You sometimes need a material that is strong and easy to work with. The 416 stainless steel properties are special because you can machine it more easily than most other stainless steels. The table below shows its machinability rating is 110%. This is much higher than other types. You also get good tensile strength, yield strength, and hardness. The chart shows these features. These properties of 416 stainless steel help you pick materials that work better. They also help save time when machining and lower costs.

Key Takeaways

- 416 stainless steel is easy to machine. It is easier to cut and shape than most other stainless steels.

- This steel has good tensile strength. It also has good yield strength. It works well for parts that need to be strong.

- The chemical makeup, especially the sulfur, helps machinability. But it can make corrosion resistance lower.

- Heat treatment can make 416 stainless steel harder and stronger. This lets you change its properties for your needs.

- 416 stainless steel can handle mild corrosion. But it does not work well in tough places like the ocean or chemical plants.

- Use 416 stainless steel for things like screws, valves, and machine parts. These need careful machining.

- Always think about what your project needs. Check if you need corrosion resistance and strong mechanical properties before picking materials.

- If you need better corrosion resistance, try 304 or 316 stainless steel. These are better for wet or salty places.

Table of Contents

416 Stainless Steel Properties

Overview

Key Features

When you look at 416 stainless steel, you see many good things.

- The martensitic structure makes it magnetic and you can make it harder.

- It is free-machining, so you can cut and shape it easily and quickly.

- This steel has both strength and is easy to machine, which is not common.

- 416 stainless steel also resists wear and can handle some corrosion.

- You can use this alloy for parts that need careful shaping and steady performance.

Alloy Type

416 stainless steel is part of the martensitic group. You can heat treat this steel to make it harder and stronger. The sulfur in it helps you machine it more easily. You can use 416 stainless steel when you need strong metal that is also easy to work with.

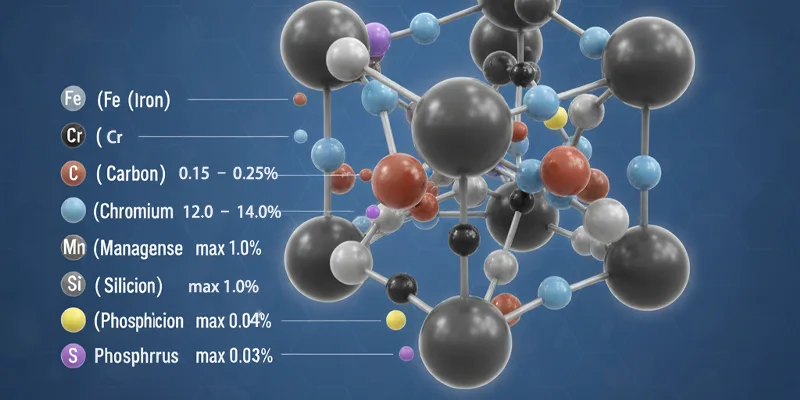

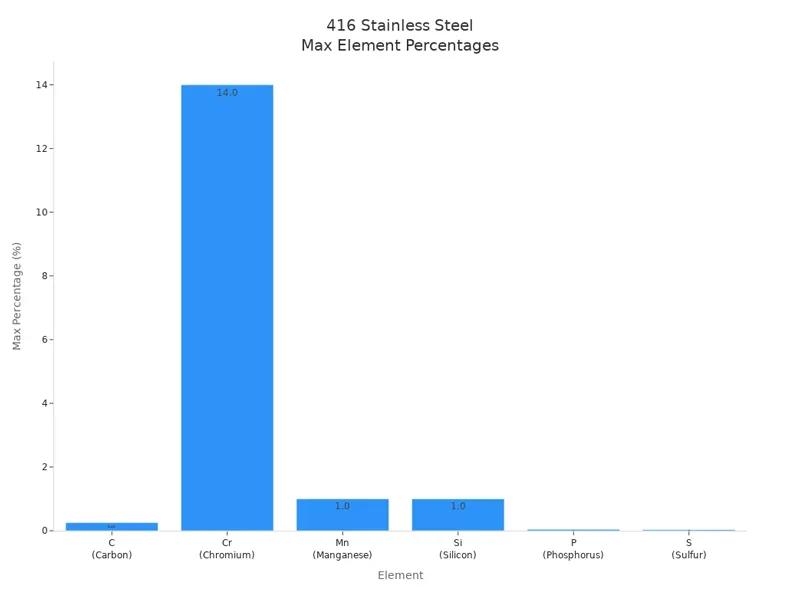

Chemical Composition

Chromium Content

Chromium is very important in 416 stainless steel. This steel has between 12.0% and 14.0% chromium. Chromium helps stop rust and protects the steel from corrosion. It also helps keep the martensitic structure. This gives you steel that is strong and can handle mild conditions.

Sulfur and Other Elements

Sulfur is another important part of this steel. 416 stainless steel has up to 0.03% sulfur. This makes it easier to machine. There are also small amounts of carbon, manganese, silicon, and phosphorus. Each one helps the steel work better. The table below shows what is in the steel:

| Element (Symbol and Name) | Percentage Range (%) |

|---|---|

| C (Carbon) | 0.15 – 0.25 |

| Cr (Chromium) | 12.0 – 14.0 |

| Mn (Manganese) | 1.0 max |

| Si (Silicon) | 1.0 max |

| P (Phosphorus) | 0.04 max |

| S (Sulfur) | 0.03 max |

Each element changes how 416 stainless steel works. The mix makes it easy to machine and strong for many jobs.

Tip: Always check what is in 416 stainless steel before you use it. This helps you pick the right material for your project.

Physical and Thermal Properties

It is also good to know about the physical and thermal properties. The density is 0.282 lb/in³ (7.80 g/cm³). The modulus of elasticity is 29.0 x 10³ KSI (200 x 10³ MPa). The specific heat is 0.110 BTU/lb-°F (480 J/kg-K). The thermal conductivity is 172.8 BTU-in/hr-ft²-°F (30 W/m-K) at 200 °F. The mean coefficient of thermal expansion is 5.50 µin/in-°F (9.90 µm/m-°C) at 32-212 °F.

| Property | Value |

|---|---|

| Density | 0.282 lb/in³ (7.80 g/cm³) |

| Modulus of Elasticity | 29.0 x 10³ KSI (200 x 10³ MPa) |

| Specific Heat | 0.110 BTU/lb-°F (480 J/kg-K) |

| Thermal Conductivity | 172.8 BTU-in/hr-ft²-°F (30 W/m-K) at 200 °F |

| Mean Coefficient of Thermal Expansion | 5.50 µin/in-°F (9.90 µm/m-°C) at 32-212 °F |

This steel can handle heat and pressure well. These 416 stainless steel properties make it a smart pick for parts that face heat or changing loads.

Mechanical Properties

Tensile Strength

Typical Values

When you choose 416 stainless steel, you get a material with solid mechanical properties. The tensile strength tells you how much pulling force the steel can handle before it breaks. For 416 stainless steel, the minimum tensile strength is 75 ksi (517 MPa). This value puts it in the same range as other martensitic stainless steels, but you also get the benefit of high machinability. You can see the main mechanical properties in the table below:

| Property | Value |

|---|---|

| Tensile Strength (ksi) | 75 |

| Yield Strength (ksi) | 40 |

| Elongation in 2 inches (%) | 30 |

| Reduction of Area (%) | 65 |

| Brinell Hardness | 155 |

You can rely on these numbers when you need a strong and easy-to-machine material. The high machinability of 416 stainless steel makes it a top choice for parts that need both strength and quick production.

Factors Affecting Strength

You can change the tensile strength of 416 stainless steel by using different heat treatments. When you harden and temper the steel, you boost its strength and hardness. The amount of chromium and carbon in the steel also plays a big role. More chromium and carbon can make the steel stronger and harder. If you only harden the steel, it may become brittle. When you temper it after hardening, you improve toughness and ductility. This balance helps you get the right mix of strength and flexibility for your project.

Note: Always consider the heat treatment process. Hardening increases strength, but tempering is key for toughness and impact resistance.

Yield Strength

Standard Values

Yield strength shows you how much force the steel can take before it starts to bend or change shape. For 416 stainless steel, the standard yield strength is 40 ksi (276 MPa) at minimum. You can use this value to decide if the steel will hold up under pressure in your application.

| Property | Value |

|---|---|

| Yield Strength | 40 KSI min (276 MPa min) |

You get a reliable material that resists bending and keeps its shape, even when you use it in tough jobs.

Hardness

Hardness Ratings

Hardness tells you how well the steel resists dents and scratches. 416 stainless steel gives you different hardness levels based on how you treat it. In the annealed state, you get a Rockwell hardness of B82. If you harden the steel, you can reach about 20RC (100RB) in the as-quenched state. These ratings help you pick the right condition for your needs.

| Condition | Rockwell Hardness |

|---|---|

| Annealed | B82 |

- In the hardened state, you can reach around 20RC (100RB).

You can also use heat treatment to adjust the hardness. Full annealing improves machinability and formability. Hardening gives you maximum hardness and tensile strength, but it lowers ductility. Tempering reduces brittleness and increases toughness and ductility.

Tip: Match the hardness level to your application. For parts that need to resist wear, use the hardened condition. For parts that need shaping or forming, use the annealed condition.

416 stainless steel stands out because you can control its mechanical properties with heat treatment. You get high machinability, good strength, and the right hardness for many jobs.

Machinability

Machining Performance

You want a material that makes your job easier and faster. 416 stainless steel stands out because you can machine it better than most other stainless steels. The high sulfur content in 416 stainless steel helps you get smooth cuts and better chip control. This means you spend less time changing tools and cleaning up after machining. You also see longer tool life, which saves you money and keeps your machines running.

When you use 416 stainless steel, you notice that cutting speeds are higher. You can produce more parts in less time. This makes 416 stainless steel a top choice for high-volume production. You get precise shapes and clean finishes, which is important for parts that need tight tolerances.

Tip: If you want to reduce tool wear and improve efficiency, choose 416 stainless steel for your machining projects.

You should know that the extra sulfur in 416 stainless steel can lower its corrosion resistance a bit. You need to balance machinability with the environment where you use the part. For most jobs, the benefits of easy machining outweigh the small drop in corrosion resistance.

Ductility and Toughness

Elongation

Ductility tells you how much a material can stretch before it breaks. 416 stainless steel gives you moderate ductility, which means you can bend or shape it without cracking. You see elongation values between 10% and 20% in the annealed condition. This range lets you form parts that need some flexibility but still hold their shape.

| Property | Condition | Value | Unit |

|---|---|---|---|

| Elongation | Annealed | 10 – 20% | % |

If you need to shape or bend 416 stainless steel, you should use it in the annealed state. This helps you avoid cracks and get the best results.

Impact Resistance

Toughness shows you how well a material can handle sudden shocks or impacts. 416 stainless steel has lower toughness than some other stainless steels, but it still performs well in many jobs. At -40 °C, you see an impact strength of 27 Joules (20 ft-lbf). This means 416 stainless steel can take a hit without breaking, but you should avoid using it in places with heavy impact or extreme cold.

| Property | Condition | Value | Unit |

|---|---|---|---|

| Impact Strength | -40 °C | 27 J | 20 ft-lbf |

Note: If your project needs high toughness, you may want to look at other stainless steel grades.

Wear and Fatigue

Abrasion

Wear resistance tells you how well a material stands up to rubbing or scraping. 416 stainless steel has lower wear resistance than some other martensitic stainless steels. You can use it for parts that face light to moderate wear, but it may not last as long in heavy-duty jobs. The hardness of 416 stainless steel ranges from 30 to 40 HRC, which gives you decent protection against abrasion.

| Stainless Steel Grade | Wear Resistance | Hardness (HRC) |

|---|---|---|

| Grade 416 | Lower | 30-40 |

| Grade 420 | Higher | 55+ |

If you need more wear resistance, you should consider other grades like 420 stainless steel.

Fatigue Life

Fatigue life measures how long a material lasts when you bend or twist it many times. 416 stainless steel has lower fatigue life compared to other martensitic grades. You can use it for parts that do not face constant stress or repeated loading. For jobs with high fatigue demands, you may want to choose a different material.

| Stainless Steel Grade | Fatigue Life |

|---|---|

| Grade 416 | Lower |

| Grade 420 | Higher |

Tip: Always match the mechanical properties of 416 stainless steel to your project needs. If you need high fatigue resistance, look for other options.

You get a good balance of machinability, ductility, and moderate wear resistance with 416 stainless steel. You can use it for many jobs, but you should check if its mechanical properties fit your requirements.

Chemical Properties

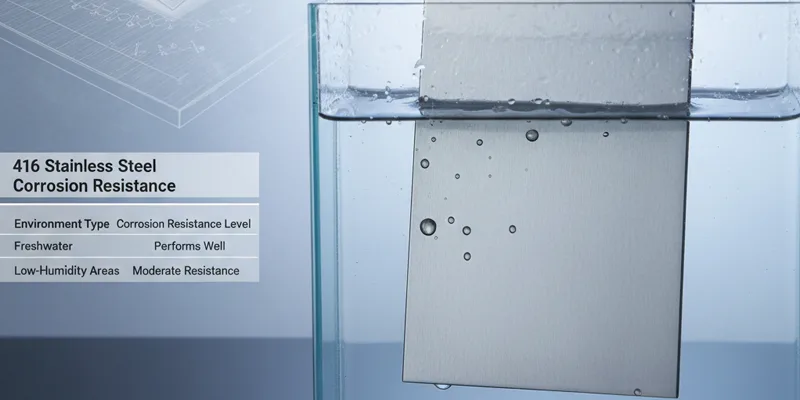

Corrosion Resistance

Mild Environments

You might want to know if 416 stainless steel can resist rust. In places that are not too harsh, this steel does a good job. It works well in areas with little moisture or in fresh water. Chromium in the steel makes a thin layer on top. This layer helps stop rust from starting. You get good results where there is not much salt or strong chemicals.

Here is a table that shows how 416 stainless steel acts in different places:

| Environment Type | Corrosion Resistance Level |

|---|---|

| Low-Humidity Areas | Moderately Resistant |

| Fresh Water | Performs Well |

| Mildly Corrosive | Suitable |

- 416 stainless steel works for mild corrosion like fresh water.

- It has moderate resistance, so it is good in dry places.

Tip: Use 416 stainless steel for machine parts, shafts, or fasteners that do not touch harsh chemicals or saltwater.

Limitations

It is important to know what 416 stainless steel cannot do. This steel does not last long in salty or tough places. Sulfur in the steel makes it easy to cut, but it also lowers its resistance to rust. In wet, salty, or chemical-filled places, the steel can rust or get pits fast. Do not use it in the ocean or in factories with lots of chlorides.

| Environment Type | Corrosion Resistance Level |

|---|---|

| Chloride Exposure | Highly Susceptible |

| Saline Environments | Prone to Pitting |

| Marine Conditions | Not Suitable |

| High Humidity | Less Resistant |

- 416 stainless steel can get pits and crevice corrosion in salty places.

- It does not resist rust as well as 304 or 316 stainless steel because it has more sulfur.

416 stainless steel does not resist rust as well as 304 or 316 grades. The sulfur can also cause trouble if you try to weld it. Cracks may show up, and the welded part may get weak. Do not use this steel for jobs that need to be very tough or take strong hits.

Note: Always check where you will use 416 stainless steel. If you need better rust resistance, pick another stainless steel grade.

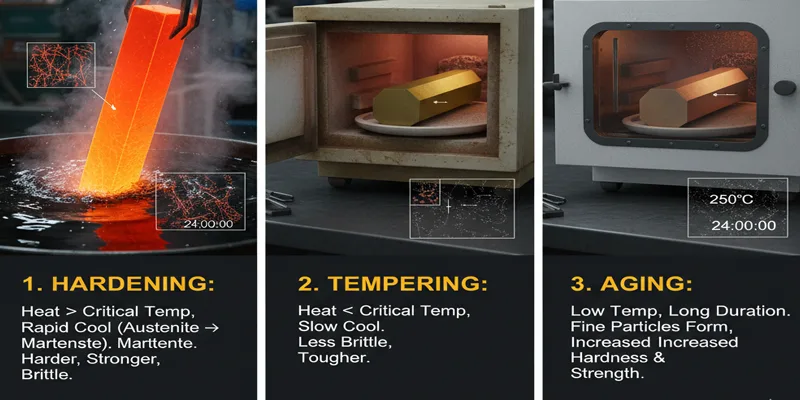

Heat Treatment

Hardening

You can make 416 stainless steel stronger and harder with heat. To harden it, you heat it up high and then cool it fast. This changes the inside from austenite to martensite. The steel gets much harder and stronger, but it can also break more easily.

- Hardening: Heat above a certain point and cool fast. This makes it harder and stronger.

- Tempering: Heat to a lower point and cool slowly. This makes it less likely to break and more tough.

- Aging: Heat at a low temperature for a long time. This makes tiny particles inside, which makes it harder and stronger.

These steps help you get the right mix of hardness and toughness for your needs.

Microstructure

The inside structure of 416 stainless steel changes with heat. When it is annealed, the steel is soft and easy to work with. After hardening, it becomes martensitic, which means it is strong and hard. If you temper it, the steel gets less likely to break and more tough. The right heat treatment lets you control how the steel acts in your project.

Tip: Pick the heat treatment that fits your needs. Hardening gives strength, but tempering gives toughness.

Magnetic Properties

Ferromagnetism

You may wonder if 416 stainless steel sticks to magnets. The answer is yes. This steel has a martensitic structure, so it is ferromagnetic. You can pick it up with a magnet, even after heating or cutting it. The magnetic pull is much stronger than in 304 or 316, which are not usually magnetic.

The magnetic permeability of 416 stainless steel is between 500 and 1,000. This means it reacts well to magnets. You can use this in parts that need to move with magnets or in sensors that find metal.

Note: If you need a magnetic stainless steel, 416 stainless steel is a good pick.

Now you know the main chemical properties of 416 stainless steel. You see how it fights rust, how you can change its hardness with heat, and how it reacts to magnets. These facts help you decide if this steel is right for your job.

Applications of 416 Stainless Steel

Industrial Uses

Machined Parts

Sometimes you need a metal that is easy to cut and keeps its shape. 416 stainless steel is good for this. You can use it for many machine parts because it cuts well and stays the right size. Here are some things made from this steel:

- Screws, nuts, and bolts

- Bushings and gears

- Studs and small machine parts

- Food processing and pharmaceutical components

This steel is easy to machine and has good strength. It also resists rust a little. These things make it a smart pick for parts that need to be shaped just right and look smooth.

Valves and Shafts

416 stainless steel is used for valves and shafts. It does not wear out fast and can handle stress. You can find it in:

- Pump shafts

- Valve parts

- Steam and gas turbine blades

This steel works well in machines that move fluids or spin. It gives you parts that last and work well.

Here is a table that shows where you might use 416 stainless steel:

| Application | Description |

|---|---|

| Pump shafts and valve components | Important for moving fluids |

| Fasteners | Needed for holding things together |

| Bushings | Helps parts last longer |

| Studs and gears | Used in machines that move |

| Cutlery and kitchen utensils | Easy to shape and resists rust |

| Washing machine components | Makes machines last longer |

Suitability

Performance Factors

You may wonder if 416 stainless steel is right for your project. Look at these things:

| Performance Factor | Description |

|---|---|

| Corrosion Resistance | Works well in places with little rust |

| Machinability | Easy to cut and shape |

| Mechanical Properties | Gets strong and hard after heat treatment |

| Magnetic Properties | Sticks to magnets, good for special uses |

You can use 416 stainless steel for many things like shafts, valves, bolts, nuts, gears, and even gun parts. It gives you a mix of strength, easy cutting, and some rust resistance.

Environmental Considerations

Think about where you will use 416 stainless steel. Some places have harsh chemicals or salty air. These can make the steel rust faster.

Different jobs and places have different risks. Some have harsh chemicals, hot or cold temperatures, or salty water. Picking the right metal and being careful can help stop rust.

Rust happens when metal touches water or air. In some places, there are more chemicals in the air. These can make rain more acidic and cause more rust. Sometimes, the metal can lose half its thickness in bad places.

Corrosion means a metal gets weaker or breaks down from the environment. How fast this happens depends on how tough the place is and how long the metal is there.

You should use 416 stainless steel in places that are not too harsh. Do not use it near the ocean or with strong chemicals. If you need better rust resistance, pick a different stainless steel.

Now you know what 416 stainless steel is used for. You also know where it works best.

Practical Implications

Selection Criteria

When to Use 416

You want to pick the right steel for your project. Here are steps to help you decide if 416 stainless steel fits your needs:

- Consider the Grade of Steel

Each grade has different properties. 416 stainless steel gives you high machinability and good strength. - Determine the Purpose of the Steel

Think about what you need the steel to do. If you need easy machining and moderate corrosion resistance, this grade works well. - Check the Size of the Bar

Make sure the size matches your load and application. The right size helps your part last longer. - Think about the Finish of the Steel

Choose a finish that looks good or meets your structural needs. - Consider the Supplier of the Steel

Pick a supplier with strong industry certifications. This helps you get quality material.

Tip: Always match the steel’s properties to your project’s needs. If you need high machinability and moderate corrosion resistance, 416 stainless steel is a smart choice.

Alternatives

You may need a different material if your project faces harsh environments or needs more corrosion resistance. Here are some options:

- 304 Stainless Steel: Good for wet or salty places. It resists rust better but is harder to machine.

- 316 Stainless Steel: Best for marine or chemical use. It costs more but lasts longer in tough spots.

- 410 Stainless Steel: Offers higher hardness. Use it when you need more wear resistance.

Note: If your job needs welding or faces strong chemicals, pick a grade with better corrosion resistance.

Cost and Availability

Market Factors

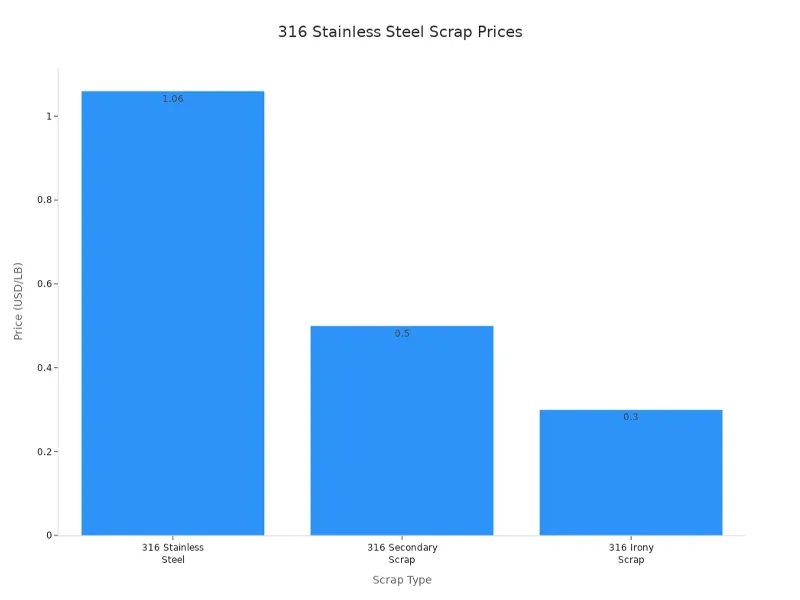

You want to know how much the steel costs and if you can get it easily. Most suppliers keep 416 and 316 stainless steel in stock. You can order sheets, rods, or custom shapes. The price changes based on grade and market demand.

| Stainless Steel Type | Average Scrap Price (USD/LB) |

|---|---|

| 316 Stainless Steel | 1.06 |

| 316 Secondary Scrap | 0.50 |

| 316 Irony Scrap | 0.30 |

- Both 416 and 316 stainless steel are easy to find.

- Suppliers offer many forms for different uses.

- Prices may change with market trends.

Supply Chain

You need to think about how you get your steel. The supply chain affects cost, quality, and delivery time. Here are key factors:

| Supply Chain Factor | Description |

|---|---|

| Supplier Capabilities | The supplier’s skills affect how well your parts are made and how much they cost. |

| Material Specifications | The steel must meet your project’s needs for best results. |

| Quality Management | Look for suppliers with ISO 9001 certification to make sure you get good quality. |

| Logistical Expertise | Good logistics help you get your steel on time and keep your project on track. |

Tip: Work with suppliers who understand your needs and have strong quality controls. This helps you avoid delays and problems.

You can choose 416 stainless steel for projects that need easy machining and moderate corrosion resistance. Always check cost, availability, and supply chain factors before you buy.

Comparison with Other Grades

416 vs 304

Mechanical

You may wonder how 416 and 304 stainless steels compare in strength and machinability. If you need a material that machines easily, 416 stands out. You can cut and shape it much faster than 304. The yield strength of 416 is higher, so it can handle more force before it bends. You can also heat treat 416 to make it harder, but you cannot do this with 304. However, 304 gives you better corrosion resistance. Here is a table to help you see the differences:

| Property | 416 Stainless Steel | 304 Stainless Steel |

|---|---|---|

| Machinability | Better | Poorer |

| Yield Strength | Higher | Lower |

| Hardness | Can be increased | Not heat treatable |

| Corrosion Resistance | Less | More |

Tip: Choose 416 if you want fast machining and higher strength. Pick 304 if you need better rust resistance.

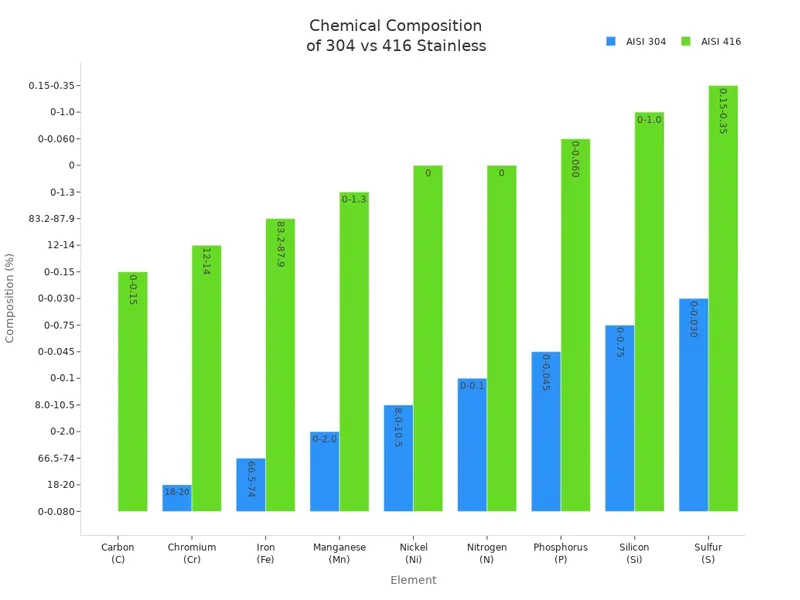

Chemical

The chemical makeup of these two steels affects how they work. 304 has more chromium and nickel, which helps it resist rust. 416 has more sulfur, which makes it easier to machine but lowers its corrosion resistance. The chart below shows the main elements in each type:

| Element | AISI 304 (%) | AISI 416 (%) |

|---|---|---|

| Carbon (C) | 0 to 0.080 | 0 to 0.15 |

| Chromium (Cr) | 18 to 20 | 12 to 14 |

| Iron (Fe) | 66.5 to 74 | 83.2 to 87.9 |

| Manganese (Mn) | 0 to 2.0 | 0 to 1.3 |

| Nickel (Ni) | 8.0 to 10.5 | 0 |

| Nitrogen (N) | 0 to 0.1 | 0 |

| Phosphorus (P) | 0 to 0.045 | 0 to 0.060 |

| Silicon (Si) | 0 to 0.75 | 0 to 1.0 |

| Sulfur (S) | 0 to 0.030 | 0.15 to 0.35 |

You see that 304 has more chromium and nickel, which helps it fight rust. 416 has more sulfur, which makes it easier to machine.

416 vs 410

Performance

When you compare 416 and 410, you notice some key differences. You get excellent machinability with 416, making it the top choice for fast, high-volume machining. 410 does not machine as easily, but it gives you better ductility and can be welded with care. Both types have limited corrosion resistance, so you should not use them in harsh environments. Here is a table to help you compare:

| Property/Application | 416 Stainless Steel | 410 Stainless Steel |

|---|---|---|

| Machinability | Excellent, most machinable stainless steel | Good, but not as high as 416 |

| Corrosion Resistance | Limited | Some, but still limited |

| Formability | Poor | Good ductility |

| Weldability | Poor | Can be welded with care |

| Typical Applications | Valve parts, pump shafts, auto screw machine parts, motor shafts, washing machine parts, fasteners | Highly stressed parts in petrochemical, automotive, and power generation industries |

Note: If you need to machine many parts quickly, 416 is your best option. If you need to form or weld the steel, 410 may work better.

Applications

You will find 416 in parts that need fast machining and a smooth finish, such as valve parts, pump shafts, and fasteners. You often see 410 in parts that need to handle more stress, like those in the automotive or power industries. 410 works better when you need to shape or weld the steel. 416 is best for jobs where you want quick production and do not need to form or weld the material.

416 stainless steel is easy to machine and has good hardness. It also resists rust a bit. These things make it good for small, exact parts, valves, and fasteners.

- You can heat treat it to make it last longer against wear.

- When it is softer, it is easier to cut and shape.

- When it is harder, it works better for tough jobs.

- Always think about price, how much rust it can handle, and how easy it is to machine before you pick it.

| Factor | Description |

|---|---|

| Cost | Think about how much you will spend over time. |

| Corrosion Resistance | Pick the grade that fits where you will use it. |

| Machining Requirements | Grades with more sulfur are easier to cut and shape. |

Tip: Look at what your project needs and check other grades before you choose your material.

FAQ

You get easy machining because 416 stainless steel has added sulfur. This sulfur helps chips break off cleanly. You can cut and shape it faster than most other stainless steels.

You should avoid welding 416 stainless steel. The high sulfur content can cause cracks and weak welds. If you must weld it, use special filler metals and preheat the steel.

Yes, you will find that 416 stainless steel is magnetic. Its martensitic structure lets it stick to magnets. You can use it in applications that need magnetic properties.

You should not use 416 stainless steel in salty, wet, or chemical-rich places. It can rust or pit quickly in these environments. For marine or chemical use, pick a different grade.

You can harden 416 stainless steel by heating it above 1700°F (927°C) and then cooling it quickly. This process increases strength and hardness. Always temper after hardening to improve toughness.

You can use 416 stainless steel for some food equipment. However, it does not resist corrosion as well as 304 or 316. For wet or salty foods, choose a more corrosion-resistant grade.

You often see 416 stainless steel in screws, shafts, gears, and valves. It works well for parts that need precise machining and moderate strength.

You can machine 416 stainless steel much easier than 304. However, 304 resists rust better. Use 416 for fast machining jobs and 304 for better corrosion resistance.

Tip: Always match the steel grade to your project’s needs for best results.