The process makes fine grains, which improve the metal. You can shape metals that are hard to extrude with other methods. You also keep tiny particles because the temperature stays low.

Here is how friction extrusion works:

- You spin the metal charge next to the die.

- Stress and change happen near the die.

- Heat builds up inside the metal, so you do not need to preheat.

- You push the metal through the die and shape it.

You use less power and force than other methods. You can make fine grains and strong, energy-absorbing parts. Friction extrusion works well for magnesium alloys and tough metals.

- Lower power use and less force

- Can make fine grains from different forms

- Can shape hard-to-process materials

- Keeps tiny particles and phases

- Improves bulk properties, like energy absorption

Friction extrusion lets you make advanced parts with special features. You use it for metals that need fine grains and strong properties.

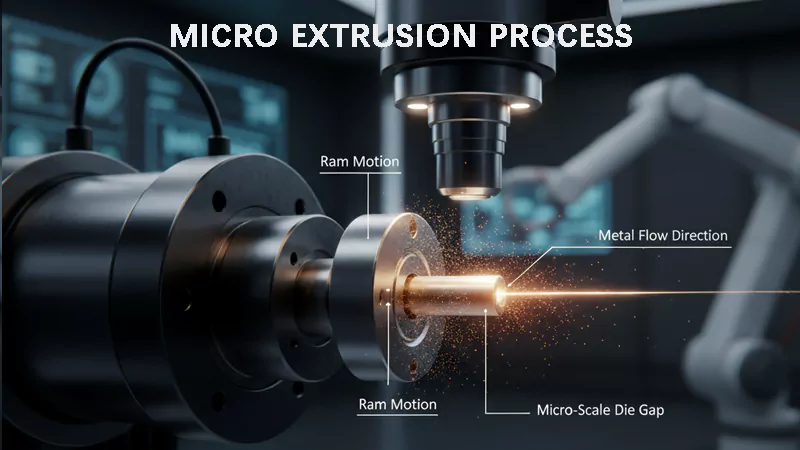

Micro-Extrusion

Micro-extrusion is a special way to shape metal. You use it to make very tiny parts that need to be exact. Micro-extrusion helps you create shapes that are only a few millimeters or micrometers wide. You push metal through a small die, just like other extrusion methods, but everything is much smaller.

You pick micro-extrusion when you need tiny, detailed parts. This process works for jobs regular metal extrusion cannot do. You can use micro-extrusion for soft metals and hard metals. You get strong, light parts with exact shapes.

Here are some main ways people use micro-extrusion:

- Medical: You make microcatheters, stents, and drug delivery devices. These parts must be very small and smooth to work inside the body.

- Electronics: You use micro-extrusion to make tiny connectors, sensors, and MEMS. These parts help devices work better and last longer.

- Microfluidics: You make microchannels, microvalves, and lab-on-a-chip devices. These tiny parts move fluids in small amounts for tests and research.

- Optics: You make micro-optical parts, lenses, and optical fibers. These parts help send light signals and improve cameras or sensors.

- Biotechnology: You make microreactors, biochips, and microarrays. These tools help study cells, DNA, and other tiny things in science.

Micro-extrusion lets you make parts smaller than a grain of rice. You can shape metal with great detail and accuracy. This process helps medicine, electronics, and science grow.

You face some big problems with micro-extrusion. Making and keeping the tools is hard. You need dies and rams smaller than a pencil tip. These tools must be perfect, with errors less than a hair’s width. You often use special machines, lasers, or electric tools to make them. Tool wear is a big problem. The small size puts more stress on the tool, so it can break or wear out faster.

You must check your tools often and replace them when needed. You also need to control the process very closely. Even a small mistake can ruin the part. You may need to work in clean rooms to keep dust and dirt away from the tiny parts.

Micro-extrusion is growing in metal extrusion. You can make parts that help save lives, power devices, and push science forward. You need skill, patience, and the right equipment to do well. If you want to work with the smallest and most advanced metal parts, micro-extrusion is the process to try.

Characteristics of Metal Extrusion

Surface Finish

You can get many kinds of surface finishes with metal extrusion. The finish depends on the extrusion type, the metal, and extra steps. Some methods make the surface smooth and shiny. Other methods give a rough or dull look. You can use special finishing steps to change how the surface looks and feels.

Here is a table that shows common finishing techniques and their effects:

| Finishing Technique | Description | Effect on Surface Finish |

|---|---|---|

| Mechanical finishes | Sanding or polishing adds texture or shine. | Can enhance gloss or create a textured surface. |

| Chemical finishes | Dipping in chemicals for etching or bright-dipping. | Produces frosted or shiny surfaces. |

| Anodizing | Using acid-based electrolyte to boost corrosion resistance. | Keeps metallic luster and allows vibrant colors. |

| Liquid coatings | Applying paints for color and protection. | Offers many aesthetic finishes. |

| Powder coating | Melting dry powder onto the metal for a tough finish. | Creates a long-lasting, textured, or glossy finish. |

You can choose a finish that fits your design. The right finish makes your product look better and last longer.

Mechanical Properties

Metal extrusion changes how strong and tough the metal is. You can make parts stronger, harder, or more bendy by changing how you extrude. Metal extrusion often makes parts last longer and work better.

Different dies and temperatures change the final properties. For example, a flat face die can make microhardness go up by 6%. It can also raise yield strength by 13%. Direct extrusion can boost microhardness by up to 15%. Adding things like graphene nanoplatelets can make compression yield strength go up by 21%.

Here is a table that shows how temperature affects strength:

| Extrusion Temperature (°C) | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Strain at Failure (%) |

|---|---|---|---|

| 250 | 321 ± 4 | 326 ± 4 | 8.8 ± 1.1 |

| 350 | Decreased | Decreased | Increased until 350, then decreased |

You can change die type and temperature to control strength and flexibility. This helps you make parts for different jobs.

Design Flexibility

Design flexibility is a key part of metal extrusion. You can make simple shapes or very tricky ones. This lets you design parts that fit your needs.

The table below shows how metal extrusion helps with design:

| Aspect | Description |

|---|---|

| Complex Profiles | You can make detailed shapes for special needs. |

| Lightweight Components | You can create parts that are light but strong. |

| Aesthetic Versatility | You can pick from many finishes to improve looks and strength. |

You see this flexibility in many industries. In cars, you can make parts that save fuel and keep people safe. In airplanes, you can make strong and light parts for better flying. In buildings, you can make structures that look good and work well.

Metal extrusion lets you try new ideas and solve hard design problems.

Dimensional Accuracy

Dimensional accuracy means how close a part is to the right size. You want each metal piece to match your design. If the size is correct, you waste less and have fewer problems. Good dimensional accuracy helps parts fit together well.

You can control accuracy by picking the right die and alloy. Some dies and metals work better than others. A good die makes parts fit together perfectly. If the die is bad, parts may be too thick or thin. Sometimes, parts are not round enough.

The table below shows how alloys and dies change accuracy:

| Alloy Type | Die Design | Dimensional Accuracy Observed | Notes |

|---|---|---|---|

| 6082 | Original Die 3 | High | Best performance in terms of accuracy |

| 7021 | Original Die 3 | High | Comparable to 6082 |

| 7021 | Die 1 & 2 | Much higher deviations | Issues with circularity, centricity, and wall thickness |

Both alloy and die design matter for accuracy. The right mix gives you good results. A poor die can cause uneven walls or off-center holes.

Here are some ways to get better accuracy:

- Choose the best die for your metal and shape.

- Check your tools often for damage or wear.

- Control the heat and speed during extrusion.

- Measure parts after making them to find mistakes early.

Tip: If you need very exact sizes, ask your supplier for help with dies and process.

Dimensional accuracy is important in many fields. In cars, parts must fit without gaps. In electronics, small mistakes can break a device. By focusing on accuracy, you save money and make better products.

Advantages and Limitations

Benefits of Metal Extrusion

Metal extrusion gives you many good things in manufacturing. You can make parts with special shapes and strong features. This process works for brittle and ductile metals. You can make lots of parts quickly. If you want tricky designs, metal extrusion lets you do more than other methods.

Here is a table that shows the main benefits:

| Benefit | Description |

|---|---|

| Complex cross sections | You can make shapes and profiles that are hard to create otherwise. |

| Material versatility | You can use both brittle and ductile materials. |

| High mechanical properties | You get strong and durable final products. |

You also get these good points:

- You can make many parts fast.

- You have more freedom with shapes.

- You can use lots of metals, even brittle ones.

Tip: Metal extrusion is great if you need parts with special shapes or strong features. You get more choices and better results.

Limitations of Metal Extrusion

There are some problems with metal extrusion you should know. Sometimes, the metal does not move evenly. This can make parts weaker in some spots. The dies used in extrusion get worn out fast. You may need to change them often. Making parts can be slower than with other methods. You might also waste more metal when cutting shapes.

Here are some common problems:

- Parts can be uneven because metal does not flow the same everywhere.

- Dies wear out quickly because they work hard.

- Making parts can be slower and waste more metal.

Note: You can fix some problems by checking your tools often and picking the best process for your job.

Applications

Typical Uses by Extrusion Type

Metal extrusion is used in lots of industries. Each extrusion type helps make different products for special jobs. You can shape metal into pipes, rods, tubes, bars, angles, and channels. These shapes are useful in building, making things, stores, and technology.

Here is a table that shows some common products and their uses:

| Product Type | Description |

|---|---|

| Pipes | Used in many different ways |

| Rods | Used for building and making things |

| Tubes | Come in many shapes for different jobs |

| Bars | Used for strong building parts |

| Angles | Used for frames and supports |

| Channels | Used in building and making things |

You see these products in lots of places. Builders use extruded metal for windows, doors, and supports. Factories use rods and bars for machines and tools. Stores use channels and angles for shelves and displays. Technology uses tubes and channels for electronics.

You can pick the best extrusion type for your project. Direct extrusion is good for long, straight shapes like rods and bars. Indirect extrusion gives smooth surfaces for parts that need to be exact. Hydrostatic extrusion helps make big or hard shapes. Lateral extrusion lets you add side holes or special features. Impact extrusion makes hollow parts quickly, like cans and tubes.

Here is a table that shows how different industries use metal extrusion:

| Industry | Application Examples | Key Requirements |

|---|---|---|

| Automotive | Aluminum parts make cars lighter | Save fuel, keep cars strong |

| Construction | Window frames, supports, and doors last long and fight rust | Stay strong, easy to build |

| Aerospace | Light parts from titanium and aluminum for planes | Less weight, work well, stay safe |

You see metal extrusion in cars, planes, and buildings. Car makers use aluminum parts to make cars lighter and save gas. Builders use extruded shapes for strong and easy frames. Planes need light and strong parts for safety and speed.

You can use metal extrusion to solve many problems. You get strong, light, and exact parts for your projects. You can choose the best process and make products that last.

Choosing an Extrusion Process

Factors to Consider

When you choose an extrusion process, you need to look at many important factors. Each factor can change how your final product turns out. You want to make sure your choice fits your needs and goals.

Here are some key things to think about:

- Cost: You should check how much money you will spend on tools, materials, and labor.

- Longevity: You want your parts to last a long time without breaking or wearing out.

- Cycle Time: You need to know how fast you can make each part.

- Recovery: You should see how much material you can reuse or recycle after making your parts.

- Energy Usage: You want to use less energy to save money and help the planet.

- Health and Safety: You need to keep workers safe and follow safety rules.

- Environmental Impact: You should think about how your process affects the air, water, and land.

- Material Properties: You need to check if your metal is strong, tough, and can handle heat.

Tip: Make a checklist of these factors before you start your project. This helps you compare different options and pick the best one.

You now know about the main types of metal extrusion. Each process has its own good points for strength, surface finish, and design. Picking the right method helps you get the best results for your project. The table below shows how things like precision, surface finish, and mold design can change how well your product works:

| Factor | Impact on Product Performance |

|---|---|

| Precision | Makes fewer mistakes and keeps things the same |

| Surface Finish Quality | Makes products look better and last longer |

| Strength and Durability | Helps products work well for a long time |

- Think about what you need and want before you pick a process.

- Talking to experts can help you choose the best method and die design for your project.

FAQ

You use metal extrusion to shape metal by forcing it through a die. This process helps you create long pieces with the same cross-section. Many industries use metal extrusion to make strong and lightweight parts.

You can extrude aluminum, copper, magnesium, and steel. Aluminum is popular because it is light and easy to shape. Copper and magnesium also work well for special uses.

You should look at your design, the metal type, and the part’s size. Think about cost, speed, and surface finish. If you need help, ask an expert for advice.

You can create rods, tubes, bars, channels, and angles. Some processes let you make hollow shapes or parts with side openings. You can design simple or complex profiles.

Yes, extrusion can make metal stronger. The process lines up the grains and removes weak spots. You get parts that last longer and work better.

You can polish, sand, or coat the metal. Anodizing and powder coating also help protect the surface and add color. These steps make your product look better and last longer.

You may see uneven flow, die wear, or surface marks. Sometimes, parts do not match the right size. You can fix these issues by checking tools and controlling the process.

You can recycle leftover metal from extrusion. Many factories melt and reuse scrap. Recycling helps you save money and protect the environment.