Press fit tolerance shows how much parts can differ to fit together tightly. Engineers use exact tolerances so parts fit well and do not break. Standards from around the world help keep assemblies safe and reliable:

- ISO 286 gives rules for sizes and tolerances. This helps makers everywhere stay consistent.

- ANSI B4.1 explains fit rules for North America. It helps companies work across borders.

- DIN 7157 helps European makers with press fit tolerance details and ways to measure.

Choosing the wrong tolerance can cause parts to fail, not last long, or be unsafe. Following standards and measuring carefully helps engineers make strong and safe fits.

Key Takeaways

- Press fit tolerance is very important. It helps parts fit tightly and safely. This stops parts from failing.

- Engineers must use rules like ISO 286 and ANSI B4.1. These rules help keep press fit designs the same.

- Picking the right tolerance stops parts from being crooked. Crooked parts can cause stress and make joints break.

- Material properties like hardness and elasticity matter a lot. They change what press fit tolerance is needed.

- Temperature changes can make parts bigger or smaller. Engineers should think about this when putting parts together.

- Using the right tools and methods is very important in the mech. It helps get the correct press fit tolerance.

- Quality control is needed to check surface finish and assembly steps. This makes sure press fit joints work well.

- Knowing how much different tolerances cost is helpful. It lets engineers balance quality and budget.

Table of Contents

Press Fit Tolerance Basics

What Is Press Fit?

A press fit is a way to join two parts by pushing one tightly into another. In mechanical engineering, a press fit happens when one part, like a shaft, is slightly bigger than the hole it goes into. The two parts stay together because of the strong friction between them. This method does not need glue, screws, or welding. The force from pressing the parts together holds them in place.

A press fit creates a strong joint by using the force of the two parts pushing against each other. The friction at the surface keeps the parts from moving.

Engineers use press fit in many machines. It helps make assemblies that last a long time. Some common examples include gears on shafts, bearings in housings, and wheels on axles. Press fit works well because it can handle heavy loads and vibrations.

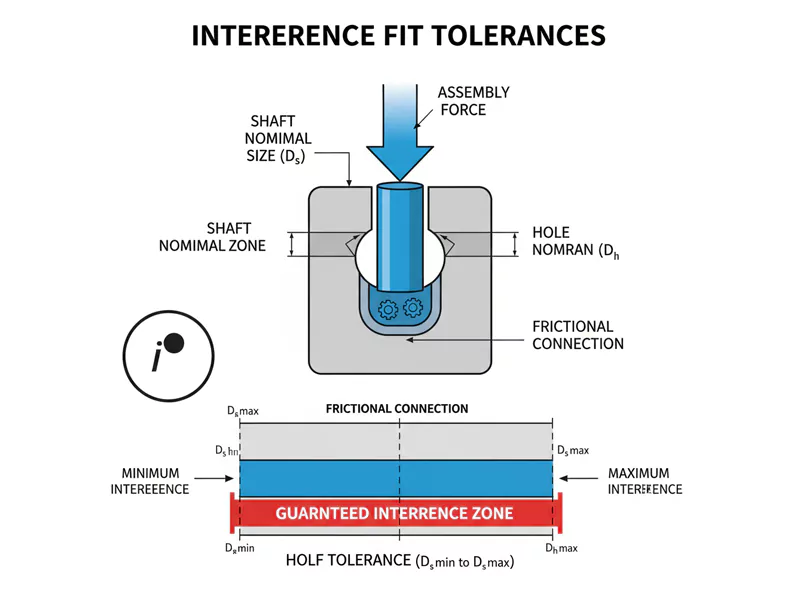

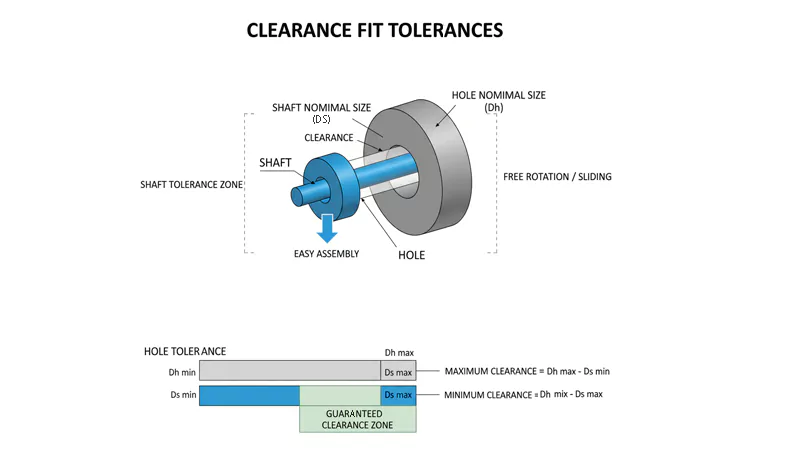

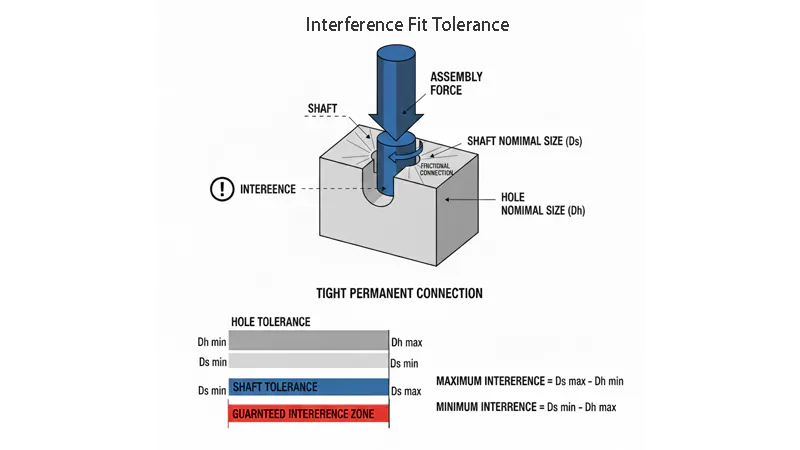

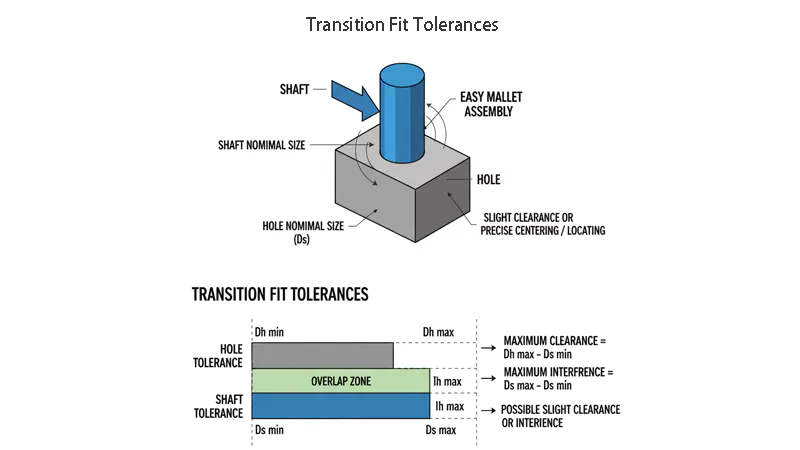

There are different types of fits in engineering. These include clearance fit, transition fit, and interference fit. Press fit belongs to the interference fit group. In this group, the parts are always slightly larger or smaller so they must be pressed together.

Why Tolerance Matters

Tolerance is the allowed difference in size between parts. In press fit, tolerance decides how tight or loose the fit will be. If the tolerance is too loose, the parts may slip or fall apart. If the tolerance is too tight, the parts may break or become damaged during assembly.

Tolerance variation plays a big role in the strength and safety of press fit assemblies. When engineers do not keep the right tolerance, the parts may not line up well. This can cause uneven stress and even joint failure. The right press fit tolerance helps the assembly last longer and work better.

- Misalignment can happen if the parts do not fit together as planned. This leads to uneven stress.

- The material of the parts affects the needed tolerance. Harder materials need a tighter fit.

- Changes in temperature can make parts expand or shrink. This also changes how the press fit works.

Engineers must choose the correct press fit tolerance for each job. They look at the material, the size of the parts, and the working conditions. This careful choice helps avoid problems and keeps machines running safely.

Press Fit Tolerance Definition

Press fit tolerance is the exact amount by which one part is made larger than the other. This difference creates a tight fit that needs force to assemble. Engineering standards call this an interference fit. The press fit tolerance makes sure the parts stay together by friction.

A press fit, also called an interference fit, is a joint where the parts hold together because of high friction at the surface. One part is always a bit bigger than the other. This positive interference is what makes the press fit work.

- Press fit tolerance means there is always interference between the parts.

- The parts cannot go together without using force.

- This makes press fit different from other types of fits, like clearance or transition fits.

Engineers use tables and charts to pick the right press fit tolerance. These tools help them match the size of the hole and the shaft. The right choice depends on the types of fits needed for the job. Press fit tolerance is key for making strong, safe, and lasting assemblies.

| Types of Fits | Description | Example Use |

|---|---|---|

| Clearance Fit | Parts slide or move easily | Door hinges |

| Transition Fit | Parts fit snugly, may need light force | Gear on shaft |

| Interference Fit | Parts need force to assemble (press fit) | Bearing in housing |

Tip: Always check the press fit tolerance before assembly. This helps avoid costly mistakes and keeps machines safe.

Standards for Press Fit Tolerance

Key Standards Overview

Engineers use standards to help design press fit joints. Standards make sure parts fit together the right way. They also help parts work as they should. Some common engineering standards are iso 286, ansi b4.1, and DIN 7157. These rules tell engineers about sizes, tolerances, and how to measure.

- iso 286 gives rules for metric fits and tolerances. It helps engineers pick the best fit for each job.

- ansi b4.1 has rules for inch-based systems. It helps makers in North America.

- DIN 7157 gives details for press fit tolerance in Europe.

Each standard explains different types of fits. Engineers use these rules to avoid mistakes. Standards also help companies work together in different countries.

Tip: Always look at the newest standards before you start a design. This helps you avoid mistakes and keeps assemblies safe.

Hole and Shaft System

The hole and shaft system is important in press fit design. Engineers use it to match the shaft size with the hole size. This system affects how parts work together. It also decides the type of fit.

- The hole and shaft system affects how parts fit together. It helps pick the right fit.

- There are different fits like clearance, interference, and transition. These fits help parts work well.

- Picking the right fit helps things like alignment pins and bearings work better.

Engineers use the hole and shaft system to choose how tight or loose the fit is. They check the size difference between the hole and the shaft. This choice affects how well parts stay together and move.

Interference and Class V Fits

Interference fits and Class V fits are important for press fit jobs. These fits make a strong bond by using force and friction. Engineers use them when they want a joint that will not come apart.

| Characteristic | Interference Fit | Class V Fit |

|---|---|---|

| Definition | Parts are made to press tightly together | Needs a lot of force to put together |

| Friction | Friction keeps parts from moving | Very strong and stays together |

| Application Example | Bearings on shafts | Flywheels on crankshafts |

Engineers use interference fits for things like bearings on shafts and wheels on axles. These fits need the right tolerance to be safe and last long.

- A true interference fit means the shaft is bigger than the hole.

- Engineers press the parts together or use heat and cold to fit them.

- These fits make a bond that does not come apart. They can replace bolts or screws.

Standards like iso 286-1 and ANSI B4.2 have charts and tables to help pick the right fit. Engineers use these tools to match the hole and shaft system to each project.

Note: Picking the right fit and following standards helps stop joint problems and makes assemblies last longer.

Types of Fits

Clearance Fit

Engineers pick clearance fit when they want parts to move easily. The hole is always a little bigger than the shaft. This space lets the parts slide or turn without sticking. Machines that need smooth movement use clearance fit often.

Clearance fit lets parts move but keeps them together. It is important in many engineering jobs. For example, pivot joints use clearance fit. The pin turns inside the frame but does not fall out.

There are different clearance fits for special jobs. Some common types are:

- Loose Running Fit: Used when free movement matters most.

- Free Running Fit: Lets parts move easily with little friction.

- Close Running Fit: Used when parts need more control but still move.

- Sliding Fit: Lets parts move with a gentle push.

- Location Fit: Keeps parts in place but allows some movement.

Clearance fit is used in rotating machines like shafts in bearings. It helps when parts need to be removed or replaced easily. Engineers choose clearance fit to stop jamming or sticking.

Tip: Always check the size difference in clearance fit. This makes sure parts move the way you want.

Interference Fit

Interference fit makes a strong bond between two parts. In this fit, the shaft is bigger than the hole. Engineers use force to put the parts together. The tight grip comes from pressure between the surfaces.

Interference fit holds parts together without glue or screws. It works well in bearings and wheel assemblies. The strong bond keeps parts from slipping or coming apart.

The table below shows how interference fit compares to other fits:

| Fit Type | Holding Force | Application Examples |

|---|---|---|

| Interference Fit | Strong mechanical bond | Bearing installations, wheel assemblies |

| Clearance Fit | Free movement between parts | Rotating machinery components |

| Transition Fit | Slight interference or clearance | Precise positioning |

Engineers use interference fit when they need a joint that stays tight. This fit is common in heavy machines and places where safety is important.

Transition Fit

Transition fit is between clearance fit and interference fit. Sometimes the parts have a small gap. Sometimes they press tightly together. Engineers use transition fit for precise positioning. They do not need a very tight or very loose fit.

Transition fit helps with alignment and load transfer. It works well in assemblies that need strength and easy assembly. The table below shows the good and bad sides of transition fit:

| Advantages of Transition Fit | Disadvantages of Transition Fit |

|---|---|

| Controlled interference makes assembly smooth and reduces damage. | Limited tolerance range makes fitting harder and may cost more. |

| Better alignment helps machines work well and lowers misalignment. | More risk of galling from friction at some points. |

| Good load transfer puts weight in the right place and lowers failure risk. | N/A |

| Less vibration and noise helps keep machines stable. | N/A |

Transition fit gives engineers more control over how parts fit. It lowers the risk of misalignment and helps machines run well. But the small tolerance range can make fitting harder and may raise costs.

Factors Affecting Press Fit

Material Properties

Material properties are very important for press fit tolerance. Hardness and elasticity decide how much force is needed. Softer materials let parts fit together more easily. They can change shape when pressed, so the fit can be looser. Harder materials do not bend much. They need a tighter fit to stay strong.

- Softer materials let parts change shape when pressed. This helps them stay in place.

- Harder materials do not bend or change shape much. The fit must be exact for them.

- Elasticity shows how much a material can stretch or squeeze. Materials with high elasticity can handle more stress and keep the joint stable.

Engineers look at these things before picking the right tolerance. If the material is hard or tricky, they use tighter tolerances. Softer materials are more flexible but may not hold heavy loads well. The material also changes how parts are made. Some are easy to machine, but others need special tools.

Tip: Always check hardness and elasticity before setting press fit tolerance. This helps stop problems during making and putting parts together.

Surface Finish

Surface finish changes how well press fit works. Rough or smooth surfaces change how parts touch and hold. Engineers measure surface finish to make sure parts fit as planned.

| Aspect | Explanation |

|---|---|

| Role of Surface Finish | Changes how much pressure and strength the joint has. |

| Variations in Roughness | Changes friction and how well parts stay together. |

| Smoothing Effects | Pushing parts together can smooth rough spots and change the surface. |

| Measurement Sensitivity | Tall rough spots can make it hard to measure pressure right. |

Smooth surfaces help parts slide together. But they may not grip as well. Rough surfaces grip better but can hurt the parts. Too much roughness can make assembly hard. Engineers must balance the surface finish for the right fit.

- The amount of interference decides if the fit will work.

- Not enough interference makes a weak joint.

- Too much can bend parts and make assembly hard.

- Measuring and controlling surface finish keeps tolerance right.

Ways like grinding, polishing, or machining change the surface finish. Each way gives a different result. Engineers pick the best one for the job.

Temperature Effects

Temperature changes can change press fit tolerance. Metals get bigger when hot and smaller when cold. Plastics get even bigger with heat and can bend easily. If engineers forget about temperature, the joint may fail.

- Heat and cold change the size of parts. This can make the fit tighter or looser.

- Parts made from different materials may fit differently as temperature changes.

- Quick temperature changes can build up stress. This can hurt the joint or make it come apart.

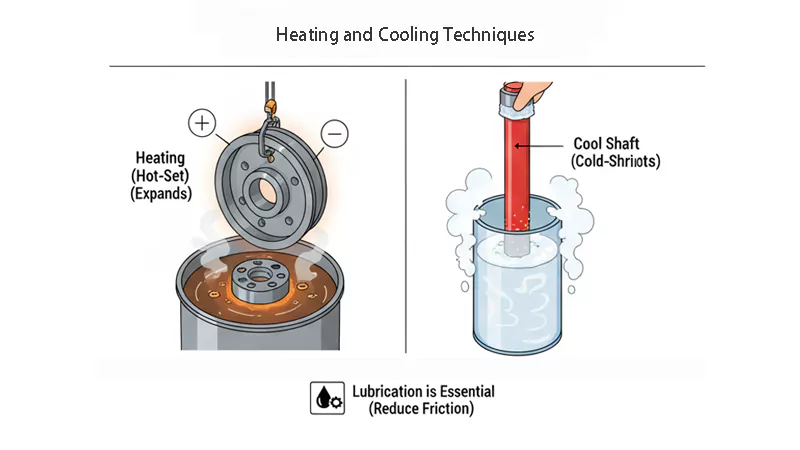

Engineers think about where and how the parts will be used. They use special ways to control temperature during assembly. Sometimes they cool one part and heat the other to make fitting easier. When the parts go back to normal temperature, the fit gets tight.

Note: Always plan for temperature changes when setting press fit tolerance. This keeps assemblies safe and strong during making and use.

Manufacturing Methods

How parts are made affects how well press fit tolerances work. Engineers pick a method based on the material, part size, and needed accuracy. Each way has good and bad points. Some ways are better for metal, while others work for plastic or special shapes.

| Manufacturing Method | Description |

|---|---|

| Machined Fits: Boring vs. Reaming | Reaming works well for H7 holes. Grinding is used for very tight fits. Drills are not good for final sizes. |

| Injection Molded or SLS Plastic Press Fits | Molded holes can change by about ±0.1 mm. Extra machining is needed for important fits. |

| Die Cast Press Fit Guidelines | Holes need drilling and reaming to be accurate. Brittle materials limit how tight the fit can be. |

| Thermal Methods | Cooling shafts and heating hubs make assembly easier. Parts must warm up slowly to stop stress. |

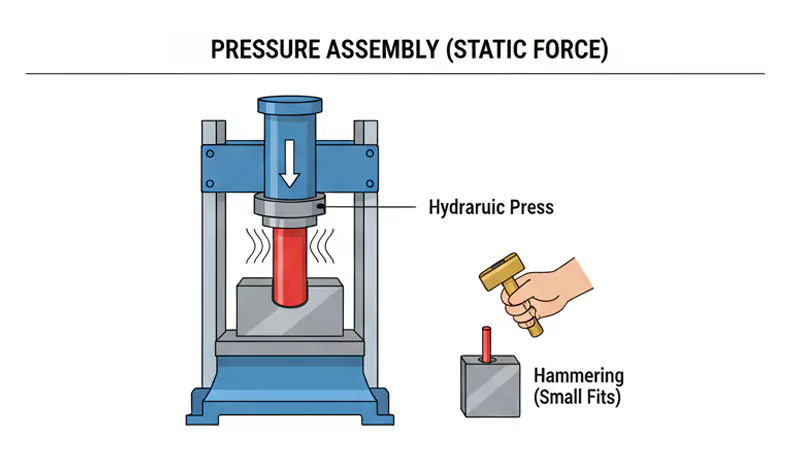

| Press Fit Assembly Methods | Big or tight fits need hydraulic presses. Small or loose fits can use hand presses. |

Machined fits use boring and reaming to make holes with close sizes. Reaming is picked for H7 holes because it gives a smooth finish. Grinding is best for very tight fits. Drills do not make holes the right size, so engineers do not use them for press fit holes.

Plastic parts made by injection molding or SLS can change size a little. Molded holes may be off by ±0.1 mm. Engineers often machine these holes after molding to get the right fit. This keeps the press fit strong.

Die casting makes metal parts with tricky shapes. The holes may not be accurate enough for press fits. Engineers drill and ream these holes after casting. Die cast parts can break easily, so the fit cannot be too tight.

Thermal methods help put parts together. Cooling the shaft and heating the hub makes fitting easier. The parts must warm up slowly. Fast changes can cause stress and damage.

Press fit assembly uses different tools. Big or tight fits need hydraulic presses. Small or loose fits can use hand presses. Engineers choose the right tool to stop damage and keep the joint strong.

Tip: Always pick the right method for the material and fit. This keeps the press fit safe and long-lasting.

Engineers must think about how each way changes the final tolerance. Good planning and the right tools help stop mistakes. Using the best method makes strong and reliable press fit joints in many machines and products.

Calculating Press Fit Tolerance

Basic Steps

Engineers follow a clear process to calculate press fit tolerance. This process helps them make sure parts fit together tightly and safely. Here are the main steps:

- Identify the Fit Type

Engineers first decide if the joint needs a clearance, transition, or interference fit. Press fits always use interference fits. This means the shaft is slightly bigger than the hole. - Check Material Properties

They look at the materials for both parts. Harder materials need tighter tolerances. Softer materials can handle more change in size. - Measure Part Sizes

Engineers measure the exact size of the hole and the shaft. They use precise tools like micrometers and calipers. - Select the Tolerance Range

They choose the right tolerance range based on the fit type and material. This range tells them how much bigger the shaft should be than the hole. - Calculate the Interference

They subtract the hole size from the shaft size. The result is the interference value. This value must match the recommended range for a safe press fit. - Adjust for Temperature and Surface Finish

Engineers think about how temperature changes and surface finish will affect the fit. They may adjust the tolerance to keep the joint strong.

Tip: Always double-check measurements before assembly. Small mistakes can cause big problems in press fit joints.

Using Standards and Charts

Engineering standards and tolerance charts help engineers pick the right press fit values. These tools make the process easier and safer.

- Standards like ISO 286, ANSI B4.1, and DIN 7157 give clear rules for fits and tolerances. They show which sizes work best for each type of fit.

- Tolerance charts list the allowed size ranges for holes and shafts. Engineers use these charts to match the right shaft to the right hole.

- Fit designations (like H7/g6 or H7/p6) tell engineers if a joint will have a gap or an overlap. This is important for press fit because the parts must overlap for a tight fit.

- Charts also show the amount of interference needed for different materials and part sizes. This helps engineers avoid joints that are too loose or too tight.

| Fit Type | Description | Example Chart Designation |

|---|---|---|

| Clearance Fit | Parts have a gap | H7/h6 |

| Transition Fit | Parts may have gap or overlap | H7/k6 |

| Interference Fit | Parts always overlap (press fit) | H7/p6, H7/u6 |

Engineers often use charts from standards to check their calculations. For example, if a shaft measures 20 mm and the chart says the hole should be 19.97 mm for an H7/p6 fit, the interference is 0.03 mm. This value falls within the safe range for many press fit applications.

Note: Using the right standard and chart helps engineers make strong, reliable press fit joints every time.

Assembly and Control

Press Fit Assembly Methods

Engineers have different ways to put press fit joints together. Each way has its own good points and best uses.

Manual presses are good for small jobs. They do not cost much and are simple to use. But they are slow and may not always give the same result. Pneumatic presses use air to push parts together. They make results more even than manual presses. Still, they are not as exact as servo presses. Servo presses use motors and sensors. They measure force and distance very well. This makes them great for big jobs where every joint must be perfect.

Engineers also use press-fit contacts in electronics. These contacts fit tightly in PCB holes. They make strong electrical links without using solder. Press-fit contacts work on both sides of a PCB. This helps make designs smaller. They handle heat better than solder joints. They also stop problems like dry joints or cracks.

Tip: Engineers pick servo presses when they need very exact and repeatable results.

Heating and Cooling Techniques

Heating and cooling help engineers put press fit parts together more easily. These ways use temperature changes to make fitting easier. Cooling a shaft makes it shrink. Heating a hole makes it get bigger. This makes the fit loose for a short time. The shaft slides into the hole with less force. When the parts go back to room temperature, the fit gets tight again.

A common way uses liquid nitrogen to cool a part. The cold makes metal shrink. This helps take out or put in a part that is too tight at normal temperatures. Heating and cooling keep parts safe from damage during assembly, especially when the interference is big.

Note: Always pick materials that expand and shrink at the same rate. This stops problems when the temperature changes.

Quality Control

Quality control makes sure every press fit joint is safe and works well. Engineers follow steps to check the assembly. First, they pick materials that expand and shrink the same way. This keeps the fit steady when temperatures change. Next, they use lubrication to make assembly easier. Lubrication also stops scratches or damage. They watch force and distance during assembly. Sensors in servo presses help track these numbers. This makes sure each joint meets the right standard.

Engineers also look at the finished joints. They check for cracks, gaps, or other issues. Good quality control helps machines last longer and stay safe.

Remember: Careful assembly and strong quality checks make press fit joints strong and reliable.

Applications of Press Fit

Automotive

Automotive engineers use press fit in many car parts. They push connector pins into special holes on a printed circuit board (PCB). This makes a strong connection with low resistance. The press fit part of the pin is bigger than the hole. When the pin goes in, it bends a little. This bending makes a cold weld inside the hole. The weld keeps air out and stops rust.

- Press fit connections help keep cars safe and steady.

- These connections work well when there is shaking or heat.

- Car PCBs use press fit to control many things.

- Press fit connectors do not need solder and are very reliable.

- They can handle tough places, shocks, and shaking.

Engineers follow these steps:

- Put the connector pin into the special hole.

- The pin bends as it goes in and fits tightly.

- The cold weld forms and keeps the connection strong.

This way, each hole in the PCB holds the pin tight. Press fit lets people build things fast and makes good electrical contact.

Aerospace

Aerospace makers need very exact press fit sizes. Engineers work with holes that must be very accurate. Even a tiny change in hole size can hurt safety or how well a plane part works.

| Tolerance Size | Why It Matters in Aerospace |

|---|---|

| 0.0005″ | Needed for strong mechanical press fit |

| 0.0002″ | Makes assembly even and lowers wear |

| 0.0001″ | Keeps parts working well for a long time |

- Engineers use careful machines to make sure holes match pins.

- Tolerances bigger than 0.001″ may not work for some plane parts.

- Very tight tolerances keep press fit joints strong during flight.

Plane parts face lots of stress and heat changes. The hole must hold the pin or shaft tight so it does not get loose. Engineers check every hole to meet strict rules.

Consumer Products

Press fit is important in making things people use every day. Many products use press fit because they do not need space for welding or soldering. This helps designers make new shapes and features. Each hole in plastic or metal can hold a pin or shaft without extra stuff.

- Press fit joints help lower costs by using less material and work.

- The process stops mistakes from filler or human error.

- Products work better because each hole holds the part tight.

Makers use press fit in toys, electronics, and small machines. The hole’s size and shape help keep things simple and strong. Press fit makes building products fast and helps avoid mistakes.

Tip: Engineers always check the size and smoothness of each hole to make sure the press fit works right.

Impact on Engineering

Reliability

Reliability means parts must fit together well. Engineers use press fit tolerance to keep assemblies strong. This helps machines last longer. Picking the right tolerance stops the shaft and hole from slipping or breaking. The way these parts fit affects how machines work every day. Good press fit tolerance helps make sure assembly is exact. This is important for stable machines and long life.

The fit between shaft and hole changes how well things work. It also affects cost. Accurate tolerance lets engineers get the fit they want. This is needed for good assembly and function. Engineers check sizes to avoid mistakes. Even a small error can break a shaft or stop a machine. Reliable fits help companies make products people trust. Following standards lowers the chance of joint failure. It keeps machines safe.

- Engineers always measure the shaft and hole before putting them together. This makes sure the fit matches the plan.

Performance

Performance gets better when parts fit as planned. Engineers use press fit tolerance to control how shaft and hole work together. Tolerance changes how well the assembly works. If the fit is too loose, the shaft may move or wear out. If it is too tight, parts may break or get damaged. Knowing about tolerance helps engineers design and make good parts.

Tolerance is important for press-fit assemblies to work right. It helps parts match the design and makes joints reliable. Bad tolerances can cause problems, wear, or even big failures. Managing tolerance is very important.

Tolerance in press fit makes sure parts meet the needed requirements. It keeps the joint strong. Tolerance sets the biggest and smallest size for a part. This helps parts fit together smoothly. Good tolerance makes the assembly strong and able to carry loads. It also helps with alignment. Press fit works well because of friction between the parts. Surface roughness changes friction and affects how the joint works.

- Engineers use size limits to guide their work. Good fits help machines run smoothly. The shaft must fit the hole for the assembly to work. Engineers test the fit so the shaft does not slip or make noise. They also check for shaking and wear. Good fits help machines last longer and work better.

Cost

Cost changes when engineers pick press fit tolerance. Tighter tolerances need more work and special tools. This makes parts cost more to make and put together. The table shows how different tolerance grades change cost:

| Tolerance Grade | Variation (mm) | Cost Impact (CU per 1000 units) |

|---|---|---|

| IT10 | ± 0.14 | Baseline (no finish machining) |

| IT7 | ± 0.03 | 800 CU (twice as much) |

| IT6 | ± 0.02 | 2400 CU (three times as much) |

Engineers balance cost and quality when picking fits. They use rules to decide how tight the shaft and hole should be. Very tight tolerances cost more for machines and checks. Looser fits save money but may not be as reliable. Engineers look for the best mix to keep products strong and not too expensive.

- Engineers plan for cost by picking the right fits and size limits for each job.

Press fit tolerance helps parts fit and work well together. Picking the right tolerance makes assembly better and cuts down on waste. It also makes things more reliable. The table below shows the main ideas:

| Key Point | Explanation |

|---|---|

| Importance of Tolerances | The right tolerance keeps things working as they should. |

| Impact on Assembly | Tolerances change how parts fit and work. This affects how well things last. |

| Management Benefits | Managing tolerance well saves money and helps products last longer. |

- Watch the process steps carefully.

- Test and check tolerances during the project.

- Compare tolerances to how the assembly really works.

Learning all the time and working together helps engineers pick better tolerances. Looking at designs early and knowing about materials makes products stronger and safer.

FAQ

Press fit tolerance means there is a size difference between two parts. Engineers use this difference to make a tight fit. The right tolerance keeps parts together without glue or screws.

Engineers use standards to help parts fit the right way. Standards like ISO 286 and DIN 7157 show the best sizes. This helps keep assemblies safe and working well.

Precision machining lets engineers make parts with exact sizes. This lowers mistakes and helps shafts and holes fit better. Good machining makes joints stronger and safer.

Temperature changes can make metal parts get bigger or smaller. Engineers plan for these changes to keep the fit tight. They may heat or cool parts during assembly.

Engineers use calipers, micrometers, and gauges to check part sizes. These tools help them see if the shaft and hole match the needed tolerance.

Engineers use press fit in cars, planes, and electronics. Press fit connects gears, bearings, and pins. It makes products strong and easy to put together.

Surface finish changes how parts touch and hold each other. Smooth finishes help parts slide together. Rough finishes grip more but can hurt the parts.

Tighter tolerances need more careful machining. This takes more time and special tools. The cost goes up, but the parts fit better and last longer.